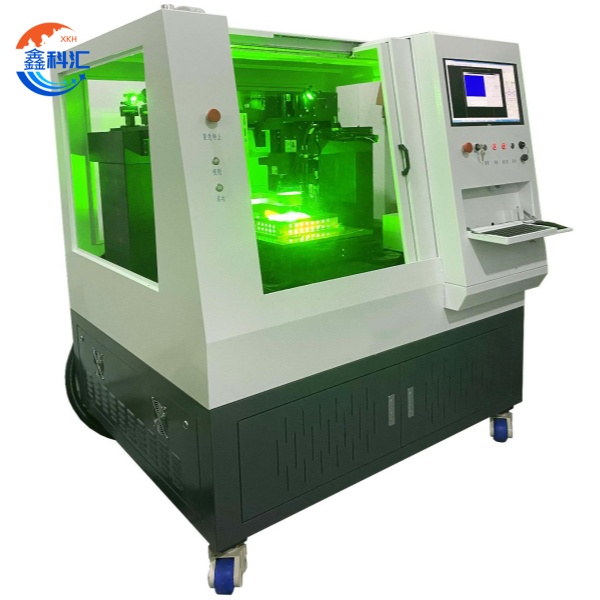

Infrared Nanosecond Laser Drilling kayan aikin don Gilashin hakowa kauri≤20mm

Babban siga

| Nau'in Laser | Infrared nanosecond |

| Girman dandamali | 800*600(mm) |

|

| 2000*1200(mm) |

| Kaurin hakowa | ≤20 (mm) |

| Gudun hakowa | 0-5000(mm/s) |

| Karye gefen hakowa | <0.5 (mm) |

| Lura: Girman dandali na iya musamman. | |

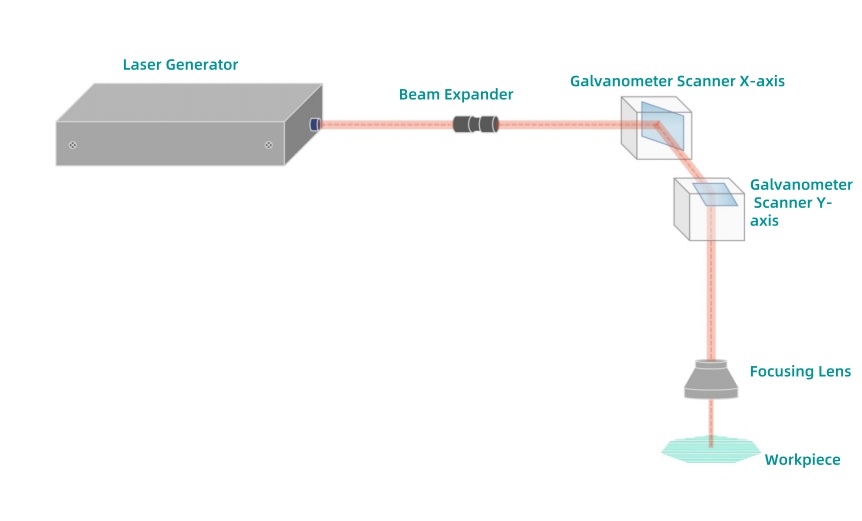

Ka'idar hakowa Laser

Laser katako yana mai da hankali a wuri mafi kyau dangane da kauri na workpiece, sa'an nan kuma bincika tare da ƙayyadaddun hanyoyin da aka ƙayyade a babban gudun. Ta hanyar hulɗa tare da katako mai ƙarfi na Laser, an cire kayan da aka yi niyya Layer-by-Layer don samar da tashoshi na yanke, cimma madaidaicin perforation ( madauwari, murabba'i, ko hadaddun geometries) tare da rarraba kayan sarrafawa.

Amfanin Hakowa Laser

Babban haɗin kai ta atomatik tare da ƙarancin amfani da wutar lantarki da sauƙaƙe aiki;

Ba a tuntuɓar aiki ba yana ba da damar ƙirar geometries mara iyaka fiye da hanyoyin al'ada;

· Aiki mara amfani yana rage farashin aiki kuma yana haɓaka dorewar muhalli;

· Madaidaicin madaidaici tare da ɗan guntun gefuna da kawar da lalacewar kayan aiki na biyu;

