Babban Ayyukan Alumina Ceramic End Effector (Fork Arm) don Semiconductor da Tsaftace Automaation

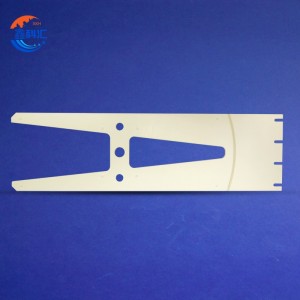

Cikakken zane

Gabatarwar Samfur

Effector na Alumina Ceramic End Effector, wanda kuma ake magana da shi azaman hannu cokali mai yatsu ko yumbu hannu na robotic, babban madaidaicin kayan sarrafa kayan aiki ne wanda aka tsara don tsarin sarrafa kansa a cikin semiconductor, hotovoltaic, nunin panel, da mahalli mai tsafta. An ƙera shi don samar da ingantaccen kwanciyar hankali na zafin jiki, ƙaƙƙarfan inji, da juriya na sinadarai, yana ba da tsabta, abin dogaro, kuma amintaccen jigilar kayayyaki masu mahimmanci kamar wafern silicon, abubuwan gilashin, da ƙananan abubuwan lantarki.

A matsayin nau'in mai amfani da ƙarshen mutum-mutumi, wannan ɓangaren yumbu shine mahaɗin ƙarshe tsakanin tsarin sarrafa kansa da kayan aikin. Yana taka muhimmiyar rawa a daidaitaccen canja wuri, daidaitawa, lodawa / saukewa, da kuma sanya ayyuka a cikin dakuna masu tsabta da mahalli.

Bayanin Kayan Aiki - Alumina Ceramic (Al₂O₃)

Alumina yumbu abu ne mai tsayi sosai kuma kayan yumbu maras amfani da sinadarai wanda aka sani don kyawawan kayan aikin injiniya da lantarki. Babban-tsarki (≥ 99.5%) alumina da aka yi amfani da shi a cikin waɗannan masu tasiri na ƙarshe yana tabbatar da:

-

Babban taurin (Mohs 9): Na biyu kawai zuwa lu'u-lu'u, alumina yana ba da juriya mai tsauri.

-

Ƙarfin zafin jiki: Yana kiyaye mutuncin tsarin sama da 1600°C.

-

Rashin rashin kuzari: Juriya ga acid, alkalis, kaushi, da kuma yanayin etching na plasma.

-

Wutar lantarki: Tare da babban ƙarfin dielectric da ƙananan asarar dielectric.

-

Low thermal fadadawa: Yana tabbatar da kwanciyar hankali a cikin yanayin hawan keke na zafi.

-

Low barbashi tsara: Mahimmanci don daidaitawar ɗaki mai tsabta (Aji na 10 zuwa Class 1000).

Waɗannan fasalulluka sun sa yumbura alumina ya zama manufa don ayyuka masu mahimmancin manufa a cikin masana'antu masu cutarwa.

Aikace-aikace masu aiki

Ƙarshen tasirin yumbura na alumina an karɓe shi sosai a cikin manyan hanyoyin masana'antu na fasaha, musamman inda kayan ƙarfe na gargajiya ko na filastik suka gaza saboda haɓakar zafi, gurɓatawa, ko batutuwan lalata. Manyan filayen aikace-aikacen sun haɗa da:

- Semiconductor wafer canja wuri

- Tsarin ɗorawa da sauke hotuna na Photolithography

- Gilashin substrate handling a OLED da LCD Lines

- Crystalline silicon wafer canja wurin a cikin hasken rana samar cell

- Duban gani na atomatik ko microelectronic dubawa

- Samfurin sufuri a cikin dakunan gwaje-gwaje na nazari ko nazarin halittu

- Tsarukan sarrafa injin mahalli

Ƙarfinsa don yin aiki ba tare da gabatar da barbashi ko cajin da ya dace ba ya sa ya zama makawa don daidaitattun ayyukan mutum-mutumi a cikin sarrafa kansa mai tsabta.

Siffofin Zane & Gyara

An ƙera kowane mai aikin ƙarshen yumbu don dacewa da takamaiman hannu na hannu ko tsarin sarrafa wafer. Muna goyon bayan cikakken gyare-gyare bisa:

-

Daidaita girman wafer: 2 ", 4", 6", 8", 12" da ƙari

-

Ramin lissafi da tazara: Yana ɗaukar riƙon baki, goyan bayan gefen baya, ko ƙirar wafer da aka ƙware

-

Tashoshin tsotsa: Haɗe-haɗen ramuka ko tashoshi don mu'amalar da ba ta sadarwa ba

-

Tsarin hawa: Ramuka, zaren, ramummuka waɗanda aka keɓance su zuwa flange na ƙarshen kayan aikin mutum-mutumi

-

Maganin saman: goge, lanƙwasa, ko ƙasa mai kyau (Ra <0.2 µm akwai)

-

Kariyar gefen: Zagaye sasanninta ko chamfering don guje wa lalacewar wafer

Ta amfani da zane-zane na CAD ko ƙirar 3D da abokan ciniki ke bayarwa, injiniyoyinmu na iya haɓaka kowane hannun cokali mai yatsa don nauyi, ƙarfi, da tsabta.

