TGV Glass substrates 12inch wafer Glass naushi

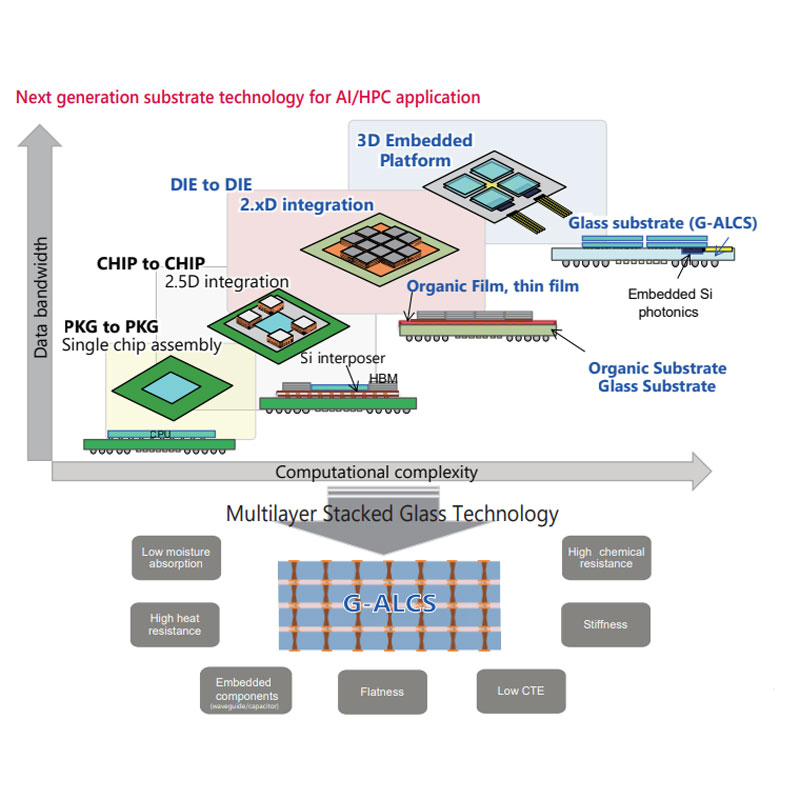

Gilashin gilashin gilashi suna yin aiki mafi kyau dangane da yanayin zafi, kwanciyar hankali na jiki, kuma sun fi tsayayya da zafi kuma sun fi dacewa da matsalolin warping ko nakasa saboda yanayin zafi;

Bugu da ƙari, ƙayyadaddun kayan lantarki na musamman na gilashin gilashi suna ba da damar ƙananan asarar dielectric, ba da izinin sigina mai haske da watsa wutar lantarki. Sakamakon haka, asarar wutar lantarki yayin watsa siginar yana raguwa kuma gabaɗayan ingancin guntu yana haɓaka ta halitta. Za'a iya rage kauri na tushen gilashin da kusan rabin idan aka kwatanta da filastik ABF, kuma bakin ciki yana inganta saurin watsa sigina da ingancin wutar lantarki.

Hole forming fasaha na TGV:

Laser induced etching hanyar da ake amfani da su jawo ci gaba denaturation zone ta pulsed Laser, sa'an nan Laser jiyya gilashin da aka sanya a cikin hydrofluoric acid bayani ga etching. Yawan etching na gilashin yanki na denaturation a cikin hydrofluoric acid yana da sauri fiye da na gilashin da ba a daɗe ba don samuwa ta cikin ramuka.

Cika TGV:

Na farko, ana yin ramukan makafi na TGV. Abu na biyu, an ajiye nau'in nau'in iri a cikin ramin makaho na TGV ta hanyar shigar da tururi ta jiki (PVD). Na uku, kasa-sama electroplating cimma nasara cika na TGV; A ƙarshe, ta hanyar haɗin gwiwa na ɗan lokaci, niƙa na baya, sinadarai na gyaran gyare-gyaren jan ƙarfe (CMP) bayyanar jan karfe, haɗawa, samar da farantin canja wuri mai cike da ƙarfe na TGV.

Cikakken zane