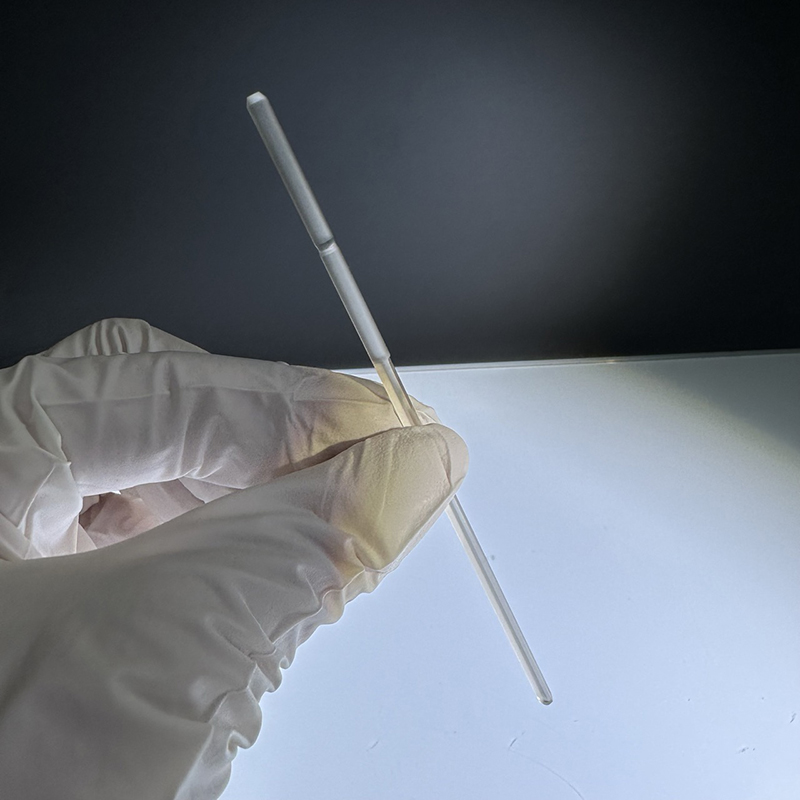

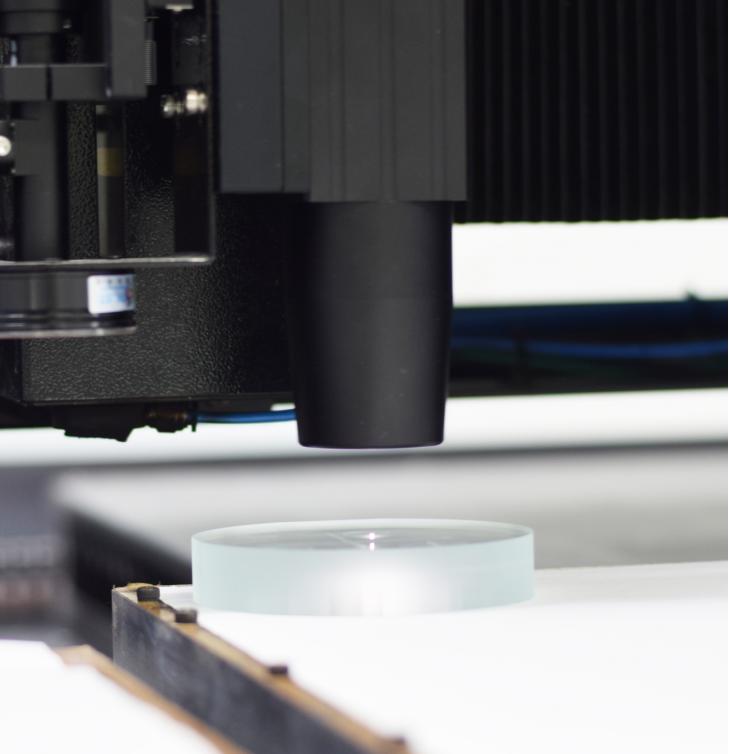

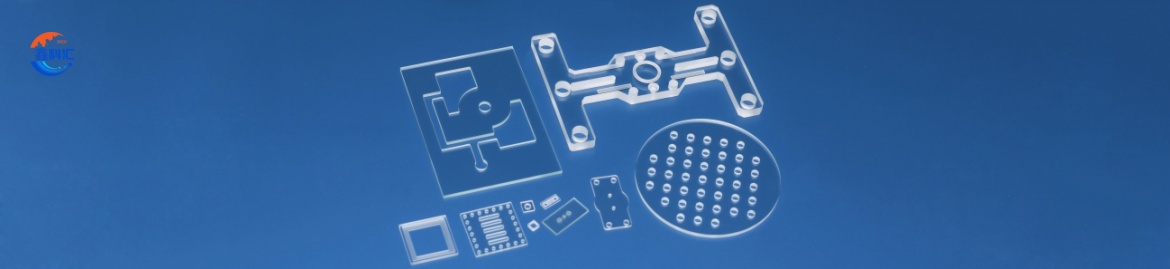

Samfurin nuni

Tsari Aikace-aikace

An ƙirƙira tsarin don daidaitaccen aiki na gaggautsa / kayan aiki masu wuya ciki har da hakowa, tsagi, cire fim, da rubutun saman. Aikace-aikace na yau da kullun sun haɗa da:

