Gabatarwa ga silicon carbide

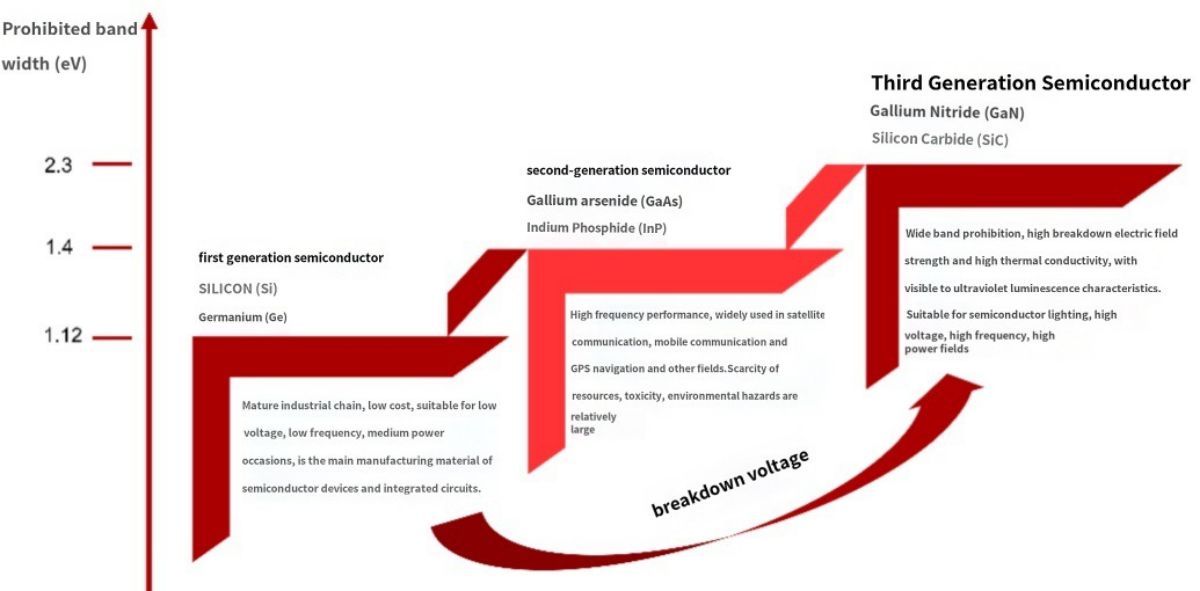

Silicon carbide (SiC) wani abu ne na semiconductor wanda ya ƙunshi carbon da silicon, wanda shine ɗayan ingantattun kayan don yin babban zafin jiki, mitar mita, babban iko da na'urori masu ƙarfin lantarki. Idan aka kwatanta da kayan siliki na gargajiya (Si), tazarar bandeji na silicon carbide ya ninka na silicon sau 3. Matsakaicin zafin jiki shine sau 4-5 na silicon; Rashin wutar lantarki shine sau 8-10 na silicon; Matsakaicin drift na lantarki shine sau 2-3 na silicon, wanda ke biyan bukatun masana'antar zamani don babban iko, babban ƙarfin lantarki da mitar mita. Ana amfani da shi ne musamman don samar da na'urorin lantarki masu sauri, mai ƙarfi, ƙarfi da haske. Filin aikace-aikacen da ke ƙasa sun haɗa da grid mai kaifin baki, sabbin motocin makamashi, ƙarfin iska na hotovoltaic, sadarwar 5G, da sauransu. Silicon carbide diodes da MOSFETs an yi amfani da su ta kasuwanci.

High zafin jiki juriya. The band rata nisa na silicon carbide ne 2-3 sau na silicon, da electrons ba sauki don canzawa a high yanayin zafi, kuma za su iya jure mafi girma aiki yanayin zafi, da thermal conductivity na silicon carbide ne 4-5 sau na silicon, sa na'urar zafi watsar da sauki da kuma iyaka aiki zafin jiki mafi girma. Babban juriya na zafin jiki na iya ƙara ƙarfin ƙarfin ƙarfi yayin da rage buƙatun akan tsarin sanyaya, yana sa tashar ta zama mai sauƙi da ƙarami.

