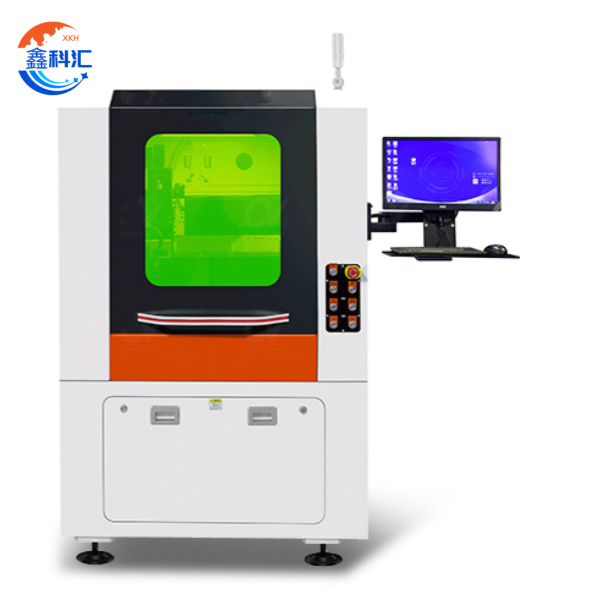

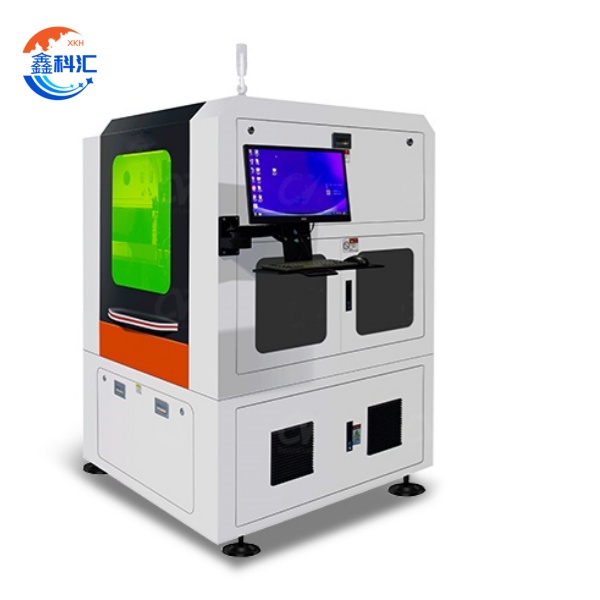

Small tebur Laser naushin inji 1000W-6000W m budewa 0.1MM za a iya amfani da karfe gilashin yumbu kayan

Abubuwan da ake buƙata

1. Metal kayan: kamar aluminum, jan karfe, titanium gami, bakin karfe, da dai sauransu.

2. Non-karfe kayan: irin su filastik (ciki har da polyethylene PE, polypropylene PP, polyester PET da sauran filastik fina-finai), gilashin (ciki har da talakawa gilashin, musamman gilashin kamar matsananci-fari gilashin, K9 gilashin, high borosilicate gilashin, ma'adini gilashin, da dai sauransu, amma tempered gilashin saboda ta musamman na jiki kaddarorin), fata da kuma ya dace da drills a kan takarda na musamman, fata da kuma rawar jiki.

3. Haɗaɗɗen abu: wanda ya ƙunshi abubuwa biyu ko fiye tare da kaddarorin daban-daban ta hanyoyin jiki ko sinadarai, tare da kyawawan kaddarorin.

4.Special kayan: A cikin takamaiman wurare, ana iya amfani da na'urorin bugun laser don aiwatar da wasu kayan aiki na musamman.

Ƙayyadaddun sigogi

| Suna | Bayanai |

| Ƙarfin Laser: | 1000W-6000W |

| Daidaitaccen yankewa: | ± 0.03MM |

| Mafi ƙarancin ƙima: | 0.1MM |

| Tsawon yanke: | 650MM×800MM |

| Daidaitaccen matsayi: | ≤±0.008MM |

| Maimaita daidaito: | 0.008MM |

| Yanke gas: | Iska |

| Kafaffen samfurin: | Ƙunƙarar bakin huhu, goyan bayan kayan aiki |

| Tsarin tuƙi: | Motar layin dakatarwar Magnetic |

| Yanke kauri | 0.01MM-3MM |

Fa'idodin fasaha

1.Efficient hakowa: Yin amfani da katako mai ƙarfi na laser mai ƙarfi don aiki maras amfani, da sauri, 1 na biyu don kammala aikin ƙananan ramuka.

2.High daidaici: Ta hanyar sarrafa iko daidai, mitar bugun jini da kuma mayar da hankali kan matsayi na laser, ana iya samun aikin hakowa tare da daidaitattun micron.

3. Yadu dacewa: na iya aiwatar da nau'i-nau'i iri-iri, masu wuyar sarrafawa da kayan aiki na musamman, irin su filastik, roba, karfe (bakin karfe, aluminum, jan karfe, titanium alloy, da dai sauransu), gilashi, yumbu da sauransu.

4. Aiki mai hankali: Na'urar ƙwanƙwasa laser tana sanye take da ingantaccen tsarin kula da lambobi, wanda yake da hankali sosai kuma yana da sauƙin haɗawa tare da ƙirar komputa da tsarin masana'antar sarrafa kwamfuta don gane saurin shirye-shirye da haɓaka hadaddun wucewa da hanyar sarrafawa.

