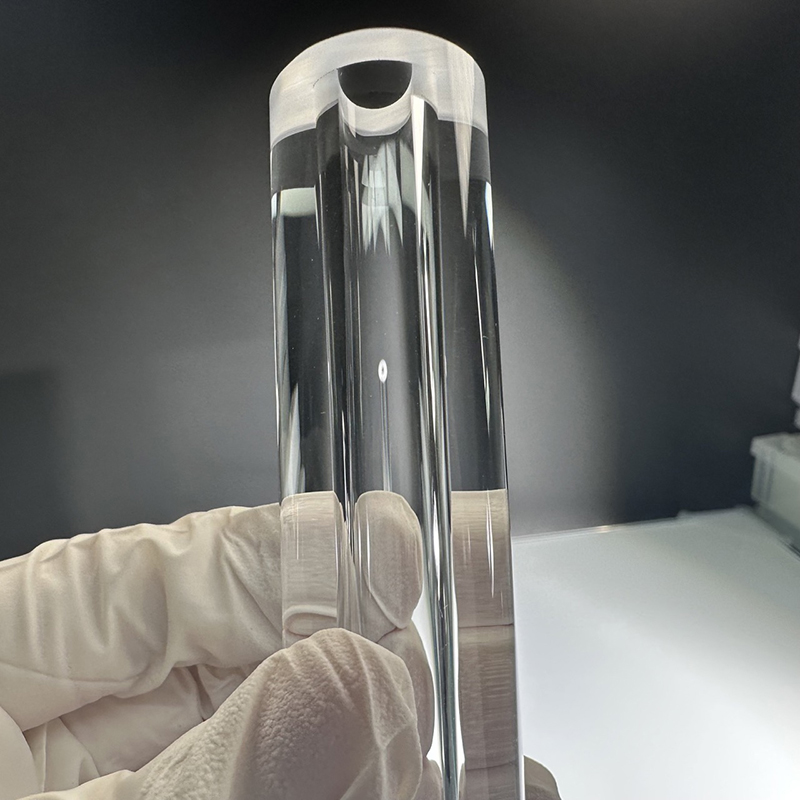

Semiconductor Laser Lift-Off Kayan Aikin Juya Juyin Ingot Thinning

Cikakken zane

Gabatarwar Samfurin Kayan Aikin Kashe Laser Semiconductor

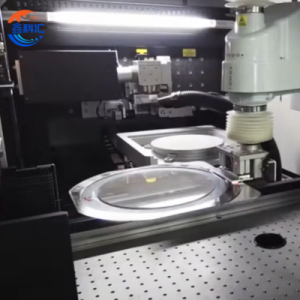

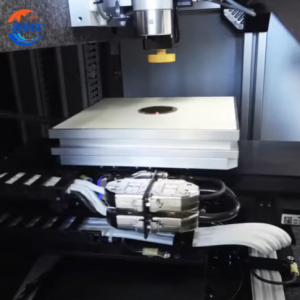

Semiconductor Laser Lift-Off Equipment wani ƙwararren ƙwararren masana'antu ne wanda aka ƙera don daidaitaccen sikelin da ba tare da tuntuɓar ingots na semiconductor ba ta hanyar dabarun ɗagawa na Laser. Wannan tsarin ci-gaba yana taka muhimmiyar rawa a cikin ayyukan wafering semiconductor na zamani, musamman a cikin ƙirƙira na ƙera wafers don babban aiki na lantarki, LEDs, da na'urorin RF. Ta hanyar ba da damar rarrabuwar yadudduka na bakin ciki daga ingots mai yawa ko masu ba da gudummawa, Kayan aikin Semiconductor Laser Lift-Off yana jujjuya ɓacin rai ta hanyar kawar da saƙar inji, niƙa, da matakan etching sinadarai.

Na al'ada thinning semiconductor ingots, kamar gallium nitride (GaN), silicon carbide (SiC), da sapphire, yawanci aiki-m, almubazzaranci, kuma mai yiwuwa ga microcracks ko surface lalacewa. Sabanin haka, Semiconductor Laser Lift-Off Equipment yana ba da mara lahani, madaidaicin madadin wanda ke rage asarar kayan abu da damuwa na saman yayin haɓaka yawan aiki. Yana goyan bayan nau'ikan kristal iri-iri da kayan fili kuma ana iya haɗa su ba tare da ɓata lokaci ba cikin layin samarwa na gaba-gaba ko tsakiyar ruwa.

Tare da daidaitawar raƙuman laser mai daidaitawa, tsarin mayar da hankali mai daidaitawa, da madaidaicin wafer chucks, wannan kayan aikin ya dace sosai don slicing ingot, ƙirƙirar lamella, da ƙwaƙƙwaran fim mai ɗorewa don tsarin na'urar a tsaye ko canja wurin Layer heteroepitaxial.