Jurewa babban matsin lamba. Ƙarfin filin lantarki na silicon carbide ya ninka sau 10 na silicon, wanda zai iya jure wa mafi girman ƙarfin lantarki kuma ya fi dacewa da na'urori masu ƙarfin lantarki.

Babban juriya. Silicon carbide yana da madaidaicin drift na lantarki sau biyu na silicon, wanda ke haifar da rashin wutsiya na yanzu yayin aikin rufewa, wanda zai iya inganta saurin sauyawa na na'urar yadda ya kamata kuma ya gane ƙarancin na'urar.

Ƙananan asarar makamashi. Idan aka kwatanta da kayan silicon, silicon carbide yana da ƙarancin juriya da ƙarancin hasara. A lokaci guda, babban band-gizon nisa na silicon carbide yana rage yawan zubewar yanzu da asarar wutar lantarki. Bugu da kari, na'urar siliki carbide ba ta da abin da zai biyo baya a halin yanzu yayin aikin rufewa, kuma asarar canzawa ta yi ƙasa.

Silicon carbide sarkar masana'antu

Ya fi haɗa da substrate, epitaxy, ƙirar na'urar, masana'anta, rufewa da sauransu. Silicon carbide daga kayan zuwa na'urar wutar lantarki na semiconductor zai sami ci gaban kristal guda ɗaya, yankan ingot, haɓaka epitaxial, ƙirar wafer, masana'anta, marufi da sauran matakai. Bayan haɗin siliki carbide foda, an fara yin ingot silicon carbide, sa'an nan kuma ana samun silin carbide substrate ta hanyar slicing, niƙa da gogewa, kuma ana samun takardar epitaxial ta haɓakar epitaxial. Wafer epitaxial an yi shi da siliki carbide ta hanyar lithography, etching, ion implantation, passivation karfe da sauran matakai, an yanke wafer a cikin mutu, an tattara na'urar, an haɗa na'urar zuwa harsashi na musamman kuma an haɗa shi cikin tsari.

Sama na sarkar masana'antu 1: substrate - ci gaban kristal shine babban hanyar haɗin yanar gizo

Silicon carbide Substrate yana lissafin kusan kashi 47% na farashin na'urorin siliki carbide, mafi girman shingen fasaha na masana'antu, mafi girman ƙima, shine tushen ci gaban manyan masana'antu na SiC na gaba.

