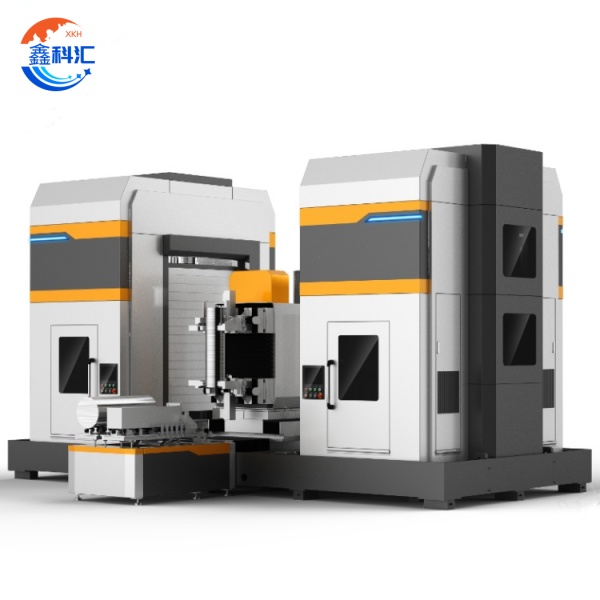

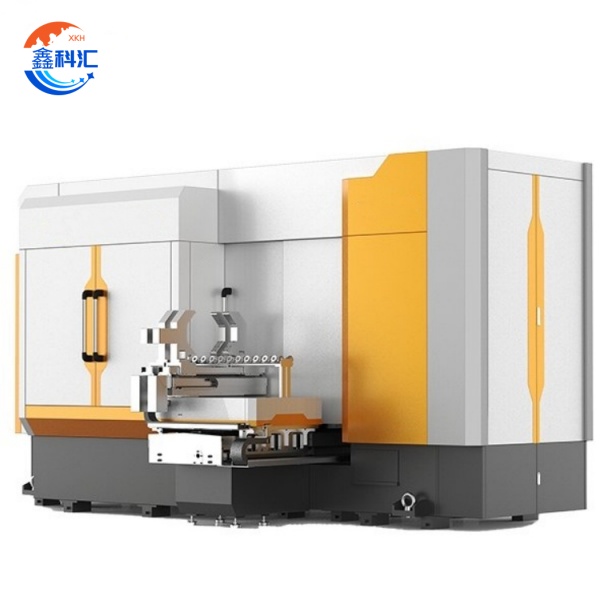

Biyu tashar square inji monocrystalline silicon sanda sarrafa 6/8/12 inch surface flatness Ra≤0.5μm

Halayen kayan aiki:

(1) sarrafa aiki tare da tashoshi biyu

· Sau biyu yadda ya dace: Yin aiki na lokaci guda na sandunan siliki guda biyu (Ø6"-12") yana ƙara yawan aiki ta hanyar 40% -60% vs. Simplex kayan aiki.

Ikon zaman kanta: Kowane tashoshi na iya daidaita sigogin yanke da kansa (tashin hankali, saurin ciyarwa) don dacewa da ƙayyadaddun sandar silicon daban-daban.

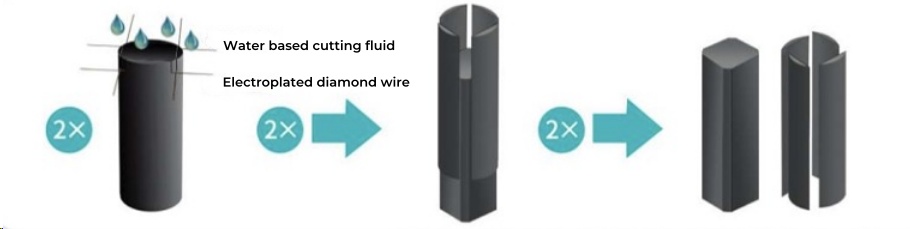

(2) Babban madaidaicin yanke

Daidaitaccen girman: jurewar nesa mai nisa murabba'i ± 0.15mm, kewayo ≤0.20mm.

· Ingancin saman: yankan tsintsiya <0.5mm, rage adadin niƙa na gaba.

