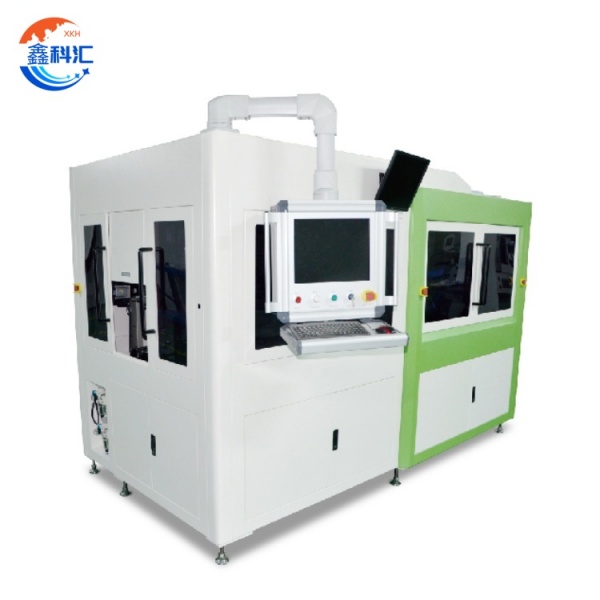

High madaidaicin Laser hako inji don sapphire yumbu abu gem hali bututun ƙarfe hakowa

Gabatarwar Samfur

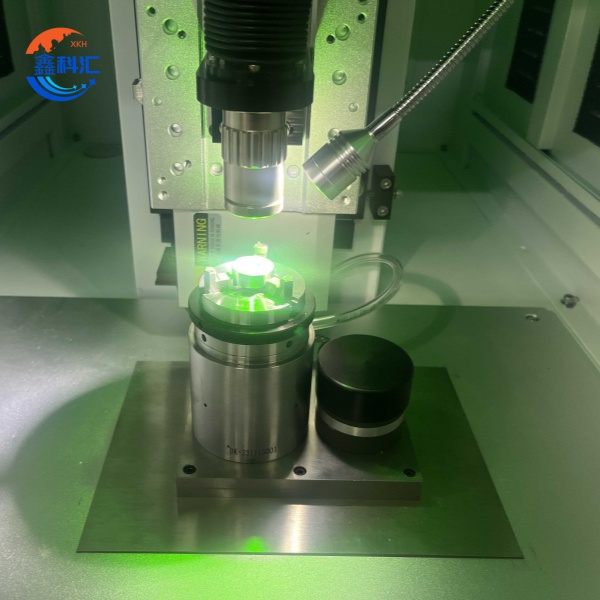

Abubuwan da ake amfani da su: Ya dace da karfe na halitta, karfe polycrystalline, ruby, sapphire, jan karfe, yumbu, rhenium, bakin karfe, karfe carbon, gami karfe da sauran superhard, babban zafin jiki resistant kayan don daban-daban siffofi, diamita, zurfin da taper hakowa.

Yanayin aiki

1. Ya dace da aiki a karkashin yanayin zafi na 18 ℃-28 ℃ da dangi zafi na 30% -60%.

2. Ya dace da samar da wutar lantarki guda biyu / 220V / 50HZ / 10A.

3. Sanya matosai waɗanda suka dace da buƙatun ƙa'idodin Sinanci masu dacewa. Idan babu irin wannan filogi, yakamata a samar da adaftar da ta dace.

4. Yadu amfani da lu'u-lu'u zane zane mutu, jinkirin waya mutu, muffler rami, allura rami, gem hali, bututun ƙarfe da sauran perforating masana'antu.

Siffofin fasaha

| Suna | Bayanai | Aiki |

| Tsayin maser na gani | 354.7nm ko 355nm | Yana ƙayyade rarrabawar makamashi da ƙarfin shigar da katako na Laser, kuma yana rinjayar ƙimar ɗaukar kayan abu da tasirin sarrafawa. |

| Matsakaicin ƙarfin fitarwa | 10.0 / 12.0/15.0 w@40khz | Shafi ingancin sarrafawa da saurin bugun naushi, mafi girman ƙarfin, saurin sarrafawa da sauri. |

| Faɗin bugun bugun jini | Kasa da 20ns@40KHz | Ƙananan nisa na bugun jini yana rage yankin zafi da ya shafa, yana inganta daidaiton machining, kuma yana guje wa lalacewar thermal na kayan. |

| Yawan maimaita bugun jini | 10 ~ 200 kHz | Ƙayyade mitar watsawa da ingancin naushi na katako na Laser, mafi girman mitar, saurin bugun bugun. |

| na gani katako ingancin | M² <1.2 | Babban katako mai inganci yana tabbatar da ingancin hakoma da ingancin inganci, yana rage asarar kuzari. |

| Tabo diamita | 0.8 ± 0.1mm | Ƙayyade ƙaramin buɗaɗɗen buɗaɗɗen buɗaɗɗen buɗaɗɗen buɗaɗɗen buɗaɗɗen buɗaɗɗen buɗaɗɗen buɗaɗɗen buɗaɗɗen buɗaɗɗen buɗaɗɗen mashin ɗin, ƙaramin tabo, ƙaramin buɗewa, mafi girman daidaito. |

| katako-banbanta kwana | Fiye da 90% | Ƙarfin mai da hankali da zurfin naushi na katakon Laser yana shafar. Karamin kusurwar banbance-banbance, zai fi ƙarfin ikon mai da hankali. |

| Hasken haske | Kasa da 3% RMS | Karamin elpticity, mafi kusancin siffar rami yana zuwa da'irar, mafi girma daidaitattun machining. |