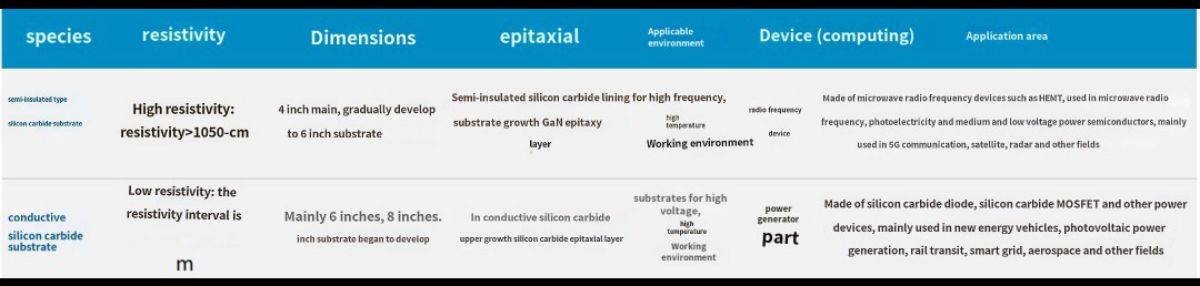

Daga hangen nesa na electrochemical bambance-bambancen dukiya, silicon carbide substrate kayan za a iya raba zuwa conductive substrates (resistivity yankin 15 ~ 30mΩ · cm) da Semi-insulated substrates (resistivity sama da 105Ω · cm). Ana amfani da waɗannan nau'ikan nau'ikan nau'ikan abubuwa guda biyu don kera na'urori masu hankali kamar na'urorin wuta da na'urorin mitar rediyo bi da bi bayan haɓakar epitaxial. Daga cikin su, siliki carbide substrate Semi-insulated an fi amfani dashi a cikin kera na'urorin gallium nitride RF, na'urorin lantarki da sauransu. Ta hanyar girma gan epitaxial Layer a kan rabin-insulated SIC substrate, sic epitaxial farantin an shirya, wanda za a iya kara shirya cikin HEMT gan iso-nitride RF na'urorin. Abubuwan da ake amfani da su na silicon carbide ana amfani da su musamman wajen kera na'urorin wuta. Daban-daban daga tsarin masana'antar wutar lantarki ta gargajiya ta gargajiya, na'urar wutar lantarki ta silicon carbide ba za a iya yin ta kai tsaye a kan siliki carbide substrate, siliki carbide epitaxial Layer yana buƙatar girma akan madaidaicin madauri don samun takardar siliki na siliki, kuma an ƙera Layer epitaxial akan Schottky diode, MOSFET, IGBT da sauran na'urori masu ƙarfi.