Yanayin aiki

1.Diversity: na iya aiwatar da nau'ikan sarrafa ramuka masu rikitarwa, kamar ramukan zagaye, ramukan murabba'i, ramukan triangle da sauran ramuka na musamman.

2.High quality: Ramin ingancin yana da girma, gefen yana da santsi, ba tare da jin dadi ba, kuma lalacewa yana da ƙananan.

3.Automation: Yana iya kammala aikin micro-rami tare da girman budewa iri ɗaya da rarraba kayan aiki a lokaci ɗaya, kuma yana tallafawa aikin ramin rukuni ba tare da sa hannun hannu ba.

Siffofin kayan aiki

■ Ƙananan girman kayan aiki, don magance matsalar kunkuntar sarari.

∎ Babban madaidaici, matsakaicin rami zai iya kaiwa 0.005mm.

n Kayan aiki yana da sauƙin aiki da sauƙin amfani.

■ Ana iya maye gurbin tushen hasken bisa ga kayan daban-daban, kuma dacewa ya fi ƙarfi.

■ Ƙananan yanki da zafi ya shafa, ƙarancin iskar oxygen a kusa da ramukan.

Filin aikace-aikace

1. Masana'antar lantarki

●Bugawa Hukumar da'ira (PCB) naushi:

Microhole machining: Ana amfani da shi don sarrafa microholes tare da diamita na ƙasa da 0.1mm akan PCBS don saduwa da buƙatun allunan haɗin haɗin kai (HDI).

Makafi da ramukan da aka binne: Yin injin makafi da ramukan binne a cikin PCBS masu yawa don haɓaka aiki da haɗin kai na hukumar.

●Marufi na Semiconductor:

Hakowa firam ɗin jagora: Ana ƙera madaidaicin ramukan a cikin firam ɗin jagorar semiconductor don haɗa guntu zuwa kewayen waje.

Taimakon yankan wafer: Punch ramuka a cikin wafer don taimakawa cikin aiwatar da yankewa da tattarawa na gaba.

2. Kayan aiki daidai

●Magungunan sarrafa sassa:

Matsakaicin hakowa na kaya: Yin gyare-gyaren madaidaicin ramuka akan ƙananan gears don daidaitaccen tsarin watsawa.

Hakowa bangaren firikwensin: Injin microholes akan abubuwan firikwensin don haɓaka hankali da saurin amsawa na firikwensin.

● Samfuran Samfura:

Mold sanyaya rami: Injin sanyaya rami a kan allura mold ko mutu simintin gyaran kafa don inganta zafi watsar da mold.

Sarrafa iska: Yin ƴan ƙanƙantar huɗa a kan mold don rage samuwar lahani.

3. Na'urorin likitanci

●Kayan aikin tiyata mafi ƙanƙanta:

Catheter perforation: Ana sarrafa microholes a cikin ƙananan catheters na tiyata don isar da magani ko magudanar ruwa.

Abubuwan Endoscope: Madaidaicin ramuka ana sarrafa su a cikin ruwan tabarau ko shugaban kayan aiki na endoscope don inganta aikin kayan aikin.

●Tsarin isar da magunguna:

Hakowa tsararrun microneedle: Injin microholes akan facin magani ko tsararrun microneedle don sarrafa adadin sakin miyagun ƙwayoyi.

Hakowa Biochip: Ana sarrafa microholes akan biochips don al'adar tantanin halitta ko ganowa.

4. Na'urorin gani

●Mai haɗa fiber optic:

Hakowa ƙarshen ramin fiber na gani: Injin microholes akan ƙarshen fuskar mai haɗin gani don haɓaka ingantaccen watsa siginar gani.

Fiber array machining: Machining high-madaidaicin ramukan akan farantin tsararrun fiber don sadarwar gani na tashoshi da yawa.

●Tace mai gani:

Tace hakowa: Machining microholes a kan Tantancewar tace don cimma zabar takamaiman wavelengths.

Machining ɓangarorin ɓangarorin: Injin microholes akan abubuwan gani da yawa don tsaga katako ko siffatawa.

5. Kera motoci

●Tsarin allurar mai:

Bututun bututun ƙarfe na allura: sarrafa ƙananan ramuka akan bututun allura don haɓaka tasirin atomization na man fetur da haɓaka haɓakar konewa.

● Ƙirƙirar Sensor:

Hakowa firikwensin matsin lamba: Injin microholes akan firikwensin matsa lamba diaphragm don haɓaka hankali da daidaiton firikwensin.

●Batir mai ƙarfi:

Hakowa guntun baturi: Injin microholes akan guntuwar igiyoyin baturin lithium don haɓaka kutsewar lantarki da jigilar ion.

XKH yana ba da cikakken kewayon sabis na tsayawa guda ɗaya don ƙananan magudanar ruwa na tebur, gami da amma ba'a iyakance ga: shawarwarin tallace-tallace na ƙwararru, ƙirar shirye-shirye na musamman, samar da kayan aiki masu inganci, ingantaccen shigarwa da ƙaddamarwa, cikakken horo na aiki, don tabbatar da cewa abokan ciniki sun sami mafi inganci, daidai da ƙwarewar sabis na rashin kulawa a cikin tsarin naushi.

Cikakken zane