Babban Madaidaicin Laser Micromachining System

Mabuɗin Siffofin

Ultra-Fine Laser Spot Focusing

Yana amfani da fadada katako da manyan na'urorin mai da hankali kan watsawa don cimma girman tabo micron ko submicron, yana tabbatar da mafi girman ƙarfin kuzari da daidaiton sarrafawa.

Tsarin Kula da hankali

Ya zo tare da PC na masana'antu da keɓaɓɓen software na keɓancewa mai hoto mai goyan bayan aiki na yaruka da yawa, daidaita siga, hangen nesa na hanyar kayan aiki, sa ido na ainihi, da faɗakarwar kuskure.

Iyawar Shirye-shiryen atomatik

Yana goyan bayan shigo da G-code da CAD tare da tsarar hanya ta atomatik don daidaitattun sifofi masu sarƙaƙƙiya da ƙayyadaddun tsari, daidaita bututun ƙira-zuwa-ƙera.

Cikakken Ma'auni na Musamman

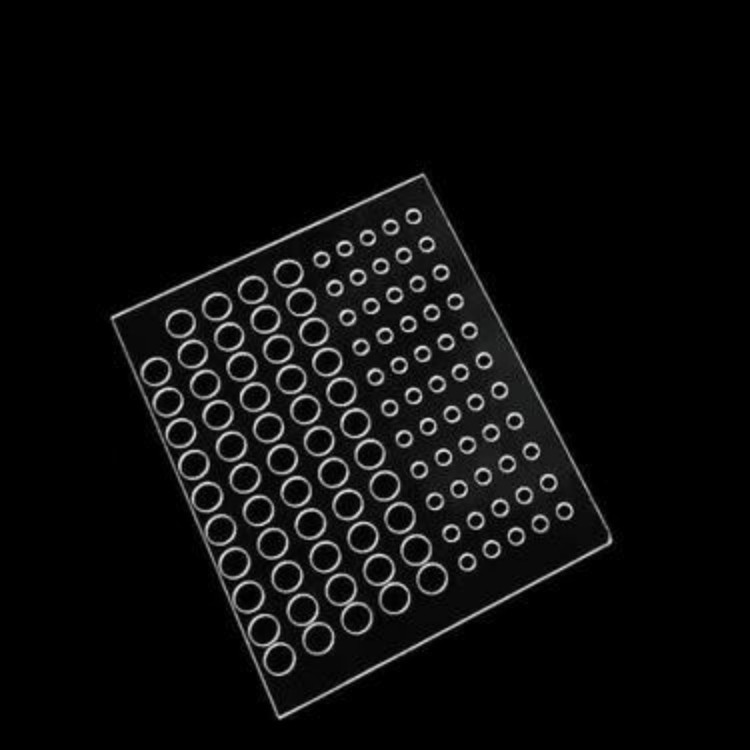

Yana ba da damar keɓance maɓalli na maɓalli kamar diamita na rami, zurfin, kusurwa, saurin dubawa, mita, da faɗin bugun bugun jini don nau'ikan kayan da kauri.

Karamin Yankin da zafi ya shafa (HAZ)

Yana amfani da gajere ko ultrashort pulse lasers (na zaɓi) don murkushe yaɗuwar zafi da hana alamun kuna, fasa, ko lalacewar tsari.

Matsayin Motsi na XYZ Mai Madaidaici

An sanye shi da madaidaicin ƙirar motsi na XYZ tare da maimaitawa <± 2μm, yana tabbatar da daidaito da daidaiton daidaitawa a cikin microstructuring.

Daidaitawar Muhalli

Ya dace da yanayin masana'antu da dakin gwaje-gwaje tare da yanayi mafi kyau na 18 ° C-28 ° C da 30% -60% zafi.

Daidaitaccen Samar da Wutar Lantarki

Daidaitaccen wutar lantarki 220V/50Hz/10A, mai dacewa da Sinanci da mafi yawan ka'idojin lantarki na duniya don kwanciyar hankali na dogon lokaci.

