Teburin Abubuwan Ciki

1. Muhimman Manufofin da Muhimmancin Tsabtace Wafer

2.Kazalika Ƙididdigar da Ƙwararren Ƙwararren Ƙwararrun Ƙwararru

3.Ingantattun hanyoyin tsaftacewa da ka'idodin fasaha

4.Tsarin Aiwatar da Fasaha da Mahimman Abubuwan Kula da Tsari

5. Hanyoyi na gaba da Sabbin Hanyoyi

6.XKH Ƙarshen-zuwa-Ƙarshen Magani da Tsarin Sabis

Tsaftace wafer muhimmin tsari ne a masana'antar semiconductor, kamar yadda ko da gurɓataccen matakin atomic na iya lalata aikin na'urar ko yawan amfanin ƙasa. Tsarin tsaftacewa yawanci ya ƙunshi matakai da yawa don cire gurɓatattun abubuwa daban-daban, kamar ragowar kwayoyin halitta, ƙazantattun ƙarfe, barbashi, da oxides na asali.

1. Manufofin Wafer Cleaning

- Cire gurɓatattun ƙwayoyin cuta (misali, ragowar hotuna, hotunan yatsa).

- Kawar da ƙazantar ƙarfe (misali, Fe, Cu, Ni).

- Kawar da gurɓataccen gurɓataccen abu (misali, ƙura, guntun silicon).

- Cire oxides na asali (misali, SiO₂ yadudduka da aka kafa yayin bayyanar iska).

2. Muhimmancin Tsabtace Wafer

- Yana tabbatar da yawan amfanin ƙasa da aikin na'urar.

- Yana rage lahani da ƙimar wafer.

- Yana haɓaka ingancin saman da daidaito.

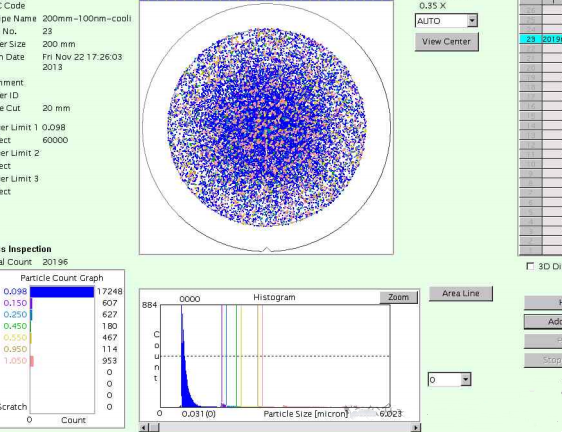

Kafin tsaftacewa mai tsanani, yana da mahimmanci don tantance gurɓatar da ke akwai. Fahimtar nau'in, girman rarrabawa, da tsarin sararin samaniya na gurɓataccen abu a saman wafer yana inganta tsabtace sunadarai da shigar da makamashin injina.

3. Babban Dabarun Nazari don Ƙimar Ƙira

3.1 Nazarin Barbashi na Surface

- Ƙwayoyin ƙididdiga na musamman suna amfani da watsawar laser ko hangen nesa na kwamfuta don ƙidaya, girma, da tarkacen taswira.

- Ƙarfin tarwatsa haske yana daidaita da girman barbashi ƙanana kamar dubun nanometers da yawa ƙasa da 0.1 barbashi/cm².

- Daidaitawa tare da ma'auni yana tabbatar da amincin kayan aiki. Binciken da aka rigaya da bayan tsaftacewa yana tabbatar da ingancin cirewa, inganta tsarin tuki.

3.2 Nazarin Tsarin Halitta

- Dabarun-hankali na saman suna gano abubuwan da aka haɗa na asali.

- X-ray Photoelectron Spectroscopy (XPS/ESCA): Yana nazarin jihohin sinadarai ta sama ta hanyar kunna wafer tare da hasken X da auna fitattun electrons.

- Glow Discharge Optical Emission Spectroscopy (GD-OES): Yana watsa manyan yadudduka masu sirara bi-da-bi-da-bi yayin da ake nazarin fitattun sifofi don tantance abubuwan da suka dogara mai zurfi.

- Iyakokin ganowa sun kai kashi ɗaya cikin miliyan (ppm), yana jagorantar zaɓin zaɓin sinadarai mafi kyau.

3.3 Binciken gurɓataccen Halittu

- Binciken Electron Microscope (SEM): Yana ɗaukar hotuna masu tsayi don bayyana sifofin gurɓatattun abubuwa da ma'auni, yana nuna hanyoyin mannewa (sinadaran vs. inji).

- Atomic Force Microscope (AFM): Maps nanoscale topography don ƙididdige tsayin barbashi da kaddarorin inji.

- Mayar da hankali Ion Beam (FIB) Milling + Transmission Electron Microscope (TEM): Yana ba da ra'ayi na ciki na abubuwan da aka binne.

