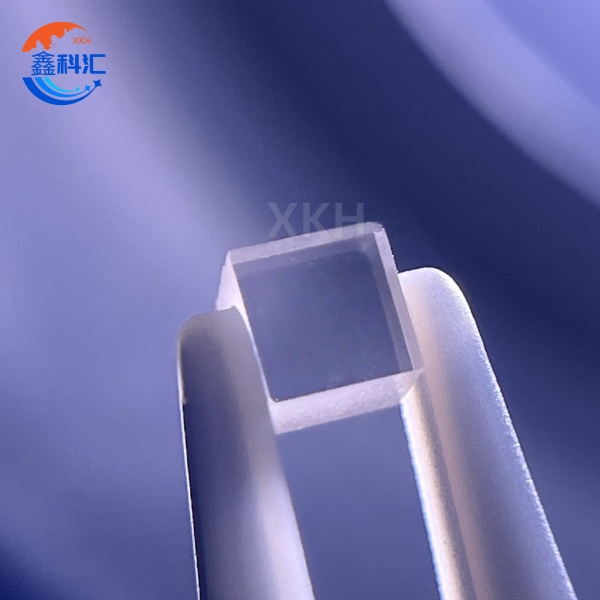

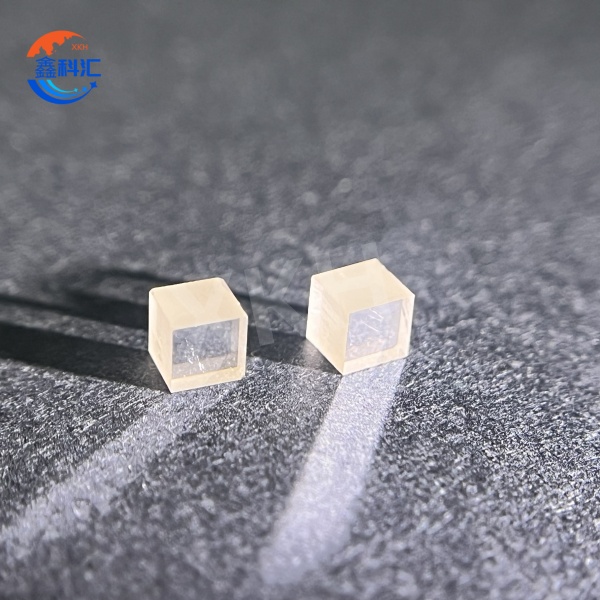

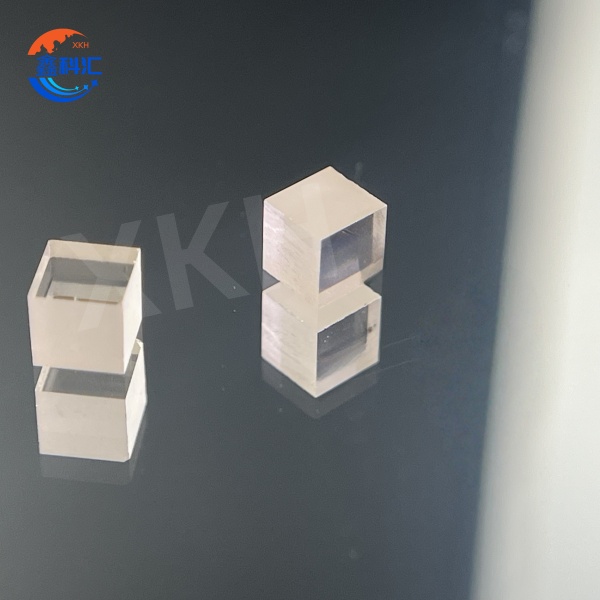

Babban Tsarkake SiC Na gani Lens Cubic 4H-Semi 6SP Girman Musamman

Halayen SiC Optical Lens

1. Matsayin Material

Matsakaicin Daidaituwar Muhalli: Yana jure yanayin zafi> 1500°C, lalatawar acid/alkali mai ƙarfi, da hasken wuta mai ƙarfi, manufa don jiragen sama da makaman nukiliya.

Ƙarfin Injini na Musamman: Ƙarfin kusada-lu'u-lu'u (Mohs 9.5), ƙarfin sassauƙa> 400 MPa, da juriya mai tasiri fiye da gilashin gani na al'ada.

Ƙarfafawar thermal: Ƙarfafawar thermal 100 × sama da silica fused, tare da CTE kawai 1/10 na gilashin talakawa, yana tabbatar da kwanciyar hankali a ƙarƙashin hawan keke mai sauri.

2. Fa'idodin Ayyuka na gani

Watsawa mai faɗi (0.2-6 μm); na musamman shafi iya inganta watsawa zuwa> 95% a takamaiman makada (misali, 3-5 μm tsakiyar-IR).

Ƙarƙashin asarar watsawa (<0.5%/cm), ƙarewar ƙasa har zuwa 10/5 ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan ƙazanta, da shimfidar ƙasa λ/10@633 nm.

Babban kofa na lalacewar Laser (LIDT)> 15 J/cm² (1064 nm, 10 ns pulses), wanda ya dace da tsarin mai da hankali na laser mai ƙarfi.

3. Daidaitaccen Machining Capabilities

Yana goyan bayan hadaddun saman (aspheric, freeform) tare da daidaiton tsari <100 nm PV da tsakiya <1 arcmin.

Mai ikon ƙirƙira manyan tabarau na SiC (diamita> 500 mm) don na'urorin hangen nesa na taurari da na'urorin gani na sararin samaniya.

