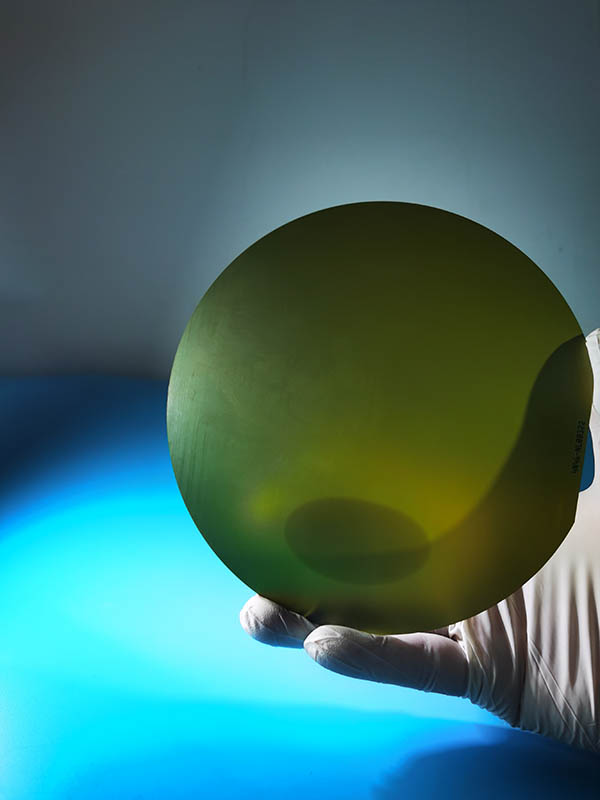

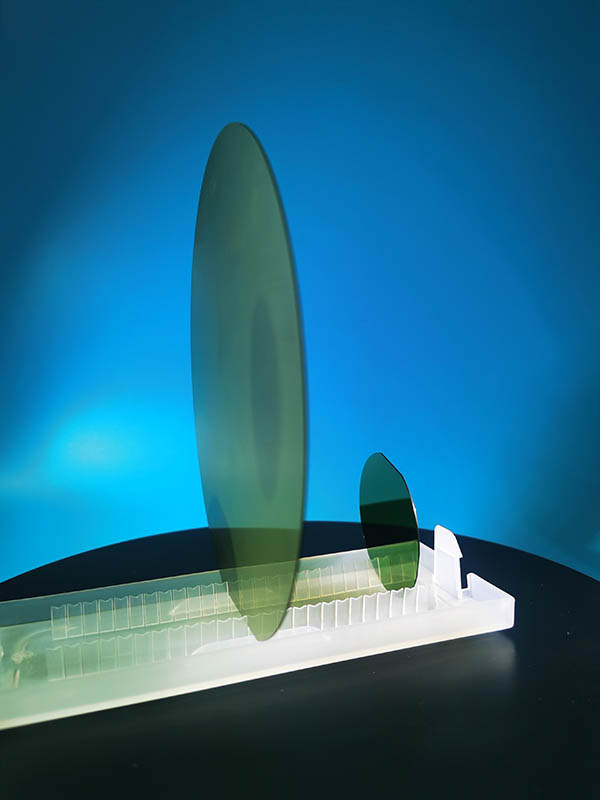

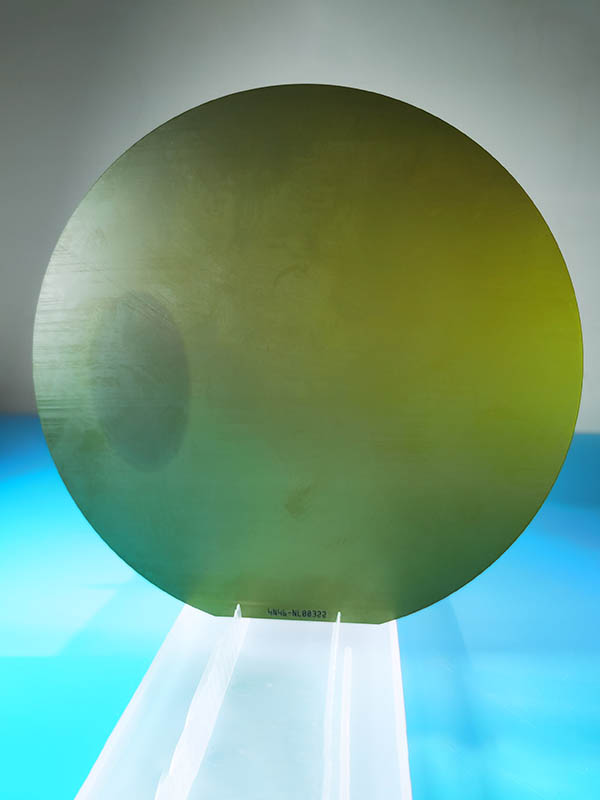

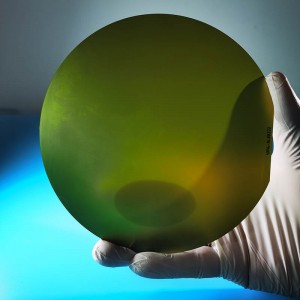

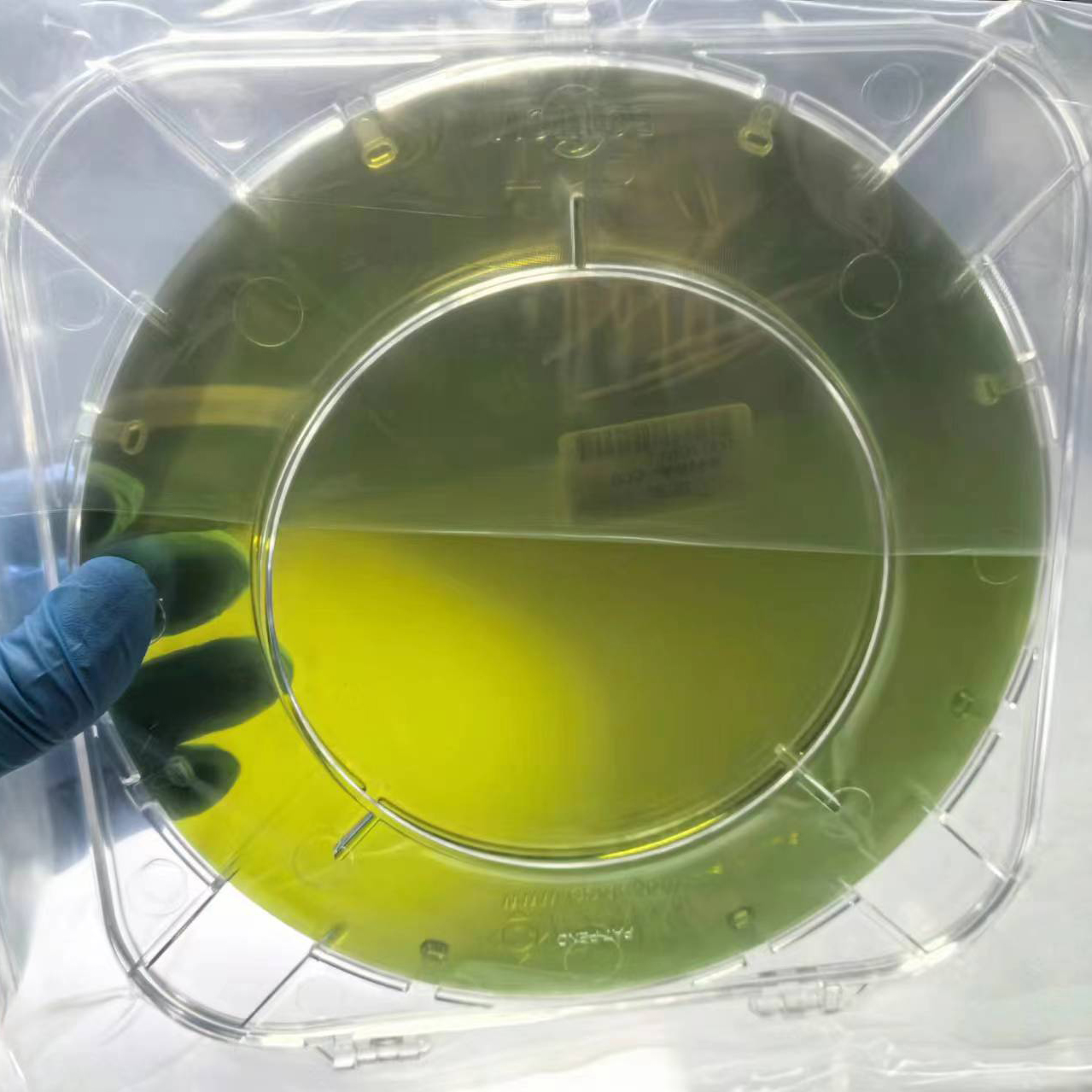

8Inch 200mm 4H-N SiC Wafer Conductive dummy grade

Saboda kaddarorinsa na musamman na zahiri da na lantarki, 200mm SiC wafer semiconductor abu ana amfani dashi don ƙirƙirar babban aiki, yanayin zafi, juriya, da na'urorin lantarki masu ƙarfi. 8inch SiC substrate farashin yana raguwa a hankali yayin da fasahar ke ƙara haɓaka kuma buƙatun ke girma. Ci gaban fasaha na kwanan nan yana haifar da samar da sikelin samarwa na 200mm SiC wafers. Babban fa'idodin SiC wafer semiconductor kayan kwatankwacin Si da GaAs wafers: Ƙarfin wutar lantarki na 4H-SiC yayin rushewar dusar ƙanƙara ya fi tsari na girma sama da daidaitattun ƙimar Si da GaAs. Wannan yana haifar da raguwa mai mahimmanci a cikin juriya na kan-jihar Ron. Low on-jihar resistivity, haɗe tare da babban halin yanzu yawa da kuma thermal watsin, damar yin amfani da sosai kananan mutu ga ikon na'urorin. Babban haɓakar thermal conductivity na SiC yana rage juriya na thermal na guntu. Kayayyakin lantarki na na'urorin da ke tushen SiC wafers suna da ƙarfi sosai akan lokaci kuma akan kwanciyar hankali, wanda ke tabbatar da babban amincin samfuran. Silicon carbide yana da