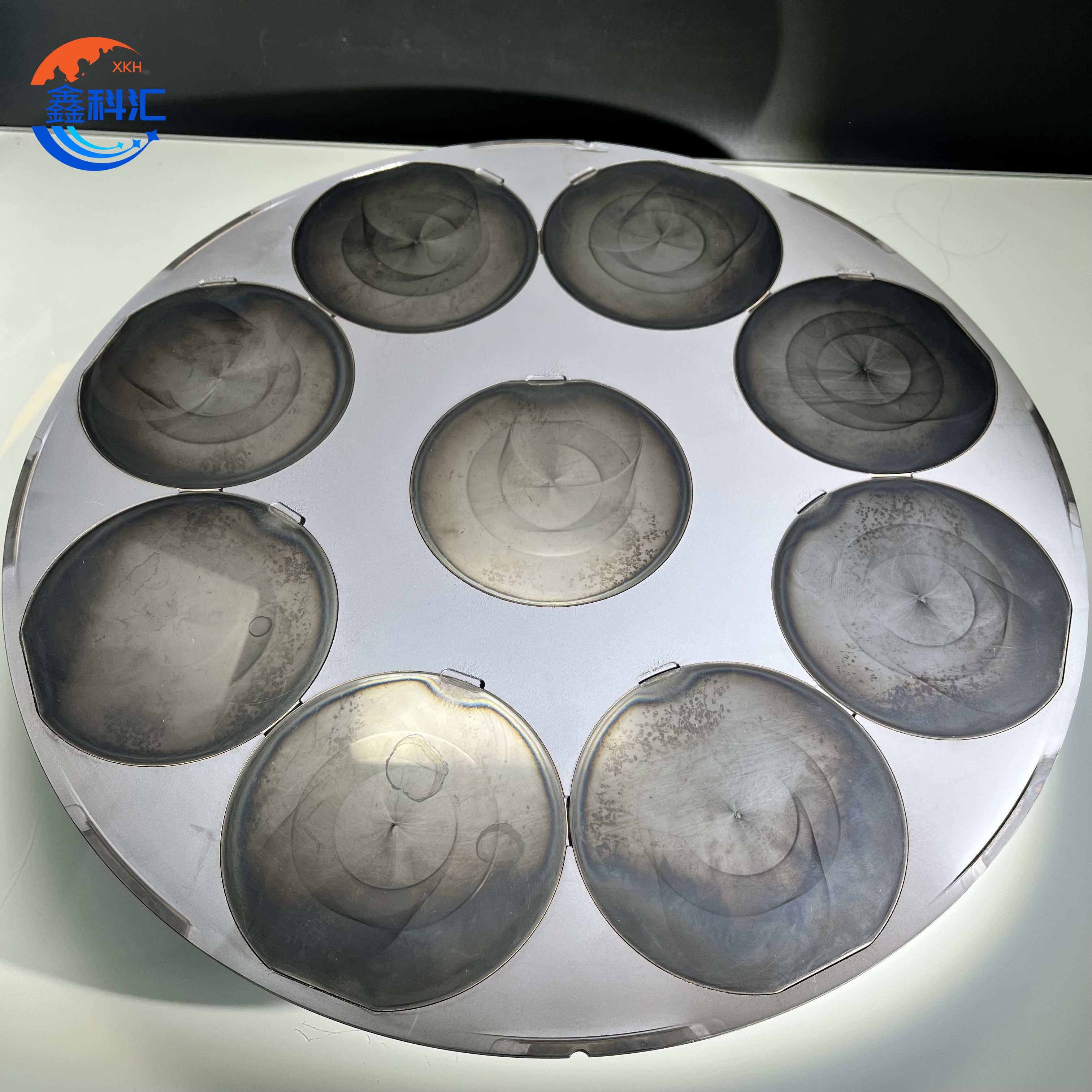

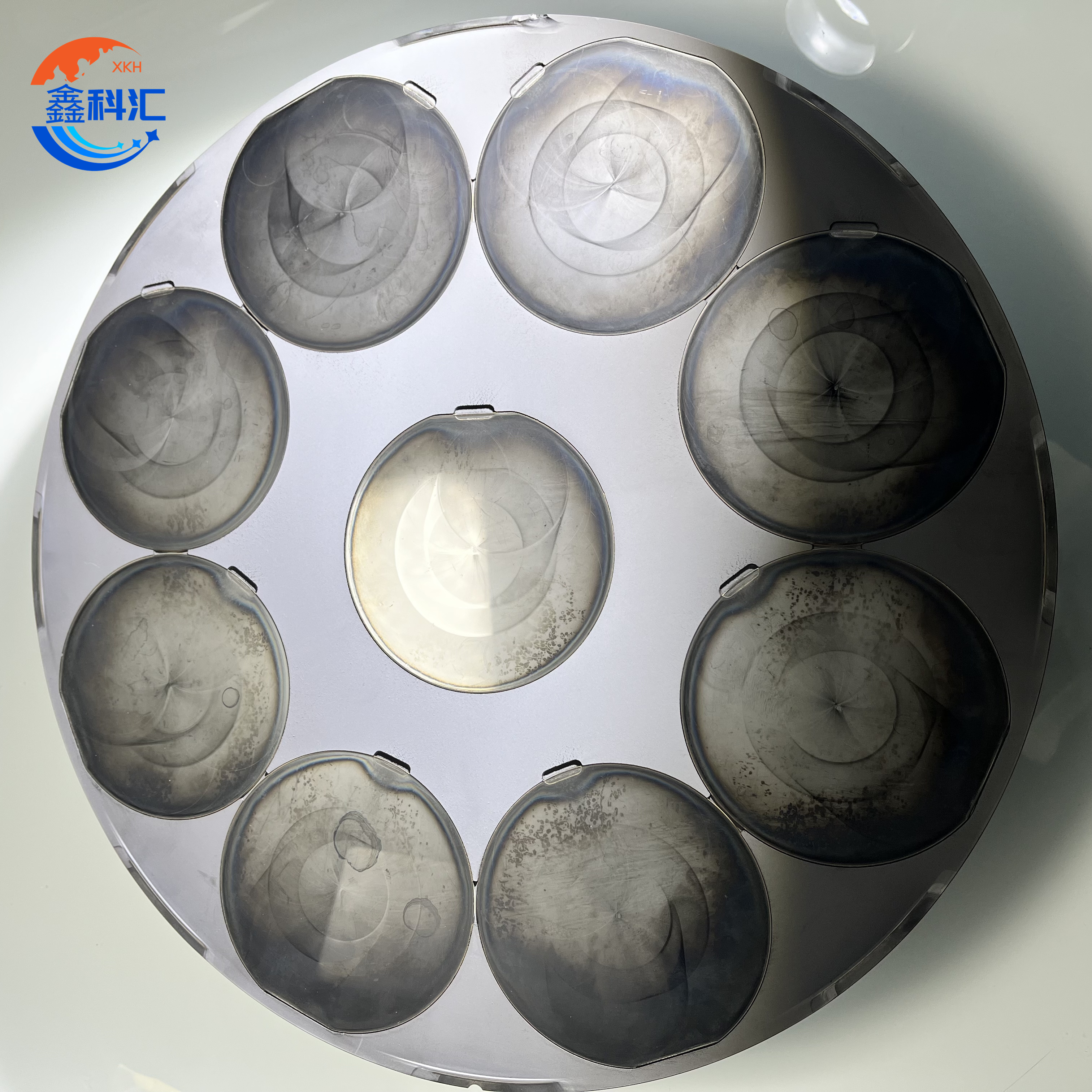

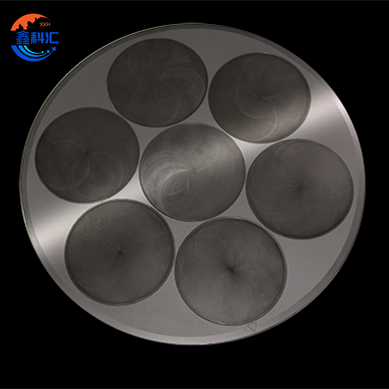

SiC yumbu farantin / tire don 4inch 6in wafer mariƙin na ICP

SiC ceramic farantin Abstract

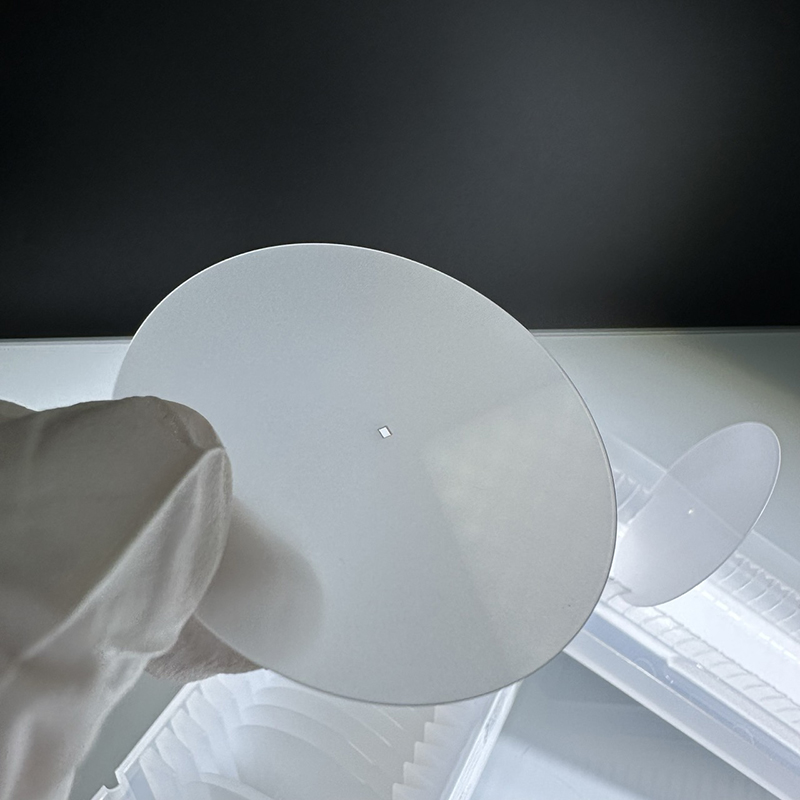

Farantin yumbura na SiC wani babban aiki ne wanda aka ƙera shi daga Silicon Carbide mai tsafta, wanda aka ƙera don amfani dashi a cikin matsanancin zafi, sinadarai, da mahalli. Shahararren don taurin sa na musamman, ƙarfin zafin zafi, da juriya na lalata, ana amfani da farantin SiC sosai azaman mai ɗaukar wafer, mai ɗaukar hoto, ko tsarin tsarin a cikin semiconductor, LED, photovoltaic, da masana'antar sararin samaniya.

