Kayan Bakin Wafer don 4 Inch-12 inch Sapphire/SiC/Si Wafers Processing

Ƙa'idar Aiki

Tsarin bakin ciki na wafer yana aiki ta matakai uku:

Nika mai Mutuwa: Dabarar lu'u-lu'u (girman grit 200-500 μm) yana cire 50-150 μm na abu a 3000-5000 rpm don rage kauri da sauri.

Niƙa Mai Kyau: Ƙaƙƙarfan dabaran (girman 1-50 μm) yana rage kauri zuwa 20-50 μm a <1 μm/s don rage lalacewar ƙasa.

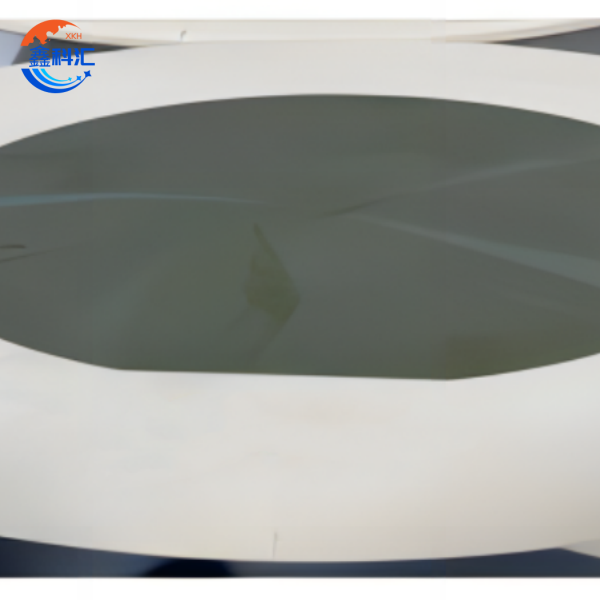

Polishing (CMP): slurry na injiniyoyin sinadarai yana kawar da ragowar lalacewa, cimma Ra <0.1 nm.

Abubuwan da suka dace

Silicon (Si): Daidaitaccen wafers na CMOS, wanda aka fidda shi zuwa 25 μm don tari 3D.

Silicon Carbide (SiC): Yana buƙatar ƙafafun lu'u-lu'u na musamman (80% maida hankali na lu'u-lu'u) don kwanciyar hankali na zafi.

Sapphire (Al₂O₃): Tinned zuwa 50 μm don aikace-aikacen LED UV.

Abubuwan Tsarin Mahimmanci

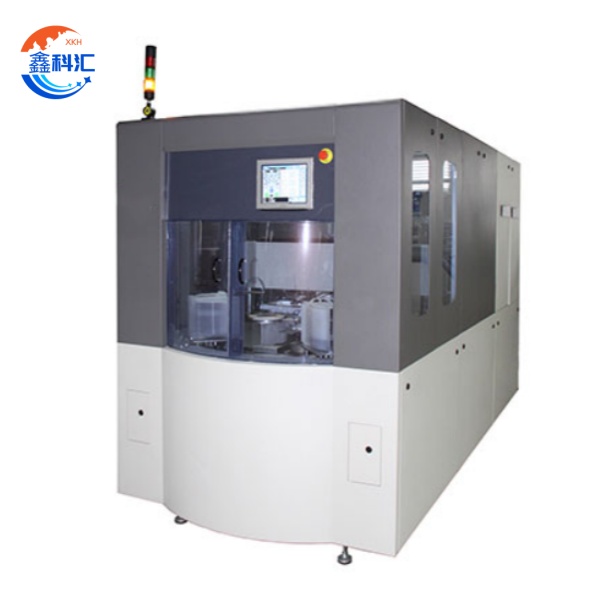

1. Tsarin Nika

Dual-Axis grinder: Haɗa m / mai kyau nika a cikin dandali guda, rage lokacin sake zagayowar da 40%.

Aerostatic Spindle: 0-6000 rpm kewayon saurin gudu tare da <0.5 μm radial runout.

2. Wafer Handling System

Vacuum Chuck:> 50 N riƙe ƙarfi tare da daidaiton matsayi na ± 0.1 μm.

