Semiconductor Laser Kashe Kayan Aikin

Cikakken zane

Bayanin Samfuri na Kayan Kashe Laser

Kayan Aikin Kashe Laser na Semiconductor yana wakiltar mafita na zamani na gaba don ci-gaban ingot thinning a sarrafa kayan semiconductor. Ba kamar hanyoyin wafering na gargajiya waɗanda ke dogaro da niƙa na inji, igiyar lu'u-lu'u, ko tsara tsarin injina ba, wannan dandali na tushen Laser yana ba da zaɓi mara lamba, madadin mara lalacewa don kawar da yadudduka masu bakin ciki daga manyan ingots na semiconductor.

An inganta don gallium nitride (GaN), silicon carbide (SiC), sapphire, da gallium arsenide (GaAs), Semiconductor Laser Lift-Off Equipment yana ba da damar yankan madaidaicin fina-finai na wafer-sikelin kai tsaye daga ingot crystal. Wannan fasaha na ci gaba yana rage sharar gida mai mahimmanci, yana inganta kayan aiki, da haɓaka amincin kayan aiki - duk waɗannan suna da mahimmanci ga na'urori masu zuwa a cikin wutar lantarki, tsarin RF, photonics, da ƙananan nuni.

Tare da girmamawa akan sarrafawa ta atomatik, ƙirar katako, da ƙididdigar hulɗar ma'amala ta Laser, Semiconductor Laser Lift-Off Equipment an ƙera shi don haɗawa cikin kwanciyar hankali a cikin ƙirar ƙirƙira na semiconductor yayin da yake tallafawa sassaucin R&D da haɓaka samar da taro.

Fasaha & Ƙa'idar Aiki na Kayan Kashe Laser

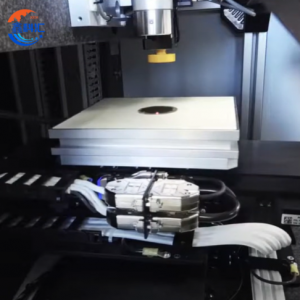

Tsarin da Semiconductor Laser Lift-Off Equipment ya yi yana farawa ta hanyar haskaka mai ba da gudummawar ingot daga gefe guda ta amfani da katako mai ƙarfi na ultraviolet laser. Wannan katako yana mai da hankali sosai a kan takamaiman zurfin ciki, yawanci tare da injin injiniya, inda aka ƙara yawan kuzarin kuzari saboda bambancin gani, zafi, ko sinadarai.

A wannan Layer na shan makamashi, dumama gida yana haifar da saurin fashewar ƙarami, faɗaɗa iskar gas, ko bazuwar layin fuska (misali, fim ɗin damuwa ko oxide hadaya). Wannan rushewar da aka sarrafa daidai yana haifar da saman lu'ulu'u na crystalline - tare da kauri na dubun micrometers - don warewa daga tushen ingot da tsabta.

Semiconductor Laser Lift-Off Equipment yana ba da damar shuwagabannin duba motsi-daidaitacce, sarrafa z-axis na shirye-shirye, da ma'aunin tunani na ainihi don tabbatar da kowane bugun jini yana ba da kuzari daidai a jirgin da aka yi niyya. Hakanan za'a iya saita kayan aikin tare da fashe-yanayin ko ƙarfin bugun jini da yawa don haɓaka santsi da rage yawan damuwa. Mahimmanci, saboda katakon Laser ba ya tuntuɓar kayan a zahiri, haɗarin microcracking, ruku'u, ko guntun saman yana raguwa sosai.

Wannan ya sa hanyar cirewar Laser ta zama mai canza wasa, musamman a aikace-aikace inda ake buƙatar wafer ultra-flat, ultra-thin wafers tare da ƙaramin micron TTV (Total kauri Bambancin).