Tare da ingantaccen kwanciyar hankali na thermal har zuwa 1600 ° C da kyakkyawan juriya ga iskar gas mai amsawa da mahalli na plasma, farantin SiC yana tabbatar da daidaiton aiki yayin etching mai zafi mai zafi, ajiya, da hanyoyin yadawa. Karamin tsarinsa mai yawa, mara fa'ida yana rage rarrabuwar barbashi, yana mai da shi manufa don aikace-aikacen tsaftataccen tsafta a cikin injin daki ko saituna masu tsabta.

Aikace-aikacen farantin yumbura na SiC

1. Semiconductor Manufacturing

Ana amfani da faranti yumbura na SiC a matsayin masu ɗaukar wafer, masu maye, da faranti a cikin kayan ƙirƙira semiconductor kamar CVD (Chemical Vapor Deposition), PVD (Tsarin Turin Jiki), da tsarin etching. Kyawawan halayen yanayin zafi da ƙananan haɓakar zafi suna ba su damar kula da rarraba yanayin zafi iri ɗaya, wanda ke da mahimmanci don sarrafa madaidaicin wafer. Juriyar SiC ga iskar gas da plasmas masu lalata suna tabbatar da dorewa a cikin yanayi mai tsauri, yana taimakawa rage gurɓataccen ƙwayar cuta da kiyaye kayan aiki.

2. LED Masana'antu - ICP Etching

A cikin masana'antar masana'antar LED, faranti na SiC sune mahimman abubuwan haɗin gwiwa a cikin tsarin etching na ICP (Inductively Coupled Plasma). Yin aiki azaman masu riƙe wafer, suna samar da ingantaccen dandamali mai ƙarfi don tallafawa sapphire ko GaN wafers yayin sarrafa plasma. Kyakkyawan juriyarsu ta plasma, shimfidar ƙasa, da kwanciyar hankali na girma suna taimakawa tabbatar da daidaiton etching da daidaituwa, yana haifar da haɓaka yawan amfanin ƙasa da aikin na'urar a cikin kwakwalwan LED.

