Infrared Picosecond Dual-Platform Laser Yankan kayan aikin don Gilashin gani / Quartz/Sapphire Processing

Babban siga

| Nau'in Laser | Infrared Picosecond |

| Girman Dandali | 700×1200 (mm) |

| 900×1400 (mm) | |

| Yanke Kauri | 0.03-80 (mm) |

| Gudun Yankewa | 0-1000 (mm/s) |

| Yanke Breakage | <0.01 (mm) |

| Lura: Girman dandali na iya musamman. | |

Mabuɗin Siffofin

1.Ultrafast Laser Technology:

Gajerun bugun jini-matakin Picosecond (10⁻¹²s) haɗe tare da fasahar kunna MOPA sun sami ƙarfin ƙarfin kololuwa>10¹² W/cm².

· Tsawon tsayin infrared (1064nm) yana shiga cikin kayan da ba a bayyana ba ta hanyar sha ba tare da layi ba, yana hana zubar da ƙasa.

Na'urar gani mai da hankali da yawa na mallakar mallaka yana haifar da wuraren sarrafawa huɗu masu zaman kansu lokaci guda.

2.Dual-Station Tsarin Aiki tare:

* Matakan injin mizani na Granite-base (daidaitaccen matsayi: ± 1μm).

· Lokacin sauya tasha <0.8s, yana ba da damar ayyukan "aiki-sarrafawa/zazzagewa" daidai gwargwado.

· Kula da zafin jiki mai zaman kansa (23 ± 0.5 ° C) ta kowane tashar yana tabbatar da kwanciyar hankali na injina na dogon lokaci.

3.Tsarin Tsarin Hankali:

Haɗe-haɗen bayanan bayanai (parameters na gilashi 200) don daidaita ma'aunin atomatik.

· Sa ido kan plasma na lokaci-lokaci yana daidaita ƙarfin laser (ƙudurin daidaitawa: 0.1mJ).

· Kariyar labulen iska yana rage ƙananan ƙananan fasa (<3μm).

A cikin yanayin aikace-aikacen yau da kullun wanda ya ƙunshi 0.5mm-kauri mai kauri na sapphire wafer dicing, tsarin yana samun saurin yankewa na 300mm/s tare da girman tsintsiya <10μm, yana wakiltar ingantaccen ingantaccen 5x akan hanyoyin gargajiya.

Amfanin Gudanarwa

1.Integrated dual-tashar yankan da tsaga tsarin don m aiki;

2.High-speed machining na hadaddun geometries kara habaka aiwatar hira yadda ya dace;

3.Taper-free yankan gefuna tare da ƙananan chipping (<50μm) da kuma mai aiki-amintaccen aiki;

4.Seamless miƙa mulki tsakanin samfurin bayani dalla-dalla tare da ilhama aiki;

5. Low aiki halin kaka, high yawan amfanin ƙasa rates, consumable-free da kuma gurbatawa-free tsari;

6.Zero ƙarni na slag, sharar gida ruwa ko sharar gida ruwa tare da tabbacin surface mutunci;

Samfurin nuni

Aikace-aikace na yau da kullun

1.Masu Amfani da Kayan Lantarki:

· Madaidaicin kwane-kwane yankan gilashin murfin 3D na wayar hannu (daidaicin kusurwar R: ± 0.01mm).

��������������������������������������������

· Ƙarshen yankunan gilashin gani da ido don kyamarorin da ke ƙarƙashin nuni.

2. Samar da Na'ura mai gani:

Mashin ɗin microstructure don tsararrun ruwan tabarau na AR/VR (girman fasali ≥20μm).

· Yanke angled na ma'adini prisms don Laser collimators (haƙuri na kwana: ± 15").

· Siffar bayanin martaba na matatun infrared (yankan taper <0.5°).

3.Semiconductor Packaging:

· Gilashin ta hanyar-ta (TGV) sarrafawa a matakin wafer (rabi na 1:10).

Microchannel etching a kan gilashin substrates don microfluidic kwakwalwan kwamfuta (Ra <0.1μm).

· Yanke juzu'i na daidaitawa ga MEMS quartz resonators.