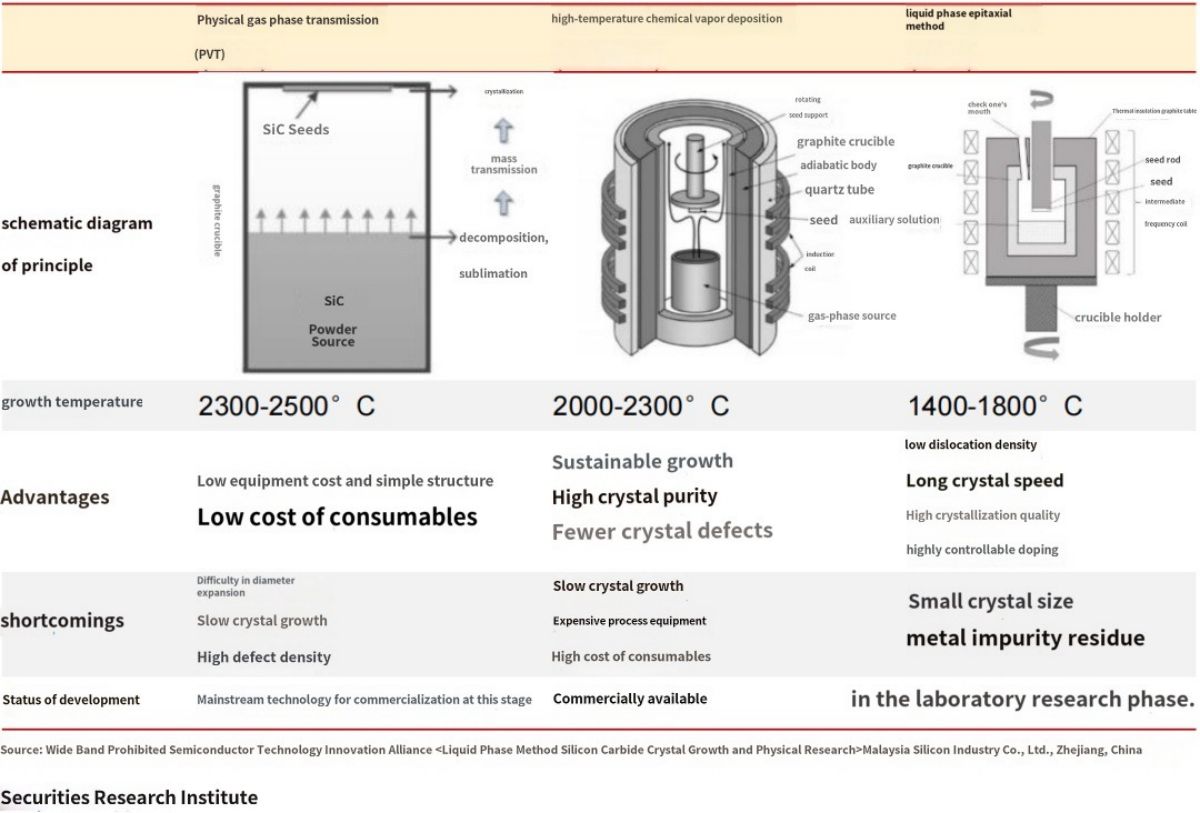

Silicon carbide foda aka hada daga high tsarki carbon foda da high tsarki silicon foda, da kuma daban-daban masu girma dabam na silicon carbide ingot aka girma a karkashin musamman zazzabi filin, sa'an nan silicon carbide substrate aka samar ta da yawa aiki matakai. Babban tsari ya haɗa da:

Raw material kira: The high-tsarki silicon foda + toner ne gauraye bisa ga dabara, da kuma dauki da za'ayi a cikin dauki dakin karkashin high zafin jiki yanayin sama 2000 ° C don hada da silicon carbide barbashi tare da takamaiman crystal irin da barbashi size. Sa'an nan kuma ta hanyar murkushewa, nunawa, tsaftacewa da sauran matakai, don saduwa da buƙatun kayan albarkatun foda mai tsabta na silicon carbide.

Girman kristal shine ainihin tsari na masana'anta na silicon carbide, wanda ke ƙayyade kaddarorin lantarki na silin carbide substrate. A halin yanzu, manyan hanyoyin haɓakar kristal sune canja wurin tururi ta jiki (PVT), ƙimar tururin sinadarai mai zafin jiki (HT-CVD) da epitaxy na ruwa (LPE). Daga cikin su, hanyar PVT ita ce hanyar da ta fi dacewa don haɓaka kasuwanci na SiC substrate a halin yanzu, tare da mafi girma na fasaha da kuma mafi yawan amfani da aikin injiniya.

