SiC wafers semiconductor ne da aka yi daga silicon carbide. An haɓaka wannan kayan a cikin 1893 kuma yana da kyau don aikace-aikace iri-iri. Musamman dace da Schottky diodes, junction shãmaki Schottky diodes, sauya da karfe-oxide-semiconductor filin-tasiri transistor. Saboda tsananin taurin sa, zaɓi ne mai kyau don kayan aikin lantarki.

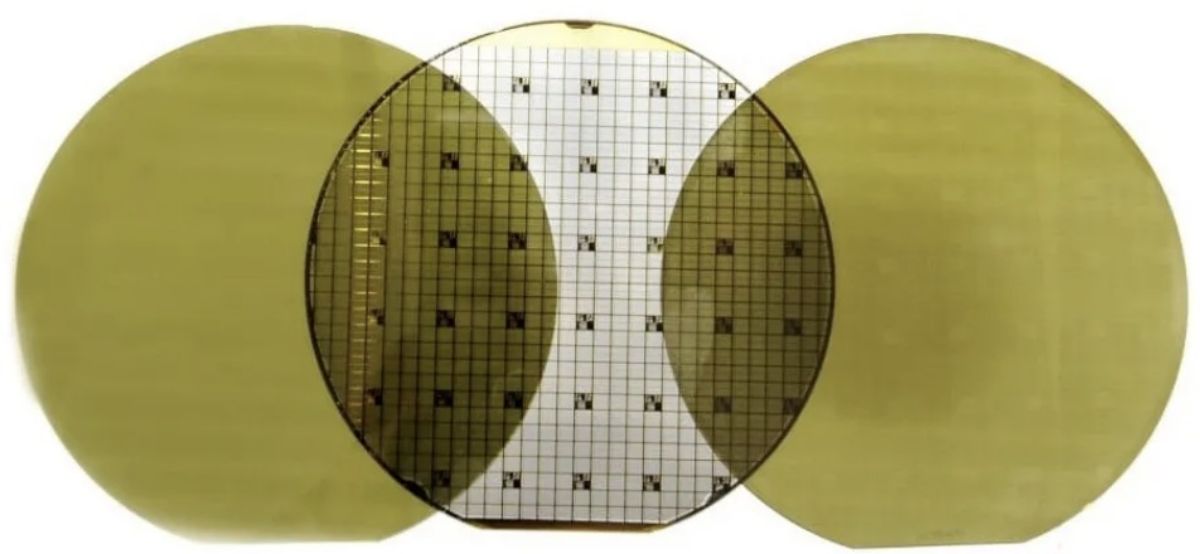

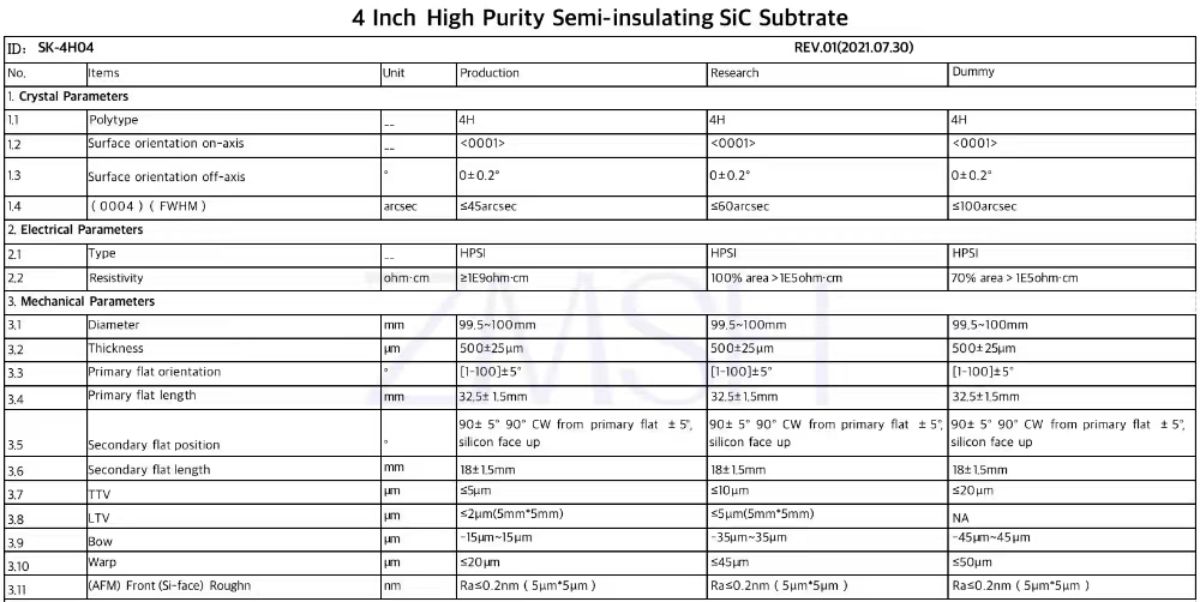

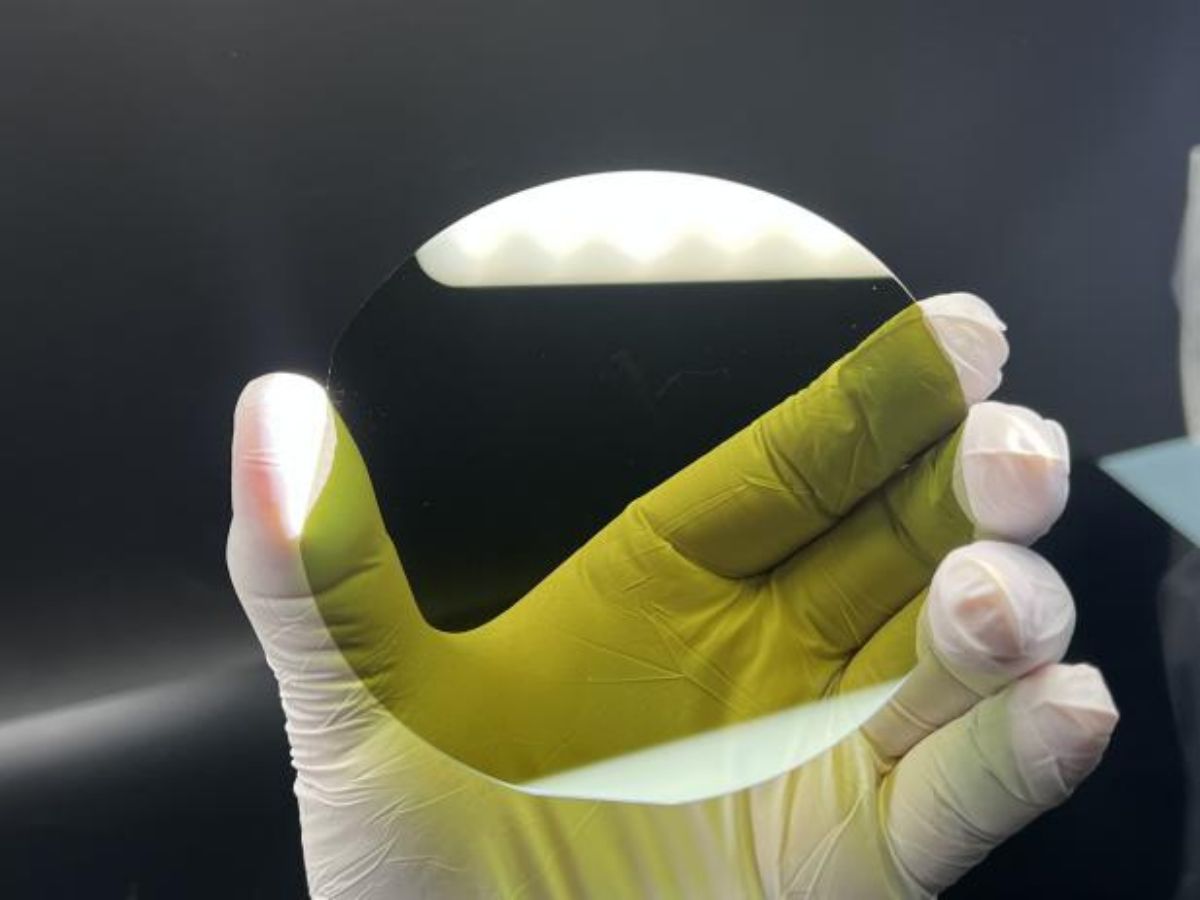

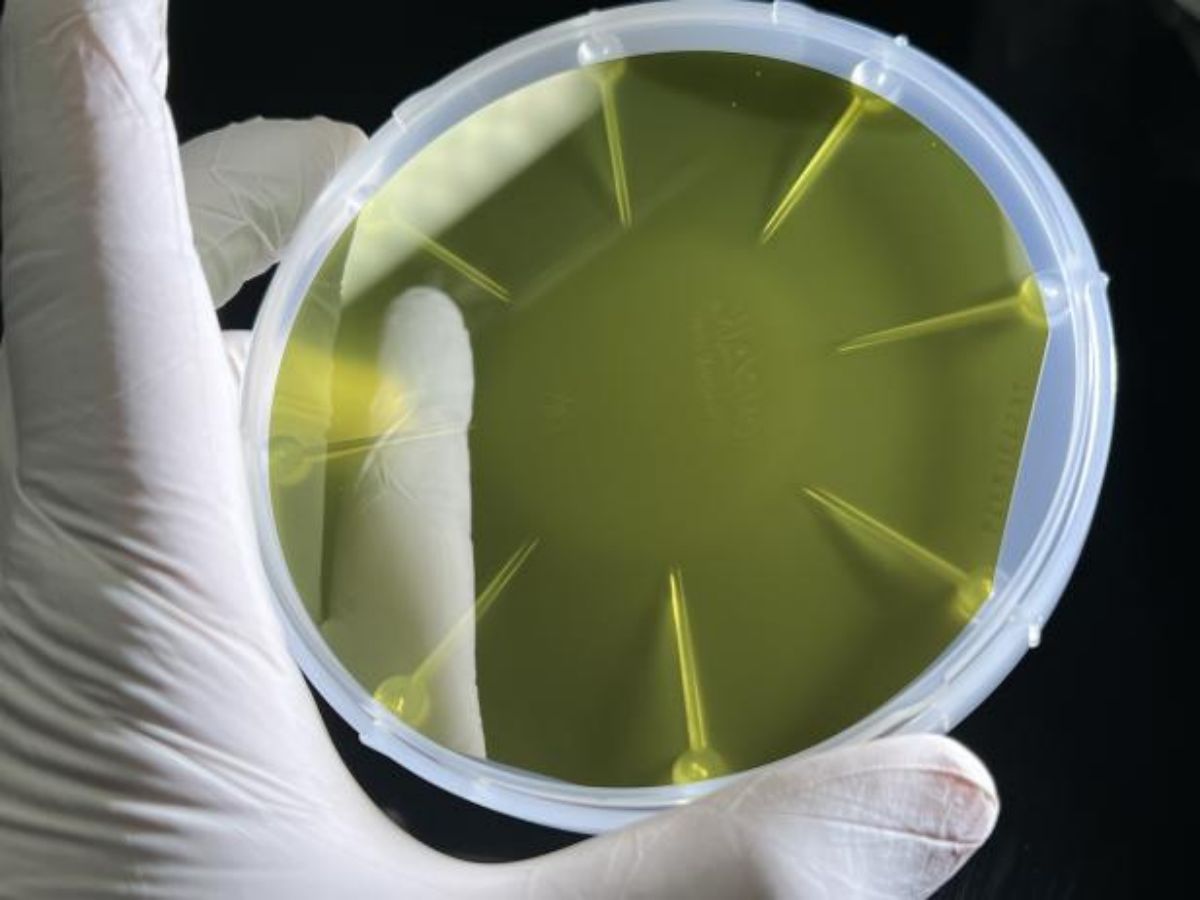

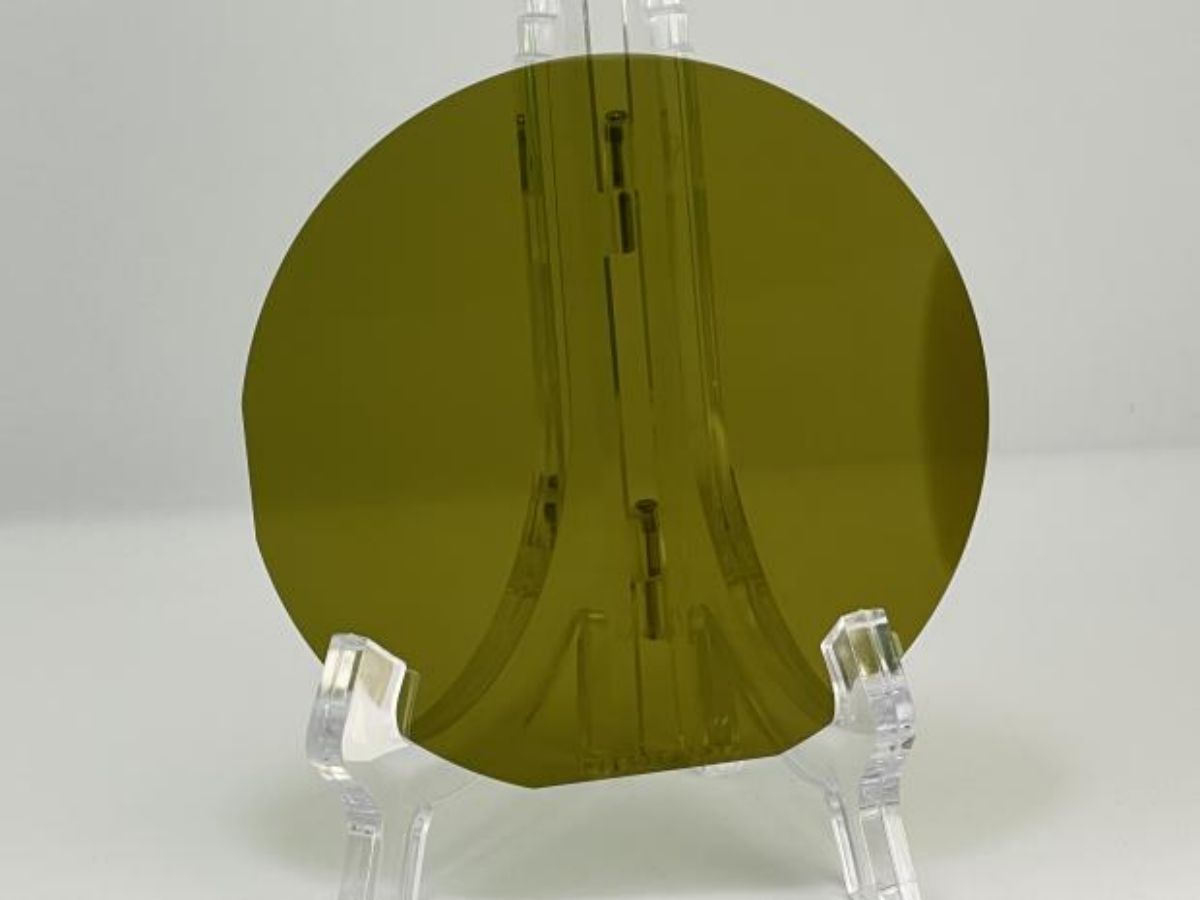

A halin yanzu, akwai manyan nau'ikan wafer na SiC guda biyu. Na farko shi ne walƙiya mai gogewa, wanda shine wafer siliki guda ɗaya. An yi shi da lu'ulu'u na SiC masu tsabta kuma yana iya zama 100mm ko 150mm a diamita. Ana amfani dashi a cikin manyan na'urorin lantarki. Nau'i na biyu shine wafer siliki carbide wafer epitaxial crystal. Ana yin wannan nau'in wafer ta hanyar ƙara wani Layer na silicon carbide crystals zuwa saman. Wannan hanya tana buƙatar daidaitaccen iko na kauri na kayan kuma an san shi da nau'in nau'in N-epitaxy.