1. Hakowa da lura da abubuwan haɗin ƙofar shawa

2. Daidaitaccen perforation na kayan gilashin gilashi

3. Solar panel ta hanyar hakowa

4. Canjawa / soket murfin farantin karfe

5. Mirror shafi cire tare da hakowa

6. Custom surface texturing da tsagi ga na musamman kayayyakin

Amfanin Gudanarwa

1. Babban tsarin dandamali yana ɗaukar nau'ikan samfura daban-daban a cikin masana'antu

2. Complex contour hakowa samu a guda-wuce aiki

3. Karamin gefen chipping tare da m saman gama (Ra <0.8μm)

4. Sauye-sauye mara kyau tsakanin ƙayyadaddun samfurin tare da aiki mai mahimmanci

5. Aiki mai inganci mai fa'ida:

Yawan yawan amfanin ƙasa (>99.2%)

· sarrafawa mara amfani

· Rashin fitar da gurbataccen iska

6.Non-lamba aiki aiki tabbatar da surface mutunci adana

Mabuɗin Siffofin

1. Daidaitaccen Fasahar Gudanar da Zazzabi:

Yana amfani da tsarin hakowa mai ci gaba da yawa tare da daidaitacce kuzarin bugun jini guda (0.1-50mJ)

Sabbin tsarin kariya na labulen iska na gefe yana iyakance yankin da zafi ya shafa zuwa tsakanin 10% na diamita

* Tsarin sa ido kan zafin jiki na infrared na ainihi yana rama sigogin makamashi ta atomatik (± 2% kwanciyar hankali)

2. Dandalin Gudanarwa na Hankali:

An sanye shi da babban matakin motar linzamin kwamfuta (maimaita daidaiton matsayi: ± 2 μm)

Haɗin tsarin daidaita hangen nesa (5-megapixel CCD, daidaiton ganewa: ± 5 μm)

Bayanan bayanai da aka riga aka ɗora tare da ingantattun sigogi don nau'ikan kayan gilashin 50+

3. Ƙirar Ƙirƙirar Ƙarfafa Ƙarfafawa:

Yanayin musanya ta tasha biyu tare da canjin lokaci ≤3 seconds

· Daidaitaccen zagayowar sarrafawa na rami 1/0.5 (Φ0.5 mm ta rami)

Zane na zamani yana ba da damar musanyawa cikin sauri na taron ruwan tabarau mai mai da hankali (kewayon sarrafawa: Φ0.1-10 mm)

Brittle Hard Material Processing Applications

| Nau'in Abu | Yanayin aikace-aikace | Abubuwan Gudanarwa |

| Gilashin soda-lime | Ƙofofin shawa | Ramin hawa & tashoshi na magudanar ruwa |

| Na'urorin sarrafa kayan aiki | Tsare-tsaren ramin magudanar ruwa | |

| Gilashin zafi | Tanda duba windows | Tsarukan ramin numfashi |

| Induction girki | Tashoshi masu kwantar da hankali | |

| Borosilicate Glass | Solar panels | Ramin hawa |

| Kayan gilashin dakin gwaje-gwaje | Tashoshin magudanar ruwa na al'ada | |

| Gilashi- yumbura | Wuraren dafa abinci | Ramukan sanya masu ƙonewa |

| Induction cookers | Tsarukan hawan ramin firikwensin | |

| Sapphire | Smart na'urar rufewa | Ramin iska |

| Abubuwan kallon masana'antu | Ƙarfafa ramuka | |

| Gilashin mai rufi | madubin wanka | Ramin hawa (cire mai rufi + hakowa) |

| Ganuwar labule | Low-E gilashin boye ramukan magudanar ruwa | |

| Gilashin yumbura | Murfin juyawa/ soket | Ramin tsaro + ramukan waya |

| Katangar wuta | Ramukan taimakon matsa lamba na gaggawa |

XKH yana ba da cikakkiyar goyon bayan fasaha da sabis na ƙima don infrared nanosecond Laser hako kayan aikin hakowa don tabbatar da kyakkyawan aiki a duk tsawon rayuwar kayan aiki. Muna ba da sabis na haɓaka tsari na musamman inda ƙungiyar injiniyoyinmu ke haɗin gwiwa tare da abokan ciniki don kafa takamaiman ɗakunan karatu na siga, gami da shirye-shiryen hakowa na musamman don kayan ƙalubale kamar sapphire da gilashin zafi tare da bambancin kauri daga 0.1mm zuwa 20mm. Don inganta haɓakawa, muna gudanar da ƙirar kayan aiki a kan kayan aiki da gwaje-gwajen tabbatar da aiki, tabbatar da ma'auni mai mahimmanci kamar haƙuri na diamita (± 5μm) da ingancin gefen (Ra <0.5μm) sun hadu da ka'idojin masana'antu.