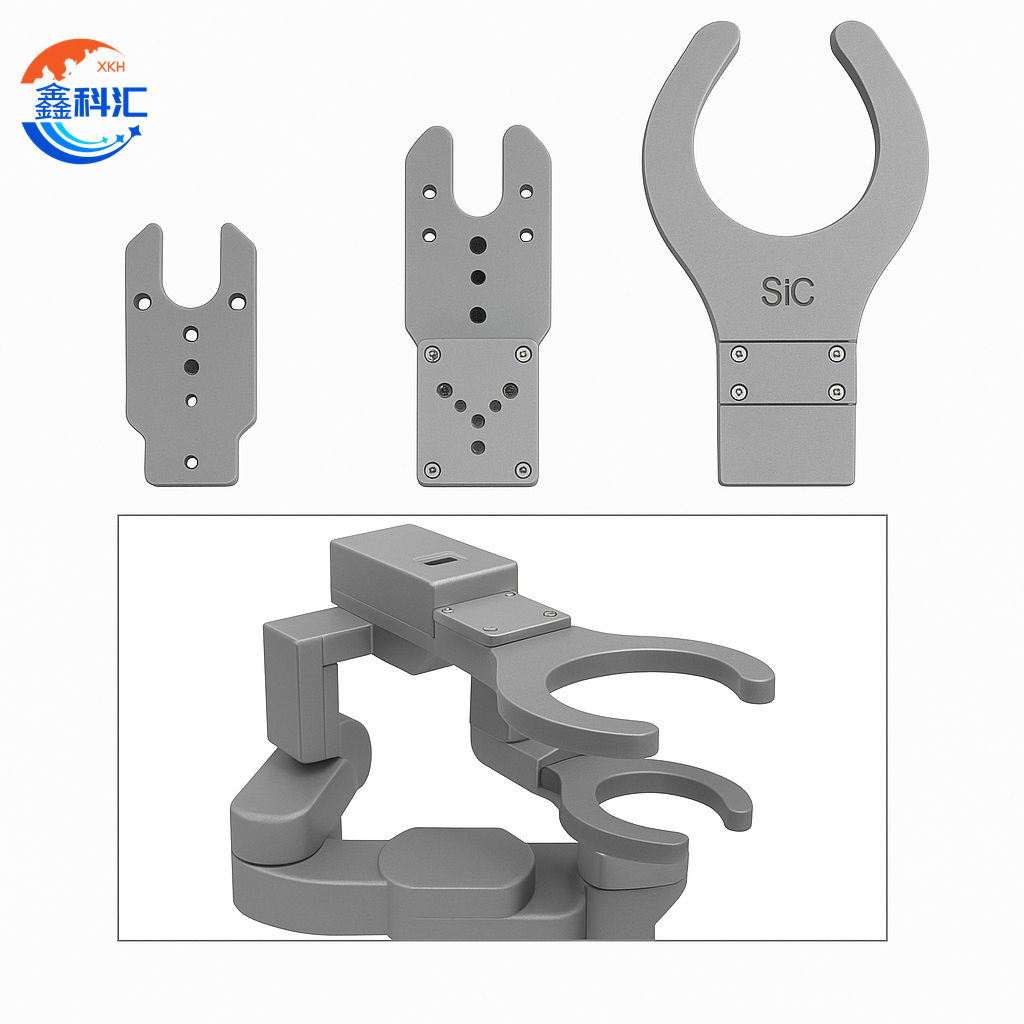

SiC ceramic end effector mika hannu don ɗaukar wafer

SiC ceramic end effector Abstract

SiC (Silicon Carbide) yumbu mai ƙare-effector muhimmin abu ne a cikin ingantattun tsarin sarrafa wafer da aka yi amfani da shi a masana'antar semiconductor da haɓakar mahallin microfabrication. An ƙera shi don biyan buƙatun buƙatun tsaftataccen tsafta, yanayin zafi mai zafi, da kwanciyar hankali, wannan ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun za ta tabbatar da abin dogaro da jigilar wafers ba tare da gurɓata ba yayin mahimman matakan samarwa kamar lithography, etching, da ajiya.

Yin amfani da ingantattun kaddarorin kayan abu na silicon carbide-kamar haɓakar zafin jiki mai ƙarfi, matsananciyar tauri, inertness mafi ƙarancin sinadarai, da ƙaramin haɓakar zafin jiki-ƙarshen yumbura na SiC yana ba da ƙaƙƙarfan inji da kwanciyar hankali mai girma ko da a ƙarƙashin saurin hawan keke ko a cikin ɗakuna masu lalata. Halayensa mara ƙanƙanta da halayyar juriya plasma suna dacewa da shi musamman don tsabtatawa da aikace-aikacen sarrafawa, inda ke riƙe da rashin iya haifar da rashin ƙarfi da rage rashin ƙarfi.

