4H-N HPSI SiC wafer 6H-N 6H-P 3C-N SiC Epitaxial wafer na MOS ko SBD

SiC Substrate SiC Epi-wafer Brief

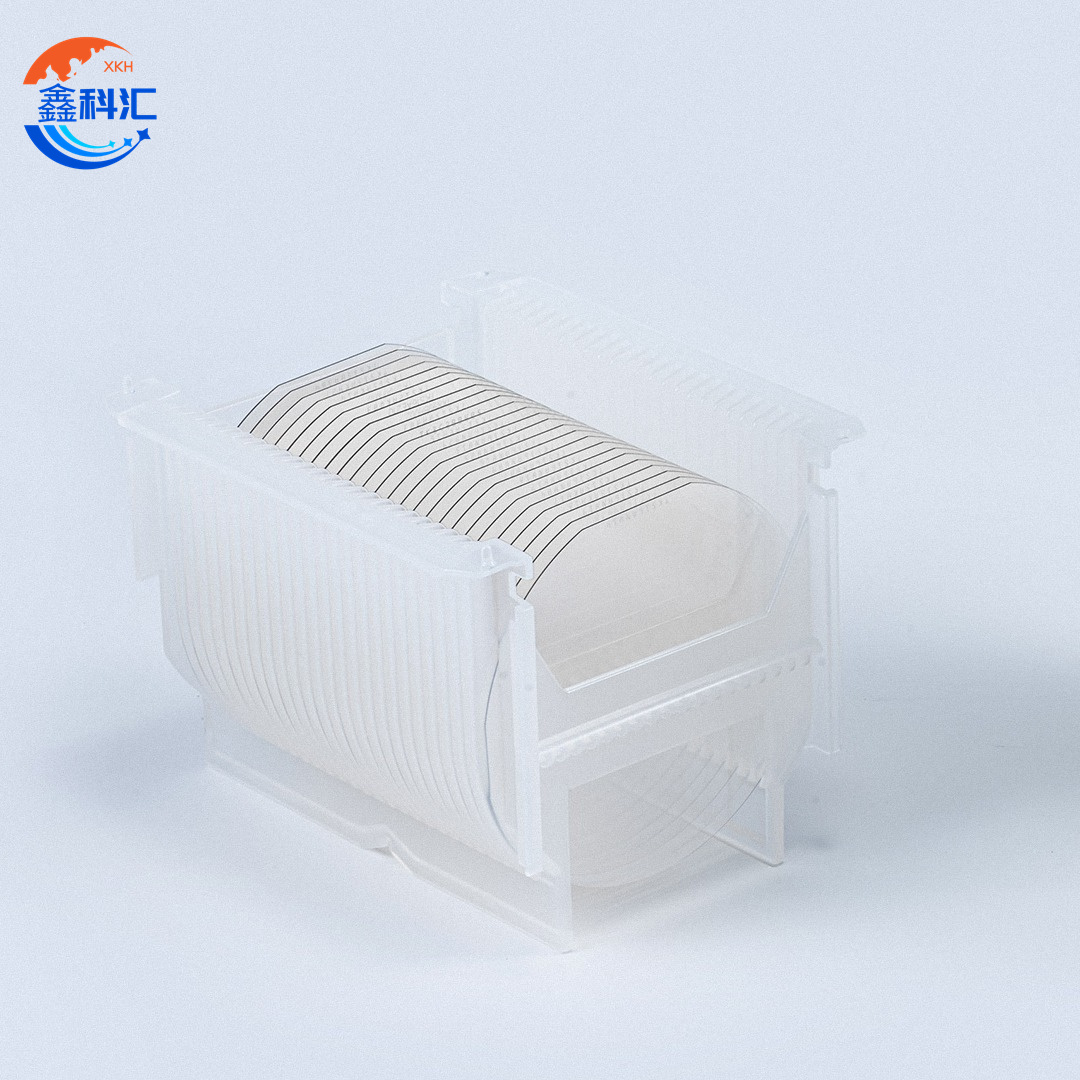

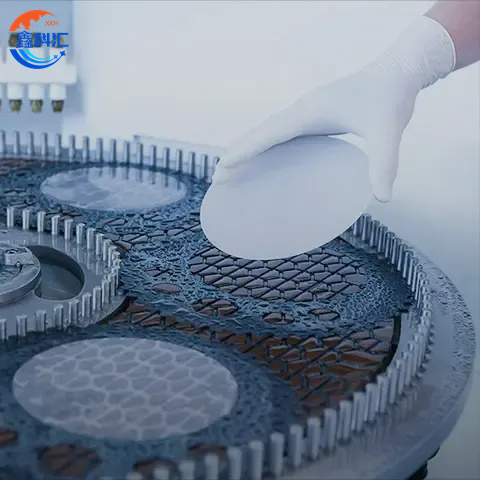

Muna ba da cikakken fayil na SiC substrates masu inganci da sic wafers a cikin nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan doping da bayanan doping-ciki har da 4H-N (n-type conductive), 4H-P (p-type conductive), 4H-HPSI (high-tsarki Semi-insulating), da 6H-P (p-type conductive) - ″ duk diamita, 8 da diamita. har zuwa 12 ″. Bayan dandali, sabis na haɓaka ƙimar mu na epi wafer yana isar da wafers na epitaxial (epi) tare da kauri mai ƙarfi (1-20 µm), yawan abubuwan ƙara kuzari, da ƙarancin lahani.

Kowane sic wafer da epi wafer yana fuskantar in-line dubawa (yawan micropipe <0.1 cm⁻², roughness surface Ra <0.2 nm) da cikakken yanayin lantarki (CV, taswirar resistivity) don tabbatar da ingantacciyar daidaiton kristal da aiki. Ko ana amfani da su don na'urorin lantarki na lantarki, masu haɓaka RF masu girma, ko na'urorin optoelectronic (LEDs, photodetectors), kayan aikin mu na SiC da layin samfurin epi wafer suna sadar da amincin, kwanciyar hankali na zafi, da ƙarfin rushewa da ake buƙata ta aikace-aikacen yau da kullun.

SiC Substrate 4H-N nau'in kaddarorin da aikace-aikace

-

4H-N SiC Tsarin Polytype (Hexagonal) Tsarin

Wide bandgap na ~ 3.26 eV yana tabbatar da ingantaccen aikin lantarki da ƙarfin zafi a ƙarƙashin yanayin zafi mai zafi da yanayin filin lantarki.