3. Photovoltaics (PV) da Hasken Rana

Hakanan ana amfani da faranti yumbura na SiC wajen samar da ƙwayoyin rana, musamman a lokacin daɗaɗɗun zafin jiki da matakan cirewa. Rashin rashin aikin su a yanayin zafi mai tsayi da ikon yin tsayayya da warping yana tabbatar da daidaiton sarrafa wafern silicon. Bugu da ƙari, ƙananan haɗarin gurɓata su yana da mahimmanci don kiyaye ingancin ƙwayoyin photovoltaic.

SiC ceramic plate Properties

1. Keɓaɓɓen Ƙarfin Injini da Tauri

SiC yumbura faranti suna nuna ƙarfin injina sosai, tare da ƙarfin sassauƙa na yau da kullun wanda ya wuce 400 MPa da taurin Vickers yana kaiwa> 2000 HV. Wannan yana sa su juriya sosai ga lalacewa na inji, abrasion, da nakasawa, yana tabbatar da tsawon rayuwar sabis ko da ƙarƙashin babban nauyi ko maimaita hawan keke.

2. High thermal Conductivity

SiC yana da kyawawan halayen thermal conductivity (yawanci 120-200 W/m·K), yana ba shi damar rarraba zafi daidai da samanta. Wannan kadarar tana da mahimmanci a cikin matakai kamar wafer etching, ajiya, ko sintiri, inda daidaiton zafin jiki ya shafi amfanin samfur da inganci kai tsaye.

3. Mafi Girman Ƙarfin Ƙarfafawa

Tare da babban ma'aunin narkewa (2700°C) da ƙarancin haɓakar haɓakar thermal (4.0 × 10⁻⁶/K), faranti yumbura na SiC suna kiyaye daidaiton girma da daidaiton tsari a ƙarƙashin saurin dumama da yanayin sanyaya. Wannan ya sa su dace don aikace-aikace a cikin tanderu masu zafi, ɗakuna masu zafi, da yanayin plasma.

| Abubuwan Fasaha | ||||

| Fihirisa | Naúrar | Daraja | ||

| Sunan Abu | Reaction Sintered Silicon Carbide | Sintered Silicon Carbide mara matsi | Silicon Carbide da aka sake buɗewa | |

| Abun ciki | RBSiC | SSiC | R-SiC | |

| Yawan yawa | g/cm3 | 3 | 3.15 ± 0.03 | 2.60-2.70 |

| Ƙarfin Flexural | MPa (kpsi) | 338 (49) | 380(55) | 80-90 (20°C) 90-100(1400°C) |

| Ƙarfin Ƙarfi | MPa (kpsi) | 1120 (158) | 3970(560) | > 600 |

| Tauri | Knoop | 2700 | 2800 | / |

| Breaking Tenacity | MPa m1/2 | 4.5 | 4 | / |

| Thermal Conductivity | W/mk | 95 | 120 | 23 |

| Coefficient na Thermal Expansion | 10-6.1/C | 5 | 4 | 4.7 |

| Takamaiman Zafi | Joule/g 0k | 0.8 | 0.67 | / |

| Matsakaicin zafin jiki a cikin iska | ℃ | 1200 | 1500 | 1600 |

| Na roba Modulus | Gpa | 360 | 410 | 240 |

SiC ceramic farantin Q&A

Q: Menene kaddarorin farantin carbide silicon?

A: Silicon carbide (SiC) faranti an san su da ƙarfin ƙarfi, taurinsu, da kwanciyar hankali. Suna ba da kyakkyawan ƙarfin wutar lantarki da ƙananan haɓakar thermal, yana tabbatar da ingantaccen aiki a ƙarƙashin matsanancin yanayin zafi. SiC kuma ba shi da ƙarancin sinadarai, mai jurewa ga acid, alkalis, da mahallin plasma, yana mai da shi manufa don sarrafa semiconductor da LED. Ƙarfin sa mai santsi, mai santsi yana rage ƙanƙantar ƙuruciya, yana kiyaye daidaiton ɗaki mai tsabta. Ana amfani da faranti na SiC ko'ina azaman masu ɗaukar wafer, masu cutarwa, da abubuwan tallafi a cikin yanayin zafi mai zafi da lalata a cikin masana'antar semiconductor, photovoltaic, da masana'antar sararin samaniya.