Shirye-shiryen SiC substrate yana da wahala, yana haifar da farashinsa mai girma

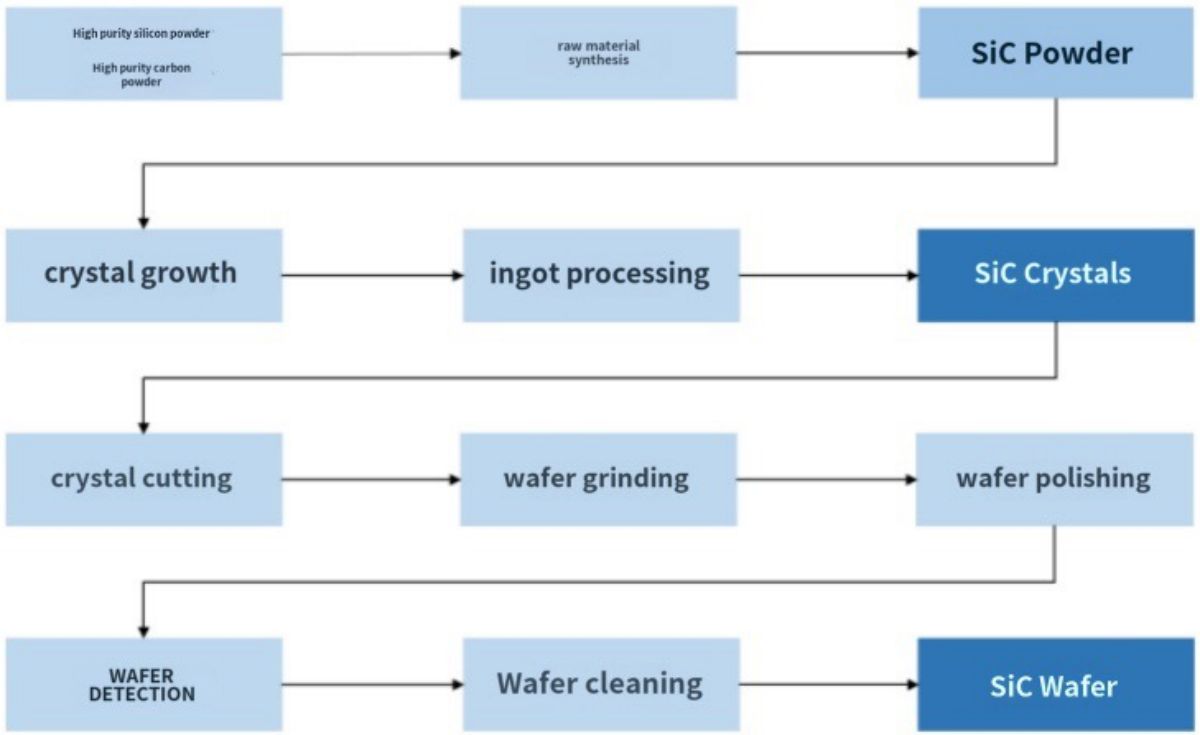

Zazzabi filin kula da wuya: Si crystal sanda girma kawai bukatar 1500 ℃, yayin da SiC crystal sanda bukatar da za a girma a wani babban zafin jiki sama da 2000 ℃, kuma akwai fiye da 250 SiC isomers, amma babban 4H-SiC guda crystal tsarin domin samar da ikon na'urorin, idan ba daidai iko, zai samu wasu crystal Tsarin. Bugu da kari, da zafin jiki gradient a cikin crucible kayyade kudi na SiC sublimation canja wurin da tsari da kuma girma yanayin gaseous atom a kan crystal dubawa, wanda rinjayar da crystal girma kudi da kuma crystal quality, don haka shi wajibi ne don samar da wani tsarin zafin jiki filin kula da fasaha. Idan aka kwatanta da kayan Si, bambanci a cikin samar da SiC kuma yana cikin matakan zafin jiki mai girma kamar haɓakar ion zafin jiki mai zafi, yawan zafin jiki mai zafi, kunna zafin jiki mai zafi, da tsarin mashin wuyar da ake buƙata ta waɗannan matakan zafin jiki.

Slow crystal girma: girma kudi na Si crystal sanda iya isa 30 ~ 150mm / h, da kuma samar da 1-3m silicon crystal sanda kawai daukan game da 1 rana; SiC crystal sanda tare da hanyar PVT a matsayin misali, girman girma shine game da 0.2-0.4mm / h, 7 kwanaki don girma ƙasa da 3-6cm, girman girma ya kasance ƙasa da 1% na kayan silicon, ƙarfin samarwa yana da iyakacin iyaka.

High samfurin sigogi da low yawan amfanin ƙasa: core sigogi na SiC substrate sun hada da microtubule yawa, dislocation yawa, resistivity, warpage, surface roughness, da dai sauransu Yana da wani hadadden tsarin injiniya shirya atom a cikin rufaffiyar high-zazzabi dakin da cikakken crystal girma, yayin da sarrafa siga fihirisa.

Kayan yana da tsayin daka, tsayin daka, dogon lokacin yankewa da lalacewa mai tsayi: SiC Mohs hardness na 9.25 shine na biyu kawai zuwa lu'u-lu'u, wanda ke haifar da haɓaka mai mahimmanci a cikin wahalar yankewa, niƙa da gogewa, kuma yana ɗaukar kimanin sa'o'i 120 don yanke 35-40 guda na ingot mai kauri 3cm. Bugu da kari, saboda babban brittleness na SiC, wafer sarrafa lalacewa zai zama mafi, da fitarwa rabo ne kawai game da 60%.