SiC ceramic end effector Application

1. Semiconductor Wafer Handling

SiC ceramic end effects ana amfani da ko'ina a cikin semiconductor masana'antu don sarrafa silicon wafers a lokacin samar da atomatik. Waɗannan masu tasirin ƙarshen yawanci ana ɗora su akan na'urorin hannu na mutum-mutumi ko tsarin canja wuri kuma an ƙirƙira su don ɗaukar wafers masu girma dabam dabam kamar 200mm da 300mm. Suna da mahimmanci a cikin matakai da suka haɗa da Jigilar Turin Sinadari (CVD), Ƙaƙƙarfan Turin Jiki (PVD), etching, da yaduwa-inda yanayin zafi mai zafi, yanayin iska, da iskar gas ke gama gari. SiC ta keɓaɓɓen juriya na zafi da kwanciyar hankali na sinadarai sun sa ya zama ingantaccen abu don jure irin wannan yanayi mai tsauri ba tare da lalacewa ba.

2. Daidaita Tsabtace Da Wuta

A cikin saitunan ɗaki mai tsabta da vacuum, inda dole ne a rage yawan gurɓataccen ƙwayar cuta, yumbu na SiC yana ba da fa'idodi masu mahimmanci. Ƙaƙƙarfan kayan abu, mai santsi yana tsayayya da tsararrun kwayoyin halitta, yana taimakawa wajen kiyaye amincin wafer yayin sufuri. Wannan yana sa masu tasiri na ƙarshen SiC sun dace sosai don matakai masu mahimmanci kamar Extreme Ultraviolet Lithography (EUV) da Atomic Layer Deposition (ALD), inda tsabta ke da mahimmanci. Bugu da ƙari kuma, ƙarancin fitar da gas na SiC da babban juriya na plasma yana tabbatar da ingantaccen aiki a cikin ɗakuna, ƙara tsawon rayuwar kayan aiki da rage mitar kulawa.

3. Tsarin Matsakaicin Matsayi Mai Girma

Daidaituwa da kwanciyar hankali suna da mahimmanci a cikin ci-gaba na tsarin sarrafa wafer, musamman a fannin awoyi, dubawa, da kayan daidaitawa. Kayan yumbura na SiC suna da ƙarancin haɓakar haɓakar haɓakar thermal da tsayi mai tsayi, wanda ke ba da damar mai amfani da ƙarshen ya kula da daidaiton tsarin sa koda ƙarƙashin hawan keken zafi ko kayan inji. Wannan yana tabbatar da cewa wafers sun kasance daidai daidai lokacin jigilar kaya, rage haɗarin ƙananan scratches, rashin daidaituwa, ko kurakuran ma'auni - abubuwan da ke daɗaɗa mahimmanci a ƙananan matakan 5nm.

SiC ceramic end effector Properties

1. Babban Karfin Injini da Tauri

SiC yumbura suna da ƙarfin injina na musamman, tare da ƙarfin sassauƙa sau da yawa fiye da 400 MPa da ƙimar taurin Vickers sama da 2000 HV. Wannan yana sa su juriya sosai ga damuwa na inji, tasiri, da lalacewa, ko da bayan dogon aiki na aiki. Babban tsauri na SiC kuma yana rage jujjuyawa yayin canja wurin wafer mai sauri, yana tabbatar da daidaito da matsayi mai maimaitawa.

2. Madalla da Ƙarfafawar thermal

Ɗaya daga cikin mafi mahimmancin kaddarorin yumbura na SiC shine ikonsu na jure yanayin zafi mai tsananin zafi-sau da yawa har zuwa 1600C a cikin yanayi mara kyau-ba tare da rasa amincin injina ba. Matsakaicin haɓakawar haɓakawar haɓakar thermal (~ 4.0 x 10⁻⁶ / K) yana tabbatar da kwanciyar hankali a ƙarƙashin hawan keken zafi, yana sa su dace don aikace-aikace kamar CVD, PVD, da ƙarar zafi mai zafi.

SiC ceramic ƙarshen sakamako Q&A

Q: Wani abu ake amfani da wafer karshen sakamako?

A:Wafer ƙarewar sakamako yawanci ana yin su ne daga kayan da ke ba da ƙarfi mai ƙarfi, kwanciyar hankali mai zafi, da ƙarancin ƙirar barbashi. Daga cikin waɗannan, Silicon Carbide (SiC) yumbura yana ɗaya daga cikin mafi haɓaka da kayan da aka fi so. Kayan yumbura na SiC suna da matuƙar wuya, tsayayyen zafin jiki, rashin ƙarfi na sinadarai, da juriya don sawa, yana mai da su manufa don sarrafa maƙallan siliki masu laushi a cikin tsabta da mahalli. Idan aka kwatanta da ma'adini ko ƙarfe mai rufi, SiC yana ba da kwanciyar hankali mai girma a ƙarƙashin yanayin zafi kuma baya zubar da barbashi, wanda ke taimakawa hana gurɓatawa.