Don ƙirƙirar taga na gani na LiDAR na mota, tsarin yana ba da damar yankan kwane-kwane na gilashin ma'adini mai kauri 2mm tare da yanke madaidaiciyar 89.5 ± 0.3 °, saduwa da buƙatun gwajin girgizar mota.

Tsari Aikace-aikace

Ƙirƙirar ƙira ta musamman don daidaitaccen yankan gaggautsa/masu wuya gami da:

1.Standard gilashin & tabarau na gani (BK7, fused silica);

2. Ma'adini lu'ulu'u & sapphire substrates;

3. Gilashin zafin jiki & masu tacewa

4. madubi substrates

Mai ikon yankan kwane-kwane da madaidaicin hako rami na ciki (mafi ƙarancin Ø0.3mm)

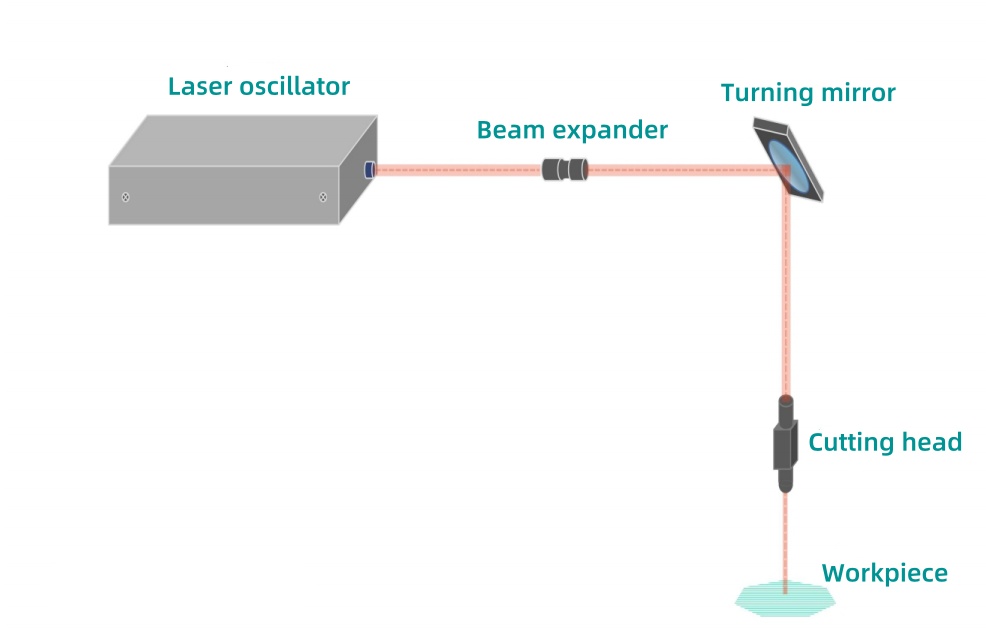

Ƙa'idar Yankan Laser

Laser yana haifar da bugun jini na ultrashort tare da babban ƙarfi mai ƙarfi wanda ke hulɗa tare da aikin aiki tsakanin lokutan femtosecond-to-picosecond. Yayin yaduwa ta hanyar kayan, katako yana rushe tsarin damuwa don samar da ramukan filamentation na micron. Ingantacciyar tazarar ramuka tana haifar da ƙananan fashe-fashe masu sarrafawa, waɗanda ke haɗuwa tare da fasahar claaving don cimma daidaitaccen rabuwa.

Amfanin Yankan Laser

1.High haɗin kai ta atomatik (hade aikin yankan / ƙwanƙwasa) tare da ƙarancin wutar lantarki da sauƙaƙe aiki;

2.Non-lamba aiki aiki yana ba da damar iyawa na musamman wanda ba a iya samuwa ta hanyar hanyoyin al'ada;

3.Aiki mara amfani da amfani yana rage farashin gudu kuma yana haɓaka dorewar muhalli;

4.Superior daidaici tare da sifili taper kwana da kuma kawar da sakandare workpiece lalacewa;

XKH yana ba da cikakkiyar sabis na gyare-gyare don tsarin yankan laser ɗinmu, gami da gyare-gyaren dandamali da aka keɓance, haɓaka siga na musamman, da ƙayyadaddun ƙayyadaddun aikace-aikacen don saduwa da buƙatun samarwa na musamman a cikin masana'antu daban-daban.