Yanayin haɓakawa: Girman haɓaka + raguwar farashin

Kasuwar SiC ta duniya layin samar da ƙarar inci 6 yana girma, kuma manyan kamfanoni sun shiga kasuwar inch 8. Ayyukan ci gaban cikin gida sun fi inci 6 ne. A halin yanzu, kodayake yawancin kamfanonin cikin gida har yanzu suna dogara ne akan layukan samar da inci 4, amma a hankali masana'antar tana haɓaka zuwa 6-inch, tare da balaga na 6-inch na tallafawa fasahar kayan aiki, fasahar substrate na gida ta SiC kuma sannu a hankali tana haɓaka tattalin arziƙin sikelin manyan layukan samar da kayayyaki, kuma gibin lokacin samar da yawan inch na cikin gida na yanzu ya ragu zuwa shekaru 7. Girman wafer mafi girma zai iya haifar da karuwa a cikin adadin kwakwalwan kwamfuta guda ɗaya, inganta yawan amfanin ƙasa, da kuma rage yawan nau'in kwakwalwan kwamfuta, kuma za a kiyaye farashin bincike da haɓakawa da asarar amfanin gona a kusan 7%, don haka inganta amfani da wafer.

Har yanzu akwai matsaloli da yawa a ƙirar na'urar

Kasuwancin SiC diode yana haɓaka sannu a hankali, a halin yanzu, yawancin masana'antun cikin gida sun tsara samfuran SiC SBD, samfuran SiC SBD matsakaici da matsakaicin ƙarfin lantarki suna da kwanciyar hankali mai kyau, a cikin motar OBC, yin amfani da SiC SBD + SI IGBT don cimma daidaito na yanzu. A halin yanzu, babu wani shinge a cikin ƙirar ƙira ta haƙƙin mallaka na samfuran SiC SBD a kasar Sin, kuma gibin da ke tsakanin kasashen waje ya yi kadan.

SiC MOS har yanzu yana da matsaloli da yawa, har yanzu akwai rata tsakanin SiC MOS da masana'antun ketare, kuma ana kan gina dandamalin masana'anta masu dacewa. A halin yanzu, ST, Infineon, Rohm da sauran 600-1700V SiC MOS sun sami yawan samarwa da sanya hannu da jigilar kayayyaki tare da masana'antun masana'antu da yawa, yayin da ƙirar SiC MOS ta gida ta yanzu ta cika, yawancin masana'antun ƙira suna aiki tare da fabs a matakin kwararar wafer, kuma daga baya tabbatar da abokin ciniki har yanzu yana buƙatar ɗan lokaci, don haka har yanzu akwai dogon lokaci kasuwanci.

A halin yanzu, tsarin tsari shine zaɓi na al'ada, kuma ana amfani da nau'in mahara sosai a cikin filin matsa lamba a nan gaba. Tsarin Planar SiC MOS masana'antun suna da yawa, tsarin tsarin ba shi da sauƙi don samar da matsalolin rushewar gida idan aka kwatanta da tsagi, yana shafar kwanciyar hankali na aikin, a cikin kasuwa da ke ƙasa 1200V yana da ƙimar ƙimar aikace-aikacen da yawa, kuma tsarin tsarin tsarin yana da sauƙi a cikin ƙarshen masana'anta, don saduwa da masana'anta da sarrafa farashin abubuwa biyu. The tsagi na'urar yana da abũbuwan amfãni na musamman low parasitic inductance, sauri sauyawa gudun, low asara da in mun gwada da high yi.

2--Labarin wafer SiC

Kasuwar Silicon carbide da haɓaka tallace-tallace, kula da rashin daidaituwar tsarin tsakanin wadata da buƙata

Tare da saurin haɓakar buƙatun kasuwa don mitoci mai ƙarfi da lantarki mai ƙarfi, ƙarancin ƙarancin jiki na na'urorin semiconductor na tushen silicon a hankali ya zama sananne, kuma kayan aikin semiconductor na ƙarni na uku waɗanda silicon carbide (SiC) ke wakilta a hankali sun zama masana'antu. Daga ra'ayi na kayan aiki, silicon carbide yana da sau 3 band rata nisa na silicon abu, 10 sau da m rushewar lantarki filin ƙarfi, 3 sau da thermal watsin, don haka silicon carbide ikon na'urorin dace da high mita, high matsa lamba, high zafin jiki da sauran aikace-aikace, taimaka wajen inganta yadda ya dace da kuma ikon yawa na ikon lantarki tsarin.