Siga na Semiconductor Laser Lift-Off Equipment

| Tsawon tsayi | IR/SHG/THG/FHG |

|---|---|

| Nisa Pulse | Nanosecond, Picosecond, Femtosecond |

| Tsarin gani | Kafaffen tsarin gani ko tsarin gani na Galvano |

| Matsayin XY | 500 mm × 500 mm |

| Rage sarrafawa | 160 mm |

| Gudun motsi | Matsakaicin 1,000 mm/sec |

| Maimaituwa | ± 1 μm ko ƙasa da haka |

| Cikakken Matsayin Daidaitawa: | ± 5 μm ko ƙasa da haka |

| Girman Wafer | 2-6 inci ko musamman |

| Sarrafa | Windows 10,11 da PLC |

| Wutar Wutar Lantarki | AC 200 V ± 20 V, Single-lokaci, 50/60 kHz |

| Girman Waje | 2400 mm (W) × 1700 mm (D) × 2000 mm (H) |

| Nauyi | 1,000 kg |

Aikace-aikacen Masana'antu na Kayan Kashe Laser

Semiconductor Laser Lift-Off Equipment yana canzawa da sauri yadda ake shirya kayan a cikin yankuna na semiconductor da yawa:

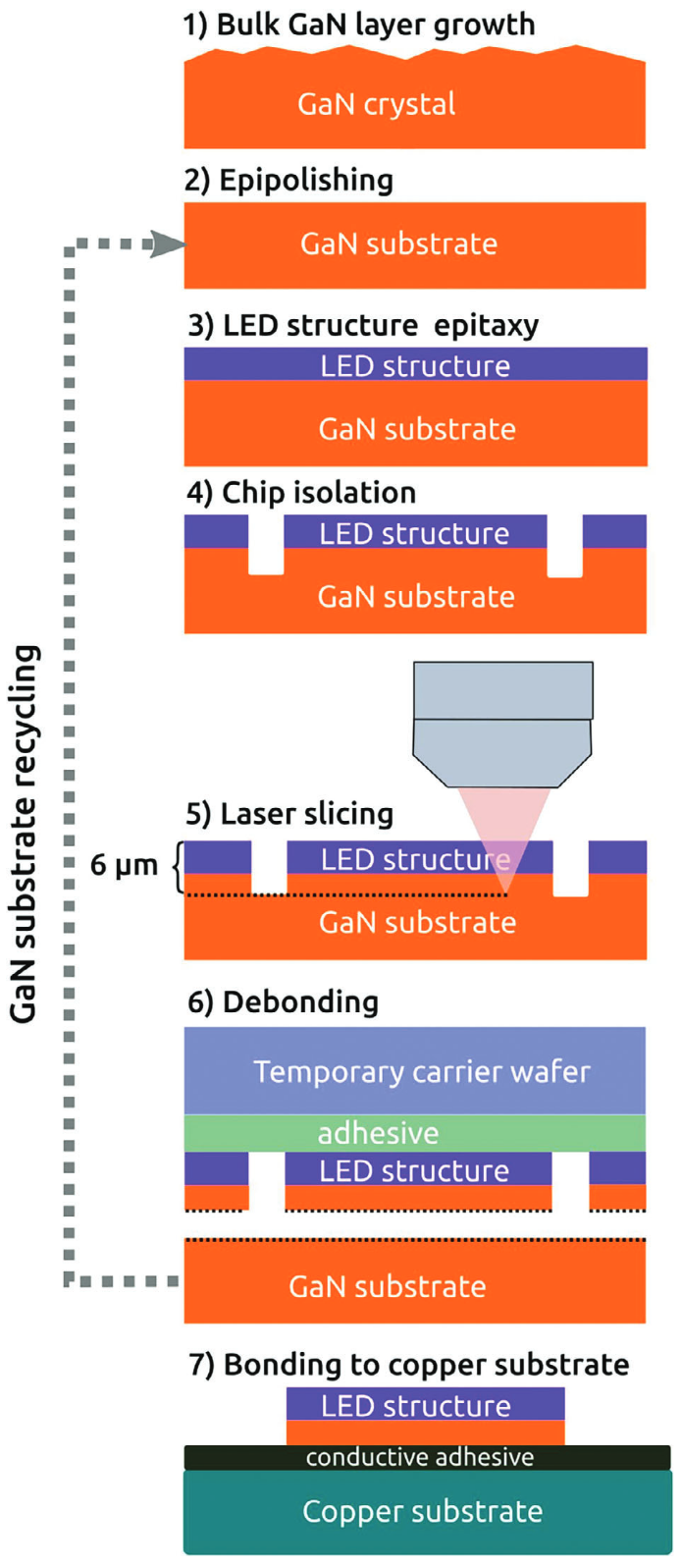

- Na'urorin Wutar GaN Na tsaye na Kayan Kashe Laser

Ɗaga fina-finai na GaN-on-GaN masu ɗanɗano kaɗan daga manyan ingots suna ba da damar gine-ginen gudanarwa na tsaye da sake amfani da kayan gini masu tsada.