-

SiC substrateN-Nau'in Doping

Daidaitaccen sarrafa nitrogen doping yana haifar da ƙima daga 1 × 10¹⁶ zuwa 1 × 10¹⁹ cm⁻³ da yawan zafin jiki na lantarki har zuwa ~ 900 cm²/V·s, yana rage asarar gudanarwa.

-

SiC substrateFaɗin Resistivity & Uniformity

Akwai kewayon juriya na 0.01-10 Ω·cm da kauri na wafer na 350-650 µm tare da ± 5% haƙuri a cikin duka doping da kauri-mai kyau don ƙirƙira na'urar mai ƙarfi.

-

SiC substrateƘarƙashin Ƙarƙashin Ƙarfafawa

Girman bututu <0.1 cm⁻² da ƙarancin rarrabuwar jirgin basal-jirgin <500 cm⁻², bayarwa> 99% yawan amfanin na'urar da ingantaccen ingancin crystal.

- SiC substrateNa Musamman Thermal Conductivity

Ƙarfafawar thermal har zuwa ~ 370 W / m · K yana sauƙaƙe ingantaccen cirewar zafi, haɓaka amincin na'urar da ƙarfin ƙarfi.

-

SiC substrateAikace-aikacen Target

SiC MOSFETs, Schottky diodes, nau'ikan wutar lantarki da na'urorin RF don tuƙi-motar lantarki, masu jujjuya hasken rana, injinan masana'antu, tsarin gogayya, da sauran kasuwannin wutar lantarki da ake buƙata.

6inch 4H-N nau'in SiC wafer's takamaiman | ||

| Dukiya | Zero MPD Production Grade (Z Grade) | Dummy Grade (D Grade) |

| Daraja | Zero MPD Production Grade (Z Grade) | Dummy Grade (D Grade) |

| Diamita | 149.5 mm - 150.0 mm | 149.5 mm - 150.0 mm |

| Nau'in poly | 4H | 4H |

| Kauri | 350 µm ± 15 µm | 350 µm ± 25 µm |

| Wafer Orientation | Kashe axis: 4.0° zuwa <1120> ± 0.5° | Kashe axis: 4.0° zuwa <1120> ± 0.5° |

| Maƙarƙashiya Maɗaukaki | 0.2 cm² | ≤ 15 cm² |

| Resistivity | 0.015 - 0.024 Ω · cm | 0.015 - 0.028 Ω · cm |

| Hannun Filayen Firamare | [10-10] ± 50° | [10-10] ± 50° |

| Tsawon Lantarki na Farko | 475 mm ± 2.0 mm | 475 mm ± 2.0 mm |

| Ƙarƙashin Ƙarfi | 3 mm ku | 3 mm ku |

| LTV / TIV / Baka / Warp | 2.5µm / ≤ 6 µm / ≤ 25 µm / ≤ 35 µm | ≤ 5 µm / ≤ 15 µm / ≤ 40 µm / ≤ 60 µm |

| Tashin hankali | Yaren mutanen Poland Ra ≤ 1 nm | Yaren mutanen Poland Ra ≤ 1 nm |

| CMP Ra | 0.2 nm | 0.5 nm |

| Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙwara | Tsayin tarawa ≤ 20 mm tsayi ɗaya ≤ 2 mm | Tsayin tarawa ≤ 20 mm tsayi ɗaya ≤ 2 mm |

| Hex Plates Ta Babban Haske mai ƙarfi | Tarin yanki ≤ 0.05% | Tarin yanki ≤ 0.1% |

| Wuraren Polytype Ta Hanyar Ƙarfin Ƙarfi | Tarin yanki ≤ 0.05% | Tarin yanki ≤ 3% |

| Haɗin Carbon Na gani | Tarin yanki ≤ 0.05% | Tarin yanki ≤ 5% |

| Silicon Surface Scratches By High Intensity Light | Tsayin tarawa ≤ diamita wafer 1 | |

| Chips Gefe Ta Babban Haske mai ƙarfi | Babu wanda aka halatta ≥ 0.2 mm faɗi da zurfin | 7 izini, ≤ 1 mm kowanne |

| Rushewar Zaren Zare | <500 cm³ | <500 cm³ |

| Lalacewar Silicon Surface Ta Babban Haske mai ƙarfi | ||

| Marufi | Cassette mai yawa-wafer ko kwantena wafer guda ɗaya | Cassette mai yawa-wafer ko kwantena wafer guda ɗaya |

8inch 4H-N nau'in SiC wafer's takamaiman | ||

| Dukiya | Zero MPD Production Grade (Z Grade) | Dummy Grade (D Grade) |

| Daraja | Zero MPD Production Grade (Z Grade) | Dummy Grade (D Grade) |

| Diamita | 199.5 mm - 200.0 mm | 199.5 mm - 200.0 mm |

| Nau'in poly | 4H | 4H |

| Kauri | 500 µm ± 25 µm | 500 µm ± 25 µm |

| Wafer Orientation | 4.0° zuwa <110> ± 0.5° | 4.0° zuwa <110> ± 0.5° |

| Maƙarƙashiya Maɗaukaki | 0.2 cm² | 5 cm² |

| Resistivity | 0.015 - 0.025 Ω · cm | 0.015 - 0.028 Ω · cm |

| Matsayi Mai Girma | ||

| Ƙarƙashin Ƙarfi | 3 mm ku | 3 mm ku |

| LTV / TIV / Baka / Warp | ≤ 5 µm / ≤ 15 µm / ≤ 35 µm / 70 µm | ≤ 5 µm / ≤ 15 µm / ≤ 35 µm / 100 µm |

| Tashin hankali | Yaren mutanen Poland Ra ≤ 1 nm | Yaren mutanen Poland Ra ≤ 1 nm |

| CMP Ra | 0.2 nm | 0.5 nm |

| Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙwara | Tsayin tarawa ≤ 20 mm tsayi ɗaya ≤ 2 mm | Tsayin tarawa ≤ 20 mm tsayi ɗaya ≤ 2 mm |

| Hex Plates Ta Babban Haske mai ƙarfi | Tarin yanki ≤ 0.05% | Tarin yanki ≤ 0.1% |

| Wuraren Polytype Ta Hanyar Ƙarfin Ƙarfi | Tarin yanki ≤ 0.05% | Tarin yanki ≤ 3% |

| Haɗin Carbon Na gani | Tarin yanki ≤ 0.05% | Tarin yanki ≤ 5% |

| Silicon Surface Scratches By High Intensity Light | Tsayin tarawa ≤ diamita wafer 1 | |

| Chips Gefe Ta Babban Haske mai ƙarfi | Babu wanda aka halatta ≥ 0.2 mm faɗi da zurfin | 7 izini, ≤ 1 mm kowanne |

| Rushewar Zaren Zare | <500 cm³ | <500 cm³ |

| Lalacewar Silicon Surface Ta Babban Haske mai ƙarfi | ||

| Marufi | Cassette mai yawa-wafer ko kwantena wafer guda ɗaya | Cassette mai yawa-wafer ko kwantena wafer guda ɗaya |

4H-SiC babban kayan aiki ne da ake amfani da shi don kayan lantarki, na'urorin RF, da aikace-aikacen zafin jiki. "4H" yana nufin tsarin crystal, wanda ke da hexagonal, kuma "N" yana nuna nau'in doping da ake amfani dashi don inganta aikin kayan.

