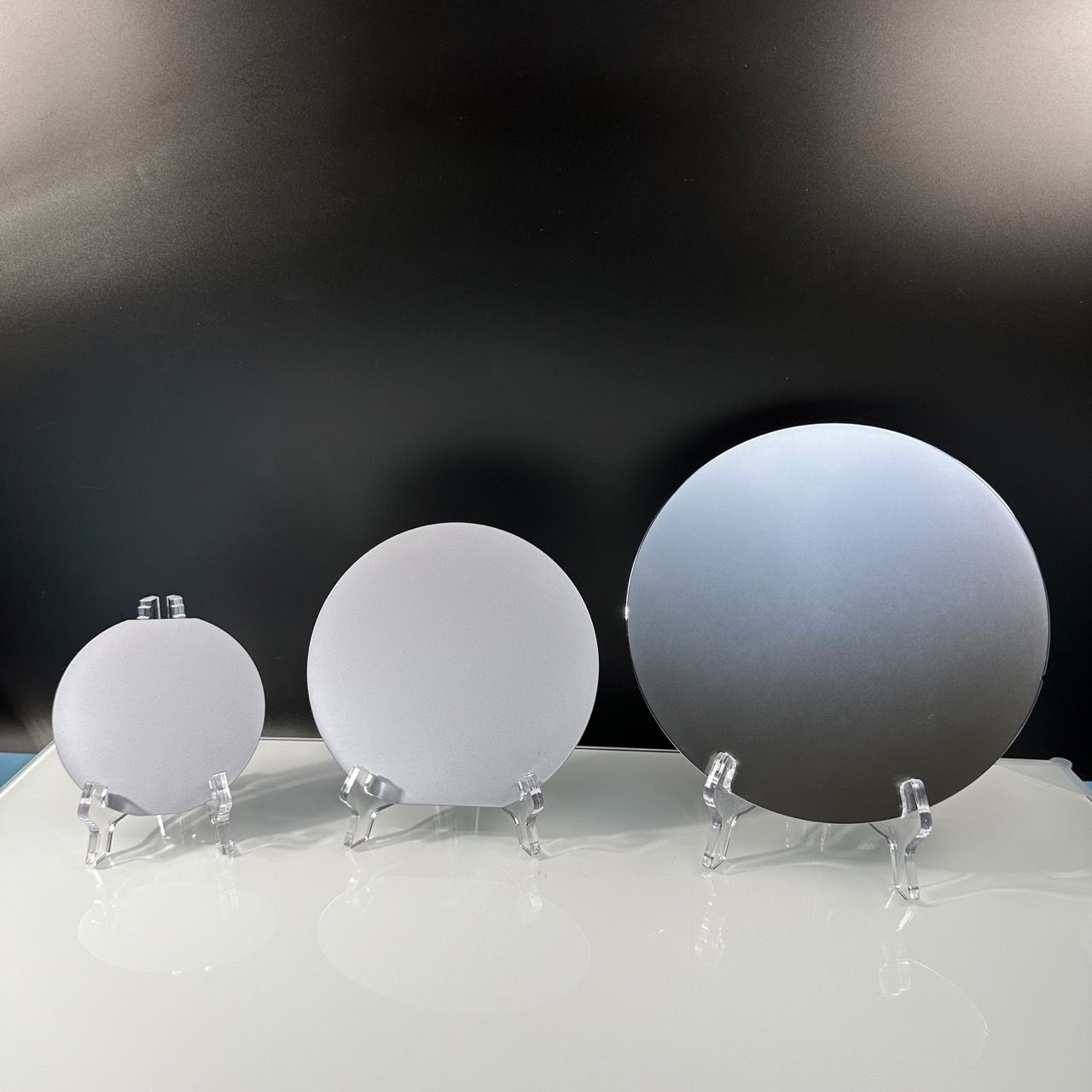

4inch Silicon wafer FZ CZ N-Type DSP ko matakin gwajin SSP

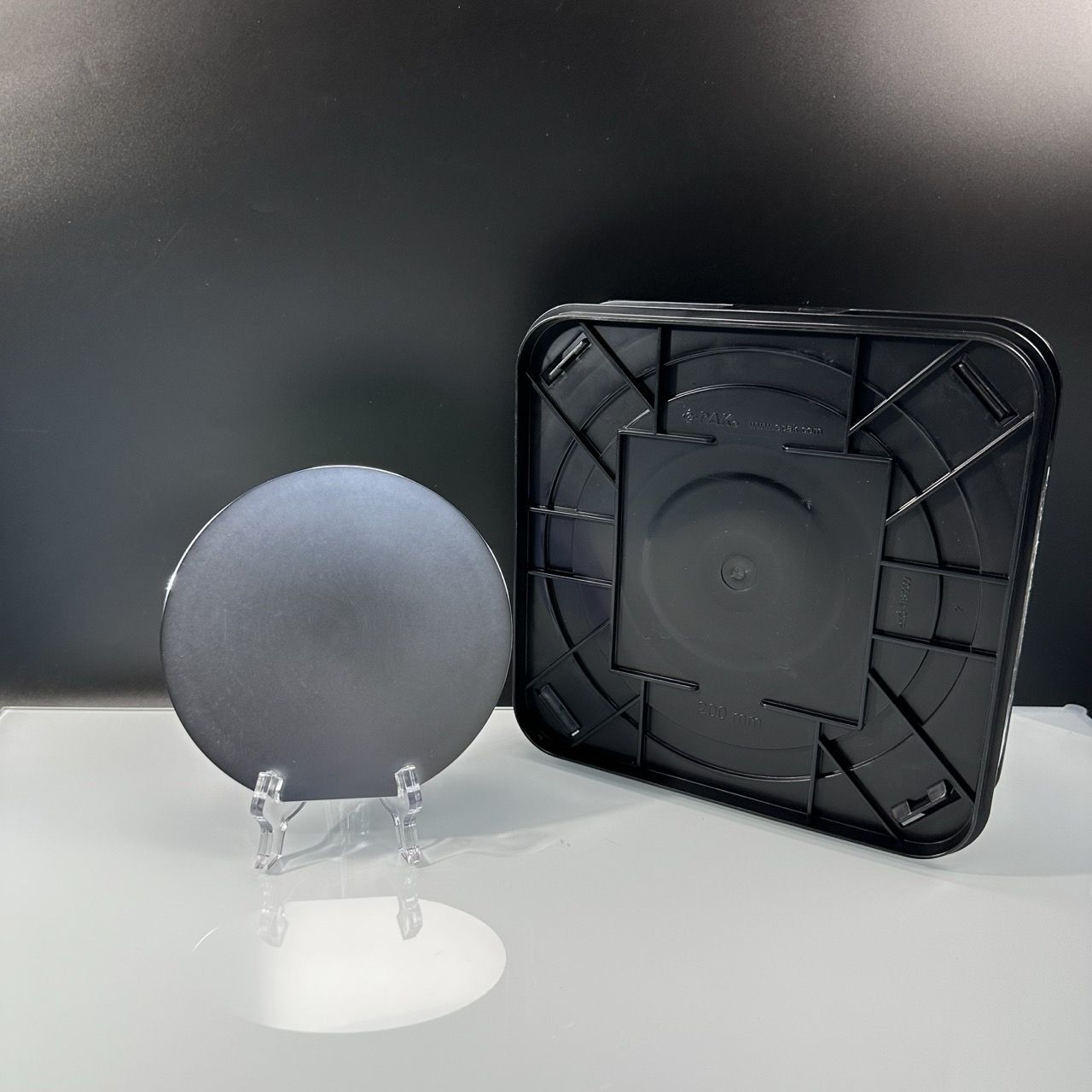

Gabatar da akwatin wafer

Silicon wafers wani muhimmin bangare ne na ci gaban fasahar zamani a yau. Kasuwancin kayan semiconductor yana buƙatar wafern siliki tare da takamaiman ƙayyadaddun bayanai don samar da adadi mai yawa na sabbin na'urorin kewayawa. Mun gane cewa yayin da farashin masana'antar semiconductor ke ƙaruwa, haka kuma farashin waɗannan kayan masana'anta, kamar wafern silicon. Mun fahimci mahimmancin inganci da ingancin farashi a cikin samfuran da muke samarwa ga abokan cinikinmu. Muna ba da wafers waɗanda suke da tsada-tasiri kuma masu inganci. Muna samar da wafers na silicon da ingots (CZ), wafers na epitaxial, da wafers na SOI.

| Diamita | Diamita | goge | Doped | Gabatarwa | Resistivity/Ω.cm | Kauri/um |

| 2 inci | 50.8 ± 0.5mm | SSP DSP | P/N | 100 | 1-20 | 200-500 |

| 3 inci | 76.2 ± 0.5mm | SSP DSP | P/B | 100 | NA | 525± 20 |

| 4 inci | 101.6 ± 0.2 101.6 ± 0.3 101.6 ± 0.4 | SSP DSP | P/N | 100 | 0.001-10 | 200-2000 |

| 6 inci | 152.5± 0.3 | SSPDSP | P/N | 100 | 1-10 | 500-650 |

| 8 inci | 200± 0.3 | DSPSSP | P/N | 100 | 0.1-20 | 625 |

Aikace-aikacen siliki wafers

Substrate: PECVD/LPCVD shafi, magnetron sputtering

Substrate: XRD, SEM, atomic karfi infrared spectroscopy, watsawa na lantarki microscopy, fluorescence spectroscopy da sauran gwaje-gwaje na nazari, girma epitaxial na kwayoyin halitta, X-ray bincike na crystal microstructure aiki: etching, bonding, MEMS na'urorin, ikon na'urorin, MOS na'urorin da sauran aiki na'urorin.

