Silicon carbide yumbu tire mai tsotsa Silicon carbide yumbu tube samar da babban zafin jiki sintering sarrafa al'ada

Babban fasali:

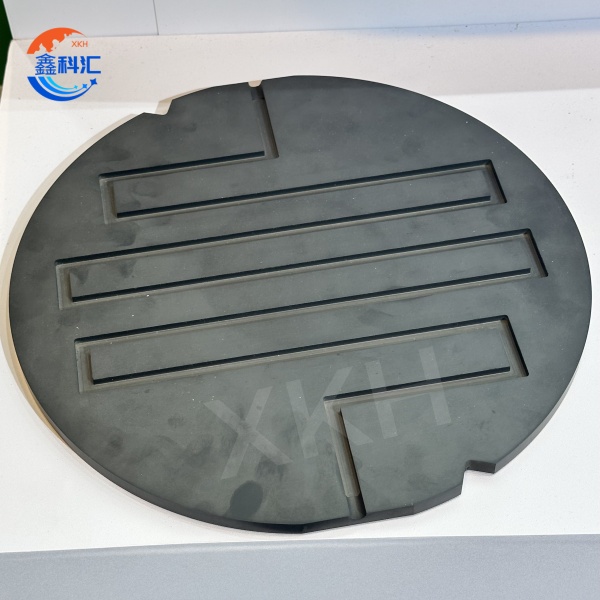

1. Silicon carbide yumbu tire

- Babban taurin da juriya: taurin yana kusa da lu'u-lu'u, kuma yana iya jurewa lalacewa ta inji a cikin sarrafa wafer na dogon lokaci.

- High thermal conductivity and low thermal expansion coefficient: saurin saurin zafi da kwanciyar hankali, guje wa nakasar da damuwa ta thermal ke haifarwa.

- Babban fa'ida da ƙarewar ƙasa: Tsarin shimfidar ƙasa ya kai matakin micron, yana tabbatar da cikakkiyar hulɗa tsakanin wafer da faifai, rage gurɓatawa da lalacewa.

Kwanciyar hankali na sinadarai: Juriya mai ƙarfi mai ƙarfi, dacewa da tsabtace rigar da matakan etching a masana'antar semiconductor.

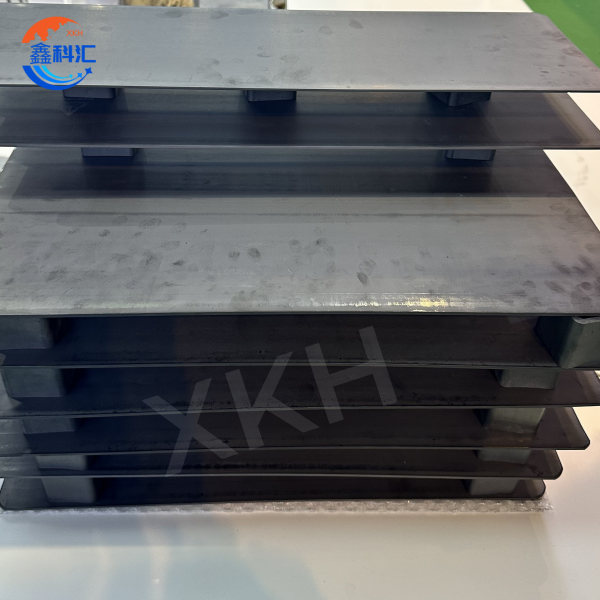

2. Silicon carbide yumbu tube

- High zafin jiki juriya: Yana iya aiki a high zafin jiki yanayi sama 1600 ° C na dogon lokaci, dace da semiconductor high zafin jiki tsari.

Kyakkyawan juriya na lalata: mai jurewa ga acid, alkalis da nau'ikan kaushi na sinadarai, dace da yanayin yanayin ƙaƙƙarfan tsari.

- High taurin da juriya: tsayayya barbashi yashwa da inji lalacewa, mika sabis rayuwa.