The4H-SiCnau'in ana amfani dashi akai-akai don:

Wutar Lantarki:Ana amfani da su a cikin na'urori kamar diodes, MOSFETs, da IGBTs don wutar lantarkin abin hawa, injinan masana'antu, da tsarin makamashi mai sabuntawa.

Fasahar 5G:Tare da buƙatun 5G don haɓaka-girma da ingantattun ingantattun kayan aiki, ikon SiC don ɗaukar manyan ƙarfin lantarki da aiki a yanayin zafi mai girma ya sa ya zama manufa ga masu haɓaka wutar lantarki na tushe da na'urorin RF.

Tsarin Makamashin Rana:Kyawawan kaddarorin sarrafa wutar lantarki na SiC sun dace don masu juyawa da masu juyawa na hotovoltaic (ikon hasken rana).

Motocin Lantarki (EVs):Ana amfani da SiC a ko'ina a cikin EV powertrains don ingantacciyar jujjuyawar makamashi, ƙarancin samar da zafi, da yawan ƙarfin ƙarfi.

SiC Substrate 4H Kaddarorin nau'in Semi-Insulating da aikace-aikace

Kaddarori:

-

Dabarun sarrafa yawa mara bututu: Yana tabbatar da rashin micropipes, inganta ingancin substrate.

-

Dabarun sarrafa Monocrystalline: Yana ba da garantin tsarin kristal guda ɗaya don ingantaccen kayan kayan haɓaka.

-

Dabarun sarrafawa na haɗawa: Yana rage ƙarancin ƙazanta ko haɗawa, yana tabbatar da tsaftataccen yanki.

-

Dabarun sarrafa juriya: Yana ba da damar daidaitaccen iko na tsayayyar wutar lantarki, wanda ke da mahimmanci don aikin na'urar.

-

Tsarin ƙazanta da dabarun sarrafawa: Yana daidaitawa da ƙayyadaddun ƙaddamar da ƙazantattun abubuwa don kiyaye amincin ƙasa.

-

Substrate mataki nisa kula dabaru: Yana ba da cikakken iko akan nisa mataki, yana tabbatar da daidaito a fadin substrate

6 Inch 4H-Semi SiC ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙa'idodin | ||

| Dukiya | Zero MPD Production Grade (Z Grade) | Dummy Grade (D Grade) |

| Diamita (mm) | 145 mm - 150 mm | 145 mm - 150 mm |

| Nau'in poly | 4H | 4H |

| Kauri (um) | 500 ± 15 | 500 ± 25 |

| Wafer Orientation | Kan axis: ± 0.0001° | Kan axis: ± 0.05° |

| Maƙarƙashiya Maɗaukaki | ≤ 15 cm-2 | ≤ 15 cm-2 |

| Resistivity (Ωcm) | 10E3 | 10E3 |

| Hannun Filayen Firamare | (0-10)° ± 5.0° | (10-10)° ± 5.0° |

| Tsawon Lantarki na Farko | Daraja | Daraja |

| Ƙimar Ƙarfi (mm) | ≤ 2.5 µm / ≤ 15 µm | ≤ 5.5 µm / ≤ 35 µm |

| LTV / Bowl / Warp | ≤3µm | ≤3µm |

| Tashin hankali | Yaren mutanen Poland Ra ≤ 1.5 µm | Yaren mutanen Poland Ra ≤ 1.5 µm |

| Chips Gefe Ta Babban Haske mai ƙarfi | ≤20µm | ≤ 60µm |

| Faranti Zafi Ta Babban Haske mai ƙarfi | Tarin ≤ 0.05% | Tarin ≤ 3% |

| Wuraren Polytype Ta Hanyar Ƙarfin Ƙarfi | Haɗin Carbon Na gani ≤ 0.05% | Tarin ≤ 3% |

| Silicon Surface Scratches By High Intensity Light | 0.05% | Tarin ≤ 4% |

| Chips Gefe Ta Babban Haske mai ƙarfi (Girman) | Ba a Izinin ba> 02 mm Nisa da Zurfin | Ba a Izinin ba> 02 mm Nisa da Zurfin |

| The Aid Screw Dilation | ≤ 500 µm | ≤ 500 µm |

| Lalacewar Silicon Surface Ta Babban Haske mai ƙarfi | ≤ 1 x 10^5 | ≤ 1 x 10^5 |

| Marufi | Cassette mai yawa-wafer ko kwantena wafer guda ɗaya | Cassette mai yawa-wafer ko kwantena wafer guda ɗaya |

4-inch 4H-Semi Insulating SiC Ƙayyadaddun Substrate

| Siga | Zero MPD Production Grade (Z Grade) | Dummy Grade (D Grade) |

|---|---|---|

| Abubuwan Jiki | ||

| Diamita | 99.5 mm - 100.0 mm | 99.5 mm - 100.0 mm |

| Nau'in poly | 4H | 4H |

| Kauri | 500 μm ± 15 μm | 500 μm ± 25 μm |

| Wafer Orientation | Kan axis: <600h>0.5° | Kan axis: <000h>0.5° |

| Abubuwan Lantarki | ||

| Maƙarƙashiya Maɗaukaki (MPD) | ≤1 cm² | ≤15 cm² |

| Resistivity | ≥150 Ω · cm | ≥1.5 Ω · cm |

| Hakuri na Geometric | ||

| Hannun Filayen Firamare | (0x10) ± 5.0° | (0x10) ± 5.0° |

| Tsawon Lantarki na Farko | 52.5 mm ± 2.0 mm | 52.5 mm ± 2.0 mm |

| Tsawon Lantarki na Sakandare | 18.0 mm ± 2.0 mm | 18.0 mm ± 2.0 mm |

| Gabatarwar Flat na Sakandare | 90° CW daga Firayim lebur ± 5.0° (Si fuskar sama) | 90° CW daga Firayim lebur ± 5.0° (Si fuskar sama) |

