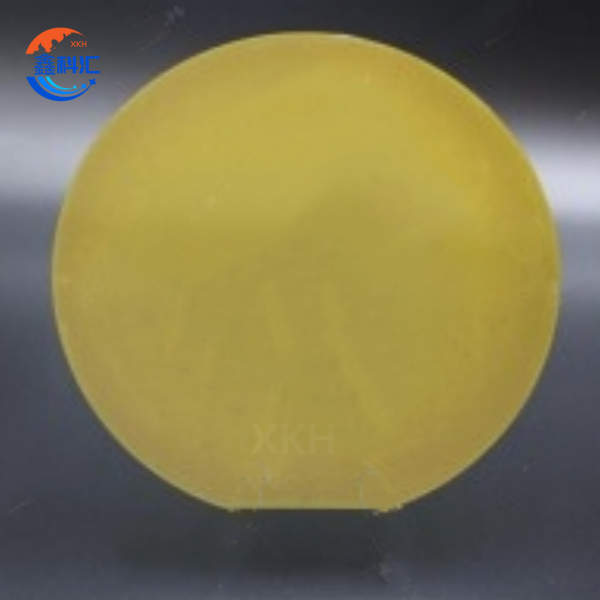

6 inch SiC kristal guda ɗaya mai ɗaukar nauyi akan polycrystalline SiC mai haɗawa da diamita 150mm P nau'in N

Siffofin fasaha

| Girma: | 6 inci |

| Diamita: | 150 mm |

| Kauri: | 400-500 mm |

| Monocrystalline SiC Film Parameters | |

| Polytype: | 4H-SiC ko 6H-SiC |

| Matsalolin Doping: | 1 × 10¹⁴ - 1 × 10¹⁸ cm⁻³ |

| Kauri: | 5-20 m |

| Resistance Sheet: | 10-1000 Ω/sq |

| Motsin Wutar Lantarki: | 800-1200 cm²/Vs |

| Motsin Ramin: | 100-300 cm²/Vs |

| Polycrystalline SiC Buffer Layer Parameters | |

| Kauri: | 50-300 mm |

| Ƙarfafa Ƙarfafawa: | 150-300 W/m·K |

| Monocrystalline SiC Substrate Parameters | |

| Polytype: | 4H-SiC ko 6H-SiC |

| Matsalolin Doping: | 1 × 10¹⁴ - 1 × 10¹⁸ cm⁻³ |

| Kauri: | 300-500 μm |

| Girman hatsi: | > 1 mm |

| Tashin Lafiya: | <0.3mm RMS |

| Kayayyakin Injini & Lantarki | |

| Tauri: | 9-10 Mohs |

| Ƙarfin Ƙarfi: | 3-4 GPA |

| Ƙarfin Ƙarfafawa: | 0.3-0.5 GPA |

| Ƙarfin Filin Rushewa: | 2 MV/cm |

| Jimlar Haƙuri na Kashi: | > 10 Mr |

| Juriya Tasirin Abu Daya: | > 100 MeV·cm²/mg |

| Ƙarfafa Ƙarfafawa: | 150-380 W/m·K |

| Tsawon Zazzabi Mai Aiki: | -55 zuwa 600 ° C |

Mabuɗin Halaye

SiC ɗin monocrystalline mai inch 6-inch akan polycrystalline SiC composite substrate yana ba da ma'auni na musamman na tsarin kayan aiki da aiki, yana sa ya dace da buƙatun yanayin masana'antu:

1.Cost-Effectiveness: The polycrystalline SiC tushe sosai rage farashin idan aka kwatanta da cikakken monocrystalline SiC, yayin da monocrystalline SiC aiki Layer tabbatar da na'urar-sa aikin, manufa domin kudin-m aikace-aikace.

2.Exceptional Electrical Properties: The monocrystalline SiC Layer yana nuna babban motsi mai ɗaukar kaya (> 500 cm² / V · s) da ƙananan ƙarancin lahani, yana goyan bayan babban mitoci da aikin na'ura mai ƙarfi.

3.High-Temperature Stability: SiC's inherent high-temperature juriya (> 600 ° C) tabbatar da hadadden substrate zauna barga a karkashin matsananci yanayi, sa shi dace da lantarki motocin da masana'antu motor aikace-aikace.

