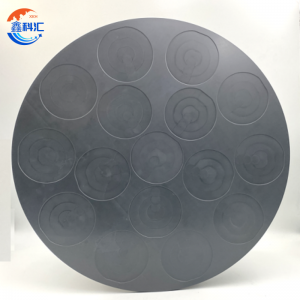

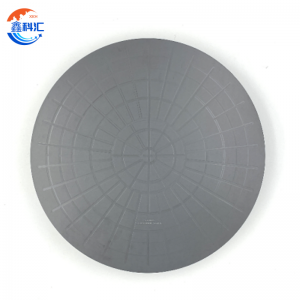

Silicon Carbide Ceramic Tray - Dogayen Tire, Babban Ayyuka don Aikace-aikacen Thermal da Chemical

Cikakken zane

Gabatarwar Samfur

Silicon carbide (SiC) tiren yumbura kayan aiki ne masu girma da aka yi amfani da su a cikin yanayin zafin jiki, babban kaya, da yanayin masana'antu masu tsauri. Injiniya daga ci-gaba na silicon carbide yumbu kayan, waɗannan trays an ƙera su don isar da ƙarfin injin na musamman, ingantaccen yanayin zafi, da kyakkyawan juriya ga girgizar zafi, iskar oxygen, da lalata. Halinsu mai ƙarfi yana sa su dace sosai don aikace-aikacen masana'antu daban-daban ciki har da masana'antar semiconductor, sarrafa hotovoltaic, sintering na sassan ƙarfe na foda, da ƙari.

Silicon carbide trays suna aiki azaman masu ɗaukar kaya masu mahimmanci ko goyan baya yayin ayyukan jiyya na zafi inda daidaiton girma, daidaiton tsari, da juriya na sinadarai ke da mahimmanci. Idan aka kwatanta da kayan yumbu na gargajiya kamar alumina ko mullite, tiren SiC suna ba da kyakkyawan aiki sosai, musamman a cikin yanayin da ya shafi maimaita hawan keke na zafi da yanayi mai ban tsoro.

Tsarin Kerawa & Haɗin Kayan Abu

Samar da tiren yumbura na SiC ya ƙunshi ingantattun injiniyoyi da fasahar sintering ci-gaba don tabbatar da babban yawa, ƙananan ƙayyadaddun tsari, da daidaiton aiki. Matakan gama gari sun haɗa da:

-

Zabin Danyen Abu

An zaɓi foda mai ƙarancin silicon carbide foda (≥99%), sau da yawa tare da ƙayyadaddun sarrafa girman barbashi da ƙarancin ƙazanta don tabbatar da manyan kaddarorin inji da thermal. -

Hanyoyin Ƙirƙira

Dangane da ƙayyadaddun tire, ana amfani da dabarun ƙira daban-daban:-

Cold Isostatic Pressing (CIP) don babban yawa, ƙaƙƙarfan ƙaƙƙarfan iri

-

Extrusion ko zamewa simintin gyare-gyare don hadaddun siffofi

-

Yin gyare-gyaren allura don madaidaicin, cikakkun bayanai na geometry

-

-

Dabarun Cin Gindi

Jikin kore yana daɗaɗawa a yanayin zafi mai tsananin zafi, yawanci a cikin kewayon 2000C, ƙarƙashin inert ko vacuum yanayi. Hanyoyi gama gari sun haɗa da:-

Reaction Bonded SiC (RB-SiC)

-

Sintered SiC (SSiC) mara ƙarfi

-

SiC (RBSiC) da aka sake buɗewa

Kowace hanya tana haifar da kaddarorin kayan abu daban-daban, kamar porosity, ƙarfi, da haɓakar thermal.

-

-

Daidaitaccen Machining

Bayan sintering, da tire suna da inji don cimma matsananciyar juriya, m surface gama, da kuma flatness. Ana iya amfani da jiyya na sama kamar lapping, niƙa, da goge goge bisa ga bukatun abokin ciniki.

Aikace-aikace na yau da kullun

Silicon carbide yumbun trays ana amfani da su a cikin masana'antu iri-iri saboda juriyarsu da juriya. Aikace-aikacen gama gari sun haɗa da:

-

Semiconductor Industry

Ana amfani da tiren SiC azaman masu ɗaukar kaya yayin cirewar wafer, watsawa, oxidation, epitaxy, da tsarin dasa. Zaman lafiyar su yana tabbatar da rarraba yanayin zafi iri ɗaya da ƙarancin gurɓata. -

Masana'antar Photovoltaic (PV).