| Ƙarƙashin Ƙarfi | 3 mm ku | 3 mm ku |

| LTV / TTV / Baka / Warp | ≤2.5 μm / ≤5 μm / ≤15 μm / ≤30 μm | ≤10 μm / ≤15 μm / ≤25 μm / ≤40 μm |

| ingancin saman | ||

| Ƙarƙashin Ƙarƙashin Ƙasa (Yaren mutanen Poland Ra) | ≤1 nm | ≤1 nm |

| Ƙarƙashin Ƙasa (CMP Ra) | ≤0.2 nm | ≤0.2 nm |

| Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙwara | Ba a yarda ba | Tsayin tarawa ≥10 mm, fashe ɗaya ≤2 mm |

| Lalacewar farantin hexagonal | ≤0.05% tara yanki | ≤0.1% tara yanki |

| Wuraren Haɗa Polytype | Ba a yarda ba | ≤1% tara yanki |

| Haɗin Carbon Na gani | ≤0.05% tara yanki | ≤1% tara yanki |

| Silicon Surface Scratches | Ba a yarda ba | ≤1 wafer diamita tara tsayi |

| Kwakwalwa na Edge | Babu wanda aka yarda (≥0.2 mm nisa/zurfin) | ≤5 kwakwalwan kwamfuta (kowane ≤1 mm) |

| Gurbacewar Silicon Surface | Ba a kayyade ba | Ba a kayyade ba |

| Marufi | ||

| Marufi | Multi-wafer cassette ko kwandon wafer guda ɗaya | Multi-wafer cassette ko |

Aikace-aikace:

TheSiC 4H Semi-insulating substratesana amfani da su da farko a cikin manyan na'urori masu ƙarfi da na'urorin lantarki, musamman a cikinfilin RF. Wadannan substrates suna da mahimmanci ga aikace-aikace daban-daban ciki har datsarin sadarwa na microwave, radar tsararru, kumamara waya ta gano lantarki. Babban haɓakar yanayin zafi da kyawawan halayen lantarki ya sa su dace don buƙatar aikace-aikace a cikin lantarki da tsarin sadarwa.

SiC epi wafer 4H-N nau'in kaddarorin da aikace-aikace

SiC 4H-N Nau'in Epi Wafer Properties da Aikace-aikace

Abubuwan SiC 4H-N Nau'in Epi Wafer:

Haɗin Abu:

SiC (Silicon Carbide): An san shi don ƙaƙƙarfan ƙaƙƙarfan ƙarfi, haɓakar haɓakar thermal, da kyawawan kaddarorin lantarki, SiC ya dace da na'urorin lantarki masu inganci.

4H-SiC Polytype: An san nau'in nau'in 4H-SiC don ingantaccen aiki da kwanciyar hankali a cikin aikace-aikacen lantarki.

Nau'in Doping: N-type doping (doped tare da nitrogen) yana ba da kyakkyawar motsi na lantarki, yana sa SiC ya dace da aikace-aikacen mita mai girma da ƙarfi.

Babban Haɓakawa na thermal:

Wafers na SiC suna da ingantaccen yanayin zafi, yawanci kama daga120–200 W/m·K, ba su damar sarrafa zafi yadda ya kamata a cikin manyan na'urori masu ƙarfi kamar transistor da diodes.

Faɗin Bandgap:

Tare da bandgap na3.26v, 4H-SiC na iya aiki a mafi girma ƙarfin lantarki, mita, da kuma yanayin zafi idan aka kwatanta da na'urorin da aka yi da silicon na gargajiya, yana sa ya zama manufa don ingantaccen aiki, aikace-aikace masu girma.

Abubuwan Lantarki:

SiC's high electron motsi da conductivity sanya shi manufa dominwutar lantarki, Yana ba da saurin sauyawa da sauri da kuma ƙarfin halin yanzu da ƙarfin lantarki, yana haifar da ingantaccen tsarin sarrafa wutar lantarki.

Juriya na Injini da Sinadarai:

SiC yana ɗaya daga cikin kayan mafi wuya, na biyu kawai zuwa lu'u-lu'u, kuma yana da matukar juriya ga oxidation da lalata, yana sa shi dawwama a cikin yanayi mai tsauri.

Aikace-aikace na SiC 4H-N Nau'in Epi Wafer:

Wutar Lantarki:

SiC 4H-N nau'in epi wafers ana amfani da su sosai a cikiikon MOSFET, IGBTs, kumadiodesdomincanza wutar lantarkia cikin tsarin kamarhasken rana inverters, motocin lantarki, kumatsarin ajiyar makamashi, bayar da ingantaccen aiki da ingantaccen makamashi.

Motocin Lantarki (EVs):

In lantarki abin hawa powertrains, masu kula da motoci, kumatashoshin caji, SiC wafers suna taimakawa wajen samun ingantaccen ƙarfin baturi, caji mai sauri, da haɓaka aikin makamashi gabaɗaya saboda ikonsu na ɗaukar iko da yanayin zafi.

Tsarin Makamashi Mai Sabuntawa:

Solar Inverters: Ana amfani da wafers na SiC a cikitsarin makamashin ranadon juyar da wutar lantarki daga hasken rana zuwa AC, haɓaka ingantaccen tsarin gabaɗaya da aiki.

Turbin na iska: Ana amfani da fasahar SiC a cikitsarin sarrafa injin injin iska, inganta samar da wutar lantarki da ingantaccen juzu'i.

Aerospace da Tsaro:

SiC wafers sun dace don amfani a cikiaerospace Electronicskumaaikace-aikacen soja, ciki har datsarin radarkumatauraron dan adam lantarki, inda high radiation juriya da thermal kwanciyar hankali suna da muhimmanci.

