Injin goge goge na Ion Beam don sapphire SiC Si

Cikakken zane

Bayanin Samfurin na Ion Beam Polishing Machine

Ion Beam Figuring and Polishing Machine ya dogara ne akan ƙa'idar sputtering ion. A cikin babban ɗaki mai ɗaki, tushen ion yana haifar da plasma, wanda aka haɓaka zuwa babban katako na ion mai ƙarfi. Wannan katako yana jefa bam a saman ɓangaren abin gani, yana cire abu a ma'aunin atomic don cimma daidaitaccen gyaran fuska da ƙarewa.

A matsayin tsarin da ba a tuntuɓar ba, ion beam polishing yana kawar da damuwa na inji kuma yana guje wa lalacewar ƙasa, yana mai da shi manufa don kera ingantattun na'urorin gani da aka yi amfani da su a sararin samaniya, sararin samaniya, semiconductor, da aikace-aikacen bincike na ci gaba.

Ƙa'idar Aiki na Injin ion Beam Polishing Machine

Ion Generation

Ana shigar da iskar gas mara ƙarfi (misali, argon) a cikin ɗakin da ba a so kuma a sanya ion ta hanyar fitarwar lantarki don samar da plasma.

Hanzarta & Samar da Haske

Ana haɓaka ions zuwa ɗaruruwa ko dubunnan volts na lantarki (eV) kuma an siffata su su zama barga, tabo mai haske.

Cire kayan

Ƙunƙarar ion a zahiri tana watsa kwayoyin halitta daga sama ba tare da fara halayen sinadarai ba.

Gano Kuskuren & Tsare Hanya

Ana auna juzu'in siffa ta sama tare da interferometry. Ana amfani da ayyukan cirewa don ƙayyade lokutan zama da samar da ingantattun hanyoyin kayan aiki.

Gyaran Rufe-Madauki

Zagaye na maimaitawa na sarrafawa da auna yana ci gaba har sai an cimma maƙasudan maƙasudin RMS/PV.

Mahimman Fassarorin Na'urar gogewa ta ion Beam

Daidaituwar Surface Universal- Yana aiwatar da filaye mai sassauƙa, mai siffa, aspherical, da sifofi masu kyauta

Matsakaicin Cire Ƙarfafa-Stable- Yana ba da damar gyaran adadi na ƙananan nanometer

Lalacewa-Kyautar sarrafawa- Babu lahani na ƙasa ko canje-canjen tsari

Daidaitaccen Ayyuka- Yana aiki daidai da kyau akan kayan taurin daban-daban

Gyaran Matsakaicin Karancin/Matsakaici- Yana kawar da kurakurai ba tare da samar da kayan tarihi na tsakiya/maɗaukaki ba

Ƙananan Bukatun Kulawa- Dogon aiki mai ci gaba tare da ƙarancin ƙarancin lokaci

Babban Bayanin Fasaha na Injin goge goge na Ion Beam

| Abu | Ƙayyadaddun bayanai |

| Hanyar sarrafawa | Ion sputtering a cikin high-vacuum yanayi |

| Nau'in sarrafawa | Figuring da gogewa mara lamba |

| Max girman girman Aiki | Φ4000 mm |

| Motion Axes | 3-axis / 5-axis |

| Cire Kwanciyar Hankali | ≥95% |

| Daidaiton Surface | PV <10 nm; RMS ≤ 0.5 nm (mafi yawan RMS <1 nm; PV <15 nm) |

| Ƙarfin Gyara Mita | Yana kawar da kurakuran ƙananan-matsakaici ba tare da gabatar da kurakurai na matsakaici/maɗaukaki ba |