4.6-inch Madaidaicin Girman Wafer: Idan aka kwatanta da sifofin SiC na al'ada 4-inch, tsarin 6-inch yana ƙara yawan amfanin guntu da sama da 30%, yana rage farashin na'urar kowane raka'a.

5.Conductive Design: Pre-doped N-type ko nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'i) sun rage girman matakan ion implantation a cikin masana'antun na'ura, inganta haɓakar samar da kayan aiki da yawan amfanin ƙasa.

6.Superior Thermal Management: The polycrystalline SiC tushe na thermal conductivity (~ 120 W / m · K) ya fuskanci cewa na monocrystalline SiC, yadda ya kamata magance zafi dissipation kalubale a high-ikon na'urorin.

Waɗannan halayen suna sanya 6-inch monocrystalline SiC mai gudanarwa akan polycrystalline SiC composite substrate a matsayin gasa mafita ga masana'antu kamar sabunta makamashi, sufurin jirgin ƙasa, da sararin samaniya.

Aikace-aikace na farko

SiC ɗin monocrystalline mai inci 6 akan polycrystalline SiC composite substrate an yi nasarar tura shi cikin manyan filayen buƙata da yawa:

1.Electric Vehicle Powertrains: An yi amfani da shi a cikin SiC MOSFETs masu ƙarfin lantarki da diodes don haɓaka ingantaccen inverter da tsawaita kewayon baturi (misali, Tesla, samfuran BYD).

2.Industrial Motor Drives: Yana ba da damar yanayin zafi mai zafi, manyan nau'ikan wutar lantarki masu saurin canzawa, rage yawan amfani da makamashi a cikin injina mai nauyi da iska.

3.Photovoltaic Inverters: Na'urorin SiC sun inganta ingantaccen canjin hasken rana (> 99%), yayin da ma'auni mai mahimmanci ya kara rage farashin tsarin.

4.Rail Transport: An yi amfani da shi a cikin masu juyawa don tsarin dogo mai sauri da tsarin jirgin karkashin kasa, yana ba da juriya mai girma (> 1700V) da ƙananan nau'i.

5.Aerospace: Ideal don tsarin wutar lantarki na tauraron dan adam da na'urorin sarrafa injin jirgin sama, masu iya jure matsanancin yanayin zafi da radiation.

A cikin ƙirƙira mai amfani, SiC ɗin monocrystalline mai inci 6 akan polycrystalline SiC composite substrate ya dace da daidaitaccen tsarin na'urar SiC (misali, lithography, etching), baya buƙatar ƙarin saka hannun jari.

Ayyukan XKH

XKH yana ba da cikakkiyar goyon baya ga 6-inch monocrystalline SiC na sic akan polycrystalline SiC composite substrate, yana rufe R&D don samar da taro:

1.Customization: Daidaitacce monocrystalline Layer kauri (5-100 μm), doping maida hankali (1e15-1e19 cm⁻³), da crystal fuskantarwa (4H / 6H-SiC) don saduwa da bambancin na'urar bukatun.

