SiO₂ Ma'adini Wafer Ma'adini Wafers SiO₂ MEMS Zazzabi 2″ 3″ 4″ 6″ 8″ 12″

Cikakken zane

Gabatarwa

Wafers na Quartz suna taka muhimmiyar rawa wajen haɓaka masana'antar lantarki, semiconductor, da masana'antar gani. An samo shi a cikin wayoyin hannu masu jagorantar GPS ɗinku, waɗanda aka saka a cikin manyan tashoshin tushe masu ƙarfin cibiyoyin sadarwa na 5G, da haɗa su cikin kayan aikin kera microchips na gaba, wafern quartz suna da mahimmanci. Waɗannan maɗaukakin maɗaukaki masu tsafta suna ba da damar ƙirƙira a cikin komai daga ƙididdige ƙididdigewa zuwa na gaba na photonics. Duk da cewa an samo su daga ɗaya daga cikin mafi yawan ma'adanai a Duniya, ma'adinan quartz ana ƙera su zuwa ƙa'idodi na musamman na daidaito da aiki.

Menene Quartz Wafers

Wafers na ma'adini sirara ne, fayafai masu madauwari waɗanda aka ƙirƙira daga kristal na roba mai tsafta. Akwai a cikin daidaitattun diamita masu jere daga inci 2 zuwa 12, wafers quartz yawanci kewayo a cikin kauri daga 0.5 mm zuwa 6 mm. Ba kamar ma'adini na halitta ba, wanda ke samar da lu'ulu'u na prismatic mara kyau, ma'adini na roba yana girma a ƙarƙashin yanayin dakin gwaje-gwajen da aka sarrafa sosai, yana samar da sifofin crystal iri ɗaya.

Halin kristal na ma'adini wafers yana ba da juriya na sinadarai mara misaltuwa, bayyananniyar gani, da kwanciyar hankali a ƙarƙashin babban zafin jiki da damuwa na inji. Waɗannan fasalulluka sun sa wafern quartz ya zama tushen tushe don ingantattun na'urorin da ake amfani da su wajen watsa bayanai, ji, ƙididdigewa, da fasahar tushen Laser.

Ƙididdigar Quartz Wafer

| Nau'in Quartz | 4 | 6 | 8 | 12 |

|---|---|---|---|---|

| Girman | ||||

| Diamita (inch) | 4 | 6 | 8 | 12 |

| Kauri (mm) | 0.05-2 | 0.25-5 | 0.3-5 | 0.4-5 |

| Haƙurin Diamita (inch) | ± 0.1 | ± 0.1 | ± 0.1 | ± 0.1 |

| Hakurin Kauri (mm) | Mai iya daidaitawa | Mai iya daidaitawa | Mai iya daidaitawa | Mai iya daidaitawa |

| Kayayyakin gani | ||||

| Fihirisar Refractive @ 365 nm | 1.474698 | 1.474698 | 1.474698 | 1.474698 |

| Fihirisar Refractive @ 546.1 nm | 1.460243 | 1.460243 | 1.460243 | 1.460243 |

| Fihirisar Refractive @ 1014 nm | 1.450423 | 1.450423 | 1.450423 | 1.450423 |

| Canjin Ciki (1250-1650 nm) | >99.9% | >99.9% | >99.9% | >99.9% |

| Jimlar Watsawa (1250-1650 nm) | >92% | >92% | >92% | >92% |

| Ingancin Machining | ||||

| TTV (Jimlar Bambancin Kauri, µm) | <3 | <3 | <3 | <3 |

| Lalata (µm) | ≤15 | ≤15 | ≤15 | ≤15 |

| Ƙarfin Sama (nm) | ≤1 | ≤1 | ≤1 | ≤1 |

| Baka (µm) | <5 | <5 | <5 | <5 |

| Abubuwan Jiki | ||||

| Girma (g/cm³) | 2.20 | 2.20 | 2.20 | 2.20 |

| Modul na Matasa (GPa) | 74.20 | 74.20 | 74.20 | 74.20 |

| Mohs Hardness | 6–7 | 6–7 | 6–7 | 6–7 |

| Shear Modulus (GPa) | 31.22 | 31.22 | 31.22 | 31.22 |

| Rabon Poisson | 0.17 | 0.17 | 0.17 | 0.17 |

| Ƙarfin Ƙarfi (GPa) | 1.13 | 1.13 | 1.13 | 1.13 |

| Ƙarfin Tensile (MPa) | 49 | 49 | 49 | 49 |

| Dielectric Constant (1 MHz) | 3.75 | 3.75 | 3.75 | 3.75 |

| Thermal Properties | ||||

| Wurin Wuta (10¹⁴.⁵ Pa·s) | 1000°C | 1000°C | 1000°C | 1000°C |

| Wurin Annealing (10¹³ Pa·s) | 1160°C | 1160°C | 1160°C | 1160°C |

| Wurin Tausasawa (10⁷.⁶ Pa·s) | 1620°C | 1620°C | 1620°C | 1620°C |

Aikace-aikace na Quartz Wafers

Wafers na Quartz an ƙera su ne na musamman don saduwa da aikace-aikacen da ake buƙata a cikin masana'antu gami da:

Kayan lantarki da na'urorin RF

- Ma'adini wafers sune ginshiƙan zuwa ma'adini crystal resonators da oscillators waɗanda ke ba da siginar agogo don wayoyin hannu, raka'a GPS, kwamfutoci, da na'urorin sadarwar mara waya.

- Ƙarƙashin haɓakar yanayin zafi da babban Q-factor suna sanya wafers na quartz cikakke don da'irar lokaci mai ƙarfi da matattarar RF.

Optoelectronics da Imaging

- Wafers na Quartz suna ba da kyakkyawar watsawar UV da IR, yana mai da su manufa don ruwan tabarau na gani, masu raba katako, tagogin laser, da masu ganowa.

- Juriyarsu ga radiation yana ba da damar amfani da su a cikin kimiyyar lissafi mai ƙarfi da kayan aikin sararin samaniya.

Semiconductor da MEMS

- Wafers na Quartz suna aiki azaman ma'auni don babban mitar semiconductor, musamman a aikace-aikacen GaN da RF.

- A cikin MEMS (Micro-Electro-Mechanical Systems), ma'auni na ma'adini suna canza siginonin inji zuwa na lantarki ta hanyar tasirin piezoelectric, yana ba da damar firikwensin kamar gyroscopes da accelerometers.

Advanced Manufacturing & Labs

- Ana amfani da wafers na ma'adini mai tsafta sosai a cikin sinadarai, likitanci, da dakunan gwaje-gwaje na photonic don sel masu gani, UV cuvettes, da sarrafa samfurin zafin jiki.

- Daidaituwarsu tare da matsananciyar yanayi ya sa su dace da ɗakunan plasma da kayan aikin ajiya.

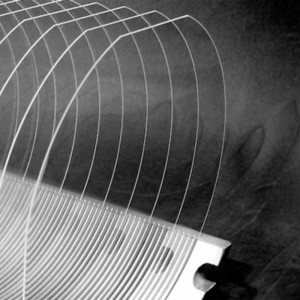

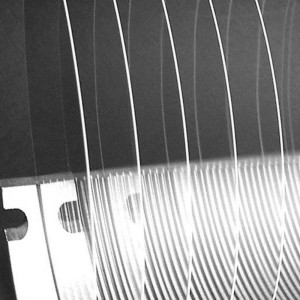

Yadda Aka Yi Wafers Quartz

Akwai hanyoyi guda biyu na masana'antu na farko don wafer quartz:

Fused Quartz Wafers

Ana yin wafers ɗin quartz ɗin ta hanyar narkewar granules na ma'adini na halitta a cikin gilashin amorphous, sa'an nan kuma a yanka tare da goge ƙaƙƙarfan toshe cikin wafers na bakin ciki. Waɗannan wafers na quartz suna ba da:

- Na musamman UV bayyananne

- Faɗin aiki na thermal (> 1100°C)

- Kyakkyawan juriya mai girgiza thermal

Sun dace da kayan aikin lithography, tanderun zafin jiki, da tagogin gani amma ba su dace da aikace-aikacen piezoelectric ba saboda rashin tsari na crystalline.

Al'adun Quartz Wafers

Wafern ma'adini na al'ada ana girma ta hanyar haɗin gwiwa don samar da lu'ulu'u marasa lahani tare da madaidaicin daidaitawar lattice. An kera waɗannan wafers don aikace-aikacen da ke buƙatar:

- Daidai yanke kusurwa (X-, Y-, Z-, AT-cut, da dai sauransu)

- Matsakaicin oscillators da matattarar SAW

- Polarizers na gani da na'urorin MEMS masu ci gaba

Tsarin samarwa ya haɗa da haɓaka iri a cikin autoclaves, sannan slicing, fuskantarwa, annealing, da gogewa.