A halin yanzu, SiC diodes da SiC MOSFETs sun koma kasuwa sannu a hankali, kuma akwai samfuran balagagge, daga cikinsu ana amfani da diodes na SiC da yawa maimakon diodes masu amfani da silicon a wasu wuraren saboda ba su da fa'ida ta dawo da cajin; Hakanan ana amfani da SiC MOSFET a hankali a cikin motoci, ajiyar makamashi, tari mai caji, hotovoltaic da sauran filayen; A fagen aikace-aikacen kera motoci, yanayin modularization yana ƙara zama sananne, mafi girman aikin SiC yana buƙatar dogaro da ci gaba da aiwatar da marufi don cimmawa, a zahiri tare da ƙaramin balagagge harsashi a matsayin babban al'ada, gaba ko zuwa ci gaban rufewar filastik, halayen haɓaka na musamman sun fi dacewa da samfuran SiC.

Farashin Silicon carbide raguwar saurin gudu ko fiye da tunani

Aikace-aikace na silicon carbide na'urorin aka yafi iyakance da high kudin, farashin SiC MOSFET a karkashin wannan matakin ne 4 sau mafi girma fiye da na Si tushen IGBT, wannan shi ne saboda aiwatar da silicon carbide ne hadaddun, a cikin abin da girma na guda crystal da epitaxial ne ba kawai matsananci a kan yanayi, amma kuma girma kudi ne jinkirin, da kuma guda crystal aiki a cikin substrate dole ne ta hanyar yankan da kuma polishing tsari. Dangane da halayen kayan sa da kuma fasahar sarrafa balagagge, yawan amfanin ƙasa na cikin gida bai wuce 50% ba, kuma abubuwan daban-daban suna haifar da babban substrate da farashin epitaxial.

Duk da haka, farashin abun da ke ciki na silicon carbide na'urorin da silicon-tushen na'urorin ne diametrically m, da substrate da epitaxial halin kaka na gaban tashar lissafi 47% da 23% na dukan na'urar bi da bi, totaling game da 70%, da na'urar zane, masana'antu da sealing links na baya tashar asusu don kawai 30%, da samar da kudin na silicon-tushen na'urorin ne yafi mayar da hankali a kan masana'antu na'urorin a cikin 5% substrate da substrate 5. kudin ya kai kashi 7% kawai. Lamarin da darajar sarkar masana'antar siliki ta juye juye yana nufin cewa masana'antun epitaxy na sama suna da ainihin haƙƙin yin magana, wanda shine mabuɗin tsarin kasuwancin gida da na waje.

Daga mahimmin ra'ayi akan kasuwa, rage farashin silicon carbide, baya ga inganta silicon carbide dogon crystal da slicing tsari, shine fadada girman wafer, wanda kuma shine babban hanyar ci gaban semiconductor a baya, bayanan Wolfspeed sun nuna cewa haɓakar siliki carbide substrate daga inci 6 zuwa 8 inci, ingantaccen guntu samarwa na iya haɓaka da 80% -90. Za a iya rage haɗin haɗin haɗin kai da kashi 50%.

2023 da aka sani da "8-inch SiC farkon shekara", a wannan shekara, gida da kuma waje silicon carbide masana'antun suna hanzarta shimfidar 8-inch silicon carbide, kamar Wolfspeed hauka zuba jari na 14.55 dalar Amurka biliyan don silicon carbide samar da fadada, wani muhimmin ɓangare na wanda shi ne gina 8-inch SiC substrate masana'antu masana'antu, Don tabbatar da nan gaba samar da wani karfe masana'antu masana'antu masana'antu na SiC 200 mm. Tianyue Advanced na cikin gida da Tianke Heda suma sun rattaba hannu kan yarjejeniyoyin dogon lokaci tare da Infineon don samar da siliki carbide substrates mai inci 8 a nan gaba.