Babban Zazzabi da Aikace-aikace Mai Girma:

SiC wafers sun yi fice a cikihigh-zazzabi lantarki, amfani ainjunan jirgin sama, jirgin sama, kumatsarin dumama masana'antu, yayin da suke kula da aiki a cikin matsanancin yanayin zafi. Bugu da ƙari, babban bandgap ɗin su yana ba da damar amfani a cikiaikace-aikace masu yawakamarRF na'urorinkumamicrowave sadarwa.

| 6-inch N-nau'in Epit axial ƙayyadaddun bayanai | |||

| Siga | naúrar | Z-MOS | |

| Nau'in | Condutivity / Dopant | - | N-type / Nitrogen |

| Layer buffer | Ƙaƙƙarfan Ƙaƙƙarfan Layer | um | 1 |

| Haƙuri da Kauri Layer | % | ± 20% | |

| Matsakaicin Ƙarfafa Layer | cm-3 | 1.00E+18 | |

| Hakuri Hakuri na Ƙarfafa Layer | % | ± 20% | |

| 1st Epi Layer | Epi Layer Kauri | um | 11.5 |

| Uniformity na kauri na Epi Layer | % | ± 4% | |

| Hakurin Hakurin Kauri na Epi ((Tallafi Max, Min)/Spec) | % | ± 5% | |

| Epi Layer Concentration | cm-3 | 1E 15~ 1E 18 | |

| Hakurin Hakuri na Epi Layer | % | 6% | |

| Epi Layer Concentity Uniformity (σ /ma'ana) | % | ≤5% | |

| Epi Layer Concentity Uniformity <(max-min)/(max+min> | % | ≤ 10% | |

| Epitaixal Wafer Siffar | Ruku'u | um | ≤±20 |

| WARP | um | ≤30 | |

| TTV | um | ≤ 10 | |

| LTV | um | ≤2 | |

| Halayen Gabaɗaya | Tsawon tsagewa | mm | ≤30mm |

| Kwakwalwa na Edge | - | BABU | |

| Ma'anar lahani | ≥97% (An auna da 2*2). Lalacewar kisa sun haɗa da: Lalacewar sun haɗa da Micropipe / Manyan ramuka, Karas, Triangular | ||

| Karfe gurbacewa | atom / cm² | d f f zan ≤5E10 atoms/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg, Na, K, Ti, Ca & Mn) | |

| Kunshin | Bayani dalla-dalla | pcs/kwali | kaset mai yawan wafer ko kwandon wafer guda ɗaya |

| 8-inch N-nau'in ƙayyadaddun epitaxial | |||

| Siga | naúrar | Z-MOS | |

| Nau'in | Condutivity / Dopant | - | N-type / Nitrogen |

| Layer na buffer | Ƙaƙƙarfan Ƙaƙƙarfan Layer | um | 1 |

| Haƙuri da Kauri Layer | % | ± 20% | |

| Matsakaicin Ƙarfafa Layer | cm-3 | 1.00E+18 | |

| Hakuri Hakuri na Ƙarfafa Layer | % | ± 20% | |

| 1st Epi Layer | Matsakaicin Kauri Epi Layers | um | 8 ~ 12 |

| Uniformity na Kauri Epi Layers (σ/ma'ana) | % | ≤2.0 | |

| Hakurin Hakurin Kauri Epi Layers((Spec-Max, Min)/Spec) | % | ± 6 | |

| Epi Layers Net Matsakaicin Doping | cm-3 | 8E+15 ~2E+16 | |

| Epi Layers Net Doping Uniformity (σ/ma'ana) | % | ≤5 | |

| Epi Layers Net DopingTolerance ((Spec-Max, | % | ± 10.0 | |

| Epitaixal Wafer Siffar | Mi)/S) Warp | um | ≤50.0 |

| Ruku'u | um | ± 30.0 | |

| TTV | um | ≤ 10.0 | |

| LTV | um | ≤4.0 (10mm × 10mm) | |

| Gabaɗaya Halaye | Scratches | - | Tsayin tarawa≤ 1/2 Diamita na Wafer |

| Kwakwalwa na Edge | - | ≤2 kwakwalwan kwamfuta, Kowane radius≤1.5mm | |

| Gurbacewar Ƙarfe-Ƙarfe | atom/cm2 | ≤5E10 atoms/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg, Na, K, Ti, Ca & Mn) | |

| Lalacewar Dubawa | % | ≥ 96.0 (Labaran 2X2 sun haɗa da Micropipe / Manyan rami, Karas, Lalacewar Triangular, Faduwa, Linear/IGSF-s, BPD) | |

| Gurbacewar Ƙarfe-Ƙarfe | atom/cm2 | ≤5E10 atoms/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg, Na, K, Ti, Ca & Mn) | |

| Kunshin | Bayani dalla-dalla | - | kaset mai yawan wafer ko kwandon wafer guda ɗaya |

Q&A na SiC wafer

Q1: Menene mahimman fa'idodin amfani da wafers na SiC akan wafern siliki na gargajiya a cikin kayan lantarki?

A1:

Wafers na SiC suna ba da fa'idodi da yawa akan wafern silicon (Si) na gargajiya a cikin kayan lantarki, gami da:

Babban inganci: SiC yana da babban bandgap (3.26 eV) idan aka kwatanta da silicon (1.1 eV), ƙyale na'urori suyi aiki a mafi girman ƙarfin lantarki, mitoci, da yanayin zafi. Wannan yana haifar da ƙananan asarar wutar lantarki da haɓaka mafi girma a cikin tsarin sauya wutar lantarki.

High thermal Conductivity: SiC's thermal conductivity ya fi girma fiye da na silicon, yana ba da damar mafi kyawun watsawar zafi a cikin aikace-aikace masu ƙarfi, wanda ke inganta aminci da tsawon rayuwar na'urorin wutar lantarki.

Higher Voltage da Gudanarwa na Yanzu: Na'urorin SiC na iya ɗaukar nauyin ƙarfin lantarki da matakan yanzu, suna sa su dace da aikace-aikace masu ƙarfi irin su motocin lantarki, tsarin makamashi mai sabuntawa, da kuma masana'antun masana'antu.

Saurin Canjawa: Na'urorin SiC suna da saurin sauyawa da sauri, wanda ke taimakawa wajen rage yawan asarar makamashi da girman tsarin, yana sa su dace da aikace-aikace masu yawa.

Q2: Menene manyan aikace-aikacen wafers na SiC a cikin masana'antar kera motoci?

A2:

A cikin masana'antar kera, SiC wafers ana amfani da su da farko a:

Motocin Wutar Lantarki (EV) Tashar wutar lantarki: Abubuwan tushen SiC kamarinverterskumaikon MOSFETinganta ingantaccen aiki da aikin wutar lantarki na motocin lantarki ta hanyar ba da damar saurin sauyawa da sauri da yawan kuzari. Wannan yana haifar da tsawon rayuwar baturi da ingantaccen aikin abin hawa gaba ɗaya.

