Hanyar CVD don samar da manyan kayan albarkatun SiC masu tsabta a cikin tanderun carbon carbide a 1600 ℃

Ƙa'idar aiki:

1. Precursor wadata. Tushen siliki (misali SiH₄) da tushen carbon (misali C₃H₈) iskar gas suna gauraye daidai gwargwado kuma ana ciyar da su cikin ɗakin amsawa.

2. High zafin jiki bazuwa: A wani babban zafin jiki na 1500 ~ 2300 ℃, da gas bazuwar haifar Si da C aiki atoms.

3. Halin da ke sama: Si da atom ɗin C ana ajiye su a saman ƙasa don samar da Layer na SiC crystal.

4. Girman Crystal: Ta hanyar kula da zafin jiki na zafin jiki, iskar gas da matsa lamba, don cimma ci gaban shugabanci tare da c axis ko axis.

Mahimman sigogi:

Zazzabi: 1600 ~ 2200 ℃ (> 2000 ℃ don 4H-SiC)

· Matsi: 50 ~ 200mbar (ƙananan matsa lamba don rage ƙwayar gas)

Rawan iskar gas: Si / C≈1.0 ~ 1.2 (don guje wa lahanin haɓaka Si ko C)

Babban fasali:

(1) Crystal ingancin

Ƙarƙashin ƙarancin lahani: ƙarancin microtubule <0.5cm ⁻², ƙarancin rarrabuwa <10⁴ cm⁻².

Polycrystalline irin iko: iya girma 4H-SiC (na al'ada), 6H-SiC, 3C-SiC da sauran crystal iri.

(2) Ayyukan kayan aiki

High zafin jiki kwanciyar hankali: graphite induction dumama ko juriya dumama, zazzabi> 2300 ℃.

Ikon Uniformity: canjin zafin jiki ± 5 ℃, ƙimar girma 10 ~ 50μm / h.

Tsarin Gas: Babban Madaidaicin Matsala (MFC), Tsabtace Gas ≥99.999%.

(3) Fa'idodin fasaha

Tsabta mai girma: Ƙashin ƙazanta na bango <10¹⁶ cm⁻³ (N, B, da sauransu).

Babban girman: Taimakawa 6 ″/8' Ci gaban substrate SiC.

(4) Amfanin makamashi da farashi

Babban amfani da makamashi (200 ~ 500kW · h ta tanda), yana lissafin 30% ~ 50% na farashin samar da SiC substrate.

Babban aikace-aikace:

1. Ƙarfin wutar lantarki: SiC MOSFETs don kera motocin lantarki da masu juyawa na hoto.

2. Rf na'urar: 5G tushe tashar GaN-on-SiC epitaxial substrate.

3.Extreme muhalli na'urorin: high zafin jiki na'urori masu auna sigina sararin samaniya da makamashin nukiliya.

Ƙayyadaddun fasaha:

| Ƙayyadaddun bayanai | Cikakkun bayanai |

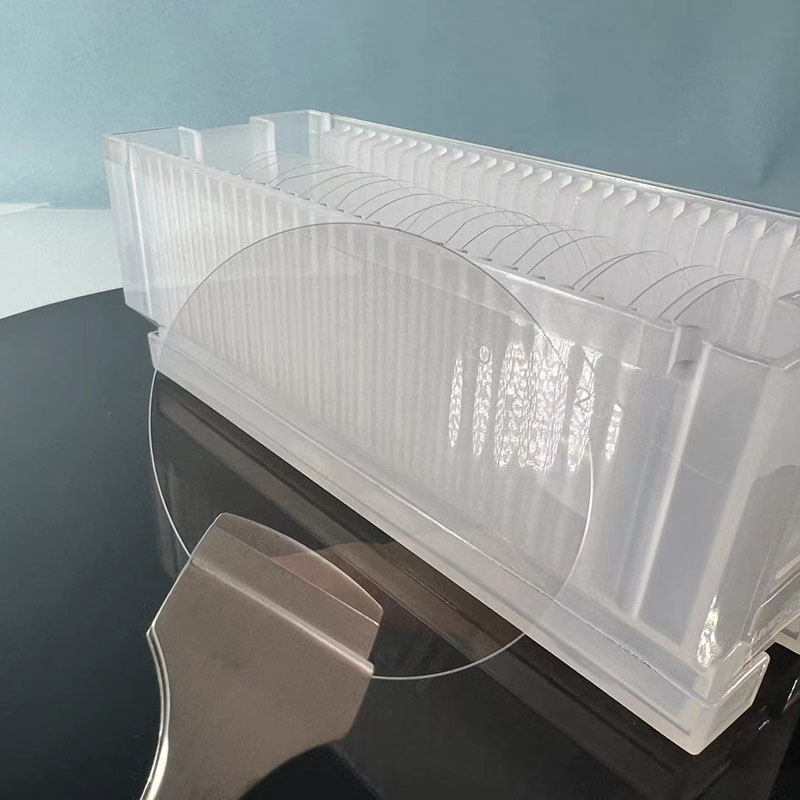

| Girma (L × W × H) | 4000 x 3400 x 4300 mm ko siffanta |

| diamita dakin murhu | 1100mm |

| Ƙarfin lodi | 50kg |

| Iyakar vacuum digiri | 10-2Pa (2h bayan fara famfo kwayoyin halitta) |

| Matsakaicin tashin ɗaki | ≤10Pa/h (bayan calcination) |

| Ƙarƙashin murfi na murfi daga bugun bugun jini | 1500mm |

| Hanyar dumama | Induction dumama |

| Matsakaicin zafin jiki a cikin tanderun | 2400°C |

| Zazzage wutar lantarki | 2 x40 kW |

| Auna zafin jiki | Ma'aunin zafin infrared mai launi biyu |

| Yanayin zafin jiki | 900 ~ 3000 ℃ |

| Daidaitaccen sarrafa zafin jiki | ±1°C |

| Sarrafa matsa lamba | 1 ~ 700 mbar |

| Daidaiton Kula da Matsi | 1 ~ 5mbar ± 0.1mbar; 5 ~ 100mbar ± 0.2mbar; 100 ~ 700mbar ± 0.5mbar |

| Hanyar lodawa | Ƙananan kaya; |

| Tsarin zaɓi na zaɓi | Wurin auna zafin jiki sau biyu, sauke cokali mai yatsu. |

Ayyukan XKH:

XKH yana ba da sabis na cikakken sake zagayowar don murhun silicon carbide CVD, gami da gyare-gyaren kayan aiki (tsarin yanki na zafin jiki, tsarin tsarin gas), haɓaka aiwatarwa (ikon crystal, haɓaka lahani), horar da fasaha (aiki da kiyayewa) da tallafin tallace-tallace bayan-tallace-tallace (kayan da aka keɓe na samar da mahimman abubuwan haɗin gwiwa, bincike mai nisa) don taimakawa abokan ciniki cimma babban ingancin SiC substrate taro samar. Kuma ba da sabis na haɓaka tsari don ci gaba da haɓaka yawan amfanin ƙasa da ƙimar girma.