Tsarin Wayar da Wafer don Ma'aunin Gabatarwar Crystal

Gabatarwar Kayan aiki

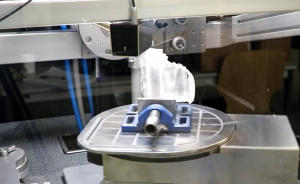

Kayan aikin Wafer sune na'urori madaidaici dangane da ka'idodin X-ray diffraction (XRD), da farko ana amfani da su a masana'antar semiconductor, kayan gani, yumbu, da sauran masana'antar kayan crystalline.

Waɗannan kayan aikin suna ƙayyadadden daidaitawar lattice ɗin kristal kuma suna jagorantar ingantattun hanyoyin yanke ko goge goge. Babban fasali sun haɗa da:

- Ma'auni masu inganci:Mai ikon warware jirage na crystallographic tare da ƙudurin kusurwa zuwa 0.001°.

- Babban dacewa samfurin:Yana goyan bayan wafers har zuwa 450 mm a diamita da nauyi na 30 kg, dace da kayan kamar silicon carbide (SiC), sapphire, da silicon (Si).

- Modular zane:Ayyukan da za a iya fadada sun haɗa da bincike mai lanƙwasa, 3D taswirar lahani, da na'urori masu tarawa don sarrafa samfura da yawa.

Maɓalli na Fasaha

| Matsayin siga | Hankali Dabi'u/Tsayawa |

| Source X-ray | Cu-Kα (0.4 × 1 mm tabo mai mahimmanci), 30kV mai haɓaka ƙarfin lantarki, 0-5 mA mai daidaitawa bututu na yanzu |

| Angular Range | θ: -10° zuwa +50°; 2θ: -10° zuwa +100° |

| Daidaito | Ƙaddamarwar kusurwa: 0.001 °, gano lahani na sama: ± 30 arcseconds (maganin girgiza) |

| Speed Scanning | Omega scan ya kammala cikakken daidaitawar lattice a cikin daƙiƙa 5; Binciken Theta yana ɗaukar ~ 1 minti |

| Samfurin Stage | V-groove, tsotsa mai huhu, jujjuyawar kusurwa da yawa, mai dacewa da wafers 2-8-inch |

| Ayyuka masu Faɗawa | Binciken lanƙwasa mai girgiza, taswirar 3D, na'urar tarawa, gano lahani na gani (scratches, GBs) |

Ƙa'idar Aiki

1. X-ray Diffraction Foundation

- X-haskoki suna yin hulɗa tare da nuclei atomic da electrons a cikin lattice crystal, suna haifar da tsarin rarrabawa. Dokar Bragg (nλ = 2d sinθ) tana sarrafa alakar da ke tsakanin kusurwoyin diffraction (θ) da tazarar lattice (d).

Masu ganowa suna ɗaukar waɗannan alamu, waɗanda aka bincika don sake gina tsarin crystallographic.

2. Omega Scanning Technology

- Crystal tana jujjuyawa akai-akai a kusa da kafaffen axis yayin da hasken X-ray ke haskaka shi.

- Masu ganowa suna tattara siginonin rarrabuwar kawuna a cikin jirage masu yawa na crystallographic, suna ba da damar ƙwaƙƙwaran ƙayyadaddun lattice a cikin daƙiƙa 5.

3. Rocking Curve Analysis

- Kafaffen kusurwar crystal tare da kusurwoyin abin da ya faru na X-ray daban-daban don auna girman nisa (FWHM), tantance lahani da iri.

4. Gudanarwa ta atomatik

- Abubuwan haɗin PLC da allon taɓawa suna ba da damar saitattun kusurwoyi, ra'ayoyin ainihin lokaci, da haɗin kai tare da injunan yanke don sarrafa madauki.

Abũbuwan amfãni da kuma Features

1. Daidaituwa da inganci

- Daidaitaccen kusurwa ± 0.001°, ƙudurin gano lahani <30 arcseconds.

- Saurin duban Omega yana da sauri 200 × fiye da sikanin Theta na gargajiya.

2. Modularity da Scalability

- Za'a iya faɗaɗa don aikace-aikace na musamman (misali, SiC wafers, ruwan turbine).

- Haɗa tare da tsarin MES don sa ido kan samarwa na lokaci-lokaci.

3. Daidaituwa da Kwanciyar hankali

- Yana ɗaukar samfuran da ba daidai ba (misali, fataccen sapphire ingots).

- Zane mai sanyaya iska yana rage bukatun kulawa.

4. Aiki mai hankali

- Dannawa ɗaya daidaitawa da sarrafa ayyuka da yawa.

- Daidaitawa ta atomatik tare da lu'ulu'u na tunani don rage kuskuren ɗan adam.

Aikace-aikace

1. Semiconductor Manufacturing

- Wafer dicing orientation: Yana ƙayyade Si, SiC, GaN wafer orientation don ingantaccen yankan yadda ya dace.

- Lalacewar taswira: Yana gano ɓarna ko ɓarna a sama don haɓaka yawan amfanin guntu.

2. Kayayyakin gani

- Lu'ulu'u marasa kan layi (misali, LBO, BBO) don na'urorin Laser.

- Sapphire wafer reference surface alama ga LED substrates.

3. Ceramics da Composites

- Yana nazarin daidaitawar hatsi a cikin Si3N4 da ZrO2 don aikace-aikacen zafi mai zafi.

4. Bincike da Kula da inganci

- Jami'o'i/dakunan gwaje-gwaje don haɓaka kayan abu na yau da kullun (misali, manyan allunan entropy).

- QC masana'antu don tabbatar da daidaiton tsari.

Ayyukan XKH

XKH yana ba da cikakken goyon bayan fasaha na rayuwa don kayan aikin wafer, gami da shigarwa, haɓaka siginar tsari, ƙididdigar lanƙwasa, da taswirar lahani na 3D. Abubuwan da aka keɓance (misali, fasahar stacking ingot) ana ba da su don haɓaka ingantaccen samar da kayan aikin na'ura da na gani sama da 30%. Ƙungiya mai sadaukarwa tana gudanar da horo a kan shafin, yayin da 24/7 goyon baya mai nisa da saurin maye gurbin kayan aiki yana tabbatar da amincin kayan aiki.