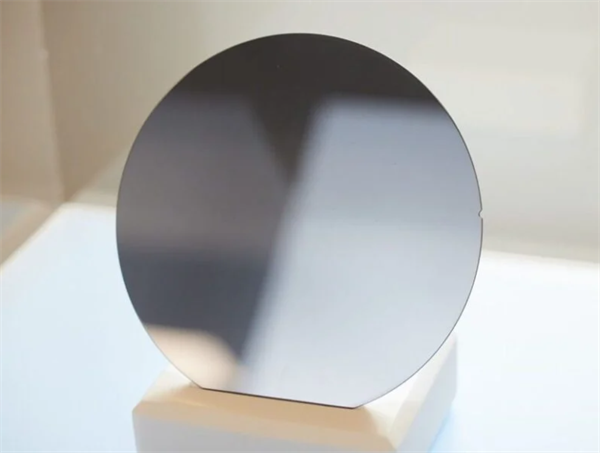

P-nau'in SiC wafer 4H/6H-P 3C-N 6inch kauri 350 μm tare da Farko Flat Orientation

Specification4H/6H-P Nau'in SiC Composite Substrates gama gari tebur siga

6 inch diamita Silicon Carbide (SiC) Substrate Ƙayyadaddun bayanai

| Daraja | Zero MPD ProductionDarasi (Z Daraja) | Standard ProductionDarasi (P Daraja) | Dummy Grade (D Daraja) | ||

| Diamita | 145.5mm ~ 150.0 mm | ||||

| Kauri | 350 μm ± 25 μm | ||||

| Wafer Orientation | -Offaxis: 2.0 ° -4.0 ° zuwa [1120] ± 0.5 ° don 4H/6H-P, A kan axis: 〈111〉± 0.5° don 3C-N | ||||

| Maƙarƙashiya Maɗaukaki | 0 cm - 2 | ||||

| Resistivity | p-nau'in 4H/6H-P | ≤0.1 Ωꞏcm | ≤0.3 Ωꞏcm | ||

| n-nau'in 3C-N | ≤0.8 mΩ cm | ≤1 m Ωꞏcm | |||

| Hannun Filayen Firamare | 4H/6H-P | -{1010} ± 5.0° | |||

| 3C-N | -{110} ± 5.0° | ||||

| Tsawon Lantarki na Farko | 32.5 mm ± 2.0 mm | ||||

| Tsawon Lantarki na Sakandare | 18.0 mm ± 2.0 mm | ||||

| Gabatarwar Flat na Sakandare | Fuskar Silicon: 90° CW. daga Firayim lebur ± 5.0° | ||||

| Ƙarƙashin Ƙarfi | 3 mm ku | 6 mm ku | |||

| LTV/TTV/Baka/Warp | ≤2.5 μm/≤5 μm/≤15 μm/≤30 μm | ≤10 μm/≤15 μm/≤25 μm/≤40 μm | |||

| Tashin hankali | Yaren mutanen Poland Ra≤1 nm | ||||

| CMP Ra≤0.2 nm | ≤0.5 nm | ||||

| Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙwara | Babu | Tsayin tarawa ≤ 10 mm, tsayi ɗaya≤2 mm | |||

| Hex Plates Ta Babban Haske mai ƙarfi | Tarin yanki ≤0.05% | Tarin yanki ≤0.1% | |||

| Wuraren Polytype Ta Hanyar Ƙarfin Ƙarfi | Babu | Tarin yanki≤3% | |||

| Haɗin Carbon Na gani | Tarin yanki ≤0.05% | Tarin yanki ≤3% | |||

| Silicon Surface Scratches By High Intensity Light | Babu | Tsayin tarawa≤1× diamita wafer | |||

| Edge Chips High By Intensity Light | Babu wanda aka halatta ≥0.2mm nisa da zurfinsa | 5 izini, ≤1 mm kowanne | |||

| Gurɓatar Silicon Surface Ta Babban Ƙarfi | Babu | ||||

| Marufi | Cassette mai yawa-wafer ko kwantena wafer guda ɗaya | ||||

Bayanan kula:

※ Iyakoki na lahani sun shafi gaba dayan farfajiyar wafer ban da yankin keɓe gefen. # Ya kamata a duba karce akan Si face o

P-type SiC wafer, 4H/6H-P 3C-N, tare da girman 6-inch da kauri 350 μm, yana taka muhimmiyar rawa a cikin samar da masana'antu na manyan kayan lantarki. Kyawawan yanayin zafinsa da ƙarfin rushewar wutar lantarki ya sa ya dace don masana'anta kamar su masu sauya wuta, diodes, da transistor da ake amfani da su a cikin yanayi masu zafi kamar motocin lantarki, grids, da tsarin makamashi mai sabuntawa. Ƙarfin wafer don yin aiki da kyau a cikin yanayi mara kyau yana tabbatar da ingantaccen aiki a aikace-aikacen masana'antu da ke buƙatar ƙarfin ƙarfin ƙarfi da ƙarfin kuzari. Bugu da ƙari, matakin firam ɗin sa na farko yana taimakawa cikin daidaitaccen jeri yayin ƙirƙira na'urar, haɓaka haɓakar samarwa da daidaiton samfur.

Fa'idodin nau'in nau'in SiC mai haɗaka sun haɗa da

- High thermal Conductivity: P-type SiC wafers yadda ya kamata ya watsar da zafi, yana sa su dace don aikace-aikacen zafi mai zafi.

- High Breakdown Voltage: Mai iya jurewa babban ƙarfin lantarki, tabbatar da aminci a cikin wutar lantarki da na'urori masu ƙarfin lantarki.

- Juriya ga Muhalli masu tsanani: Kyakkyawan karko a cikin matsanancin yanayi, irin su yanayin zafi mai zafi da lalata yanayi.

- Ingantacciyar Canjin Wuta: Tsarin doping na nau'in P yana sauƙaƙe ingantaccen sarrafa wutar lantarki, yana sa wafer ya dace da tsarin canjin makamashi.

- Hannun Filayen Firamare: Yana tabbatar da daidaitattun daidaito yayin samarwa, inganta daidaiton na'urar da daidaito.

- Tsarin Bakin ciki (350 μm): Mafi kyawun kauri na wafer yana goyan bayan haɗin kai zuwa na'urorin lantarki masu ƙarancin sarari.

Gabaɗaya, nau'in P-type SiC wafer, 4H / 6H-P 3C-N, yana ba da fa'idodi da yawa waɗanda ke sa ya dace sosai don aikace-aikacen masana'antu da na lantarki. Babban ƙarfin wutar lantarki da rushewar wutar lantarki yana ba da damar ingantaccen aiki a cikin yanayin zafi mai ƙarfi da ƙarfin lantarki, yayin da juriya ga yanayin ƙaƙƙarfan yanayi yana tabbatar da dorewa. Doping na nau'in P-nau'in yana ba da damar ingantacciyar canjin wutar lantarki, yana mai da shi manufa don tsarin lantarki da makamashi. Bugu da ƙari, matakin firamare na wafer yana tabbatar da daidaitaccen jeri yayin aikin masana'anta, yana haɓaka daidaiton samarwa. Tare da kauri na 350 μm, ya dace sosai don haɗawa cikin ci gaba, ƙananan na'urori.

Cikakken zane