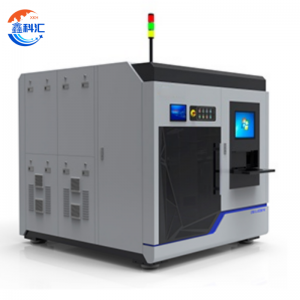

Siga na Semiconductor Laser Lift-Off Equipment

| Tsawon tsayi | IR/SHG/THG/FHG |

|---|---|

| Nisa Pulse | Nanosecond, Picosecond, Femtosecond |

| Tsarin gani | Kafaffen tsarin gani ko tsarin gani na Galvano |

| Matsayin XY | 500 mm × 500 mm |

| Rage sarrafawa | 160 mm |

| Gudun motsi | Matsakaicin 1,000 mm/sec |

| Maimaituwa | ± 1 μm ko ƙasa da haka |

| Cikakken Matsayin Daidaitawa: | ± 5 μm ko ƙasa da haka |

| Girman Wafer | 2-6 inci ko musamman |

| Sarrafa | Windows 10,11 da PLC |

| Wutar Wutar Lantarki | AC 200 V ± 20 V, Single-lokaci, 50/60 kHz |

| Girman Waje | 2400 mm (W) × 1700 mm (D) × 2000 mm (H) |

| Nauyi | 1,000 kg |

Ƙa'idar Aiki na Kayan Aikin Kashe Laser Semiconductor

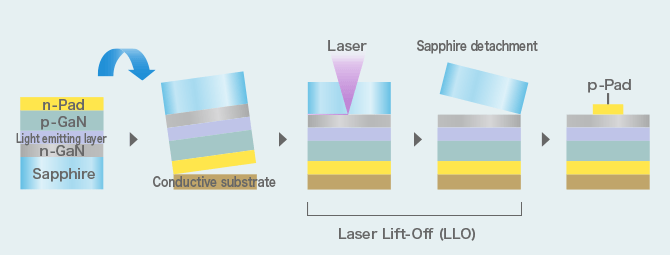

Babban tsarin na'urar Laser Lift-Off Equipment na Semiconductor yana dogara ne akan zaɓaɓɓen bazuwar photothermal ko ablation a mahaɗin tsakanin ingot mai bayarwa da epitaxial ko Layer manufa. Laser UV mai ƙarfi mai ƙarfi (yawanci KrF a 248 nm ko ingantattun lasers UV a kusa da 355 nm) ana mai da hankali ne ta hanyar mai ba da gudummawa mai haske ko tsaka-tsaki, inda ake zaɓin kuzari a zurfin da aka ƙaddara.

Wannan gurɓataccen makamashin da aka keɓe yana haifar da lokacin iskar gas mai matsananciyar matsa lamba ko Layer faɗaɗa zafin zafi a mahaɗin, wanda ke fara tsaftataccen ma'aunin wafer na sama ko Layer na na'ura daga tushen ingot. An daidaita tsarin da kyau ta hanyar daidaita sigogi kamar girman bugun jini, saurin laser, saurin dubawa, da zurfin zurfafa zurfafa zu-axis. Sakamakon wani yanki ne na bakin ciki-sau da yawa a cikin kewayon 10 zuwa 50 µm-wanda aka raba shi da tsaftar mahaifa ba tare da lalata injina ba.

Wannan hanya ta Laser dagawa-kashe don ingot thinning yana guje wa asarar kerf da lalacewar saman da ke da alaƙa da sawing na wayar lu'u-lu'u ko lapping na inji. Hakanan yana kiyaye mutuncin crystal kuma yana rage buƙatun gogewa na ƙasa, yana mai da kayan aikin Semiconductor Laser Lift-Off kayan aikin canza wasa don samar da wafer na gaba.

Aikace-aikace na Semiconductor Laser Lift-Off Equipment

Semiconductor Laser Lift-Off Equipment yana samun fa'ida sosai a cikin ingot thinning a cikin kewayon kayan haɓakawa da nau'ikan na'urori, gami da:

-

GaN da GaAs Ingot Thinning don Na'urorin Wuta

Yana ba da damar ƙirƙirar wafer na bakin ciki don inganci mai ƙarfi, transistor da diodes mai ƙarancin juriya.

-

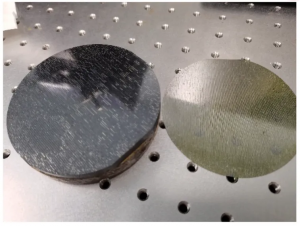

SiC Substrate Reclamation da Lamella Separation

Yana ba da damar ɗaukar ma'aunin wafer daga babban sikelin SiC don tsarin na'urar tsaye da sake amfani da wafer.