4. Hanyoyin Tsabtace Na Ci gaba

Yayin da tsaftataccen ƙarfi yana kawar da gurɓataccen ƙwayoyin halitta yadda ya kamata, ana buƙatar ƙarin dabarun ci gaba don ƙwayoyin inorganic, ragowar ƙarfe, da gurɓataccen ion:

;

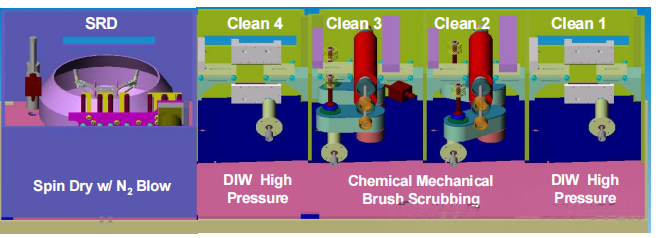

4.1 RCA Tsabtace

- RCA Laboratories ne suka haɓaka, wannan hanyar tana amfani da tsarin wanka biyu don cire gurɓataccen polar.

- SC-1 (Standard Clean-1): Yana kawar da gurɓatattun ƙwayoyin cuta da ƙwayoyin cuta ta amfani da cakuda NH₄OH, H₂O₂, da H₂O (misali, 1: 1: 5 rabo a ~ 20 ° C). Yana samar da sirin siliki dioxide Layer.

- SC-2 (Standard Tsabtace-2): Yana kawar da ƙazantattun ƙarfe ta amfani da HCl, H₂O₂, da H₂O (misali, 1:1:6 rabo a ~80°C). Yana barin wani wuri mai wucewa.

- Daidaita tsafta tare da kariya ta saman.

;

4.2 Tsabtace Ozone

- Yana nutsar da wafers a cikin ruwa mai cike da ruwa (O₃/H₂O) .

- Ingantacciyar oxidizes da kawar da kwayoyin halitta ba tare da lalata wafer ba, yana barin wani wuri mai wuce gona da iri.

;

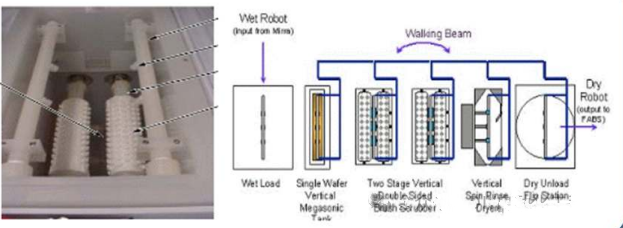

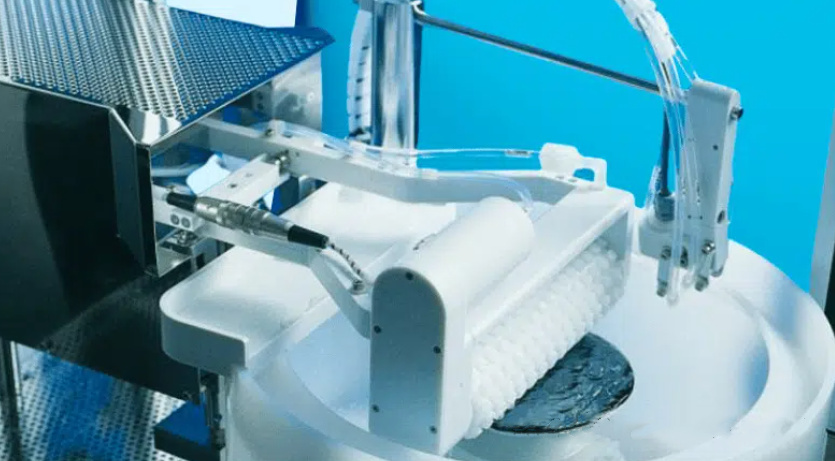

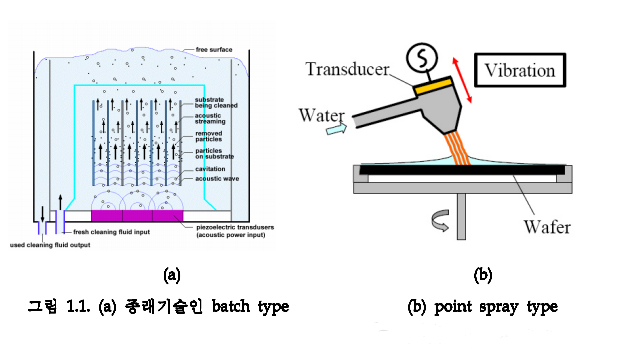

4.3 Megasonic Tsabtace;

- Yana amfani da makamashi mai ƙarfi na ultrasonic (yawanci 750-900 kHz) tare da mafita mai tsaftacewa.

