SiCOI wafer 4inch 6inch HPSI SiC SiO2 Si tsarin subbatrate

SiCOI tsarin wafer

HPB (High-Performance Bonding) BIC (Bonded Integrated Circuit) da SOD (Silicon-on-Diamond ko Silicon-on-Insulator-kamar fasaha). Ya hada da:

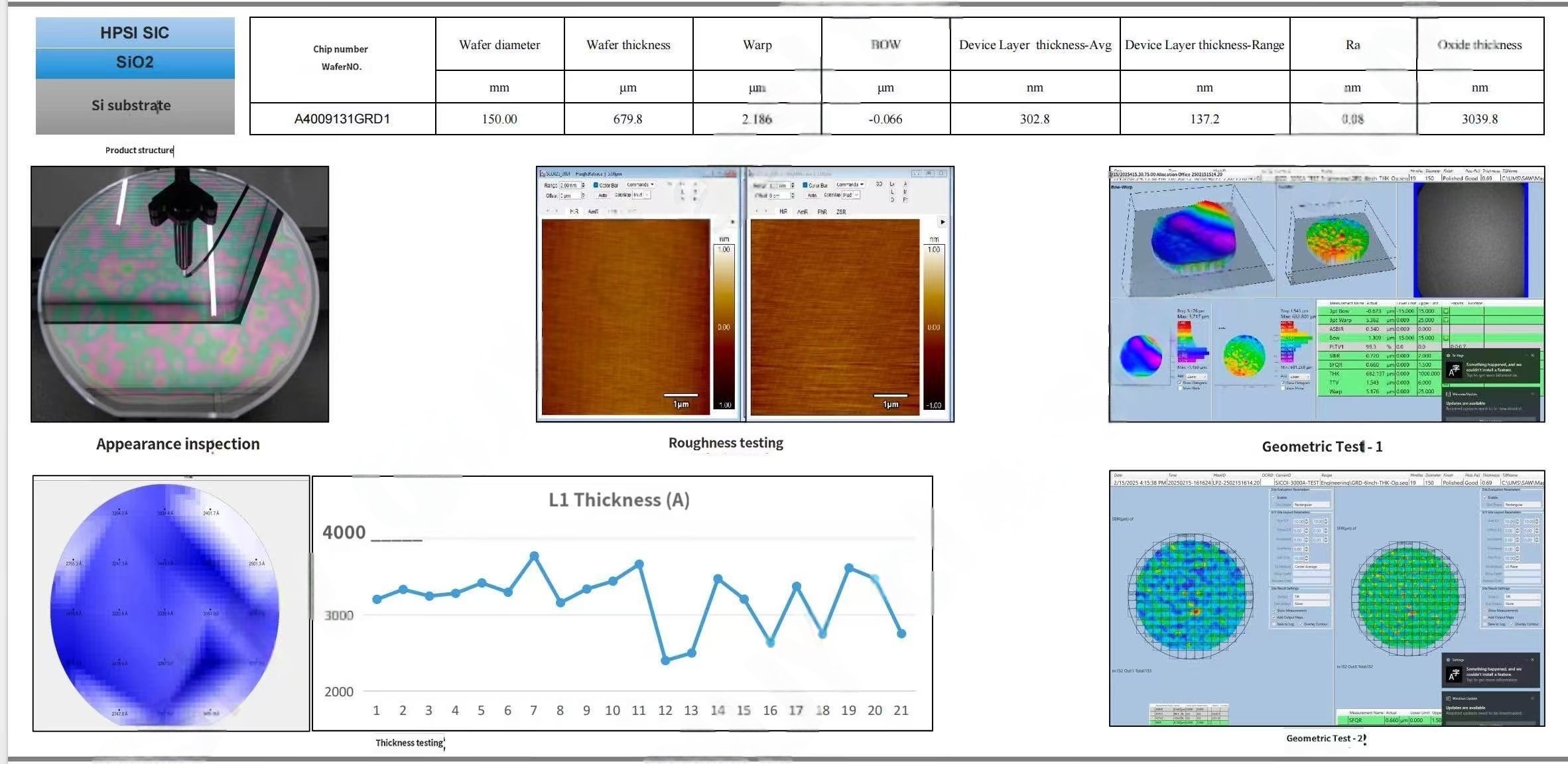

Ma'aunin Aiki:

Ya lissafa sigogi kamar daidaito, nau'ikan kurakurai (misali, "Babu kuskure," "Tsarin darajar"), da ma'aunin kauri (misali, "Direct-Layer kauri/kg").