Aikace-aikacen Farko na SiC Optical Lens

1. Space Optics & Tsaro

Lenses na tauraron dan adam nesa nesa da na'urorin hangen nesa na sararin samaniya, yin amfani da kaddarorin masu nauyi na SiC (yawan 3.21 g/cm³) da juriya na radiation.

Gilashin mai neman makami mai linzami, mai jurewa dumama iska (>1000°C) yayin jirgin sama.

2. High-Power Laser Systems

Mayar da hankali ruwan tabarau ga masana'antu Laser sabon / waldi kayan aiki, dore shafe tsawon daukan hotuna zuwa kW-class ci gaba da Laser.

Abubuwan da ke siffanta katako a cikin tsarin inertial confinement fusion (ICF), yana tabbatar da madaidaicin watsa laser mai ƙarfi.

3. Semiconductor & Ma'anar Mahimmanci

SiC madubi substrates ga EUV lithography optics, tare da thermal nakasawa <1 nm karkashin 10 kW/m² zafin zafi.

Ruwan tabarau na lantarki don kayan aikin dubawa na e-beam, suna amfani da halayen SiC don sarrafa zafin jiki mai aiki.

4. Binciken Masana'antu & Makamashi

Endoscope ruwan tabarau na high-zazzabi tanderu (1500 ° C ci gaba da aiki).

Abubuwan infrared na gani don kayan aikin rijiyar mai, tsayayya da matsananciyar ƙasa (> 100 MPa) da kafofin watsa labarai masu lalata.

Babban Amfanin Gasa

1. Cikakken Jagorancin Ayyuka

Ruwan tabarau na SiC sun zarce kayan aikin gani na gargajiya (fused silica, ZnSe) a cikin kwanciyar hankali na thermal/mechanical/chemical, tare da “high conductivity + low fadada” kaddarorinsu na magance ƙalubalen nakasar zafi a cikin manyan na'urorin gani.

2. Ƙimar Kuɗin Rayuwa

Yayin da farashin farko ya fi girma, tsawon rayuwar sabis na ruwan tabarau na SiC (gilashin na al'ada 5-10 ×) da kuma aikin da ba a kiyayewa yana rage yawan farashin mallakar (TCO).

3. Zane 'Yanci

Abubuwan haɗin kai ko tsarin CVD suna ba da damar SiC na gani mai sauƙi (ƙwayoyin zumar zuma), cimma madaidaitan ƙima-zuwa nauyi.

Ƙarfin Sabis na XKH

1. Custom Manufacturing Services

Ƙarshe-zuwa-ƙarshen mafita daga ƙirar gani (Zemax/Code V simulation) zuwa bayarwa na ƙarshe, yana goyan bayan fassarori na aspheric/off-axis parabolic freeform.

Na musamman shafi: anti-waiwa (AR), lu'u-lu'u-kamar carbon (LIDT> 50 J / cm²), conductive ITO, da dai sauransu

2. Tsarin Tabbatar da inganci

Kayan aikin ilimin awo da suka haɗa da 4D interferometers da masu bayyana farin-haske suna tabbatar da daidaiton λ/20.

QC-matakin kayan abu: XRD nazarin daidaitawa na crystallographic ga kowane SiC mara kyau.

3. Ƙimar-Ƙara Ayyuka

Thermo-structural coupling analysis (ANSYS simulation) don hasashen aiki.

Haɗe-haɗen SiC lens ɗin haɓaka tsarin haɓaka ƙira.

Kammalawa

Gilashin ruwan tabarau na SiC suna sake fasalin iyakokin aiki na ingantattun tsarin gani na gani ta hanyar abubuwan kayansu marasa misaltuwa. Ƙarfin haɗin gwiwarmu a tsaye a cikin haɗakar kayan aikin SiC, ingantattun mashin ɗin, da gwaji suna ba da mafita na gani na juyi don sararin samaniya da ɓangarorin masana'antu na ci gaba. Tare da ci gaba a cikin ci gaban kristal na SiC, abubuwan da ke faruwa a nan gaba za su mai da hankali kan manyan wuraren buɗe ido (> 1m) da ƙarin hadadden geometries (tsararru masu kyauta).

A matsayin babban masana'anta na kayan aikin gani na ci gaba, XKH ya kware a cikin manyan kayan aikin da suka hada da sapphire, silicon carbide (SiC), da wafer siliki, suna ba da mafita na ƙarshen zuwa ƙarshe daga sarrafa albarkatun ƙasa zuwa daidaitaccen karewa. Ƙwarewarmu ta ƙunshi:

1. Ƙirƙirar Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwaƙwalwa na Ƙaƙwalwa na Ƙaƙwalwa na Ƙaƙwalwa na Ƙaƙwalwa na Ƙaƙwalwa na Ƙaƙwalwa na Ƙaƙwalwa ) da Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwaƙwalwa na Ƙaƙwalwa na Ƙaƙwalwa na Ƙaddamarwa na Ƙaƙwalwa na Ƙaƙwalwa na Ƙaƙwalwa na Ƙaƙwalwa na Ƙaƙwalwa ) ke yi tare da Haƙuri zuwa ± 0.001mm

2. Material Versatility: Sapphire Processing (UV-IR windows), SiC (high-power optics), da silicon (IR/micro-optics)

3. Ƙimar-Ƙara Ayyuka:

Rubutun Anti-reflective/Drewa (UV-FIR)

Tabbacin inganci mai goyan bayan awoyi (λ/20 flatness)

Taro mai tsafta don aikace-aikace masu cutarwa

Yin hidimar sararin samaniya, semiconductor, da masana'antun laser, muna haɗa ƙwarewar kimiyyar kayan aiki tare da masana'antu na ci gaba don sadar da na'urorin gani waɗanda ke jure matsanancin yanayi yayin haɓaka aikin gani.