- SiC Wafer Thinning don na'urorin Schottky da MOSFET

Yana rage kaurin Layer na na'ura yayin da yake kiyaye tsarin tsarin ƙasa - manufa don na'urorin lantarki mai saurin sauyawa.

- Tushen LED na Sapphire da Abubuwan Nuni na Kayan Kashe Laser

Yana ba da damar ingantacciyar rabuwa da yadudduka na na'ura daga ɓangarorin sapphire don tallafawa sirara, ingantaccen samar da ƙananan LED-LED.

- III-V Injiniyan Material na Kayan Kashe Laser

Yana sauƙaƙe warewar GaAs, InP, da AlGaN yadudduka don haɓaka haɗin kai na optoelectronic.

- Thin-Wafer IC da Sensor Fabrication

Yana samar da yadudduka na aiki na bakin ciki don na'urori masu auna matsa lamba, accelerometers, ko photodiodes, inda mafi girma shine cikas ɗin aiki.

- Lantarki mai sassauƙa da Gaskiya

Yana shirya filaye masu sirara da suka dace da sassauƙan nuni, da'irori masu sawa, da fitattun tagogi masu wayo.

A cikin kowane ɗayan waɗannan wuraren, Semiconductor Laser Lift-Off Equipment yana taka muhimmiyar rawa wajen ba da damar ƙara ƙaranci, sake amfani da kayan, da sauƙaƙe aiwatarwa.

Tambayoyin da ake yawan yi (FAQ) na Kayan Kashe Laser

Q1: Menene mafi ƙarancin kauri da zan iya cimma ta amfani da Semiconductor Laser Lift-Off Equipment?

A1:Yawanci tsakanin 10-30 microns dangane da kayan. Tsarin yana da ikon haifar da ƙananan sakamako tare da saitunan da aka gyara.

Q2: Za a iya amfani da wannan don yanki wafers da yawa daga ingot iri ɗaya?

A2:Ee. Abokan ciniki da yawa suna amfani da dabarar ɗagawa ta Laser don aiwatar da abubuwan cirewar siraren bakin ciki da yawa daga ingot ɗaya.

Q3: Wadanne fasalulluka na aminci ne aka haɗa don aikin laser mai ƙarfi?

A3:Rukunin aji na 1, tsarin kulle-kulle, garkuwar katako, da kashewa ta atomatik duk daidaitattun su ne.

Q4: Ta yaya wannan tsarin ya kwatanta da saws na wayar lu'u-lu'u dangane da farashi?

A4:Yayin da capex na farko na iya zama mafi girma, cirewar Laser yana rage yawan farashin da ake amfani da shi, lalacewar da ake amfani da shi, da matakan aiwatarwa - rage yawan farashin mallakar (TCO) na dogon lokaci.

Q5: Shin tsarin zai iya daidaitawa zuwa ingots 6-inch ko 8-inch?

A5:Lallai. Dandalin yana tallafawa har zuwa 12-inch substrates tare da rarraba katako iri ɗaya da matakan motsi mai girma.

Game da Mu

XKH ya ƙware a cikin haɓaka fasahar fasaha, samarwa, da tallace-tallace na gilashin gani na musamman da sabbin kayan kristal. Kayayyakinmu suna hidimar kayan lantarki na gani, na'urorin lantarki na mabukaci, da sojoji. Muna ba da abubuwan haɗin gani na Sapphire, murfin ruwan tabarau na wayar hannu, Ceramics, LT, Silicon Carbide SIC, Quartz, da wafers kristal semiconductor. Tare da ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun kayan aiki, mun yi fice a cikin sarrafa samfuran da ba daidai ba, da nufin zama babban kamfani na kayan fasaha na optoelectronic.