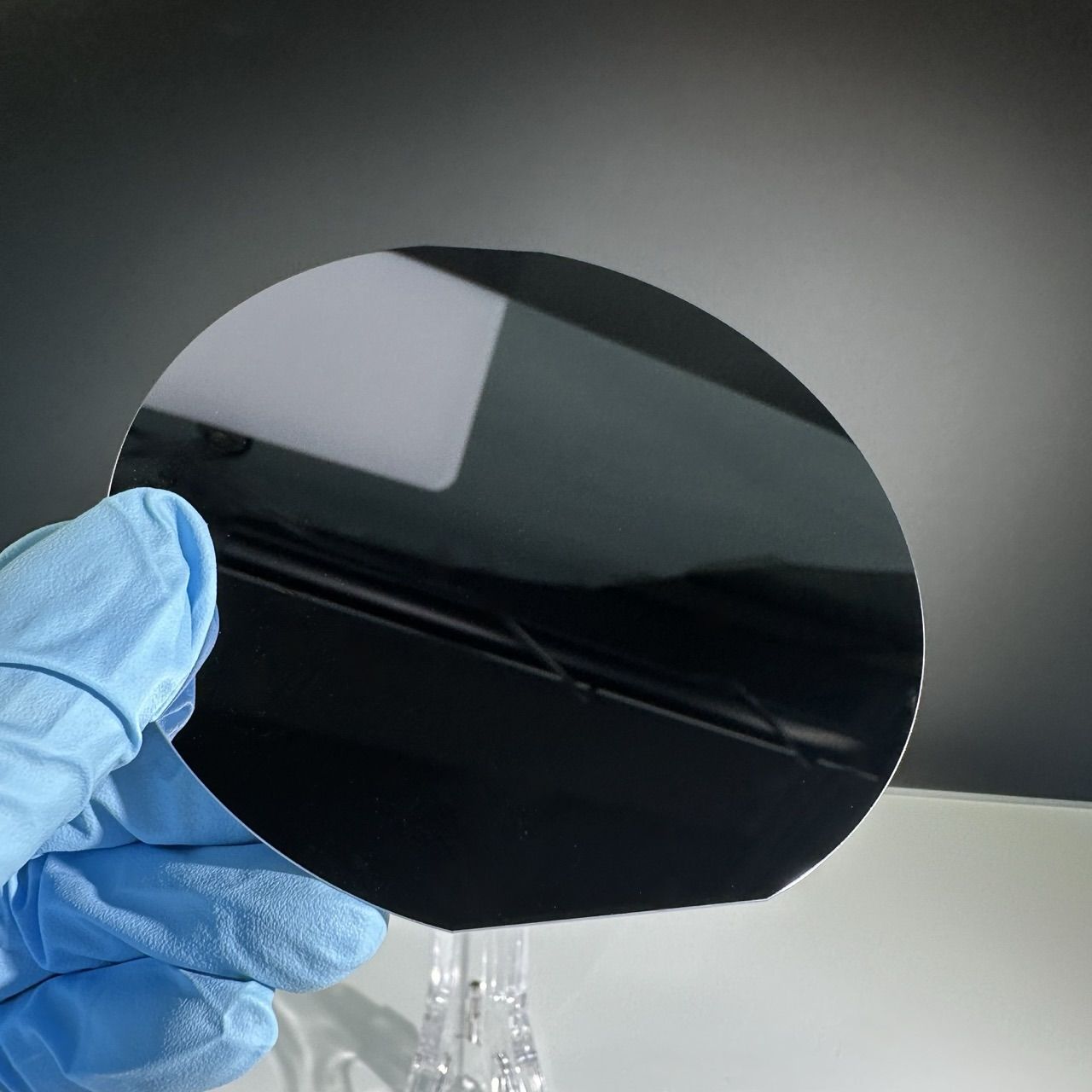

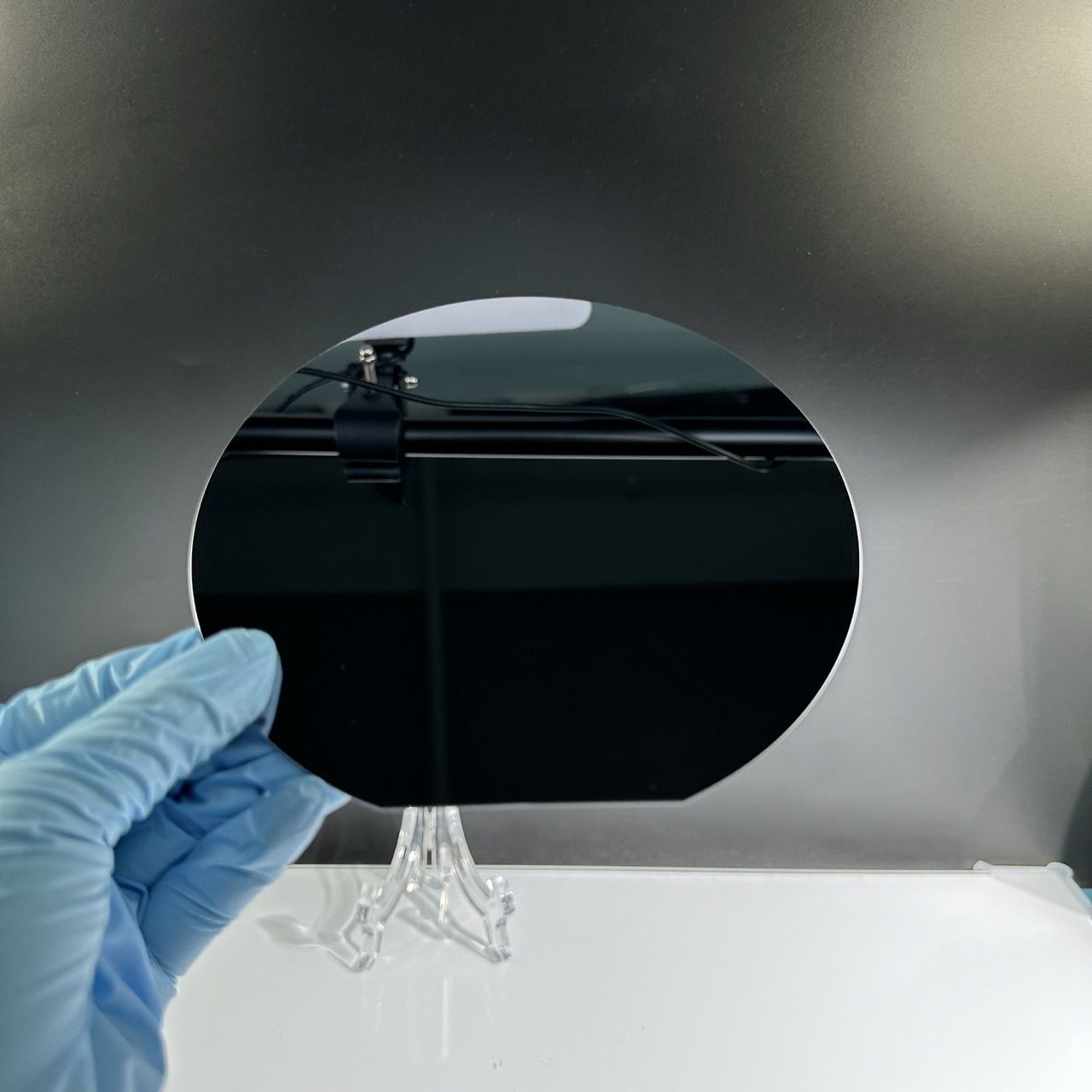

Tun 2010, Shanghai XKH Material Tech. Co., Ltd da aka sadaukar don samar da abokan ciniki tare da m 4-inch wafer Silicon Wafer mafita, daga debugging matakin wafers Dummy Wafer, gwajin matakin wafers Gwajin Wafer, zuwa samfurin matakin wafers Firayim Wafer, kazalika da musamman wafers, Oxide wafers Oxide, Nitride wafers Si3N4, Aluminum Copper wafer, silicon plated, Aluminum plated wafer. Gilashi, musamman ultra-kauri da ultra-lebur wafers, da dai sauransu, tare da masu girma dabam daga 50mm-300mm, kuma za mu iya samar da semiconductor wafers tare da guda-gefe / biyu-gefe polishing, thinning, dicing, MEMS da sauran aiki da gyare-gyare ayyuka.

Cikakken zane