Robotic Arm: Yana jigilar 4-12-inch wafers a 100 mm/s.

3. Tsarin Gudanarwa

Interferometry Laser: Kula da kauri na ainihi (ƙuduri 0.01 μm).

Ciyarwar Mai-Daukewar AI: Yana tsinkayar lalacewa ta hannu kuma yana daidaita sigogi ta atomatik.

4. Cooling & Tsaftacewa

Ultrasonic Cleaning: Yana kawar da barbashi> 0.5 μm tare da ingancin 99.9%.

Ruwan Deionized: Yana sanya wafer zuwa <5°C sama da yanayi.

Babban Amfani

1. Madaidaicin Maɗaukaki: TTV (Jimillar Bambancin Kauri) <0.5 μm, WTW (Bambancin Kauri Tsakanin-Wafer) <1 μm.

2. Haɗin Tsari da yawa: Haɗa niƙa, CMP, da etching plasma a cikin injin guda ɗaya.

3. Dacewar Abu:

Silicon: Rage kauri daga 775 μm zuwa 25 μm.

SiC: Cimma <2 μm TTV don aikace-aikacen RF.

Doped Wafers: Phosphorus-doped InP wafers tare da <5% juriya juriya.

4. Smart Automation: Haɗin MES yana rage kuskuren ɗan adam da 70%.

5. Amfanin Makamashi: 30% ƙananan amfani da wutar lantarki ta hanyar sabunta birki.

Maɓallin Aikace-aikace

1. Advanced Packaging

• 3D ICs: Wafer thinning yana ba da damar stacking na dabaru / kwakwalwan ƙwaƙwalwar ajiya a tsaye (misali, HBM stacks), cimma 10 × mafi girma bandwidth da 50% rage yawan amfani da wutar lantarki idan aka kwatanta da mafita na 2.5D. Kayan aiki yana goyan bayan haɗin gwiwar matasan da TSV (Ta hanyar Silicon Via) haɗin kai, mai mahimmanci ga masu sarrafa AI / ML da ke buƙatar <10 μm haɗin haɗin haɗin gwiwa. Misali, wafers na inch 12 da aka yi wa bakin ciki zuwa μm 25 suna ba da damar tara yadudduka 8+ yayin da suke kiyaye <1.5% warpage, mai mahimmanci ga tsarin LiDAR na kera motoci.

• Kunshin-Fita Fan: Ta hanyar rage kaurin wafer zuwa 30 μm, an rage tsawon haɗin haɗin kai da 50%, rage jinkirin sigina (<0.2 ps/mm) da ba da damar 0.4 mm chiplets ultra-bakin ciki don SoCs ta hannu. Tsarin yana yin amfani da algorithms na niƙa da aka biya don hana warpage (> 50 μm TTV iko), yana tabbatar da aminci a cikin manyan aikace-aikacen RF.

2. Power Electronics

• Modules na IGBT: Rarraba zuwa 50 μm yana rage juriya na thermal zuwa <0.5 ° C / W, yana ba da damar 1200V SiC MOSFETs suyi aiki a yanayin zafi na 200 ° C. Kayan aikinmu suna ɗaukar matakan niƙa (m: 46 μm grit → lafiya: 4 μm grit) don kawar da lalacewar ƙasa, cimma> 10,000 hawan keke na amincin hawan keke. Wannan yana da mahimmanci ga masu juyawa EV, inda 10 μm-kauri SiC wafers suna haɓaka saurin sauyawa da 30%.

• GaN-on-SiC Power Na'urorin: Wafer thinning zuwa 80 μm yana haɓaka motsin lantarki (μ> 2000 cm²/V·s) don 650V GaN HEMTs, yana rage asarar gudanarwa da 18%. Tsarin yana amfani da dicing-taimakon Laser don hana tsagewa yayin bakin ciki, cimma <5 μm gefen chipping don amplifiers ikon RF.