- Yana haifar da kumfa cavitation waɗanda ke kawar da gurɓataccen abu. Yana shiga hadaddun geometries yayin da yake rage lalacewa ga sifofi masu laushi.

4.4 Cryogenic Cleaning

- Da sauri yana sanyaya wafers zuwa yanayin zafi na cryogenic, gurɓataccen gurɓataccen abu.

- Kurkure na gaba ko a hankali gogewa yana cire sassan da aka saki. Yana hana sake gurɓacewa da yaɗuwa cikin saman.

- Saurin tsari, bushewa tare da ƙarancin amfani da sinadarai.

Kammalawa:

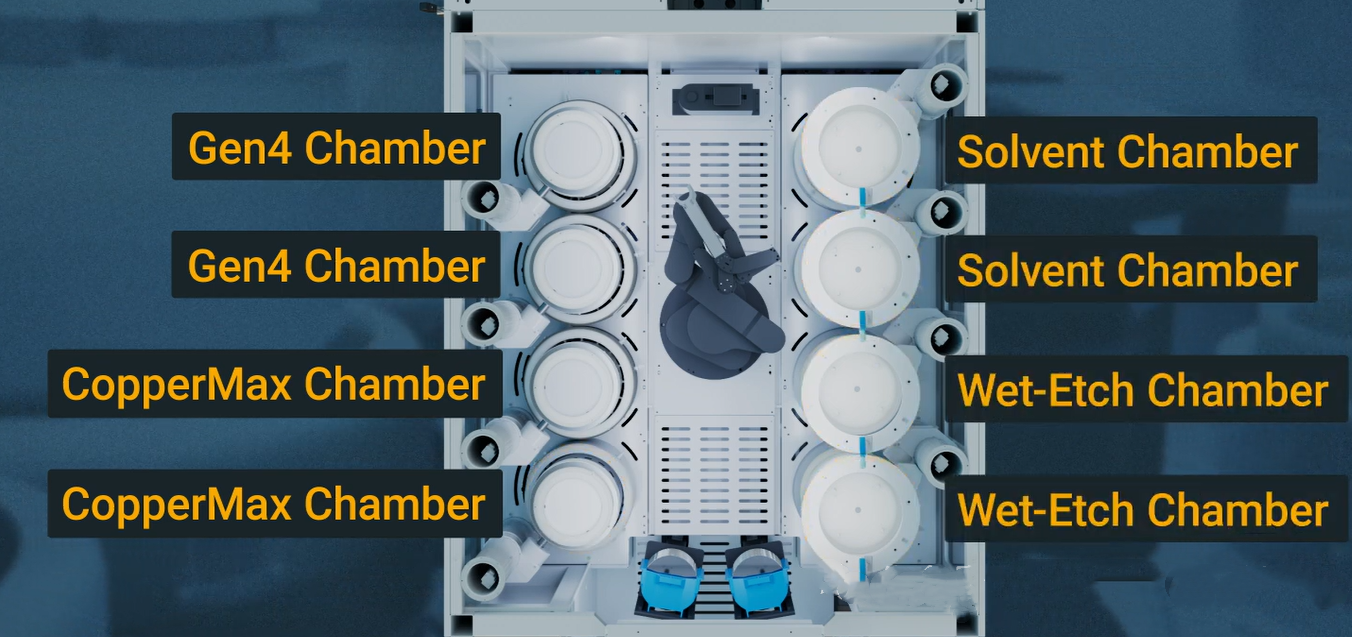

A matsayin babban mai ba da mafita na semiconductor mai cikakken sarkar, XKH ke motsawa ta hanyar sabbin fasahohi kuma abokin ciniki yana buƙatar isar da yanayin yanayin sabis na ƙarshe zuwa ƙarshe wanda ya ƙunshi wadataccen kayan aiki na ƙarshe, ƙirƙira wafer, da tsabtace tsabta. Ba wai kawai muna samar da kayan aikin semiconductor da aka sani ba (misali, injin lithography, tsarin etching) tare da ingantattun mafita amma har da fasahar mallakar majagaba - gami da tsaftacewar RCA, tsarkakewar ozone, da tsaftacewar megasonic - don tabbatar da tsaftar matakin atomic don masana'antar wafer, haɓaka yawan amfanin abokin ciniki da ingantaccen samarwa. Yin amfani da ƙungiyoyi masu saurin amsawa da kuma hanyoyin sadarwar sabis na fasaha, muna ba da cikakken tallafi tun daga shigarwa kayan aiki da haɓaka tsari zuwa kiyaye tsinkaya, ƙarfafa abokan ciniki don shawo kan ƙalubalen fasaha da ci gaba zuwa daidaici mafi girma da ci gaban semiconductor mai dorewa. Zaba mu don haɗin kai mai nasara biyu na ƙwarewar fasaha da ƙimar kasuwanci.

Lokacin aikawa: Satumba-02-2025