LNOI Wafer (Lithium Niobate akan Insulator) Sadarwar Sadarwar Yana Haɓaka High Electro-Optic

Cikakken zane

Dubawa

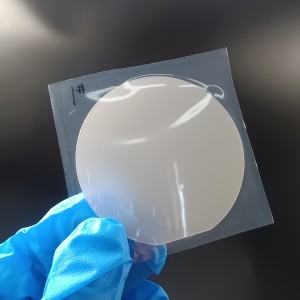

A cikin akwatin wafer akwai tsagi mai ma'ana, wanda girmansa ya kasance daidai da daidaituwa don tallafawa bangarorin biyu na wafer. Akwatin kristal gabaɗaya an yi shi da kayan PP na filastik translucent wanda ke da juriya ga zafin jiki, lalacewa da wutar lantarki. Ana amfani da launuka daban-daban na additives don rarrabe sassan tsarin ƙarfe a cikin samar da semiconductor. Saboda da kananan key size na semiconductor, m alamu, kuma sosai m barbashi size bukatun a samar, da wafer akwatin dole ne a ba da garantin yanayi mai tsabta don haɗawa da microenvironment akwatin dauki rami na daban-daban samar inji.

Hanyar Kera

Ƙirƙirar wafers na LNOI ya ƙunshi ingantattun matakai da yawa:

Mataki 1: Shigar Helium ionAna shigar da ions helium a cikin babban lu'ulu'u na LN ta amfani da ion implanter. Wadannan ions suna kwana a wani zurfin zurfi, suna samar da jirgin sama mai rauni wanda zai sauƙaƙe ƙaddamar da fim.

Mataki na 2: Samuwar Tushen TushenSilicone daban ko wafer na LN yana oxidized ko yadudduka tare da SiO2 ta amfani da PECVD ko iskar oxygen ta thermal. An tsara saman samanta don ingantaccen haɗin gwiwa.

Mataki 3: Haɗin LN zuwa SubstrateLN crystal da aka dasa ion ana jujjuya shi kuma an haɗe shi zuwa wafern tushe ta amfani da haɗin kai tsaye. A cikin saitunan bincike, ana iya amfani da benzocyclobutene (BCB) azaman mannewa don sauƙaƙe haɗin gwiwa a ƙarƙashin ƙarancin yanayi mai ƙarfi.

Mataki na 4: Maganin zafi da Rarrabuwar FimAnnealing yana kunna samuwar kumfa a zurfin da aka dasa, yana ba da damar rabuwa da sikirin fim (Layin LN na sama) daga mafi girma. Ana amfani da ƙarfin injina don kammala fitarwar.

Mataki na 5: Goge samanAna amfani da Polishing Mechanical Mechanical (CMP) don santsi saman saman LN, inganta ingancin gani da yawan amfanin na'urar.