Amfanin Ƙarshen Ƙarshen yumbu

| Siffar | Amfani |

|---|---|

| Babban Rigidity na Injiniyanci | Yana kiyaye daidaiton ƙima a ƙarƙashin ƙarfin lodin mutum-mutumi |

| Kyakkyawan Ayyukan thermal | Yana aiwatar da dogaro a cikin matsanancin zafi ko yanayin plasma |

| Rashin Karfe Sifili | Babu haɗarin kamuwa da ion a cikin sarrafa semiconductor mai mahimmanci |

| Ƙarƙashin Ƙarƙashin Ƙarfafawa | Yana rage haɗari akan wafer ko gilashin gilashi |

| Anti-Static da Non-Magnetic | Baya jan hankalin ƙura ko rinjayar abubuwan da ke da ƙarfin maganadisu |

| Tsawon Rayuwa | Babban juriya na sawa a cikin manyan hawan keke mai saurin gaske ta atomatik |

| Daidaita Tsabtace Tsabtace | Ya dace da ɗakunan tsabta na ISO 14644 (class 100 da ƙasa) |

Idan aka kwatanta da filastik ko makamai na alumina, yumbu na alumina yana ba da ingantacciyar sinadarai da kwanciyar hankali tare da ƙarancin buƙatun kulawa.

| Dukiya | Karfe Arm | Hannun Filastik | Alumina Ceramic Arm |

|---|---|---|---|

| Tauri | Matsakaici | Ƙananan | Mafi Girma (Mohs 9) |

| Zaman Lafiya | ≤ 500°C | ≤ 150°C | ≥ 1600°C |

| Juriya na Chemical | Matsakaici | Talakawa | Madalla |

| Dacewar ɗaki mai tsabta | Matsakaici | Ƙananan | Mai Girma |

| Saka Resistance | Matsakaici | Ƙananan | Fitacciyar |

| Ƙarfin Dielectric | Ƙananan | Matsakaici | Babban |

| Daidaitaccen Machining na Musamman | Iyakance | Matsakaici | Maɗaukaki (± 0.01mm mai yiwuwa) |

Ƙididdiga na Fasaha

| Siga | Daraja |

|---|---|

| Kayan abu | Alumina mai tsabta (≥ 99.5%) |

| Yanayin Aiki | Har zuwa 1600 ° C |

| Tashin Lafiya | Ra ≤ 0.2 µm (na zaɓi) |

| Girman Wafer masu jituwa | 2"zuwa 12" ko al'ada |

| Hakuri na Kwanciya | ± 0.01 mm (dangane da aikace-aikacen) |

| Vacuum tsotsa Support | Na zaɓi, tashoshi na musamman |

| Zaɓuɓɓukan hawa | Bolt-ta, flange, ramukan ramuka |

Tambayoyin da ake yawan yi (FAQ)

Q1: Shin za a iya haɗa mai amfani da ƙarshen a cikin tsarin robotic da ke akwai?

A1:Ee. Muna goyan bayan keɓancewa dangane da ƙa'idar mutum-mutumin ku. Kuna iya aiko mana da zanen CAD ko girman flange don daidaitawa daidai.

Q2: Shin yumbura makamai zai karye cikin sauƙi yayin amfani?

A2:Yayin da yumbu ke da rauni ta yanayi, ƙirarmu tana amfani da ingantacciyar lissafi don rage yawan damuwa. Ƙarƙashin yanayin amfani da ya dace, suna ba da rayuwar sabis mai tsayi fiye da ƙarfe ko filastik.

Q3: Shin zai yiwu a yi amfani da wannan a cikin matsananci-high vacuum ko plasma etching chambers?

A3:Ee. Alumina yumbu ba mai fitar da iskar gas ba ne, kwanciyar hankali da zafin jiki, da juriya na lalata-ya dace da matsananciyar injin, iskar gas, ko mahallin plasma.

Q4: Yaya ake tsaftace ko kiyaye waɗannan abubuwan?

A4:Ana iya tsaftace su ta amfani da ruwan DI, barasa, ko kayan wanke-wanke masu dacewa da ɗaki. Ba a buƙatar kulawa ta musamman saboda kwanciyar hankalin sinadarai da kuma inert surface.

Game da Mu

XKH ya ƙware a cikin haɓaka fasahar fasaha, samarwa, da tallace-tallace na gilashin gani na musamman da sabbin kayan kristal. Kayayyakinmu suna hidimar kayan lantarki na gani, na'urorin lantarki na mabukaci, da sojoji. Muna ba da abubuwan haɗin gani na Sapphire, murfin ruwan tabarau na wayar hannu, Ceramics, LT, Silicon Carbide SIC, Quartz, da wafers kristal semiconductor. Tare da ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun kayan aiki, mun yi fice a cikin sarrafa samfuran da ba daidai ba, da nufin zama babban kamfani na kayan fasaha na optoelectronic.