FZ CZ Si wafer a cikin hannun jari 12inch Silicon wafer Prime ko Gwaji

Gabatar da akwatin wafer

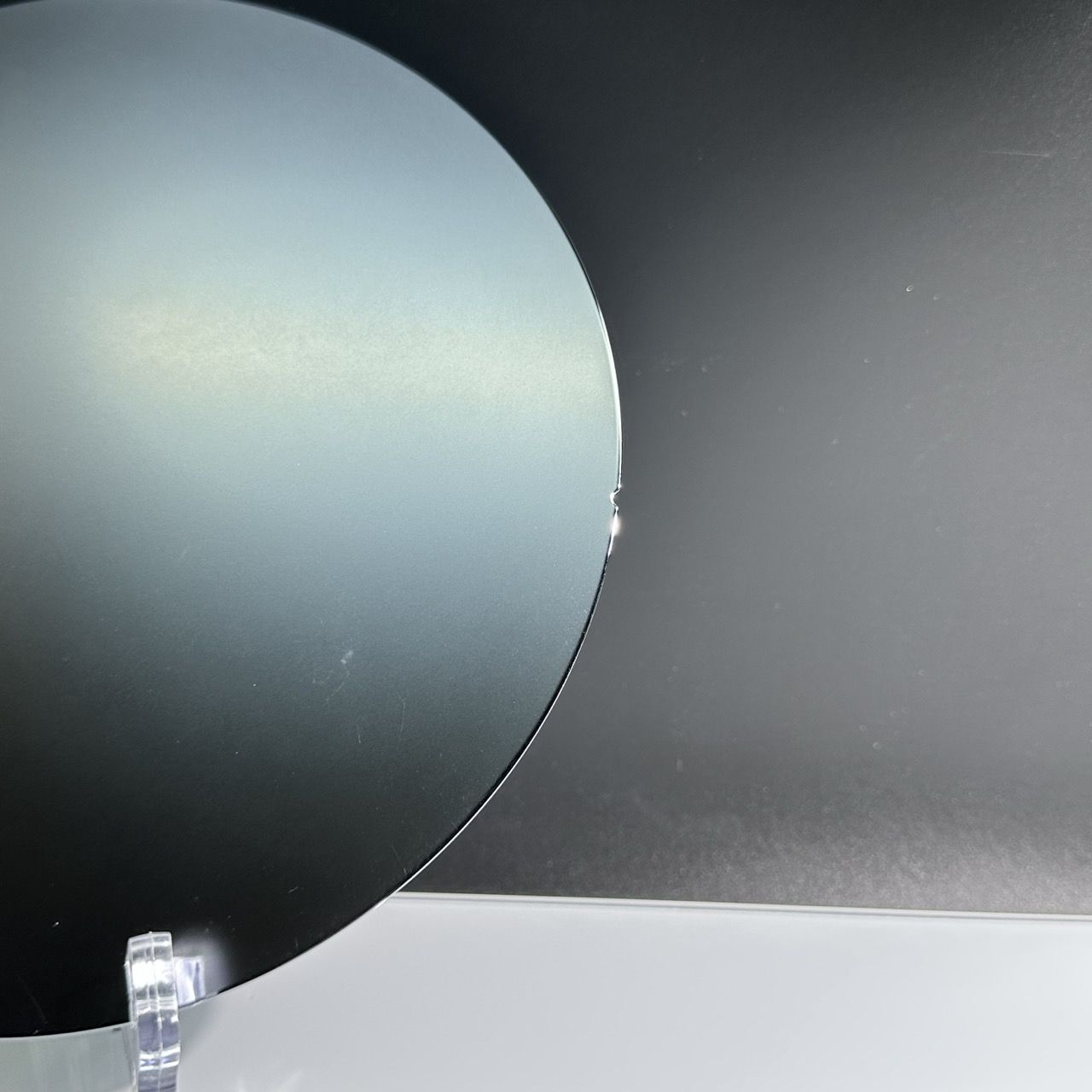

Wafers da aka goge

Silicon wafers waɗanda aka goge musamman a bangarorin biyu don samun saman madubi. Halayen maɗaukaki irin su tsabta da kwanciyar hankali suna bayyana mafi kyawun halayen wannan wafer.

Silicon Wafers mara kwance

Ana kuma san su da wafern silicon na ciki. Wannan semiconductor wani nau'i ne na siliki mai tsafta ba tare da kasancewar kowane dopant a duk faɗin wafer ba, don haka ya mai da shi manufa kuma cikakkiyar semiconductor.

Doped Silicon Wafers

Nau'in N-nau'in da nau'in P-nau'in nau'ikan nau'ikan wafer siliki ne guda biyu.

Nau'in N-nau'in doped silicon wafers sun ƙunshi arsenic ko phosphorus. Ana amfani da shi sosai wajen kera na'urorin CMOS na ci gaba.