Tebu mai kimar lamba (wataƙila gwaji ko sigogin tsari) ƙarƙashin taken kamar "ADDR/SYGBDT," "10/0," da dai sauransu.

Bayanan Kauri Na Layer:

Matsakaicin shigarwar maimaitawa mai lakabi "L1 Kauri (A)" zuwa "L270 Kauri (A)" (wataƙila a cikin Ångströms, 1 Å = 0.1 nm).

Yana ba da shawarar tsari mai nau'i-nau'i tare da madaidaicin kulawar kauri ga kowane Layer, na yau da kullun a cikin manyan wafers na semiconductor.

SiCOI Wafer Tsarin

SiCOI (Silicon Carbide akan Insulator) ƙirar wafer ce ta musamman wacce ke haɗa silicon carbide (SiC) tare da Layer insulating, kama da SOI (Silicon-on-Insulator) amma an inganta shi don aikace-aikacen manyan ƙarfi/zazzabi. Babban fasali:

Haɗin Layer:

Babban Layer: Silicon Carbide Single-Crystal (SiC) don babban motsi na lantarki da kwanciyar hankali na thermal.

Insulator da aka binne: Yawanci SiO₂ (oxide) ko lu'u-lu'u (a cikin SOD) don rage ƙarfin parasitic da haɓaka keɓewa.

Base Substrate: Silicon ko polycrystalline SiC don tallafin injina

SiCOI wafer's Properties

Abubuwan Lantarki Wide Bandgap (3.2 eV don 4H-SiC): Yana ba da damar babban ƙarfin rushewa (> 10 × mafi girma fiye da silicon) .Ya rage kwararar ruwa, inganta haɓakawa a cikin na'urorin wuta.

Babban Motsi na Electron:~900 cm²/V·s (4H-SiC) vs. ~ 1,400 cm²/V·s (Si), amma mafi kyawun aikin filin.

Ƙananan Juriya:SiCOI na tushen transistor (misali, MOSFETs) suna nuna ƙananan asarar gudanarwa.

Kyakkyawan Insulation:Oxide da aka binne (SiO₂) ko lu'u lu'u-lu'u yana rage ƙarfin iyawa da magana.

- Thermal PropertiesBabban Haɗin Ƙarfafawa: SiC (~ 490 W / m · K don 4H-SiC) vs. Si (~ 150 W / m · K) .Diamond (idan an yi amfani da shi azaman insulator) zai iya wuce 2,000 W / m · K, yana inganta haɓaka zafi.

Ƙarfin Ƙarfi:Yana aiki da dogaro a>300°C (vs. ~ 150°C don silicon) .Yana rage buƙatun sanyaya a cikin kayan lantarki.

3. Makanikai & Abubuwan SinadaraiMatsananciyar Tauri (~ 9.5 Mohs): Yana tsayayya da lalacewa, yana sa SiCOI ya dawwama don matsananciyar yanayi.

Rashin Inertness:Yana tsayayya da oxidation da lalata, ko da a cikin yanayin acidic/alkaline.

Ƙarƙashin Ƙarfafa Ƙwararru:Yayi daidai da sauran kayan zafi mai zafi (misali, GaN).

4. Fa'idodin Tsari (vs. Bulk SiC ko SOI)

Rage Asarar Substrate:Insulating Layer yana hana zub da jini a halin yanzu.

Ingantattun Ayyukan RF:Ƙananan ƙarfin ƙarfin parasitic yana ba da damar sauyawa da sauri (mai amfani ga na'urorin 5G/mmWave).