matukar juriya ga radiyo mai ƙarfi, wanda baya lalata kaddarorin lantarki na guntu. Babban iyakance zafin aiki na kristal (fiye da 6000C) yana ba ku damar ƙirƙirar na'urori masu dogaro sosai don matsananciyar yanayin aiki da aikace-aikace na musamman. A halin yanzu, za mu iya samar da ƙananan 200mmSiC wafers a hankali kuma a ci gaba da samun wasu kayayyaki a cikin sito.

Ƙayyadaddun bayanai

| Lamba | Abu | Naúrar | Production | Bincike | Dummy |

| 1. Ma'auni | |||||

| 1.1 | nau'in poly | -- | 4H | 4H | 4H |

| 1.2 | fuskar fuska | ° | <11-20>4±0.5 | <11-20>4±0.5 | <11-20>4±0.5 |

| 2. Wutar lantarki | |||||

| 2.1 | dopant | -- | n-nau'in Nitrogen | n-nau'in Nitrogen | n-nau'in Nitrogen |

| 2.2 | resistivity | ku · cm | 0.015 ~ 0.025 | 0.01 ~ 0.03 | NA |

| 3. Mechanical siga | |||||

| 3.1 | diamita | mm | 200± 0.2 | 200± 0.2 | 200± 0.2 |

| 3.2 | kauri | μm | 500± 25 | 500± 25 | 500± 25 |

| 3.3 | Matsayin daraja | ° | [1-100] ± 5 | [1-100] ± 5 | [1-100] ± 5 |

| 3.4 | Zurfin Daraja | mm | 1 ~ 1.5 | 1 ~ 1.5 | 1 ~ 1.5 |

| 3.5 | LTV | μm | ≤5(10mm*10mm) | ≤5(10mm*10mm) | ≤10 (10mm*10mm) |

| 3.6 | TTV | μm | ≤10 | ≤10 | ≤15 |

| 3.7 | Ruku'u | μm | -25-25 | -45-45 | -65-65 |

| 3.8 | Warp | μm | ≤30 | ≤50 | ≤70 |

| 3.9 | AFM | nm | ≤0.2 | ≤0.2 | ≤0.2 |

| 4. Tsari | |||||

| 4.1 | micropipe yawa | ku/cm2 | ≤2 | ≤10 | ≤50 |