| Ci gaba da Aiki | Makonni 3-5 ba tare da kula da injin ba |

| Kudin Kulawa | Ƙananan |

Ƙarfin sarrafa Na'ura na Ion Beam Polishing Machine

Nau'o'in saman da ke goyan baya

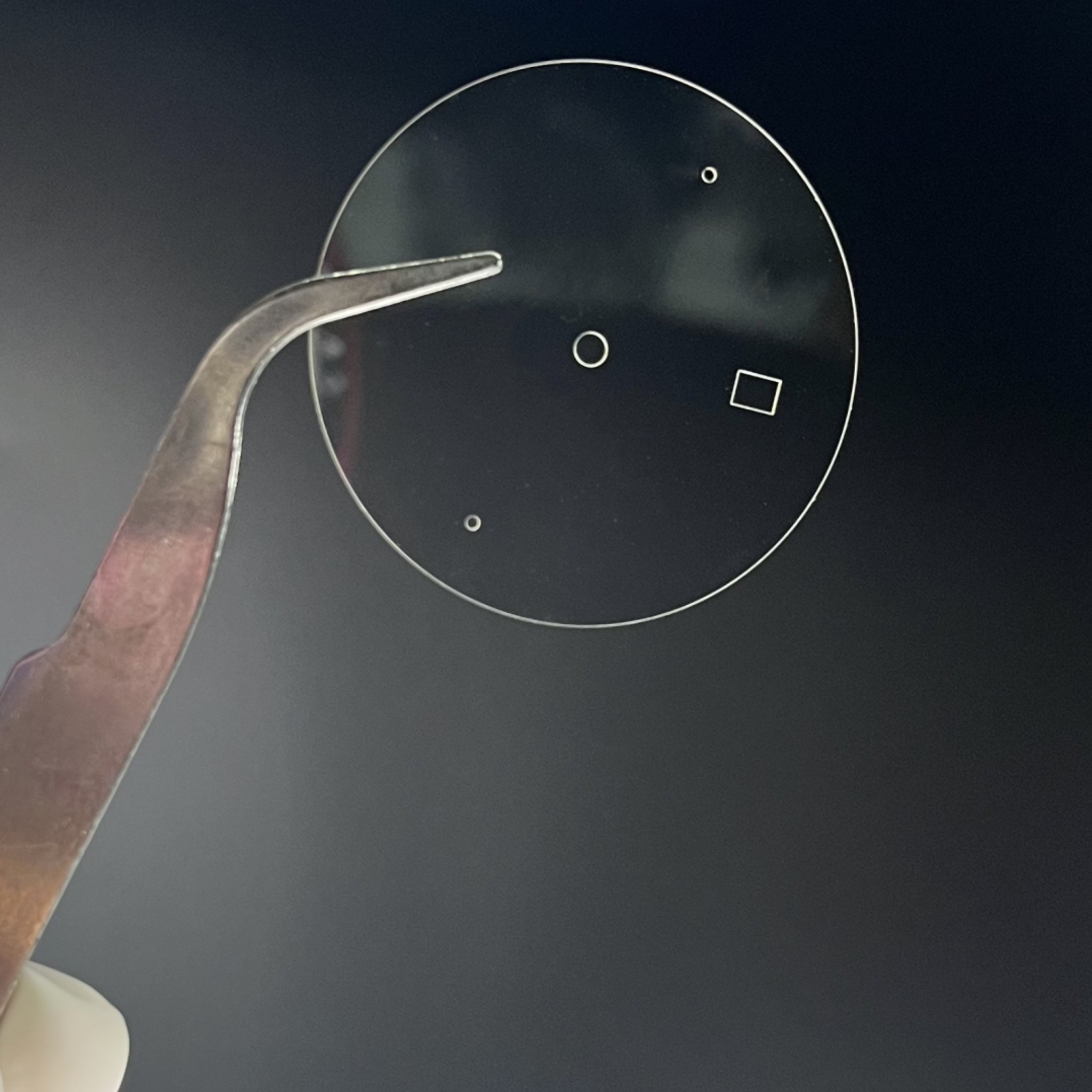

Mai sauƙi: Flat, mai siffar zobe, priism

Complex: Symmetric/ asymmetric asphere, off-axis asphere, cylindrical

Na musamman: Ultra-bakin gani na gani, slat optics, hemispherical optics, conformal optics, phase plates, freeform surfaces

Kayayyakin tallafi

Gilashin gani: Quartz, microcrystalline, K9, da dai sauransu.

Infrared kayan: Silicon, germanium, da dai sauransu.

Karfe: aluminum, bakin karfe, titanium gami, da dai sauransu.