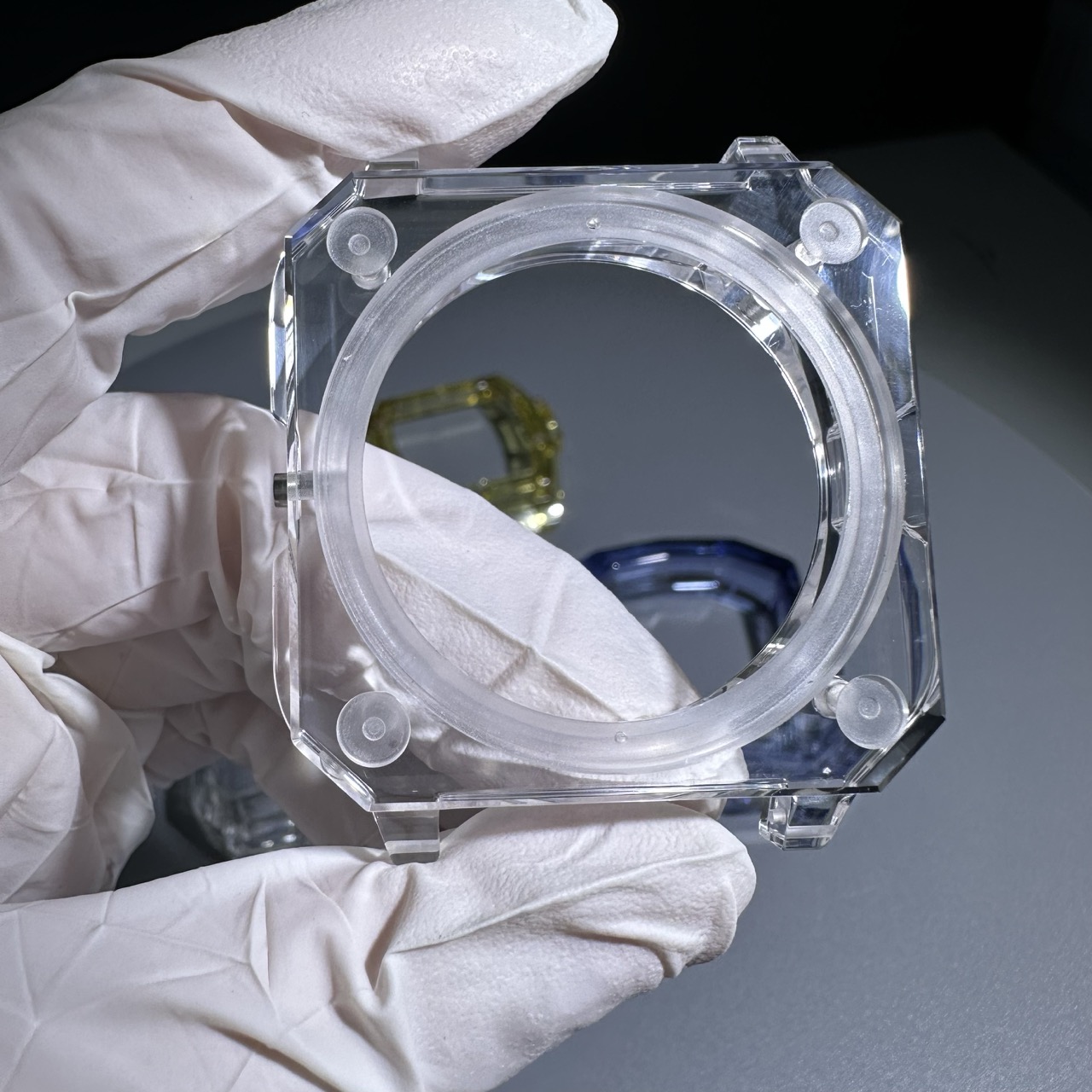

2.Wafer Processing: Bulk wadata na 6-inch substrates tare da backside thinning da metallization sabis don toshe-da-play hadewa.

3.Technical Validation: Ya hada da bincike na crystallinity XRD, gwajin sakamako na Hall, da ma'aunin juriya na thermal don ƙaddamar da cancantar kayan aiki.

4.Rapid Prototyping: 2- zuwa 4-inch samfurori (tsari iri ɗaya) don cibiyoyin bincike don haɓaka hawan haɓakawa.

5.Failure Analysis & Optimization: Material-level Solution for sarrafa kalubale (misali, epitaxial Layer lahani).

Manufarmu ita ce kafa 6-inch monocrystalline SiC a kan polycrystalline SiC composite substrate a matsayin mafi kyawun aikin aiwatarwa don kayan lantarki na SiC, yana ba da tallafi na ƙarshe zuwa ƙarshe daga samfuri zuwa samar da girma.

Kammalawa

SiC ɗin monocrystalline mai inci 6 akan polycrystalline SiC mai haɗaɗɗen kayan aikin yana samun daidaiton ci gaba tsakanin aiki da farashi ta hanyar ingantaccen tsarinsa na mono/polycrystalline. Kamar yadda motocin lantarki ke yaɗuwa da ci gaban masana'antu 4.0, wannan madaidaicin yana ba da ingantaccen tushe na kayan abu don na'urorin wutar lantarki na gaba. XKH na maraba da haɗin gwiwa don ƙara gano yuwuwar fasahar SiC.