- High thermal conductivity da low coefficient na thermal faɗaɗa: saurin tafiyar da zafi da kwanciyar hankali, rage nakasawa ko fashewa da ya haifar da damuwa na thermal.

Sigar Samfuri:

Silicon carbide yumbu tire siga:

| (Kayan abu) | (Naúrar) | (sic) | |

| (Abincin SiC) | (Wt)% | >99 | |

| (Matsakaicin girman hatsi) | micron | 4-10 | |

| (Yawan yawa) | kg/dm3 | > 3.14 | |

| (Bayyana porosity) | Vo1% | <0.5 | |

| (Vickers hardness) | HV 0.5 | GPA | 28 |

| *() Ƙarfin sassauƙa* (maki uku) | 20ºC | MPa | 450 |

| (Karfin matsawa) | 20ºC | MPa | 3900 |

| (Elastic Modulus) | 20ºC | GPA | 420 |

| (Taurin karaya) | MPa/m'% | 3.5 | |

| (Thermal conductivity) | 20ºC | W/(m*K) | 160 |

| (Resistivity) | 20ºC | Ohm.cm | 106-108 |

(Thermal expansion coefficient) | (RT**...80ºC) | K-1*10-6 | 4.3 |

(Mafi girman zafin aiki) | oºC | 1700 | |

Silicon carbide yumbu tube siga:

| Abubuwa | Fihirisa |

| α-SIC | 99% min |

| Bayyanar Porosity | 16% max |

| Yawan yawa | 2.7g/cm 3 min |

| Ƙarfin Lankwasa a Babban Zazzabi | 100 Mpa min |

| Coefficient na Thermal Expansion | K-1 4.7x10 -6 |

| Ƙididdigar Ƙarfafa Ƙarfafawa (1400ºC) | 24 W/mk |

| Max. Yanayin Aiki | 1650ºC |

Manyan aikace-aikace:

1. Silicon carbide yumbu farantin karfe

- Yanke wafer da gogewa: yana aiki azaman dandamali mai ɗaukar nauyi don tabbatar da daidaito da kwanciyar hankali yayin yankewa da gogewa.

- Tsarin lithography: Ana gyara wafer a cikin injin lithography don tabbatar da daidaitaccen matsayi yayin fallasa.

- Chemical Mechanical Polishing (CMP): yana aiki azaman dandamali na tallafi don goge goge, samar da matsa lamba iri ɗaya da rarraba zafi.

2. Silicon carbide yumbu tube

- High zafin jiki tanderu tube: amfani da high zafin jiki kayan aiki kamar watsawa makera da hadawan abu da iskar shaka makera don ɗaukar wafers ga high zafin jiki tsari magani.

- Tsarin CVD/PVD: A matsayin bututu mai ɗaukar nauyi a cikin ɗakin amsawa, mai jurewa ga yanayin zafi da iskar gas.

- Na'urorin haɗi na kayan aikin Semiconductor: don masu musayar zafi, bututun gas, da dai sauransu, don inganta ingantaccen sarrafa kayan aiki na thermal.

XKH yana ba da cikakken kewayon sabis na al'ada don tiren yumbu na siliki, kofuna na tsotsa da bututun yumbu na siliki. Silicon carbide yumbu trays da tsotsa kofuna, XKH za a iya musamman bisa ga abokin ciniki bukatun na daban-daban masu girma dabam, siffofi da surface roughness, da kuma goyon bayan musamman shafi jiyya, inganta lalacewa juriya da kuma lalata juriya; Domin silicon carbide yumbu tubes, XKH iya siffanta da dama ciki diamita, waje diamita, tsawo da kuma hadaddun tsarin (kamar siffar tube ko porous tube), da kuma samar da polishing, anti-oxidation shafi da sauran surface jiyya matakai. XKH yana tabbatar da cewa abokan ciniki za su iya yin amfani da fa'idodin aikin silicon carbide yumbura don biyan buƙatun buƙatun manyan masana'antun masana'antu irin su semiconductor, leds da photovoltaics.

Cikakken zane