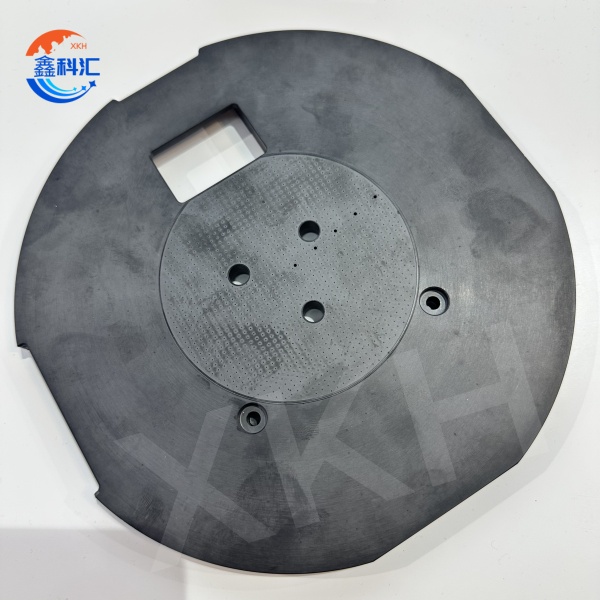

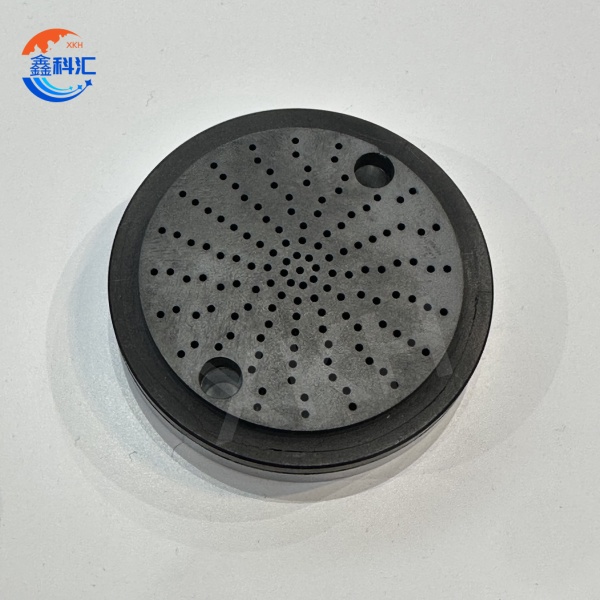

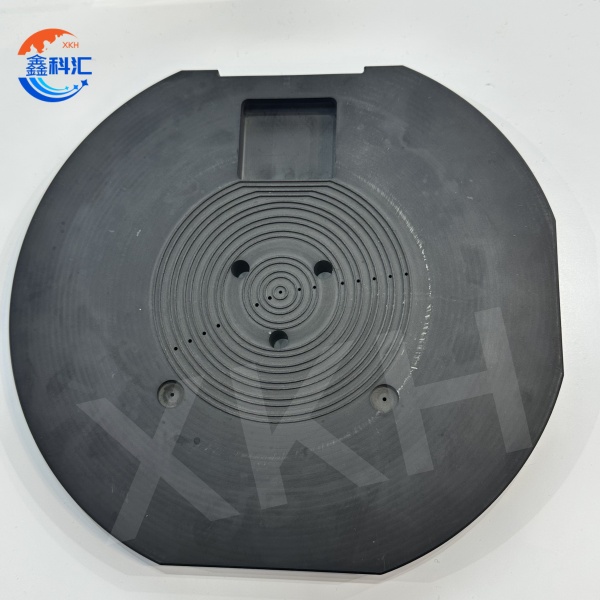

SiC ceramic chuck tray yumbu tsotsa kofuna na daidaitaccen mashin ɗin da aka keɓance

Halayen kayan aiki:

1.High hardness: da Mohs hardness na silicon carbide ne 9.2-9.5, na biyu kawai zuwa lu'u-lu'u, tare da karfi lalacewa juriya.

2. High thermal conductivity: thermal conductivity na silicon carbide ya kai 120-200 W / m · K, wanda zai iya watsar da zafi da sauri kuma ya dace da yanayin zafi mai zafi.

3. Low thermal fadada coefficient: silicon carbide thermal fadada coefficient ne low (4.0-4.5 × 10⁻⁶ / K), har yanzu iya kula da girma kwanciyar hankali a high zafin jiki.

4. Chemical kwanciyar hankali: silicon carbide acid da alkali lalata juriya, dace da amfani a cikin sinadaran lalata yanayi.

5. Babban ƙarfin injiniya: silicon carbide yana da ƙarfin lanƙwasawa da ƙarfin matsawa, kuma yana iya jure babban damuwa na inji.

Siffofin:

1.A cikin masana'antar semiconductor, ana buƙatar saka wafers na bakin ciki sosai a kan ƙoƙon tsotsawa, ana amfani da tsotsa don gyara wafers, kuma ana aiwatar da aikin kakin zuma, bakin ciki, kakin zuma, tsaftacewa da yankan akan wafers.

2.Silicon carbide sucker yana da kyau thermal watsin, iya yadda ya kamata rage da kakin zuma da kakin zuma lokaci, inganta samar da yadda ya dace.