(3) Gudanar da hankali

· Yanke mai daidaitawa: saka idanu na gaske na tsarin halittar sandar siliki, daidaitawa mai ƙarfi na hanyar yanke (kamar sarrafa sandar silicon mai lankwasa).

Binciken bayanan: yin rikodin sigogin sarrafawa na kowane sandar silicon don tallafawa docking tsarin MES.

(4) Karancin tsadar kayan amfani

· Amfanin waya na lu'u-lu'u: ≤0.06m/mm (tsawon sandar siliki), diamita na waya ≤0.30mm.

· Coolant wurare dabam dabam: Tsarin tacewa yana tsawaita rayuwar sabis kuma yana rage zubar da ruwa.

Fa'idodin fasaha da haɓakawa:

(1) Yanke haɓaka fasahar fasaha

- Multi-line yankan: 100-200 lu'u-lu'u Lines ana amfani da a layi daya, da kuma yankan gudun ne ≥40mm / min.

- Kula da tashin hankali: Rufe tsarin daidaita madauki (± 1N) don rage haɗarin fashewar waya.

(2) Tsawaita dacewa

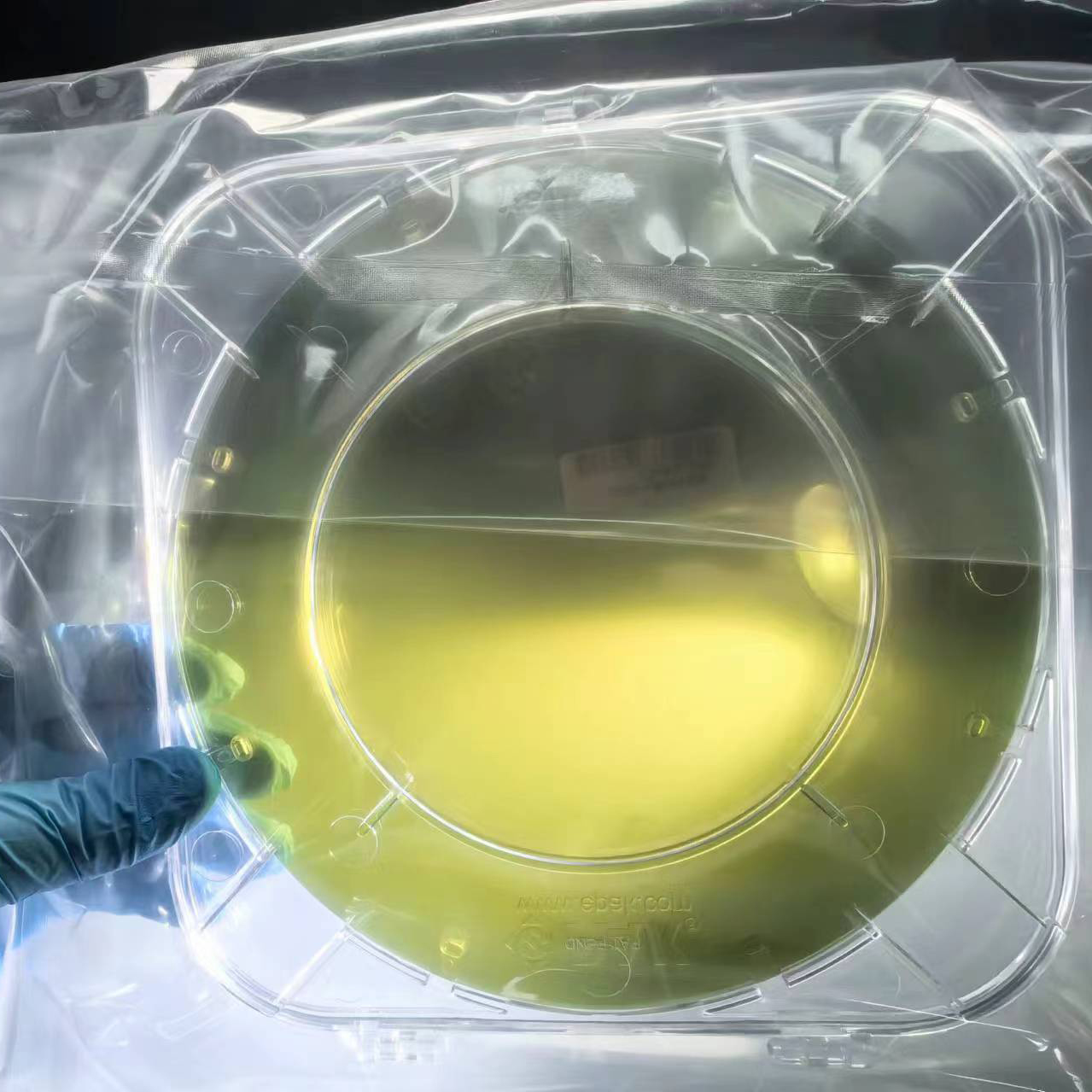

- Abun daidaitawa: Taimakawa nau'in P-type / nau'in silicon monocrystalline, mai jituwa tare da TOPCon, HJT da sauran sandunan siliki na baturi mai inganci.

- Girman sassauƙa: tsayin sandar silicon 100-950mm, nisan sandar murabba'i 166-233mm daidaitacce.

(3) Haɓakawa ta atomatik

- Robot Loading da saukewa: atomatik loading / sauke na silicon sanduna, doke ≤3 minutes.

- Bincike na hankali: Kulawa da tsinkaya don rage lokacin da ba a shirya ba.

(4) Jagorancin masana'antu

- Tallafin wafer: na iya aiwatar da ≥100μm silicon ultra-bakin ciki tare da sandunan murabba'i, ƙimar rarrabuwa <0.5%.

- Inganta amfani da makamashi: Amfani da makamashi a kowace naúrar sandar siliki yana raguwa da 30% (kamar kayan aikin gargajiya).

