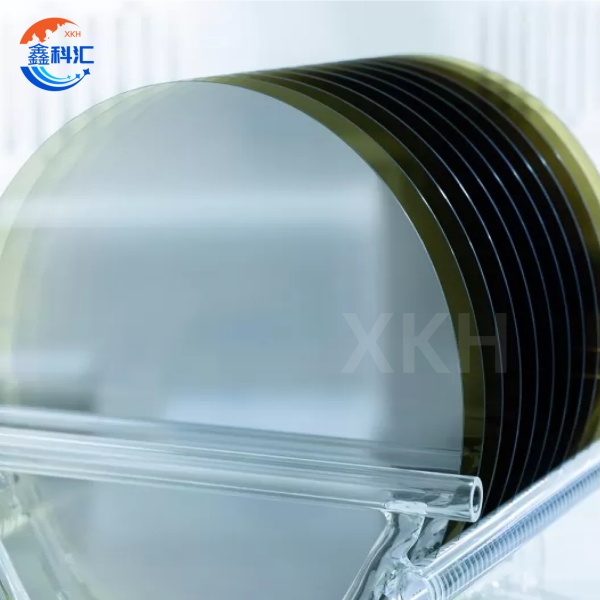

Musamman SiC Seed Crystal Substrates Dia 205/203/208 4H-N Nau'in don Sadarwar Na gani

Siffofin fasaha

Silicon carbide iri wafer | |

Polytype | 4H |

Kuskuren daidaita yanayin saman | 4° zuwa <11-20>±0.5º |

Resistivity | keɓancewa |

Diamita | 205 ± 0.5mm |

Kauri | 600± 50μm |

Tashin hankali | CMP, Ra≤0.2nm |

Maƙarƙashiya Maɗaukaki | ≤1 ea/cm2 |

Scratches | ≤5, Jimlar Tsawon≤2* Diamita |

Gefen kwakwalwan kwamfuta / indents | Babu |

Alamar Laser ta gaba | Babu |

Scratches | ≤2, Jimlar Tsawon≤ Diamita |

Gefen kwakwalwan kwamfuta / indents | Babu |

Yankunan polytype | Babu |

Alamar Laser na baya | 1mm (daga saman gefen) |

Gefen | Chamfer |

Marufi | Multi-wafer cassette |

Mabuɗin Halaye

1. Crystal Structure da Electrical Performance

· Ƙarfafawar Crystallographic: 100% 4H-SiC polytype rinjaye, sifili multicrystalline inclusions (misali, 6H/15R), tare da XRD rocking kwana cika-nisa a rabin-mafi girma (FWHM) ≤32.7 arcsec.

Motsi mai ɗaukar nauyi: Motsawar lantarki na 5,400 cm²/V·s (4H-SiC) da motsin rami na 380 cm²/V·s, yana ba da damar ƙirar na'ura mai tsayi.

Taurin Radiation: Yana jurewa 1 MeV neutron iska mai guba tare da madaidaicin lalacewa na 1 × 10¹⁵ n/cm², manufa don aikace-aikacen sararin samaniya da makaman nukiliya.

2. Thermal da Mechanical Properties

Na Musamman Thermal Conductivity: 4.9 W/cm · K (4H-SiC), sau uku na silicon, goyon bayan aiki sama da 200°C.

Ƙwararren Ƙwararren Ƙwararrun Ƙwararru: CTE na 4.0 × 10⁻⁶ / K (25-1000 ° C), yana tabbatar da dacewa tare da marufi na tushen silicon da rage yawan damuwa na thermal.

3. Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwaƙwalwa

Yawan bututu: <0.3 cm⁻² (wafers 8-inch), ƙarancin rarrabuwa <1,000 cm⁻² (an tabbatar ta hanyar KOH etching).

Ingancin saman: CMP-gyara zuwa Ra <0.2 nm, saduwa da buƙatun flatness na darajar EUV.

Maɓallin Aikace-aikace

| Domain | Yanayin aikace-aikace | Amfanin Fasaha |

| Hanyoyin sadarwa na gani | 100G/400G Laser, silicon photonics matasan kayayyaki | InP iri substrates suna ba da damar bandgap kai tsaye (1.34 eV) da heteroepitax na tushen Si, yana rage asarar haɗaɗɗun gani. |

| Sabbin Motocin Makamashi | 800V high-voltage inverters, onboard caja (OBC) | 4H-SiC substrates jure> 1,200 V, rage conduction asarar da 50% da tsarin girma da 40%. |

| 5G Sadarwa | Millimeter-wave RF na'urorin (PA/LNA), ma'aunin wutar lantarki na tushe | Semi-insulating SiC substrates (resistivity> 10⁵ Ω·cm) yana ba da damar haɗin kai mai tsayi (60 GHz+). |

| Kayayyakin Masana'antu | Na'urori masu auna zafin jiki, masu canza wuta na yanzu, na'urori masu sarrafa makamashin nukiliya | InSb iri substrates (0.17 eV bandgap) suna isar da hankalin maganadisu har zuwa 300%@10 T. |

Mabuɗin Amfani

SiC (silicon carbide) nau'in kristal iri-iri yana ba da aikin da ba a iya kwatanta shi da 4.9 W / cm · K thermal conductivity, 2-4 MV / cm rushewar filin, da 3.2 eV wide bandgap, yana ba da damar babban iko, mita mai girma, da aikace-aikace masu zafi. Yana nuna girman sifili na micropipe da <1,000 cm⁻² yawan rarrabuwar kawuna, waɗannan sifofin suna tabbatar da dogaro a cikin matsanancin yanayi. Inertness na sinadaran su da saman CVD-jituwa (Ra <0.2 nm) suna tallafawa ci gaban heteroepitaxial girma (misali, SiC-on-Si) don optoelectronics da tsarin wutar lantarki na EV.