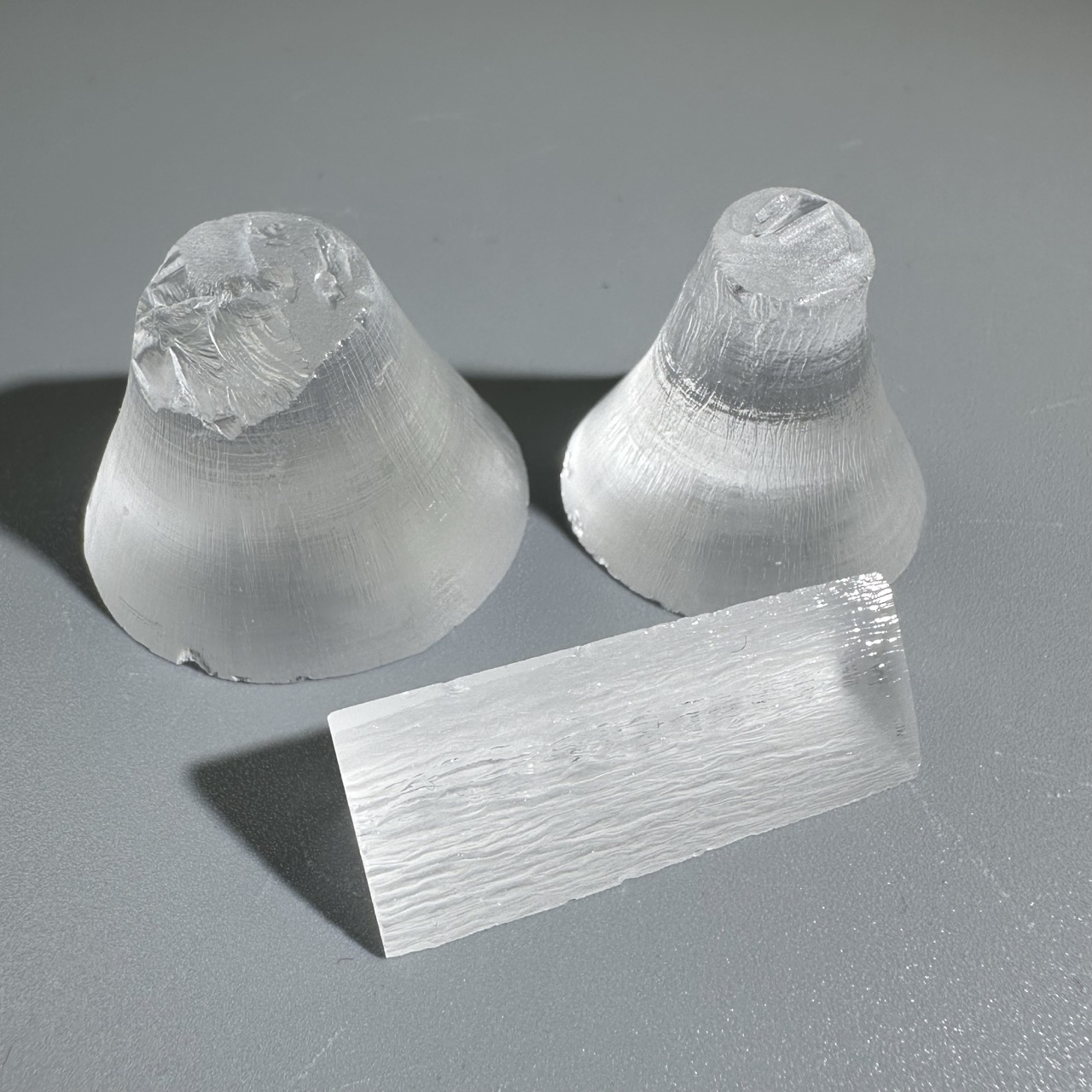

Lu'ulu'u: YAG, silicon carbide guda-crystal, da dai sauransu.

Hard/karguje kayan: Silicon carbide, da dai sauransu.