Akan-Board Chargers: Na'urorin SiC suna taimakawa wajen inganta ingantaccen tsarin cajin kan jirgi ta hanyar ba da damar lokutan caji da sauri da mafi kyawun kula da zafi, wanda ke da mahimmanci ga EVs don tallafawa tashoshin caji mai ƙarfi.

Tsarin Gudanar da Baturi (BMS): SiC fasahar inganta yadda ya dace natsarin sarrafa baturi, bada izinin ingantaccen tsarin wutar lantarki, mafi girman iko, da tsawon rayuwar baturi.

Masu Canza DC-DC: Ana amfani da wafers na SiC a cikiDC-DC masu canzawadon juyar da wutar lantarki mai ƙarfi na DC zuwa ƙarancin wutar lantarki na DC da inganci, wanda ke da mahimmanci a cikin motocin lantarki don sarrafa wuta daga baturi zuwa sassa daban-daban a cikin abin hawa.

Babban aikin SiC a cikin babban ƙarfin lantarki, yanayin zafi, da aikace-aikace masu inganci ya sa ya zama mahimmanci ga canjin masana'antar kera motoci zuwa motsi na lantarki.

6inch 4H-N nau'in SiC wafer's takamaiman | ||

| Dukiya | Zero MPD Production Grade (Z Grade) | Dummy Grade (D Grade) |

| Daraja | Zero MPD Production Grade (Z Grade) | Dummy Grade (D Grade) |

| Diamita | 149.5 mm - 150.0 mm | 149.5 mm - 150.0 mm |

| Nau'in poly | 4H | 4H |

| Kauri | 350 µm ± 15 µm | 350 µm ± 25 µm |

| Wafer Orientation | Kashe axis: 4.0° zuwa <1120> ± 0.5° | Kashe axis: 4.0° zuwa <1120> ± 0.5° |

| Maƙarƙashiya Maɗaukaki | 0.2 cm² | ≤ 15 cm² |

| Resistivity | 0.015 - 0.024 Ω · cm | 0.015 - 0.028 Ω · cm |

| Hannun Filayen Firamare | [10-10] ± 50° | [10-10] ± 50° |

| Tsawon Lantarki na Farko | 475 mm ± 2.0 mm | 475 mm ± 2.0 mm |

| Ƙarƙashin Ƙarfi | 3 mm ku | 3 mm ku |

| LTV / TIV / Baka / Warp | 2.5µm / ≤ 6 µm / ≤ 25 µm / ≤ 35 µm | ≤ 5 µm / ≤ 15 µm / ≤ 40 µm / ≤ 60 µm |

| Tashin hankali | Yaren mutanen Poland Ra ≤ 1 nm | Yaren mutanen Poland Ra ≤ 1 nm |

| CMP Ra | 0.2 nm | 0.5 nm |

| Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙwara | Tsayin tarawa ≤ 20 mm tsayi ɗaya ≤ 2 mm | Tsayin tarawa ≤ 20 mm tsayi ɗaya ≤ 2 mm |

| Hex Plates Ta Babban Haske mai ƙarfi | Tarin yanki ≤ 0.05% | Tarin yanki ≤ 0.1% |

| Wuraren Polytype Ta Hanyar Ƙarfin Ƙarfi | Tarin yanki ≤ 0.05% | Tarin yanki ≤ 3% |

| Haɗin Carbon Na gani | Tarin yanki ≤ 0.05% | Tarin yanki ≤ 5% |

| Silicon Surface Scratches By High Intensity Light | Tsayin tarawa ≤ diamita wafer 1 | |

| Chips Gefe Ta Babban Haske mai ƙarfi | Babu wanda aka halatta ≥ 0.2 mm faɗi da zurfin | 7 izini, ≤ 1 mm kowanne |

| Rushewar Zaren Zare | <500 cm³ | <500 cm³ |

| Lalacewar Silicon Surface Ta Babban Haske mai ƙarfi | ||

| Marufi | Cassette mai yawa-wafer ko kwantena wafer guda ɗaya | Cassette mai yawa-wafer ko kwantena wafer guda ɗaya |

8inch 4H-N nau'in SiC wafer's takamaiman | ||

| Dukiya | Zero MPD Production Grade (Z Grade) | Dummy Grade (D Grade) |

| Daraja | Zero MPD Production Grade (Z Grade) | Dummy Grade (D Grade) |

| Diamita | 199.5 mm - 200.0 mm | 199.5 mm - 200.0 mm |

| Nau'in poly | 4H | 4H |

| Kauri | 500 µm ± 25 µm | 500 µm ± 25 µm |

| Wafer Orientation | 4.0° zuwa <110> ± 0.5° | 4.0° zuwa <110> ± 0.5° |

| Maƙarƙashiya Maɗaukaki | 0.2 cm² | 5 cm² |

| Resistivity | 0.015 - 0.025 Ω · cm | 0.015 - 0.028 Ω · cm |

| Matsayi Mai Girma | ||

| Ƙarƙashin Ƙarfi | 3 mm ku | 3 mm ku |

| LTV / TIV / Baka / Warp | ≤ 5 µm / ≤ 15 µm / ≤ 35 µm / 70 µm | ≤ 5 µm / ≤ 15 µm / ≤ 35 µm / 100 µm |

| Tashin hankali | Yaren mutanen Poland Ra ≤ 1 nm | Yaren mutanen Poland Ra ≤ 1 nm |

| CMP Ra | 0.2 nm | 0.5 nm |

| Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙwara | Tsayin tarawa ≤ 20 mm tsayi ɗaya ≤ 2 mm | Tsayin tarawa ≤ 20 mm tsayi ɗaya ≤ 2 mm |

| Hex Plates Ta Babban Haske mai ƙarfi | Tarin yanki ≤ 0.05% | Tarin yanki ≤ 0.1% |

| Wuraren Polytype Ta Hanyar Ƙarfin Ƙarfi | Tarin yanki ≤ 0.05% | Tarin yanki ≤ 3% |

| Haɗin Carbon Na gani | Tarin yanki ≤ 0.05% | Tarin yanki ≤ 5% |

| Silicon Surface Scratches By High Intensity Light | Tsayin tarawa ≤ diamita wafer 1 | |

| Chips Gefe Ta Babban Haske mai ƙarfi | Babu wanda aka halatta ≥ 0.2 mm faɗi da zurfin | 7 izini, ≤ 1 mm kowanne |

| Rushewar Zaren Zare | <500 cm³ | <500 cm³ |

| Lalacewar Silicon Surface Ta Babban Haske mai ƙarfi | ||

| Marufi | Cassette mai yawa-wafer ko kwantena wafer guda ɗaya | Cassette mai yawa-wafer ko kwantena wafer guda ɗaya |