Ƙarfin sarrafawa

Na'urorin hakowa na Laser masu tsayi suna da ƙarfin sarrafawa kuma suna iya haƙa ramuka daga ƴan microns zuwa ƴan millimeters a diamita, kuma siffar, girman, matsayi da kusurwar ramukan ana iya sarrafa su daidai. A lokaci guda kuma, kayan aikin suna tallafawa aikin hakowa na 360-digiri na kowane zagaye, wanda zai iya biyan buƙatun hakowa na sifofi da sifofi daban-daban. Bugu da kari, da high madaidaicin Laser punching inji kuma yana da kyau kwarai gefen ingancin da surface gama, da sarrafa ramukan ne burr free, babu gefen narkewa, da rami surface ne santsi da lebur.

Aikace-aikace na high ainihin Laser naushi inji:

1. Masana'antar lantarki:

Printed Circuit Board (PCB): Ana amfani da shi don sarrafa microhole don saduwa da buƙatun haɗin kai mai girma.

Marufi na Semiconductor: Punch ramukan wafers da kayan marufi don haɓaka yawan fakiti da aiki.

2. Aerospace:

Ramukan sanyaya ruwan injin: Micro ramukan sanyaya ramukan ana yin injina akan manyan ruwan wukake don inganta injin injuna.

Haɗe-haɗe-haɗe-haɗe: Don hakowa mai inganci na abubuwan haɗin fiber carbon don tabbatar da ƙarfin tsari.

3. Kayan Aikin Lafiya:

Ƙananan kayan aikin tiyata masu ɓarna: Yin injin microholes a cikin kayan aikin tiyata don inganta daidaito da aminci.

Tsarin isar da ƙwayoyi: Punch ramuka a cikin na'urar isar da magunguna don sarrafa adadin sakin miyagun ƙwayoyi.

4. Kera Motoci:

Tsarin allurar mai: Injin ƙananan ramuka akan bututun allurar mai don inganta tasirin atomization mai.

Ƙirƙirar firikwensin: Haɗa ramuka a cikin sashin firikwensin don haɓaka azancinsa da saurin amsawa.

5. Na'urorin gani:

Mai haɗa fiber na gani: Machining microholes akan mahaɗin fiber na gani don tabbatar da ingancin watsa sigina.

Fitar gani: Punch ramukan a cikin tacewa na gani don cimma takamaiman zaɓi na tsawon zango.

6. Ingantattun injina:

Madaidaicin gyare-gyare: Machining microholes a kan mold don inganta aiki da rayuwar sabis na mold.

Micro sassa: Punch ramukan a kan ƙananan sassa don saduwa da bukatun babban madaidaicin taro.

XKH yana ba da cikakkiyar sabis na injin hakowa na laser mai mahimmanci, ciki har da tallace-tallace na kayan aiki, goyon bayan fasaha, gyare-gyare na musamman, shigarwa da ƙaddamarwa, horo na aiki da goyon bayan tallace-tallace, da dai sauransu, don tabbatar da cewa abokan ciniki a cikin yin amfani da ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararru .

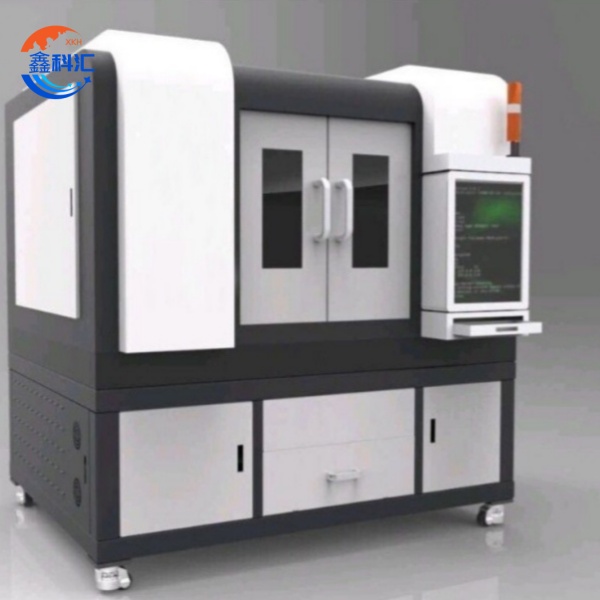

Cikakken zane