| 4.2 | abun ciki na karfe | atom/cm2 | ≤1E11 | ≤1E11 | NA |

| 4.3 | TSD | ku/cm2 | ≤500 | ≤1000 | NA |

| 4.4 | BPD | ku/cm2 | ≤2000 | ≤5000 | NA |

| 4.5 | TED | ku/cm2 | ≤7000 | ≤10000 | NA |

| 5. Kyakkyawan inganci | |||||

| 5.1 | gaba | -- | Si | Si | Si |

| 5.2 | saman gamawa | -- | Farashin CMP | Farashin CMP | Farashin CMP |

| 5.3 | barbashi | e/wafar | ≤100(size≥0.3μm) | NA | NA |

| 5.4 | karce | e/wafar | ≤5, Jimlar Tsawon≤200mm | NA | NA |

| 5.5 | Gefen kwakwalwan kwamfuta / indents / fasa / tabo / gurɓatawa | -- | Babu | Babu | NA |

| 5.6 | Yankunan polytype | -- | Babu | Yanki ≤10% | Yanki ≤30% |

| 5.7 | alamar gaba | -- | Babu | Babu | Babu |

| 6. Baya ingancin | |||||

| 6.1 | dawo gama | -- | C-face MP | C-face MP | C-face MP |

| 6.2 | karce | mm | NA | NA | NA |

| 6.3 | Gefen lahani na baya kwakwalwan kwamfuta / indents | -- | Babu | Babu | NA |

| 6.4 | Baƙar fata | nm | Ra ≤5 | Ra ≤5 | Ra ≤5 |

| 6.5 | Alamar baya | -- | Daraja | Daraja | Daraja |

| 7. Gaba | |||||

| 7.1 | baki | -- | Chamfer | Chamfer | Chamfer |

| 8. Kunshin | |||||

| 8.1 | marufi | -- | Epi-shirye tare da injin marufi | Epi-shirye tare da injin marufi | Epi-shirye tare da injin marufi |

| 8.2 | marufi | -- | Multi-wafer kaset marufi | Multi-wafer kaset marufi | Multi-wafer kaset marufi |

Cikakken zane