3. Optoelectronics

• GaN-on-SiC LEDs: 50 μm sapphire substrates suna inganta ingantaccen haɓaka haske (LEE) zuwa 85% (vs. 65% don 150 μm wafers) ta hanyar rage girman tarkon photon. Ikon TTV mai ƙarancin ƙarancin kayan aikin mu (<0.3 μm) yana tabbatar da fitowar LED iri ɗaya a cikin wafers 12-inch, mai mahimmanci ga nunin Micro-LED waɗanda ke buƙatar daidaiton tsayin tsayin 100nm.

• Silicon Photonics: 25μm-kauri silicon wafers taimaka 3 dB / cm ƙananan yaduwa asarar a cikin waveguides, da muhimmanci ga 1.6 Tbps na gani transceivers. Tsarin yana haɗawa da santsi na CMP don rage ƙarancin ƙasa zuwa Ra <0.1 nm, haɓaka haɓakar haɗin gwiwa da 40%.

4. Sensors na MEMS

• Accelerometers: 25 μm silicon wafers cimma SNR> 85 dB (vs. 75 dB don 50 μm wafers) ta hanyar ƙara hujja- taro hankali. Tsarin niƙa mai-axis ɗinmu na ramawa ga matakan damuwa, yana tabbatar da <0.5% juyewar hankali sama da -40°C zuwa 125°C. Aikace-aikace sun haɗa da gano haɗarin mota da bin diddigin motsi na AR/VR.

• Sensors na matsa lamba: Baƙar fata zuwa 40 μm yana ba da damar 0-300 ma'aunin ma'aunin mashaya tare da <0.1% FS hysteresis. Yin amfani da haɗin kai na wucin gadi (Masu ɗaukar gilashin), tsarin yana guje wa karayar wafer yayin etching ta baya, samun jurewa <1 μm overpressure don na'urori masu auna firikwensin IoT na masana'antu.

• Haɗin Fasaha: Kayan aikin wafer ɗin mu yana haɗa injin niƙa, CMP, da etching na plasma don magance kalubale iri-iri (Si, SiC, Sapphire). Misali, GaN-on-SiC yana buƙatar niƙa matasan (lu'u lu'u-lu'u + plasma) don daidaita tauri da haɓakar zafi, yayin da na'urori masu auna firikwensin MEMS suna buƙatar ƙarancin ƙasa-5 nm ta hanyar gogewar CMP.

• Tasirin Masana'antu: Ta hanyar ba da damar wafers mai ƙarfi, mafi girma, wannan fasaha yana haifar da sababbin abubuwa a cikin kwakwalwan AI, 5G mmWave modules, da kuma na'urorin lantarki masu sassauƙa, tare da jurewar TTV <0.1 μm don nunin nuni da <0.5 μm don na'urori masu auna firikwensin LiDAR na mota.

Ayyukan XKH

1. Magani na Musamman

Siffar Tsare-tsare: Tsararrun ɗaki na 4-12-inch tare da lodawa / saukewa ta atomatik.

Tallafin Doping: girke-girke na yau da kullun don lu'ulu'u na Er/Yb-doped da wafers InP/GaAs.

2. Ƙarshe-zuwa-Ƙarshe Support

Haɓaka Tsari: Gwajin kyauta yana gudana tare da haɓakawa.

Koyarwar Duniya: Taro na fasaha kowace shekara akan kulawa da magance matsala.

3. Multi-Material Processing

SiC: Wafer bakin ciki zuwa 100 μm tare da Ra <0.1 nm.

Sapphire: 50μm kauri don UV Laser windows (watsawa> 92% @ 200 nm).

4. Ƙimar-Ƙara Ayyuka

Abubuwan da ake amfani da su: Tayoyin lu'u-lu'u (2000+ wafers / rayuwa) da slurries CMP.

Kammalawa

Wannan wafer thinning kayan aiki yana isar da daidaitattun masana'antu-jagoranci, versatility na abubuwa da yawa, da aiki da kai mai kaifin baki, yana mai da shi ba makawa ga haɗin gwiwar 3D da lantarki. Cikakkun ayyuka na XKH-daga keɓancewa zuwa bayan-aiki-tabbatar da abokan ciniki sun sami ingantaccen farashi da ingantaccen aiki a masana'antar semiconductor.