3.Silicon carbide vacuum sucker shima yana da kyau acid da alkali lalata juriya.

4.Idan aka kwatanta da farantin jigilar corundum na gargajiya, rage lokacin ɗorawa da saukewar dumama da lokacin sanyaya, inganta aikin aiki; A lokaci guda, zai iya rage lalacewa tsakanin faranti na sama da na ƙasa, kula da daidaiton jirgin sama mai kyau, da kuma tsawaita rayuwar sabis da kusan 40%.

5.The abu rabo ne kananan, nauyi nauyi. Yana da sauƙi ga masu aiki su ɗauki pallets, rage haɗarin haɗarin haɗari da matsalolin sufuri ya haifar da kusan 20%.

6.Size: matsakaicin diamita 640mm; Flatness: 3um ko ƙasa da haka

Filin aikace-aikace:

1. Semiconductor masana'antu

● sarrafa wafer:

Don gyaran wafer a cikin photolithography, etching, ƙaddamar da fim na bakin ciki da sauran matakai, yana tabbatar da daidaitattun daidaito da tsari. Babban zafinsa da juriya na lalata sun dace da yanayin masana'anta na semiconductor.

● Girman Epitaxial:

A cikin SiC ko GaN girma epitaxial, a matsayin mai ɗaukar hoto don zafi da gyara wafers, tabbatar da daidaiton zafin jiki da ingancin crystal a yanayin zafi mai girma, inganta aikin na'urar.

2. Kayan aikin hoto

● LED Manufacturing:

Ana amfani da shi don gyara sapphire ko SiC substrate, kuma azaman mai ɗaukar zafi a cikin tsarin MOCVD, don tabbatar da daidaituwar haɓakar epitaxial, haɓaka ingantaccen haske da inganci na LED.

●Laser diode:

A matsayin babban madaidaicin daidaito, gyarawa da dumama substrate don tabbatar da kwanciyar hankali na zafin jiki, haɓaka ƙarfin fitarwa da amincin diode laser.

3. Machining daidai

●Tsarin kayan aikin gani:

Ana amfani da shi don daidaita daidaitattun abubuwan da aka gyara kamar ruwan tabarau na gani da tacewa don tabbatar da daidaitattun daidaito da ƙarancin ƙazanta yayin aiki, kuma ya dace da ƙirar ƙira mai ƙarfi.

●Tsarin yumbu:

A matsayin babban kwanciyar hankali, ya dace da daidaitattun kayan aikin yumbura don tabbatar da daidaiton mashin ɗin da daidaito a ƙarƙashin yanayin zafi da lalata.

4. Gwaje-gwajen kimiyya

● Gwajin zafin zafi:

A matsayin samfurin gyara na'urar a cikin yanayin zafi mai girma, yana goyan bayan gwaje-gwajen zafin jiki mai tsanani sama da 1600 ° C don tabbatar da daidaiton zafin jiki da kwanciyar hankali samfurin.

● Gwajin Vacuum:

A matsayin samfurin gyarawa da mai ɗaukar dumama a cikin yanayi mara kyau, don tabbatar da daidaito da maimaita gwajin gwajin, wanda ya dace da murfin injin da kuma kula da zafi.

Bayanan fasaha:

| (Kayan abu) | (Naúrar) | (sic) | |

| (Abincin SiC) |

| (Wt)% | >99 |

| (Matsakaicin girman hatsi) |

| micron | 4-10 |

| (Yawan yawa) |

| kg/dm3 | > 3.14 |

| (Bayyana porosity) |

| Vo1% | <0.5 |

| (Vickers hardness) | HV 0.5 | GPA | 28 |

| *(ƙarfin sassauƙa) | 20ºC | MPa | 450 |

| (Karfin matsawa) | 20ºC | MPa | 3900 |

| (Elastic Modulus) | 20ºC | GPA | 420 |

| (Taurin karaya) |

| MPa/m'% | 3.5 |

| (Thermal conductivity) | 20ºC | W/(m*K) | 160 |

| (Resistivity) | 20ºC | Ohm.cm | 106-108 |

|

| (RT**...80ºC) | K-1*10-6 | 4.3 |

|

|

| oºC | 1700 |

Tare da shekaru na tarawar fasaha da ƙwarewar masana'antu, XKH yana iya daidaita ma'auni masu mahimmanci kamar girman, hanyar dumama da ƙirar tallan talla na chuck bisa ga takamaiman bukatun abokin ciniki, tabbatar da cewa samfurin ya dace da tsarin abokin ciniki. SiC silicon carbide yumbu chucks sun zama abubuwan da ba dole ba a cikin sarrafa wafer, haɓaka epitaxial da sauran mahimman hanyoyin aiwatarwa saboda kyakkyawan yanayin yanayin zafi, kwanciyar hankali mai zafi da kwanciyar hankali na sinadarai. Musamman a cikin masana'antar kayan aikin semiconductor na ƙarni na uku kamar SiC da GaN, buƙatar siliki carbide yumbura chucks yana ci gaba da girma. A nan gaba, tare da saurin haɓakar 5G, motocin lantarki, hankali na wucin gadi da sauran fasahohin, aikace-aikacen yumburan yumbura na silicon carbide a cikin masana'antar semiconductor zai fi girma.

Cikakken zane