A cikin samar da ƙwayoyin rana, trays na SiC suna tallafawa ingots na silicon ko wafers yayin yaduwar zafin jiki da matakan ɓacin rai. -

Powder Metallurgy da Ceramics

An yi amfani da shi don tallafawa abubuwan haɗin gwiwa yayin ɓarkewar foda na ƙarfe, yumbu, da kayan haɗin gwiwa. -

Gilashin da Nuni Panel

Ana amfani da shi azaman tire na kiln ko dandamali don kera gilashin musamman, filayen LCD, ko wasu kayan aikin gani. -

Sarrafa sinadarai da Tanderu mai zafi

Yi aiki azaman dillalai masu jure lalata a cikin sinadarai masu sarrafa sinadarai ko azaman tiren tallafi na thermal a cikin vacuum da tanderun yanayi mai sarrafawa.

Mabuɗin Ayyukan Ayyuka

-

✅Nasuwar Zazzabi Na Musamman

Yana tsayayya da ci gaba da amfani da yanayin zafi har zuwa 1600-2000 ° C ba tare da warping ko lalacewa ba. -

✅Babban Ƙarfin Injini

Yana ba da ƙarfin juzu'i mai ƙarfi (yawanci> 350 MPa), yana tabbatar da dorewa na dogon lokaci ko da a ƙarƙashin babban kaya. -

✅Juriya Shock Thermal

Kyakkyawan aiki a cikin mahalli tare da saurin canjin zafin jiki, rage haɗarin fashewa. -

✅Lalata da Oxidation Resistance

Tsayayyen sinadarai a yawancin acid, alkalis, da oxidizing/rage gas, dace da tsauraran matakan sinadarai. -

✅Daidaiton Girman Girma da Lalaci

Machined zuwa babban madaidaici, yana tabbatar da aiki iri ɗaya da dacewa tare da tsarin sarrafa kansa. -

✅Dogon Rayuwa & Ƙarfin Kuɗi

Ƙananan sauye-sauye da kuma rage farashin kulawa ya sa ya zama mafita mai mahimmanci a kan lokaci.

Ƙididdiga na Fasaha

| Siga | Mahimmanci Na Musamman |

|---|---|

| Kayan abu | Reaction Bonded SiC / Sintered SiC |

| Max. Yanayin Aiki | 1600-2000 ° C |

| Ƙarfin Flexural | ≥350 MPa |

| Yawan yawa | ≥3.0 g/cm³ |

| Thermal Conductivity | ~ 120-180 W/m·K |

| Lalacewar saman | ≤ 0.1 mm |

| Kauri | 5-20 mm (mai iya canzawa) |

| Girma | Standard: 200×200 mm, 300×300 mm, da dai sauransu. |

| Ƙarshen Sama | Machined, goge (bisa bukata) |

Tambayoyin da ake yawan yi (FAQ)

Q1: Shin za a iya amfani da trays carbide silicon a cikin tanda mara amfani?

A:Ee, SiC trays suna da kyau don mahalli mara kyau saboda ƙarancin fitar da iskar gas ɗin su, kwanciyar hankali na sinadarai, da juriya mai zafi.

Q2: Akwai siffofi na al'ada ko ramummuka?

A:Lallai. Muna ba da sabis na gyare-gyare ciki har da girman tire, siffa, fasalulluka (misali, ramuka, ramuka), da goge ƙasa don saduwa da buƙatun abokin ciniki na musamman.

Q3: Ta yaya SiC ya kwatanta da alumina ko ma'adini trays?

A:SiC yana da ƙarfi mafi girma, mafi kyawun yanayin zafi, da juriya mafi girma ga girgiza zafi da lalata sinadarai. Yayin da alumina ya fi tsada-tsari, SiC yana aiki mafi kyau a cikin yanayin da ake buƙata.

Q4: Akwai madaidaicin kauri don waɗannan tire?

A:Kauri yawanci yana cikin kewayon 5-20 mm, amma za mu iya daidaita shi dangane da aikace-aikacenku da buƙatun ɗaukar kaya.

Q5: Menene lokacin jagora na yau da kullun don na'urorin SiC na musamman?

A:Lokutan jagora sun bambanta dangane da rikitarwa da yawa amma gabaɗaya suna kewayo daga makonni 2 zuwa 4 don takamaiman umarni.

Game da Mu

XKH ya ƙware a cikin haɓaka fasahar fasaha, samarwa, da tallace-tallace na gilashin gani na musamman da sabbin kayan kristal. Kayayyakinmu suna hidimar kayan lantarki na gani, na'urorin lantarki na mabukaci, da sojoji. Muna ba da abubuwan haɗin gani na Sapphire, murfin ruwan tabarau na wayar hannu, Ceramics, LT, Silicon Carbide SIC, Quartz, da wafers kristal semiconductor. Tare da ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun kayan aiki, mun yi fice a cikin sarrafa samfuran da ba daidai ba, da nufin zama babban kamfani na kayan fasaha na optoelectronic.