6 Inch 4H-Semi SiC ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙa'idodin | ||

| Dukiya | Zero MPD Production Grade (Z Grade) | Dummy Grade (D Grade) |

| Diamita (mm) | 145 mm - 150 mm | 145 mm - 150 mm |

| Nau'in poly | 4H | 4H |

| Kauri (um) | 500 ± 15 | 500 ± 25 |

| Wafer Orientation | Kan axis: ± 0.0001° | Kan axis: ± 0.05° |

| Maƙarƙashiya Maɗaukaki | ≤ 15 cm-2 | ≤ 15 cm-2 |

| Resistivity (Ωcm) | 10E3 | 10E3 |

| Hannun Filayen Firamare | (0-10)° ± 5.0° | (10-10)° ± 5.0° |

| Tsawon Lantarki na Farko | Daraja | Daraja |

| Ƙimar Ƙarfi (mm) | ≤ 2.5 µm / ≤ 15 µm | ≤ 5.5 µm / ≤ 35 µm |

| LTV / Bowl / Warp | ≤3µm | ≤3µm |

| Tashin hankali | Yaren mutanen Poland Ra ≤ 1.5 µm | Yaren mutanen Poland Ra ≤ 1.5 µm |

| Chips Gefe Ta Babban Haske mai ƙarfi | ≤20µm | ≤ 60µm |

| Faranti Zafi Ta Babban Haske mai ƙarfi | Tarin ≤ 0.05% | Tarin ≤ 3% |

| Wuraren Polytype Ta Hanyar Ƙarfin Ƙarfi | Haɗin Carbon Na gani ≤ 0.05% | Tarin ≤ 3% |

| Silicon Surface Scratches By High Intensity Light | 0.05% | Tarin ≤ 4% |

| Chips Gefe Ta Babban Haske mai ƙarfi (Girman) | Ba a Izinin ba> 02 mm Nisa da Zurfin | Ba a Izinin ba> 02 mm Nisa da Zurfin |

| The Aid Screw Dilation | ≤ 500 µm | ≤ 500 µm |

| Lalacewar Silicon Surface Ta Babban Haske mai ƙarfi | ≤ 1 x 10^5 | ≤ 1 x 10^5 |

| Marufi | Cassette mai yawa-wafer ko kwantena wafer guda ɗaya | Cassette mai yawa-wafer ko kwantena wafer guda ɗaya |

4-inch 4H-Semi Insulating SiC Ƙayyadaddun Substrate

| Siga | Zero MPD Production Grade (Z Grade) | Dummy Grade (D Grade) |

|---|---|---|

| Abubuwan Jiki | ||

| Diamita | 99.5 mm - 100.0 mm | 99.5 mm - 100.0 mm |

| Nau'in poly | 4H | 4H |

| Kauri | 500 μm ± 15 μm | 500 μm ± 25 μm |

| Wafer Orientation | Kan axis: <600h>0.5° | Kan axis: <000h>0.5° |

| Abubuwan Lantarki | ||

| Maƙarƙashiya Maɗaukaki (MPD) | ≤1 cm² | ≤15 cm² |

| Resistivity | ≥150 Ω · cm | ≥1.5 Ω · cm |

| Hakuri na Geometric | ||

| Hannun Filayen Firamare | (0×10) ± 5.0° | (0×10) ± 5.0° |

| Tsawon Lantarki na Farko | 52.5 mm ± 2.0 mm | 52.5 mm ± 2.0 mm |

| Tsawon Lantarki na Sakandare | 18.0 mm ± 2.0 mm | 18.0 mm ± 2.0 mm |

| Gabatarwar Flat na Sakandare | 90° CW daga Firayim lebur ± 5.0° (Si fuskar sama) | 90° CW daga Firayim lebur ± 5.0° (Si fuskar sama) |

| Ƙarƙashin Ƙarfi | 3 mm ku | 3 mm ku |

| LTV / TTV / Baka / Warp | ≤2.5 μm / ≤5 μm / ≤15 μm / ≤30 μm | ≤10 μm / ≤15 μm / ≤25 μm / ≤40 μm |

| ingancin saman | ||

| Ƙarƙashin Ƙarƙashin Ƙasa (Yaren mutanen Poland Ra) | ≤1 nm | ≤1 nm |

| Ƙarƙashin Ƙasa (CMP Ra) | ≤0.2 nm | ≤0.2 nm |

| Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙwara | Ba a yarda ba | Tsayin tarawa ≥10 mm, fashe ɗaya ≤2 mm |

| Lalacewar farantin hexagonal | ≤0.05% tara yanki | ≤0.1% tara yanki |

| Wuraren Haɗa Polytype | Ba a yarda ba | ≤1% tara yanki |

| Haɗin Carbon Na gani | ≤0.05% tara yanki | ≤1% tara yanki |

| Silicon Surface Scratches | Ba a yarda ba | ≤1 wafer diamita tara tsayi |

| Kwakwalwa na Edge | Babu wanda aka yarda (≥0.2 mm nisa/zurfin) | ≤5 kwakwalwan kwamfuta (kowane ≤1 mm) |

| Gurbacewar Silicon Surface | Ba a kayyade ba | Ba a kayyade ba |

| Marufi | ||

| Marufi | Multi-wafer cassette ko kwandon wafer guda ɗaya | Multi-wafer cassette ko |

| 6-inch N-nau'in Epit axial ƙayyadaddun bayanai | |||

| Siga | naúrar | Z-MOS | |

| Nau'in | Condutivity / Dopant | - | N-type / Nitrogen |

| Layer buffer | Ƙaƙƙarfan Ƙaƙƙarfan Layer | um | 1 |

| Haƙuri da Kauri Layer | % | ± 20% | |

| Matsakaicin Ƙarfafa Layer | cm-3 | 1.00E+18 | |

| Hakuri Hakuri na Ƙarfafa Layer | % | ± 20% | |

| 1st Epi Layer | Epi Layer Kauri | um | 11.5 |

| Uniformity na kauri na Epi Layer | % | ± 4% | |

| Hakurin Hakurin Kauri na Epi ((Tallafi Max, Min)/Spec) | % | ± 5% | |

| Epi Layer Concentration | cm-3 | 1E 15~ 1E 18 | |

| Hakurin Hakuri na Epi Layer | % | 6% | |

| Epi Layer Concentity Uniformity (σ /ma'ana) | % | ≤5% | |

| Epi Layer Concentity Uniformity <(max-min)/(max+min> | % | ≤ 10% | |

| Epitaixal Wafer Siffar | Ruku'u | um | ≤±20 |

| WARP | um | ≤30 | |

| TTV | um | ≤ 10 | |

| LTV | um | ≤2 | |

| Halayen Gabaɗaya | Tsawon tsagewa | mm | ≤30mm |

| Kwakwalwa na Edge | - | BABU | |

| Ma'anar lahani | ≥97% (An auna da 2*2). Lalacewar kisa sun haɗa da: Lalacewar sun haɗa da Micropipe / Manyan ramuka, Karas, Triangular | ||