Sigar fasaha:

| Sunan siga | Ƙimar fihirisa |

| Adadin sanduna da aka sarrafa | 2 guda / saiti |

| Tsawon tsayin sandar sarrafawa | 100-950 mm |

| Machining gefe iyaka | 166-233 mm |

| Yanke gudun | ≥40mm/min |

| Gudun waya ta Diamond | 0 ~ 35m/s |

| Diamita na Diamond | 0.30 mm ko fiye |

| Amfani da layi | 0.06m/mm ko žasa |

| Diamita na sanda mai jituwa | Ƙarshen murabba'in sanda diamita +2mm, Tabbatar da ƙimar izinin goge goge |

| Sarrafa ɓacin rai | Raw baki ≤0.5mm, Babu chipping, high surface quality |

| Tsawon Arc uniformity | Matsakaicin tsinkaya <1.5mm, Banda murdiya sandar silicon |

| Girman inji (na'ura ɗaya) | 4800×3020×3660mm |

| Jimlar ƙarfin ƙididdigewa | 56 kW |

| Mataccen nauyin kayan aiki | 12t |

Teburin daidaiton injina:

| Madaidaicin abu | Kewayon haƙuri |

| Hakuri na bargon square | ± 0.15mm |

| Matsakaicin gefen gefen mashaya | ≤0.20mm |

| Angle a kan dukkan bangarorin square sanda | 90°±0.05° |

| Flatness na square sanda | ≤0.15mm |

| Robot ya maimaita daidaiton matsayi | ± 0.05mm |

Ayyukan XKH:

XKH yana ba da sabis na cikakken sake zagayowar don injunan tashoshi biyu na silicon mono-crystalline, gami da gyare-gyaren kayan aiki (wanda ya dace da manyan sandunan siliki), ƙaddamar da aiwatarwa (yanke ingantaccen sigar), horo na aiki da goyon bayan tallace-tallace (samar da maɓalli mai mahimmanci, bincike mai nisa), tabbatar da cewa abokan ciniki sun sami babban yawan amfanin ƙasa (> 99%) da ƙananan samar da farashi masu amfani, da kuma samar da haɓakar fasaha (kamar AI). Lokacin bayarwa shine watanni 2-4.

Cikakken zane