Ayyukan XKH:

1. Musamman Production

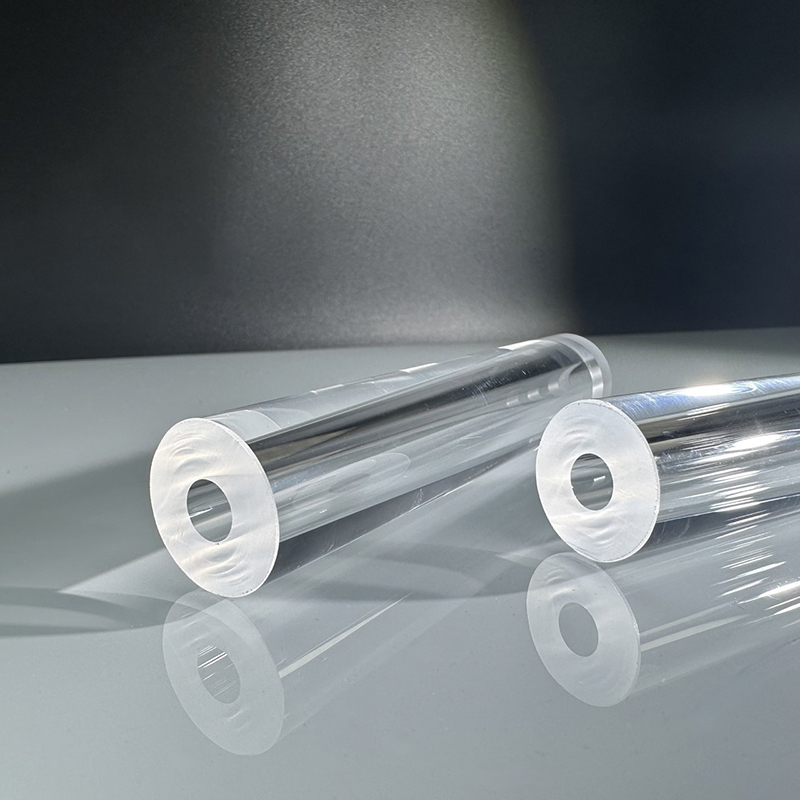

Tsarukan Wafer Mai Sauƙi: 2-12-inch wafers tare da madauwari, rectangular, ko yankan sifofi na al'ada (± 0.01 mm haƙuri).

Ikon Doping: Madaidaicin nitrogen (N) da aluminum (Al) doping ta hanyar CVD, samun juriya daga 10⁻³ zuwa 10⁶ Ω·cm.

2. Advanced Process Technologies;

· Heteroepitaxy: SiC-on-Si (wanda ya dace da layin silicon 8-inch) da SiC-on-Diamond (ɗaukar zafi> 2,000 W / m · K).

Rage lahani: Hydrogen etching da annealing don rage micropipe / yawa lahani, inganta wafer yawan amfanin ƙasa zuwa>95%.

3. Tsarin Gudanar da Inganci;

Gwajin Ƙarshe zuwa Ƙarshe: Raman spectroscopy (tabbacin polytype), XRD (crystallinity), da SEM (binciken lahani).

Takaddun shaida: Mai yarda da AEC-Q101 (motoci), JEDEC (JEDEC-033), da MIL-PRF-38534 (jin soja).

4. Tallafin Sarkar Kayayyakin Duniya;

Ƙarfin Ƙarfafawa: Fitowa na wata-wata> wafers 10,000 (60% 8-inch), tare da isar da gaggawa na sa'o'i 48.

· Sadarwar Sadarwa: Rufewa a Turai, Arewacin Amurka, da Asiya-Pacific ta hanyar jigilar iska / teku tare da marufi mai sarrafa zafin jiki.

5. Fasaha Co-Ci gaba;

Haɗin gwiwa R&D Labs: Haɗin kai akan haɓaka marufi na wutar lantarki na SiC (misali, haɗin kai na DBC).

· Lasisin IP: Samar da GaN-on-SiC RF lasisin haɓaka fasahar haɓakar epitaxial don rage farashin R&D abokin ciniki.

Takaitawa

SiC (silicon carbide) iri kristal substrates, a matsayin dabarun abu, suna sake fasalin sarƙoƙi na masana'antu na duniya ta hanyar ci gaba a cikin ci gaban crystal, sarrafa lahani, da haɗin kai iri-iri. Ta ci gaba da haɓaka raguwar lahani na wafer, haɓaka samar da 8-inch, da haɓaka dandamali na heteroepitaxial (misali, SiC-on-Diamond), XKH yana ba da ingantaccen dogaro, mafita mai tsada don optoelectronics, sabon kuzari, da masana'antu na ci gaba. Ƙaddamar da ƙaddamarwarmu ga ƙididdigewa yana tabbatar da abokan ciniki suna jagoranci a cikin tsaka-tsakin carbon da tsarin fasaha, suna haifar da zamani na gaba na tsarin yanayin mahalli mai fadi-bandgap.