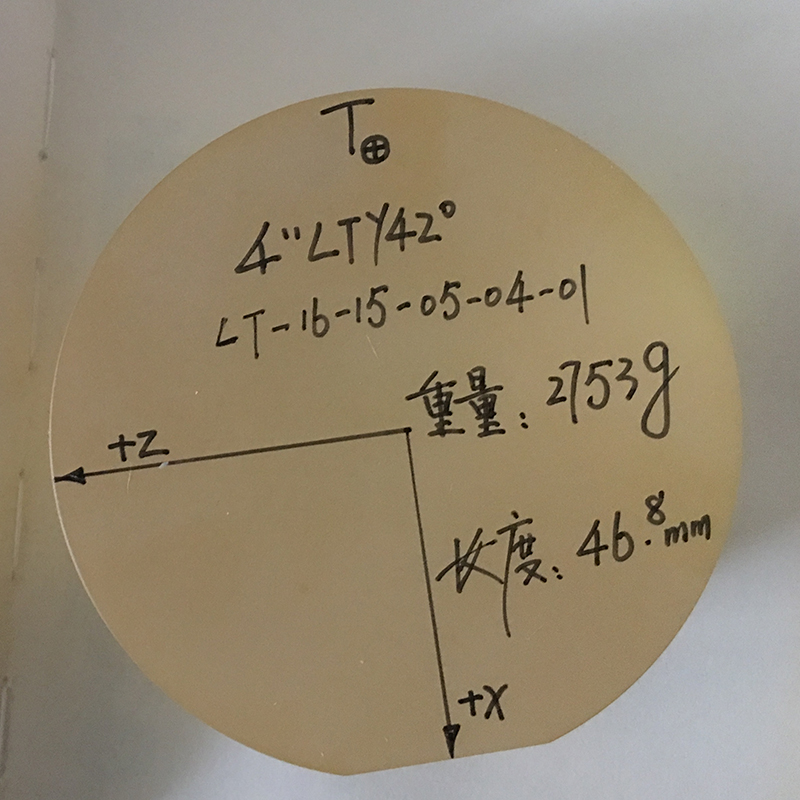

Ma'aunin Fasaha

| Kayan abu | Na gani Daraja LiNbO3 fari (White or Baki) | |

| Kuri Temp | 1142 ± 0.7 ℃ | |

| Yanke Angle | X/Y/Z da dai sauransu | |

| Diamita/girma | 2"/3"/4" ± 0.03mm | |

| Tol(±) | <0.20mm ±0.005mm | |

| Kauri | 0.18 ~ 0.5mm ko fiye | |

| Firamare Flat | 16mm/22mm/32mm | |

| TTV | <3 μm | |

| Ruku'u | -30 | |

| Warp | <40 μm | |

| Gabatarwa Flat | Duk akwai | |

| Surface Nau'in | Goge Gefe Guda Daya(SSP)/Goge Gefe Biyu(DSP) | |

| goge gefe Ra | <0.5nm | |

| S/D | 20/10 | |

| Gefen Ma'auni | R=0.2mm Nau'in C or Bullnose | |

| inganci | Kyauta of crack (kumfa kuma hadawa) | |

| Na gani doped | Mg/Fe/Zn/MgO da dai sauransu domin na gani daraja LN wafers per nema | |

| Wafer Surface Ma'auni | Indexididdigar refractive | No=2.2878/Ne=2.2033 @632nm hanya mai tsayi/prism coupler. |

| gurbacewa, | Babu | |

| Barbashi c>0.3μ m | <= 30 | |

| Scratch, Chipping | Babu | |

| Lalabi | Babu tsage gefen, scratches, alamun gani, tabo | |

| Marufi | Akwatin Qty/Wafer | 25pcs kowane akwati |

Amfani da Cases

Saboda iyawar sa da aikin sa, ana amfani da LNOI a cikin masana'antu da yawa:

Photonics:Karamin modulators, multixers, da da'irori na photonic.

RF/Acoustics:Acousto-optic modulators, RF tacewa.

Ƙididdigar Ƙididdigar Ƙididdiga:Mitar mitar da ba ta kan layi ba da na'urorin samar da photon-biyu.

Tsaro & Jirgin Sama:Gyros na gani mara ƙarancin hasara, na'urori masu canza mita.

Na'urorin Lafiya:Na'ura mai gani da ido da bincike na sigina mai tsayi.

FAQ

Tambaya: Me yasa aka fi son LNOI akan SOI a cikin tsarin gani?

A:LNOI yana fasalta ingantattun hanyoyin haɗin lantarki-na gani da faffadan fa'ida, yana ba da damar aiki mafi girma a cikin da'irori na photonic.

Tambaya: Shin CMP wajibi ne bayan rabuwa?

A:Ee. Filayen LN da aka fallasa yana da ƙaƙƙarfan bayan ion-slicing kuma dole ne a goge shi don saduwa da ƙayyadaddun matakan gani.

Tambaya: Menene matsakaicin girman wafer da ake samu?

A:Wafers na kasuwanci na LNOI sune 3” da 4”, kodayake wasu masu samar da kayayyaki suna haɓaka bambance-bambancen 6”.

Tambaya: Za a iya sake amfani da Layer na LN bayan tsagawa?

A:Za a iya sake goge kristal tushe kuma a sake amfani da shi sau da yawa, kodayake ingancin na iya raguwa bayan zagayawa da yawa.

Tambaya: Shin wafers na LNOI sun dace da sarrafa CMOS?

A:Ee, an ƙirƙira su don daidaitawa tare da hanyoyin ƙirƙira semiconductor na al'ada, musamman lokacin da ake amfani da abubuwan siliki.