An fara daga wannan shekara, silicon carbide zai hanzarta daga 6 inci zuwa 8 inci, Wolfspeed yana tsammanin cewa ta 2024, da naúrar guntu kudin na 8 inci substrate idan aka kwatanta da naúrar guntu kudin na 6 inci substrate a 2022 za a rage fiye da 60%, da kuma rage farashin zai kara bude aikace-aikace kasuwa, Ji Bond Consulting bayanai bincike nuna. Kasuwar kasuwa na yanzu na samfuran inci 8 bai kai kashi 2% ba, kuma ana sa ran kasuwar kasuwar za ta yi girma zuwa kusan 15% nan da 2026.

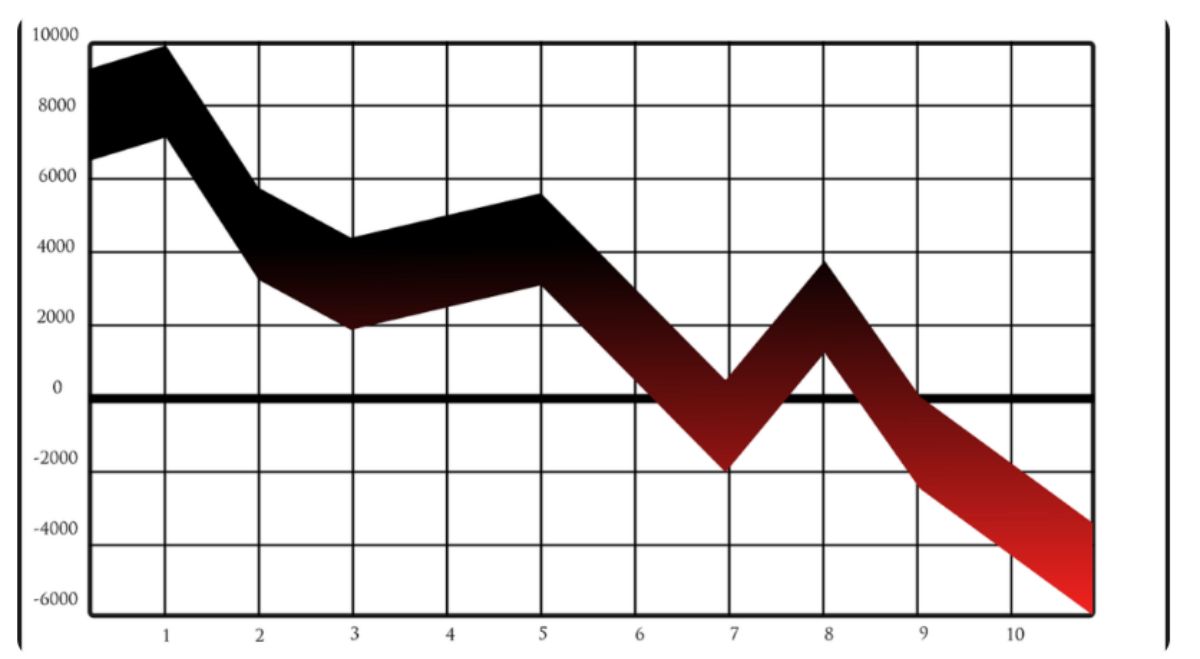

A gaskiya ma, yawan raguwa a cikin farashin silicon carbide substrate na iya wuce tunanin mutane da yawa, tayin kasuwa na yanzu na 6-inch substrate shine 4000-5000 yuan / yanki, idan aka kwatanta da farkon shekara ya fadi da yawa, ana sa ran faduwa kasa da yuan 4000 a shekara mai zuwa, yana da daraja a lura cewa wasu masana'antun don samun farashin farko na kasuwa a ƙasa, farashin farashi ya ragu a ƙasa, farashin kasuwa ya rage farashin kasuwa, farashin farashin kasuwa ya ragu. Yaƙi, wanda aka fi mayar da hankali a cikin samar da kayan aikin silicon carbide ya kasance mai isa sosai a cikin ƙananan ƙarancin wutar lantarki, masana'antun gida da na waje suna haɓaka ƙarfin samarwa, ko barin siliki carbide substrate oversupply mataki a baya fiye da tunanin.

Lokacin aikawa: Janairu-19-2024