Ingancin Fassara / Daidaitawa

PV <10 nm

RMS ≤ 0.5 nm

Gudanar da Nazarin Harka na Ion Beam Polishing Machine

Case 1 – Madubin Fitacce Madaidaici

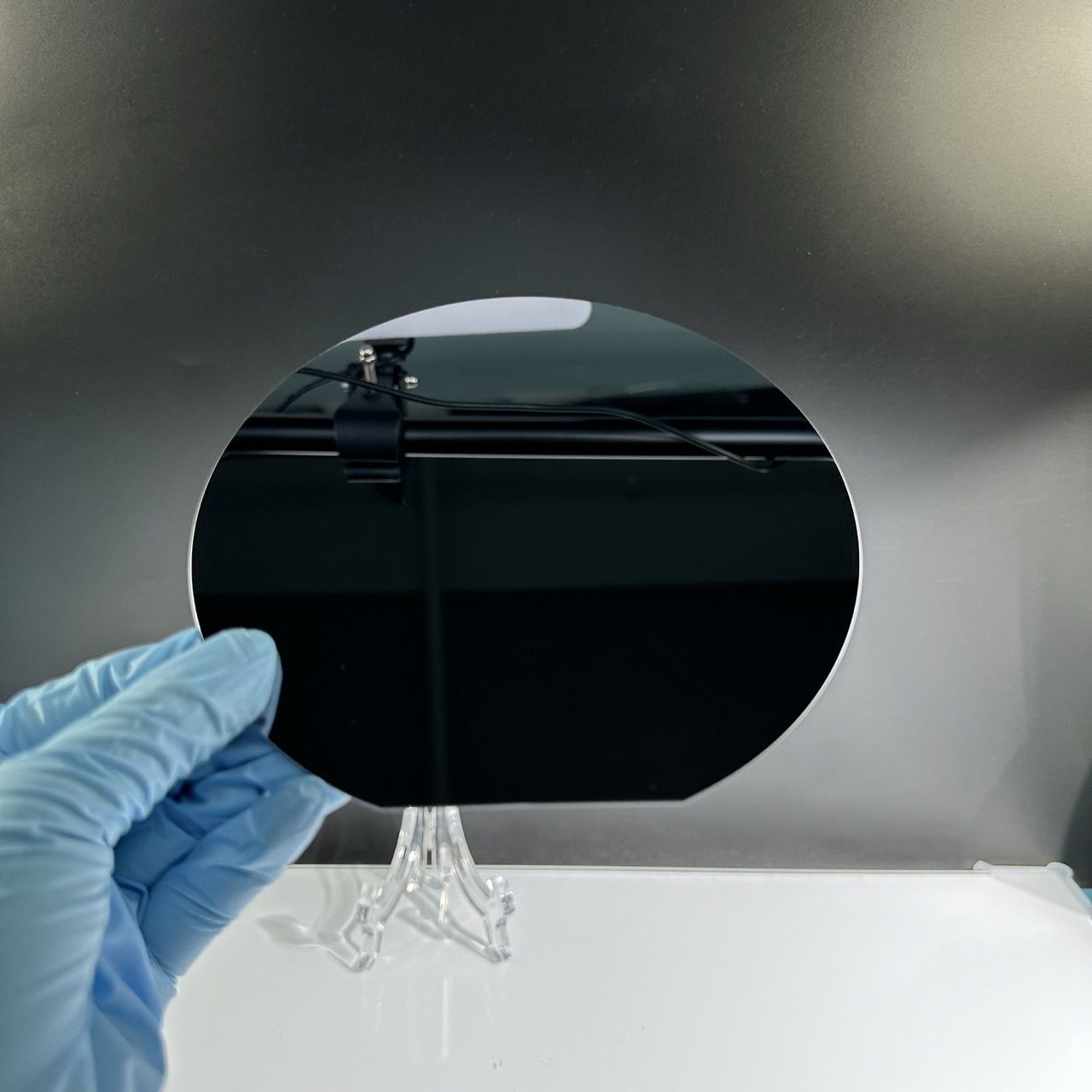

Kayan aiki: D630mm quartz lebur

Sakamakon: PV 46.4 nm; RMS 4.63 nm

Case na 2 - Madubin Nuna X-ray

Kayan aiki: 150 × 30 mm silicon lebur

Sakamakon: PV 8.3 nm; RMS 0.379 nm; Zuciya 0.13 µrad

Case 3 - Madubin Kashe-Axis

Aiki: D326 mm kashe-axis ƙasa madubi

Sakamakon: PV 35.9 nm; RMS 3.9 nm

FAQ na Gilashin Quartz

FAQ – Ion Beam Polishing Machine

Q1: Menene ion katako polishing?

A1:Ion bim polishing wani tsari ne wanda ba na tuntuɓar sadarwa ba wanda ke amfani da katako mai mahimmanci na ions (irin su argon ions) don cire abu daga saman kayan aiki. Ana ƙara haɓaka ion ɗin kuma ana karkatar da su zuwa sama, suna haifar da cire matakin-atomic, yana haifar da ƙarewa mai laushi. Wannan tsari yana kawar da damuwa na inji da lalacewar ƙasa, yana mai da shi manufa don daidaitattun kayan aikin gani.

Q2: Wadanne nau'ikan saman ne na Ion Beam Polishing Machine zai iya aiwatarwa?

A2:TheInjin goge goge na ion Beamna iya aiwatar da sassa daban-daban, gami da sassauƙan kayan aikin gani kamarflats, spheres, da prisms, da kuma hadaddun geometries kamaraspheres, kashe-axis aspheres, kumafreeform saman. Yana da tasiri musamman akan kayan kamar gilashin gani, infrared optics, karafa, da kayan wuya/raguwa.

Q3: Waɗanne kayan aikin ion Beam Polishing Machine zai iya aiki da su?

A3:TheInjin goge goge na ion Beamna iya goge abubuwa da yawa, gami da:

-

Gilashin gani: ma'adini, microcrystalline, K9, da dai sauransu.

-

Infrared kayan: Silicon, germanium, da dai sauransu.

-

Karfe: Aluminum, bakin karfe, titanium gami, da dai sauransu.

-

Crystal kayan: YAG, silicon carbide guda-crystal, da dai sauransu.

-

Sauran abubuwa masu tauri/karguje: Silicon carbide, da dai sauransu.

Game da Mu

XKH ya ƙware a cikin haɓaka fasahar fasaha, samarwa, da tallace-tallace na gilashin gani na musamman da sabbin kayan kristal. Kayayyakinmu suna hidimar kayan lantarki na gani, na'urorin lantarki na mabukaci, da sojoji. Muna ba da abubuwan haɗin gani na Sapphire, murfin ruwan tabarau na wayar hannu, Ceramics, LT, Silicon Carbide SIC, Quartz, da wafers kristal semiconductor. Tare da ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun kayan aiki, mun yi fice a cikin sarrafa samfuran da ba daidai ba, da nufin zama babban kamfani na kayan fasaha na optoelectronic.