Manyan Masu Kayayyakin Wafer Quartz

Masu samar da kayayyaki na duniya ƙware a cikin madaidaicin madaidaicin wafers sun haɗa da:

- Heraeus(Jamus) - Fused da roba quartz

- Shin Etsu Quartz(Japan) - mafita mai tsabta mai tsabta

- WaferPro(Amurka) – Faɗin diamita ma'adini wafers da substrates

- Korth Kristale(Jamus) – roba wafers crystal

Haɓaka Matsayin Quartz Wafers

Wafers na Quartz suna ci gaba da haɓakawa azaman mahimman abubuwan haɗin gwiwa a cikin shimfidar wuraren fasaha masu tasowa:

- Miniaturization- Ana ƙirƙira wafers na quartz tare da ƙarin juriya don haɗakar na'urar.

- Mafi Girma Mitar Lantarki- Sabbin ƙirar wafer quartz suna turawa cikin mmWave da THz yankuna don 6G da radar.

- Gaba-Gen Sensing- Daga motocin masu cin gashin kansu zuwa masana'antar IoT, na'urori masu auna firikwensin quartz suna zama mafi mahimmanci.

Tambayoyi akai-akai game da wafers na quartz

1. Menene wafer quartz?

Wafer ma'adini siriri ne, lebur diski da aka yi daga silicon dioxide crystalline (SiO₂), yawanci ana ƙera shi a daidaitattun girman semiconductor (misali, 2, 3, 4, 6, 8, ko 12)). An san shi don tsaftarta mai girma, kwanciyar hankali na zafi, da bayyananniyar gani, ana amfani da wafer ma'adini azaman ma'auni ko mai ɗaukar hoto a cikin manyan madaidaitan aikace-aikace daban-daban kamar ƙirƙira semiconductor, na'urorin MEMS, tsarin gani, da tafiyar matakai.

2. Menene bambanci tsakanin ma'adini da silica gel?

Quartz wani nau'in siliki ne mai ƙarfi na crystalline (SiO₂), yayin da silica gel wani nau'i ne na SiO₂ amorphous da porous, wanda aka saba amfani dashi azaman desiccant don sha danshi.

- Quartz yana da wuya, bayyananne, kuma ana amfani dashi a aikace-aikacen lantarki, gani, da masana'antu.

- Gel silica yana bayyana azaman ƙananan beads ko granules kuma ana amfani dashi da farko don sarrafa zafi a cikin marufi, lantarki, da ajiya.

3. Menene lu'ulu'u na quartz da ake amfani dasu?

Ana amfani da lu'ulu'u na ma'adini sosai a cikin kayan lantarki da na gani saboda abubuwan da suke da shi na piezoelectric (suna haifar da cajin lantarki a ƙarƙashin damuwa na inji). Aikace-aikacen gama gari sun haɗa da:

- Oscillators da sarrafa mita(misali, agogon quartz, agogo, microcontrollers)

- Abubuwan abubuwan gani(misali, ruwan tabarau, faranti, tagogi)

- Resonators da tacewaa cikin RF da na'urorin sadarwa

- Sensorsdon matsa lamba, hanzari, ko karfi

- Ƙirƙirar Semiconductora matsayin substrates ko aiwatar da windows

4. Me yasa ake amfani da quartz a cikin microchips?

Ana amfani da Quartz a aikace-aikacen da ke da alaƙa da microchip saboda yana bayar da:

- Zaman lafiyar thermala lokacin matakan zafi mai zafi kamar yadawa da annealing

- Wutar lantarkisaboda da dielectric Properties

- Juriya na sinadaranzuwa acid da kaushi da aka yi amfani da su a masana'antar semiconductor

- Matsakaicin daidaitoda ƙananan haɓakar thermal don ingantaccen daidaitawar lithography

- Duk da yake ba a amfani da ma'adini da kansa azaman kayan aikin semiconductor (kamar silicon), yana taka muhimmiyar rawa a cikin yanayin ƙirƙira-musamman a cikin tanderu, ɗakuna, da ma'aunin hoto.

Game da Mu

XKH ya ƙware a cikin haɓaka fasahar fasaha, samarwa, da tallace-tallace na gilashin gani na musamman da sabbin kayan kristal. Kayayyakinmu suna hidimar kayan lantarki na gani, na'urorin lantarki na mabukaci, da sojoji. Muna ba da abubuwan haɗin gani na Sapphire, murfin ruwan tabarau na wayar hannu, Ceramics, LT, Silicon Carbide SIC, Quartz, da wafers kristal semiconductor. Tare da ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun kayan aiki, mun yi fice a cikin sarrafa samfuran da ba daidai ba, da nufin zama babban kamfani na kayan fasaha na optoelectronic.