| Karfe gurbacewa | atom / cm² | d f f zan ≤5E10 atoms/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg, Na, K, Ti, Ca & Mn) | |

| Kunshin | Bayani dalla-dalla | pcs/kwali | kaset mai yawan wafer ko kwandon wafer guda ɗaya |

| 8-inch N-nau'in ƙayyadaddun epitaxial | |||

| Siga | naúrar | Z-MOS | |

| Nau'in | Condutivity / Dopant | - | N-type / Nitrogen |

| Layer na buffer | Ƙaƙƙarfan Ƙaƙƙarfan Layer | um | 1 |

| Haƙuri da Kauri Layer | % | ± 20% | |

| Matsakaicin Ƙarfafa Layer | cm-3 | 1.00E+18 | |

| Hakuri Hakuri na Ƙarfafa Layer | % | ± 20% | |

| 1st Epi Layer | Matsakaicin Kauri Epi Layers | um | 8 ~ 12 |

| Uniformity na Kauri Epi Layers (σ/ma'ana) | % | ≤2.0 | |

| Hakurin Hakurin Kauri Epi Layers((Spec-Max, Min)/Spec) | % | ± 6 | |

| Epi Layers Net Matsakaicin Doping | cm-3 | 8E+15 ~2E+16 | |

| Epi Layers Net Doping Uniformity (σ/ma'ana) | % | ≤5 | |

| Epi Layers Net DopingTolerance ((Spec-Max, | % | ± 10.0 | |

| Epitaixal Wafer Siffar | Mi)/S) Warp | um | ≤50.0 |

| Ruku'u | um | ± 30.0 | |

| TTV | um | ≤ 10.0 | |

| LTV | um | ≤4.0 (10mm × 10mm) | |

| Gabaɗaya Halaye | Scratches | - | Tsayin tarawa≤ 1/2 Diamita na Wafer |

| Kwakwalwa na Edge | - | ≤2 kwakwalwan kwamfuta, Kowane radius≤1.5mm | |

| Gurbacewar Ƙarfe-Ƙarfe | atom/cm2 | ≤5E10 atoms/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg, Na, K, Ti, Ca & Mn) | |

| Lalacewar Dubawa | % | ≥ 96.0 (Labaran 2X2 sun haɗa da Micropipe / Manyan rami, Karas, Lalacewar Triangular, Faduwa, Linear/IGSF-s, BPD) | |

| Gurbacewar Ƙarfe-Ƙarfe | atom/cm2 | ≤5E10 atoms/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg, Na, K, Ti, Ca & Mn) | |

| Kunshin | Bayani dalla-dalla | - | kaset mai yawan wafer ko kwandon wafer guda ɗaya |

Q1: Menene mahimman fa'idodin amfani da wafers na SiC akan wafern siliki na gargajiya a cikin kayan lantarki?

A1:

Wafers na SiC suna ba da fa'idodi da yawa akan wafern silicon (Si) na gargajiya a cikin kayan lantarki, gami da:

Babban inganci: SiC yana da babban bandgap (3.26 eV) idan aka kwatanta da silicon (1.1 eV), ƙyale na'urori suyi aiki a mafi girman ƙarfin lantarki, mitoci, da yanayin zafi. Wannan yana haifar da ƙananan asarar wutar lantarki da haɓaka mafi girma a cikin tsarin sauya wutar lantarki.

High thermal Conductivity: SiC's thermal conductivity ya fi girma fiye da na silicon, yana ba da damar mafi kyawun watsawar zafi a cikin aikace-aikace masu ƙarfi, wanda ke inganta aminci da tsawon rayuwar na'urorin wutar lantarki.

Higher Voltage da Gudanarwa na Yanzu: Na'urorin SiC na iya ɗaukar nauyin ƙarfin lantarki da matakan yanzu, suna sa su dace da aikace-aikace masu ƙarfi irin su motocin lantarki, tsarin makamashi mai sabuntawa, da kuma masana'antun masana'antu.

Saurin Canjawa: Na'urorin SiC suna da saurin sauyawa da sauri, wanda ke taimakawa wajen rage yawan asarar makamashi da girman tsarin, yana sa su dace da aikace-aikace masu yawa.

Q2: Menene manyan aikace-aikacen wafers na SiC a cikin masana'antar kera motoci?

A2:

A cikin masana'antar kera, SiC wafers ana amfani da su da farko a:

Motocin Wutar Lantarki (EV) Tashar wutar lantarki: Abubuwan tushen SiC kamarinverterskumaikon MOSFETinganta ingantaccen aiki da aikin wutar lantarki na motocin lantarki ta hanyar ba da damar saurin sauyawa da sauri da yawan kuzari. Wannan yana haifar da tsawon rayuwar baturi da ingantaccen aikin abin hawa gaba ɗaya.

Akan-Board Chargers: Na'urorin SiC suna taimakawa wajen inganta ingantaccen tsarin cajin kan jirgi ta hanyar ba da damar lokutan caji da sauri da mafi kyawun kula da zafi, wanda ke da mahimmanci ga EVs don tallafawa tashoshin caji mai ƙarfi.

Tsarin Gudanar da Baturi (BMS): SiC fasahar inganta yadda ya dace natsarin sarrafa baturi, bada izinin ingantaccen tsarin wutar lantarki, mafi girman iko, da tsawon rayuwar baturi.

Masu Canza DC-DC: Ana amfani da wafers na SiC a cikiDC-DC masu canzawadon juyar da wutar lantarki mai ƙarfi na DC zuwa ƙarancin wutar lantarki na DC da inganci, wanda ke da mahimmanci a cikin motocin lantarki don sarrafa wuta daga baturi zuwa sassa daban-daban a cikin abin hawa.

Babban aikin SiC a cikin babban ƙarfin lantarki, yanayin zafi, da aikace-aikace masu inganci ya sa ya zama mahimmanci ga canjin masana'antar kera motoci zuwa motsi na lantarki.