-

LED Wafer Slicing

Yana sauƙaƙe ɗaga yadudduka na GaN daga ingots na sapphire mai kauri don samar da filayen LED masu bakin ciki.

-

RF da Ƙirƙirar Na'urar Microwave

Yana goyan bayan tsarukan transistor-motsitor (HEMT) mai tsananin bakin ciki da ake buƙata a cikin tsarin 5G da radar.

-

Canja wurin Layer Epitaxial

Daidai yana cire yadudduka na epitaxial daga ingots na crystalline don sake amfani da su ko haɗawa cikin tsarin heterostructures.

-

Sirin-Fim Solar Cells da Photovoltaics

An yi amfani da shi don ware yadudduka na abin sha na bakin ciki don sassauƙan ƙwayoyin rana ko ingantaccen aiki.

A cikin kowane ɗayan waɗannan wuraren, Semiconductor Laser Lift-Off Equipment yana ba da iko mara misaltuwa akan daidaituwar kauri, ingancin saman, da amincin Layer.

Fa'idodin Ingot Thining na tushen Laser

-

Asarar Abubuwan Sifili-Kerf

Idan aka kwatanta da hanyoyin slicing wafer na gargajiya, tsarin laser yana haifar da kusan amfani da kayan aiki kusan 100%.

-

Karamin Damuwa da Warping

Kashewar da ba a tuntuɓar ba yana kawar da girgizar injina, rage bakan wafer da samuwar microcrack.

-

Kiyaye ingancin saman

Ba a buƙatar latsawa bayan bakin ciki ko goge goge da ake buƙata a yawancin lokuta, saboda cirewar laser yana kiyaye amincin saman saman.

-

Babban kayan aiki da Shirye-shiryen Automation

Mai ikon sarrafa ɗaruruwan ma'auni a kowane motsi tare da lodawa / saukewa ta atomatik.

-

Mai daidaitawa zuwa Kayayyaki da yawa

Mai jituwa tare da GaN, SiC, sapphire, GaAs, da kayan III-V masu tasowa.

-

Amintaccen muhalli

Yana rage amfani da abrasives da matsananciyar sinadarai na yau da kullun a cikin matakai na tushen slurry.

-

Sake amfani da Substrate

Za a iya sake yin fa'ida ingots masu ba da gudummawa don zagayowar ɗagawa da yawa, yana rage tsadar kayan aiki sosai.

Tambayoyin da ake Yi akai-akai (FAQ) na Kashe-kashe Laser Laser Semiconductor

-

Q1: Menene kauri kewayo na Semiconductor Laser Lift-Off kayan aikin zai iya cimma don yankan wafer?

A1:Yawan kaurin yanki ya bambanta daga 10 µm zuwa 100 µm ya danganta da kayan aiki da tsari.Q2: Za a iya amfani da wannan kayan aikin don bakin ciki ingots da aka yi da kayan da ba su da kyau kamar SiC?

A2:Ee. Ta hanyar daidaita tsayin igiyoyin Laser da haɓaka aikin injiniyan mu'amala (misali, masu shiga tsakani), har ma da kayan da ba su da tushe za a iya sarrafa su.Q3: Ta yaya ake daidaita ma'aunin mai ba da gudummawa kafin cirewar laser?

A3:Tsarin yana amfani da juzu'in daidaitawar tushen hangen nesa na ƙananan micron tare da amsawa daga alamomin gaskiya da sikanin hangen nesa.Q4: Menene lokacin sake zagayowar da ake tsammanin don aikin ɗagawa na Laser ɗaya?

A4:Dangane da girman wafer da kauri, yawan hawan keke yana wucewa daga mintuna 2 zuwa 10.Q5: Shin tsarin yana buƙatar yanayi mai tsabta?

A5:Duk da yake ba dole ba ne, ana ba da shawarar haɗin ɗakin tsafta don kula da tsaftar ƙasa da yawan amfanin na'urar yayin ayyuka masu inganci.

Game da Mu

XKH ya ƙware a cikin haɓaka fasahar fasaha, samarwa, da tallace-tallace na gilashin gani na musamman da sabbin kayan kristal. Kayayyakinmu suna hidimar kayan lantarki na gani, na'urorin lantarki na mabukaci, da sojoji. Muna ba da abubuwan haɗin gani na Sapphire, murfin ruwan tabarau na wayar hannu, Ceramics, LT, Silicon Carbide SIC, Quartz, da wafers kristal semiconductor. Tare da ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun kayan aiki, mun yi fice a cikin sarrafa samfuran da ba daidai ba, da nufin zama babban kamfani na kayan fasaha na optoelectronic.