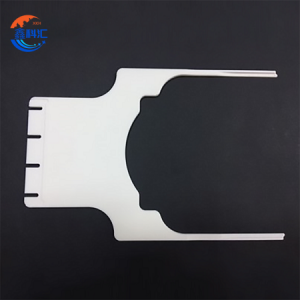

Alumina Ceramic End Effector / Fork Arm don Wafer da Sarrafa Substrate

Cikakken zane

Bayanin Alumina Ceramic End Effector

Alumina Ceramic End Effector, wanda aka fi sani da cokali mai yatsa mai yatsa ko yumbu, kayan aiki ne mai mahimmanci da ake amfani da shi a cikin injina na atomatik da layin samarwa na ɗaki mai tsabta. Alumina Ceramic End Effector an shigar da shi akan hannun mutum-mutumi a matsayin mu'amala ta ƙarshe tare da samfurin, mai alhakin ɗauka, riƙewa, daidaitawa, da kuma canja wurin sassa masu mahimmanci kamar wafern silicon, bangarorin gilashi, ko abubuwan microelectronic.

Kerarre daga matsananci-tsarki alumina yumbu (Al2O3), wannan cokali mai yatsa yana ba da ingantaccen tsari mai tsafta da tsayayye don mahalli inda ba za a iya jure gurɓatar ƙarfe, nakasar filastik, ko ƙirar barbashi ba.

Abubuwan Kaya - Me yasa Alumina

Game da Alumina Ceramic End Effector, Alumina (Al2O3) shine ɗayan mafi kafa kuma abin dogaro.ci-gaba aikin yumbura. Matsayin da muke amfani da shi (≥99.5% tsarki) yana ba da haɗin keɓaɓɓen haɗin halayen jiki da na sinadarai waɗanda suka sa ya zama kayan zaɓi don aikace-aikacen semiconductor da vacuum:

-

Matsanancin taurin- Tare da ƙimar taurin Mohs na 9, yana ba da dorewa mai dorewa da juriya.

-

Jimiri na thermal- Yana kiyaye mutuncin tsarin sama da 1600 ° C, yana fin ƙarfin ƙarfe da takwarorinsu na polymer.

-

Wutar lantarki- Yana kawar da tsayayyen gini kuma yana ba da cikakkiyar kariya ta dielectric.

-

Magungunan rigakafi- Ba shi da tasiri ta acid, alkalis, gas ɗin plasma, da tsaftataccen mafita.

-

Haɗarin gurɓataccen abu mai ƙarancin ƙarfi- Rashin fitar da hayaki, ƙasa mara ƙarfi wanda ke rage sakin barbashi a cikin ɗakunan tsabta.

Waɗannan halayen suna ba da damar masu aikin ƙarshen yumbura na alumina suyi aiki mara aibi a cikin matsananci, madaidaicin mahalli.

Core Applications na Alumina Ceramic End Effector

Haɓaka ƙarfin alumina yumbura ƙarshen sakamako na kayan aiki yana sanya su mahimmanci a cikin manyan masana'antu masu fasaha da yawa:

-

Semiconductor wafer tsarin sufuri- Amintaccen motsi siliki wafers daga tsari zuwa aiwatarwa ba tare da ɓata lokaci ba.

-

Flat panel nuni samar- Gudanar da ƙananan gilashin gilashi don OLED, LCD, ko ƙirar microLED.

-

Photovoltaic (PV) masana'anta- Taimakawa lodin wafer na hasken rana da saukewa a ƙarƙashin manyan hawan keke na robotic.

-

Ƙungiyar gani da lantarki- Riƙe sassa masu laushi kamar na'urori masu auna firikwensin, resistors, da ƙananan kwakwalwan kwamfuta.

-

Vacuum da tsabtace ɗaki ta atomatik- Yin daidaitattun ayyuka a cikin tsaftataccen tsafta, yanayin sarrafa barbashi.

A cikin kowane yanayi, Alumina Ceramic End Effector yana ba da muhimmiyar hanyar haɗin kai tsakanin keɓancewar mutum-mutumi da samfurin da ake motsawa.

Zaɓuɓɓukan Ƙirƙirar Ƙira da Ƙirar Ƙarshen Ƙarshen Ƙarshen Ƙarshen Alumina

Kowane layin samarwa yana da buƙatu na musamman. Don haka, muna samar da mafita na Alumina Ceramic End Effector wanda aka kera don girman wafer daban-daban, tsarin robotic, da hanyoyin sarrafawa:

Daidaitawar Wafer: Yana ɗaukar wafers daga 2" zuwa 12" kuma ana iya ƙididdige shi don sassa na al'ada.

Zaɓuɓɓukan Geometry: cokali ɗaya, cokali mai yatsu biyu, ramummuka da yawa, ko sifofi na al'ada tare da haɗaɗɗun wuraren hutu.