Boron doped P-type silicon wafers. Mafi yawa, ana amfani da shi don yin da'irori da aka buga ko photolithography.

Epitaxial Wafers

Epitaxial wafers ne na al'ada da ake amfani da su don samun daidaiton saman. Ana samun wafers na Epitaxial a cikin wafers masu kauri da sirara.

Multilayer epitaxial wafers da kauri epitaxial wafers kuma ana amfani da su don daidaita yawan makamashi da sarrafa wutar lantarki na na'urori.

Ana amfani da wafers na bakin ciki na epitaxial a cikin manyan kayan aikin MOS.

SOI Wafers

Ana amfani da waɗannan wafers don keɓance kyawawan yadudduka na silikon kristal guda ɗaya daga duk wafer silicon. Ana amfani da wafers na SOI a cikin siliki photonics da aikace-aikacen RF mai girma. Hakanan ana amfani da wafers na SOI don rage ƙarfin na'urar parasitic a cikin na'urorin microelectronic, wanda ke taimakawa haɓaka aiki.

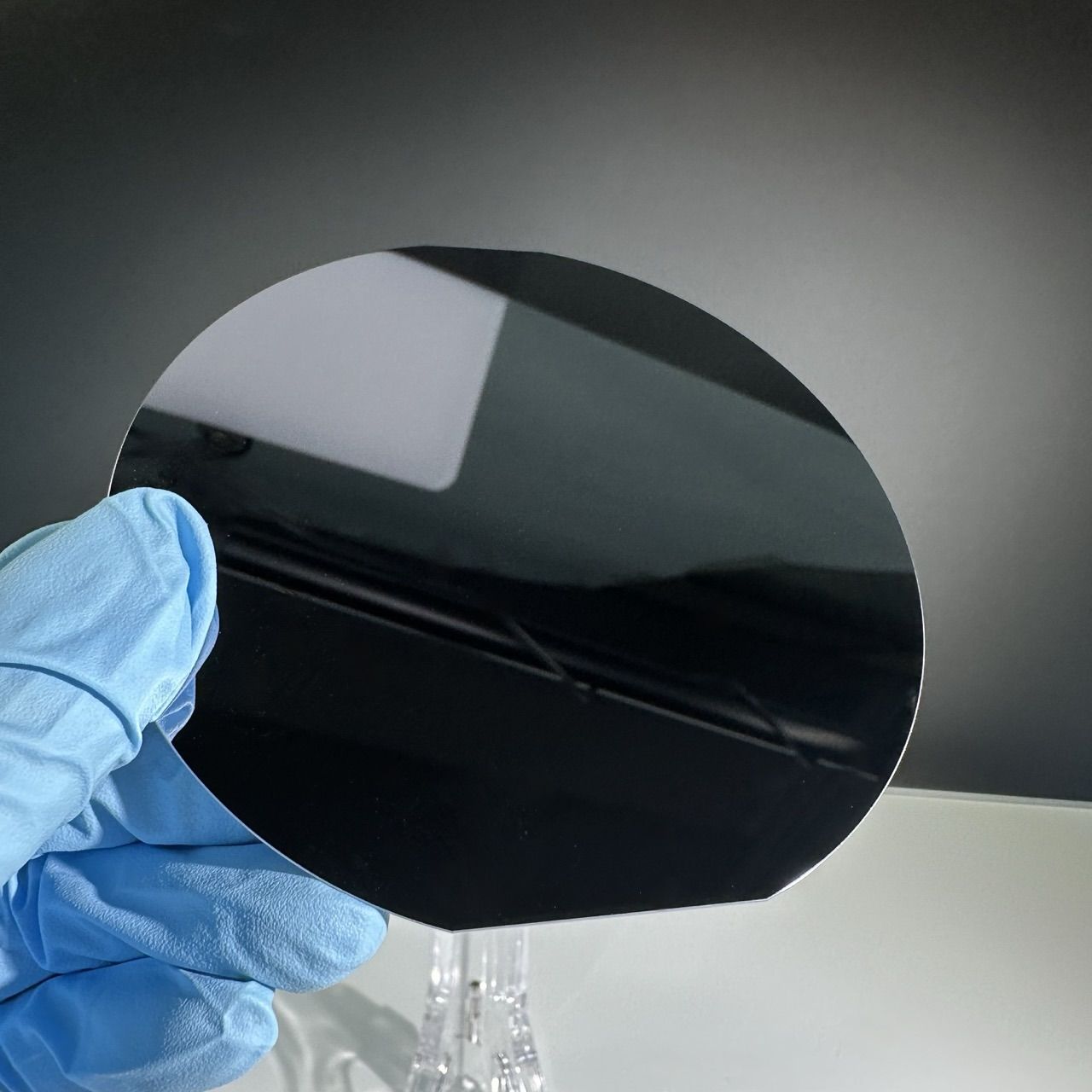

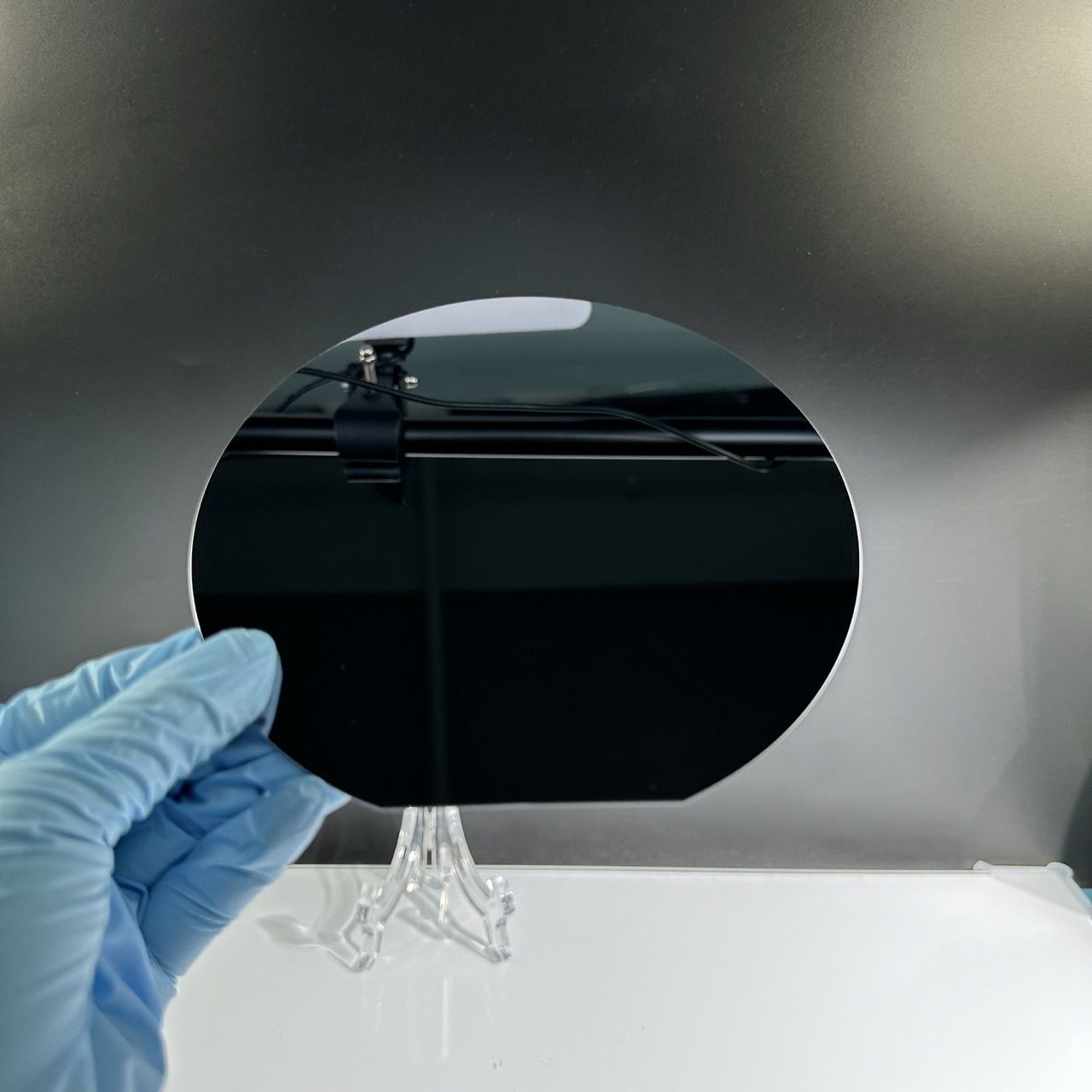

Me yasa ƙirƙira wafer ke da wahala?

12-inch silicon wafers suna da matukar wahala a yanki dangane da yawan amfanin ƙasa. Ko da yake silicon yana da wuya, amma kuma yana da rauni. An ƙirƙiri wurare masu ƙazanta kamar yadda gefuna wafer yakan karye. Ana amfani da fayafai na lu'u-lu'u don santsin gefuna na wafer da cire duk wani lalacewa. Bayan yanke, wafers suna karya cikin sauƙi saboda yanzu suna da gefuna masu kaifi. An tsara gefuna na wafer ta hanyar da za a kawar da lalacewa, masu kaifi kuma an rage damar zamewa. Sakamakon aiki na gefen gefen, ana daidaita diamita na wafer, ana yin zagaye na wafer (bayan slicing, abin da aka yanke ya zama m), kuma ana yin notches ko jiragen sama masu girma.

Cikakken zane