Yankunan aikace-aikace

Zane Diamond Waya Die Hakowa

Yana ba da zagaye sosai, ƙananan ramuka masu daidaitawa tare da madaidaicin kulawar diamita, haɓaka rayuwar mutuƙar mahimmanci da daidaiton samfur.

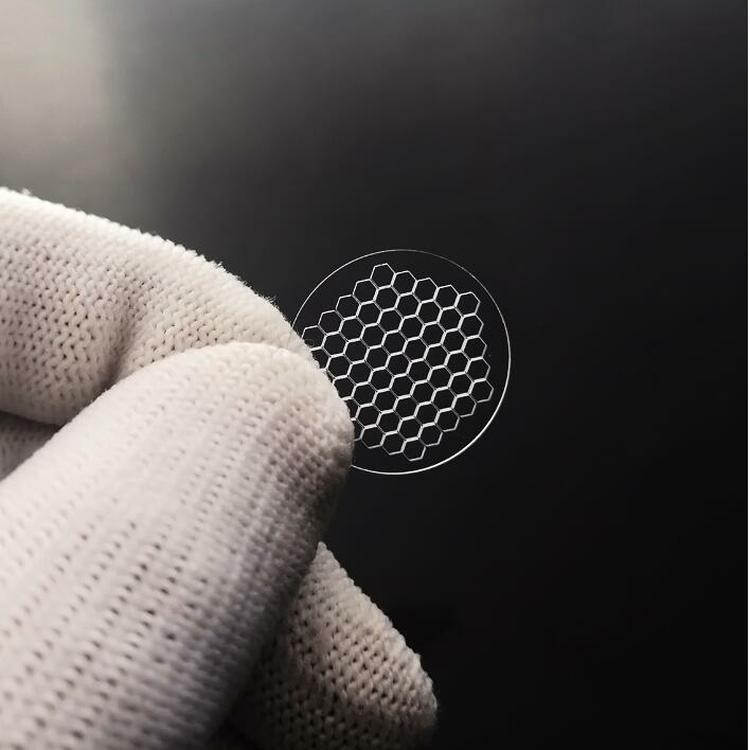

Micro-perforation don Silencers

Yana aiwatar da tsattsauran ra'ayi mai yawa kuma iri ɗaya akan ƙarfe ko kayan haɗin gwiwa, manufa don aikace-aikacen motoci, sararin samaniya, da makamashi.

Micro-Yanke na Superhard Materials

Laser katako mai ƙarfi da ƙarfi ya yanke PCD, sapphire, yumbu, da sauran kayan aiki mai ƙarfi tare da madaidaicin madaidaici, gefuna marasa burr.

Microfabrication don R&D

Mafi dacewa ga jami'o'i da cibiyoyin bincike don ƙirƙira microchannels, microneedles, da micro-optical structures tare da goyan bayan ci gaba na musamman.

Tambaya&A

Q1: Menene kayan aikin tsarin zai iya aiwatarwa?

A1: Yana goyan bayan sarrafa lu'u-lu'u na halitta, PCD, sapphire, bakin karfe, yumbu, gilashi, da sauran kayan aiki masu ƙarfi ko babban narkewa.

Q2: Shin yana goyan bayan hakowa 3D?

A2: Zabin 5-axis module yana goyan bayan hadaddun 3D saman machining, dace da sassan da ba na ka'ida ba kamar gyaggyarawa da injin turbine.

Q3: Za a iya maye gurbin tushen Laser ko musamman?

A3: Yana goyan bayan maye gurbin tare da wutar lantarki daban-daban ko lasers mai tsayi, kamar lasers fiber ko femtosecond/picosecond lasers, daidaitawa gwargwadon buƙatun ku.

Q4: Ta yaya zan iya samun goyan bayan fasaha da sabis na tallace-tallace?

A4: Muna ba da bincike mai nisa, kulawar wurin, da maye gurbin kayan gyara. Duk tsarin sun haɗa da cikakken garanti da fakitin goyan bayan fasaha.

Cikakken zane