Tireshin yumbura na SiC don Mai ɗaukar Wafer tare da Juriya mai Tsafta

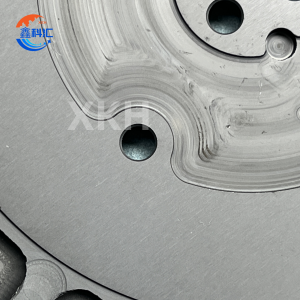

Silicon Carbide Ceramic Tray (SiC Tray).

Babban kayan aikin yumbu mai inganci dangane da kayan silicon carbide (SiC), wanda aka ƙera don aikace-aikacen masana'antu na ci gaba kamar masana'antar semiconductor da samar da LED. Ayyukansa na asali sun haɗa da yin aiki azaman mai ɗaukar wafer, dandamalin tsarin etching, ko goyon bayan tsari mai zafi, haɓaka ƙayyadaddun yanayin zafi, juriya mai zafi, da kwanciyar hankali na sinadarai don tabbatar da daidaiton tsari da yawan amfanin ƙasa.

Key Features

1. Thermal Performance

- Babban Haɓakawa: 140-300 W / m · K, wanda ya zarce graphite na gargajiya (85 W / m · K), yana ba da damar saurin saurin zafi da rage damuwa na thermal.

- Low Thermal Expansion Coefficient: 4.0 × 10⁻⁶ / ℃ (25-1000 ℃), kusa matching silicon (2.6 × 10⁻⁶ / ℃), rage girman thermal nakasar kasada.

2. Mechanical Properties

- Babban Ƙarfi: Ƙarfin sassauƙa ≥320 MPa (20 ℃), mai jurewa da matsawa da tasiri.

- High Hardness: Mohs hardness 9.5, na biyu kawai zuwa lu'u-lu'u, yana ba da juriya mai girma.

3. Tsawon Sinadarai

- Juriya na Lalata

- Mara-Magnetic

4. Matsanancin Haƙurin Muhalli

- Babban Zazzabi Durability: Dogon aiki zazzabi har zuwa 1600-1900 ℃; juriya na gajeren lokaci har zuwa 2200 ℃ (yanayin da ba shi da iskar oxygen).

- Juriya Shock Thermal: Yana jure wa canje-canjen zafin jiki ba zato ba tsammani (ΔT> 1000 ℃) ba tare da tsagewa ba.

Aikace-aikace

| Filin aikace-aikace | Takamaiman Al'amuran | Ƙimar Fasaha |

| Semiconductor Manufacturing | Wafer etching (ICP), jigon fim na bakin ciki (MOCVD), gogewar CMP | Babban haɓakar thermal yana tabbatar da filayen zafin jiki iri ɗaya; ƙananan haɓakar thermal yana rage girman shafi na wafer. |

| LED Production | Girman Epitaxial (misali, GaN), wafer dicing, marufi | Yana kashe lahani iri-iri, yana haɓaka ingantaccen haske na LED da tsawon rayuwa. |

| Kamfanin Photovoltaic | Silicon wafer sintering tanderu, PECVD kayan aiki goyan bayan | Maɗaukakin zafin jiki da juriya mai zafi yana ƙara tsawon rayuwar kayan aiki. |

| Laser & Optics | Babban iko Laser sanyaya substrates, Tantancewar tsarin goyon bayan | High thermal conductivity yana ba da damar saurin zubar da zafi, daidaita abubuwan da ke gani. |

| Analytical Instruments | Masu riƙe samfurin TGA/DSC | Ƙananan ƙarfin zafi da saurin amsawar zafi suna haɓaka daidaiton aunawa. |

Amfanin Samfura

- Cikakkun Ayyuka: Ƙarfafawar thermal, ƙarfi, da juriya na lalata da nisa sun wuce yumbura alumina da silicon nitride, suna biyan matsananciyar buƙatun aiki.

- Zane mai sauƙi

- Tsawon Rayuwa & Dogara

- Keɓancewa: Yana goyan bayan hadaddun geometries (misali, kofuna na tsotsa, tire mai yawa) tare da kuskuren lallashi <15 μm don ainihin aikace-aikacen.

Ƙayyadaddun Fasaha

| Parameter Category | Mai nuna alama |

| Kayayyakin Jiki | |

| Yawan yawa | ≥3.10 g/cm³ |

| Ƙarfin Ƙarfi (20 ℃) | 320-410 MPa |

| Ƙarfafa Ƙarfafawa (20 ℃) | 140–300 W/(m·K) |

| Ƙididdigar Faɗaɗɗa ta thermal (25-1000 ℃) | 4.0×10⁻⁻⁻/℃ |

| Chemical Properties | |

| Resistance Acid (HF/H₂SO₄) | Babu lalata bayan nutsewar sa'o'i 24 |

| Machining Precision | |

| Lalata | ≤15 μm (300×300 mm) |

| Tashin Lafiya (Ra) | ≤0.4 μm |

Ayyukan XKH

XKH yana ba da cikakkiyar mafita na masana'antu wanda ya haɗa da haɓaka al'ada, ƙirar ƙira, da ingantaccen kulawa. Don ci gaban al'ada, yana ba da tsabta mai tsabta (> 99.999%) da porous (30-50% porosity) mafita kayan aiki, an haɗa su tare da ƙirar 3D da kwaikwaiyo don haɓaka hadaddun geometries don aikace-aikace kamar semiconductor da sararin samaniya. Daidaitaccen mashin ɗin yana biye da tsari mai sauƙi: sarrafa foda → isostatic / bushe latsa → 2200 ° C sintering → CNC / lu'u-lu'u nika → dubawa, tabbatar da matakin nanometer polishing da ± 0.01 mm juriya juzu'i. Gudanar da inganci ya haɗa da gwajin cikakken tsari ( abun da ke ciki na XRD, microstructure SEM, 3-point lankwasawa) da goyan bayan fasaha (ingantawar tsari, shawarwarin 24/7, isar da samfurin sa'o'i 48), yana ba da abin dogara, abubuwan da suka dace don buƙatun masana'antu na ci gaba.

Tambayoyin da ake yawan yi (FAQ)

1. Q: Wadanne masana'antu ke amfani da tiren yumbura na silicon carbide?

A: An yi amfani da shi sosai a masana'anta na semiconductor

2. Tambaya: Ta yaya silicon carbide ya wuce ma'adini/gilashi?

A: Higher thermal shock juriya (har zuwa 1800°C vs. quartz's 1100°C), sifili magnetic tsangwama, da kuma tsawon rayuwa (5+ shekaru vs. quartz ta 6-12 watanni).

3. Q: Shin silikon carbide trays na iya sarrafa yanayin acidic?

A: iya. Juriya ga HF, H2SO4, da NaOH tare da lalata <0.01mm / shekara, yana mai da su manufa don etching sinadarai da tsabtace wafer.

4. Q: Shin silicon carbide trays sun dace da aiki da kai?

A: iya. An ƙera shi don ɗaukar injin da kuma sarrafa mutum-mutumi, tare da shimfidar ƙasa <0.01mm don hana gurɓataccen ƙwayar cuta a cikin fabs masu sarrafa kansa.

5. Tambaya: Menene kwatanta farashi da kayan gargajiya?

A: Mafi girman farashi na gaba (3-5x quartz) amma 30-50% ƙananan TCO saboda tsawaita rayuwa, rage raguwar lokaci, da tanadin makamashi daga ingantaccen yanayin zafi.