Zane mai sassauƙa:Babban Layer SiC na bakin ciki yana ba da damar ingantaccen sikelin na'urar (misali, tashoshi masu bakin ciki a cikin transistor).

Kwatanta da SOI & Bulk SiC

| Dukiya | SiCOI | SOI (Si/SiO₂/Si) | Babban SiC |

| Bandgap | 3.2 eV (SiC) | 1.1 eV (Si) | 3.2 eV (SiC) |

| Thermal Conductivity | Babban (SiC + lu'u-lu'u) | Low (SiO₂ yana iyakance kwararar zafi) | Babban (SiC kawai) |

| Rushewar Wutar Lantarki | Mai Girma | Matsakaici | Mai Girma |

| Farashin | Mafi girma | Kasa | Mafi girma (SiC mai tsafta) |

Aikace-aikacen wafer na SiCOI

Kayan Wutar Lantarki

Ana amfani da wafers na SiCOI a cikin babban ƙarfin lantarki da na'urorin semiconductor masu ƙarfi kamar MOSFETs, Schottky diodes, da masu sauya wuta. Faɗin bandgap da babban ƙarfin rushewar wutar lantarki na SiC yana ba da damar ingantacciyar jujjuyawar wutar lantarki tare da rage asara da haɓaka aikin zafi.

Na'urorin Mitar Rediyo (RF).

Layin da aka rufe a cikin wafers na SiCOI yana rage ƙarfin parasitic, yana sa su dace da transistor masu tsayi da amplifiers da ake amfani da su a cikin sadarwa, radar, da fasahar 5G.

Tsarin Microelectromechanical Systems (MEMS)

SiCOI wafers suna ba da ingantaccen dandamali don ƙirƙira na'urori masu auna firikwensin MEMS da masu kunnawa waɗanda ke aiki da dogaro a cikin matsananciyar yanayi saboda rashin kuzarin sinadarai na SiC da ƙarfin injina.

Babban Zazzabi Electronics

SiCOI yana ba da damar na'urorin lantarki waɗanda ke kula da aiki da aminci a yanayin zafi mai tsayi, suna amfanar motoci, sararin samaniya, da aikace-aikacen masana'antu inda na'urorin silicon na al'ada suka gaza.

Photonic da na'urorin Optoelectronic

Haɗuwa da kaddarorin gani na SiC da rufin insulating yana sauƙaƙe haɗawa da da'irori na photonic tare da ingantaccen sarrafa zafi.

Radiation-Hardened Electronics

Saboda jurewar radiyo na SiC, wafers na SiCOI sun dace don sararin samaniya da aikace-aikacen nukiliya da ke buƙatar na'urorin da ke jure yanayin yanayin hasken rana.

Q&A na wafer na SiCOI

Q1: Menene wafer na SiCOI?

A: SiCOI yana nufin Silicon Carbide-on-Insulator. Tsarin wafer na semiconductor ne inda wani bakin ciki na silicon carbide (SiC) ke haɗe a kan wani rufin mai rufewa (yawanci silicon dioxide, SiO₂), wanda ke tallafawa ta hanyar siliki. Wannan tsarin yana haɗa kyawawan kaddarorin SiC tare da keɓewar lantarki daga insulator.

Q2: Menene babban fa'idodin wafers na SiCOI?

A: Babban abũbuwan amfãni sun haɗa da babban ƙarfin wutan lantarki, faffadan bandgap, kyakkyawan yanayin zafin jiki, ingantaccen ƙarfin injin, da rage ƙarfin parasitic godiya ga insulating Layer. Wannan yana haifar da ingantaccen aikin na'urar, inganci, da aminci.

Q3: Menene aikace-aikace na yau da kullun na wafers na SiCOI?

A: Ana amfani da su a cikin wutar lantarki, na'urorin RF masu girma, na'urori masu auna firikwensin MEMS, na'urorin lantarki masu zafi, na'urorin photonic, da na'urorin lantarki masu taurara.

Cikakken zane