Gudanar da Vacuum: Tashoshin tsotsa na zaɓi don tallafin wafer mara lamba.

Matsakaicin hawa: Ramukan ƙulli na al'ada, flanges, ko ƙirar ƙira don dacewa da kowane hannu na mutum-mutumi.

Yana gamawa: Filayen goge ko manyan da aka kammala (har zuwa Ra <0.15 μm).

Bayanan martaba: Haɗaɗɗen gefuna ko zagaye don iyakar kariyar wafer.

Our Alumina Ceramic End Effector injiniya tawagar iya aiki daga abokin ciniki CAD zane ko samfurin sassa, tabbatar da m hadewa cikin data kasance aiki da kai tsarin.

Muhimman Fa'idodin Ƙarshen Ƙarshen Ƙarshen Alumina

| Siffar | Me Yasa Yayi Muhimmanci |

|---|---|

| Matsakaicin daidaito | Yana kiyaye daidaitattun jeri ko da a cikin babban sauri, maimaita hawan keke. |

| Mara lalacewa | Ba ya haifar da kusan babu barbashi, yana saduwa da tsaftataccen buƙatun. |

| Hujja mai zafi da lalata | Yana jurewa matakan sarrafawa masu ƙarfi da girgizar zafi. |

| Ba a tsaye caji | Yana kare wafers masu hankali da abubuwan haɗin gwiwa daga haɗarin electrostatic. |

| Mai nauyi amma mai tsauri | Yana ba da tauri mai tsayi ba tare da lahani nauyin hannu na mutum-mutumi ba. |

| Tsawaita rayuwar sabis | Ya fi ƙarfin ƙarfe da polymer makamai a tsawon rayuwa da aminci. |

Kwatanta Material na Alumina Ceramic End Effector

| Siffa | Hannun Fork na Filastik | Aluminum/Metal Fork Arm | Alumina Ceramic Fork Arm |

|---|---|---|---|

| Tauri | Ƙananan | Matsakaici | Mai Girma |

| Ragewar thermal | ≤ 150°C | ≤ 500°C | Har zuwa 1600 ° C |

| Kwanciyar Hankali | Talakawa | Matsakaici | Madalla |

| Matsayin Tsabtace Tsabta | Ƙananan | Matsakaicin | Mafi dacewa don Class 100 ko mafi kyau |

| Saka Resistance | Iyakance | Yayi kyau | Fitacciyar |

| Matsayin Keɓancewa | Matsakaici | Iyakance | M |

Tambayoyin da ake yawan yi (FAQ) na Alumina Ceramic End Effector

Q1: Menene ya sa alumina yumbura ƙarshen sakamako ya bambanta da karfe?

A1:Ba kamar alumina ko hannun karfe ba, yumbun alumina baya lalata, ɓata, ko shigar da ions ƙarfe cikin matakan semiconductor. Yana tsayawa tsayin daka a ƙarƙashin matsanancin yanayi kuma yana sakin kusan babu barbashi.

Q2: Shin waɗannan Alumina Ceramic End Effector za a iya amfani da su a cikin ɗakuna masu girma da kuma ɗakunan plasma?

A2:Ee. Alumina yumbura neba fitar gas bada juriya ga plasma, wanda ya sa ya zama abin da aka fi so don sarrafa injin da kayan aiki.

Q3: Ta yaya ake iya yin gyare-gyaren waɗannan Alumina Ceramic End Effector cokali mai yatsu?

A3:Kowane naúrar na iya zamacikakken musamman-ciki har da siffa, ramummuka, ramukan tsotsa, salon hawa, da gamawa - don dacewa da buƙatun tsarin robot ɗin ku.

Q4: Shin suna da rauni?

A4:Duk da yake yumbu yana da ɓarna na halitta, injiniyan ƙirar mu yana rarraba kaya daidai gwargwado kuma yana rage abubuwan damuwa. Lokacin da aka sarrafa daidai, rayuwar sabis yakan wuce na ƙarfe ko polymer madadin.

Game da Mu

XKH ya ƙware a cikin haɓaka fasahar fasaha, samarwa, da tallace-tallace na gilashin gani na musamman da sabbin kayan kristal. Kayayyakinmu suna hidimar kayan lantarki na gani, na'urorin lantarki na mabukaci, da sojoji. Muna ba da abubuwan haɗin gani na Sapphire, murfin ruwan tabarau na wayar hannu, Ceramics, LT, Silicon Carbide SIC, Quartz, da wafers kristal semiconductor. Tare da ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun kayan aiki, mun yi fice a cikin sarrafa samfuran da ba daidai ba, da nufin zama babban kamfani na kayan fasaha na optoelectronic.