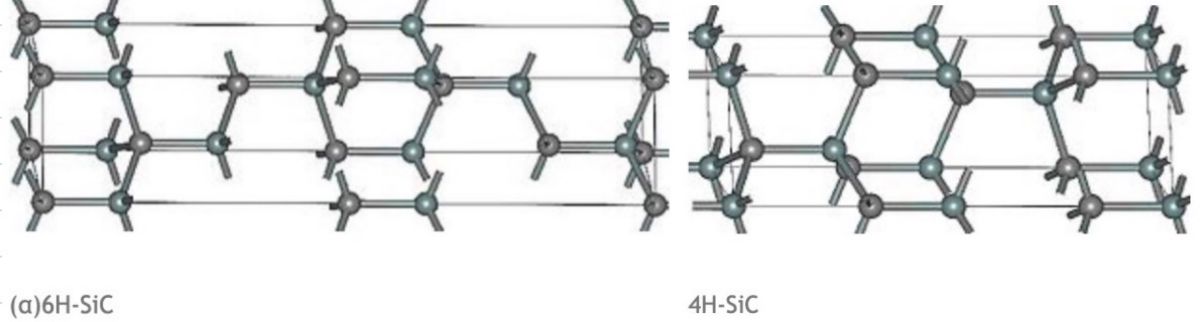

Nau'in na gaba shine beta silicon carbide. Ana samar da Beta SiC a yanayin zafi sama da digiri 1700 ma'aunin Celsius. Alpha carbides sune mafi yawan gama gari kuma suna da tsarin crystal hexagonal mai kama da wurtzite. Sigar beta yayi kama da lu'u-lu'u kuma ana amfani dashi a wasu aikace-aikace. Koyaushe ya kasance zaɓi na farko don samfuran wutar lantarki da aka kammala. A halin yanzu masu samar da wafer na silicon carbide na ɓangare na uku suna aiki akan wannan sabon kayan.

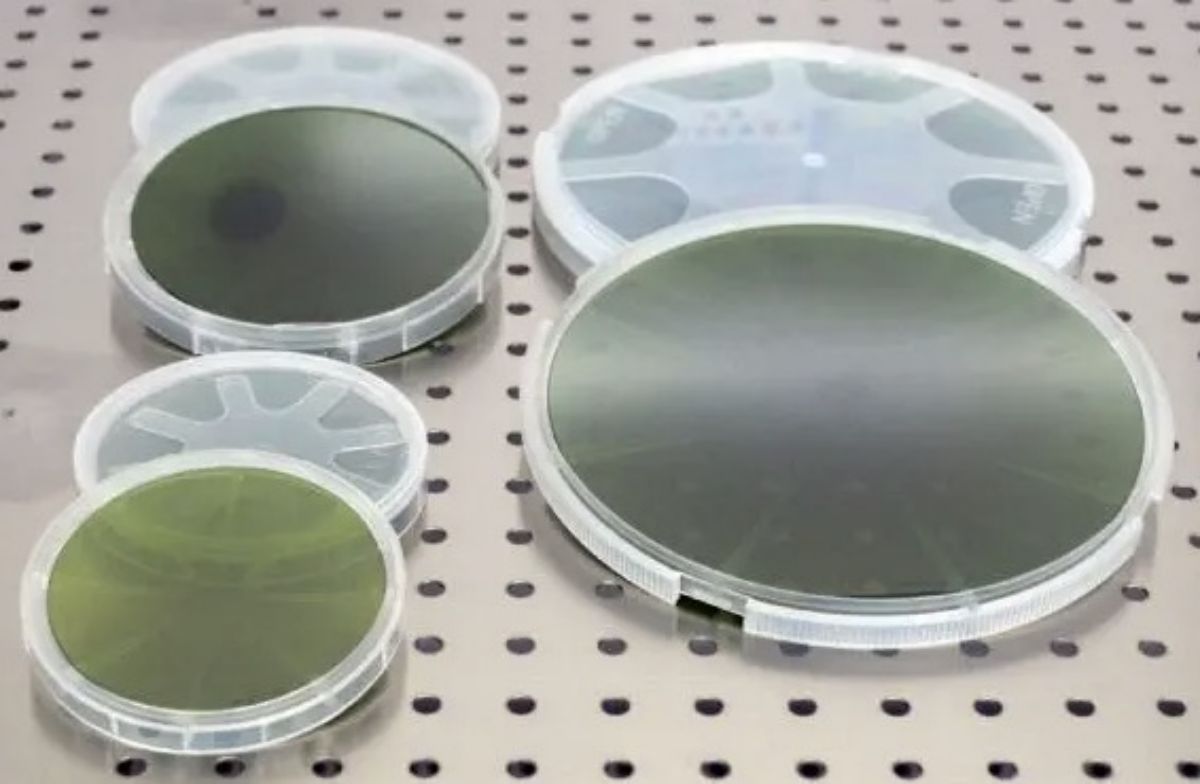

Wafers na ZMSH SiC sune shahararrun kayan semiconductor. Abu ne mai inganci mai inganci wanda ya dace da aikace-aikace da yawa. ZMSH silicon carbide wafers abu ne mai matukar amfani ga na'urorin lantarki iri-iri. ZMSH yana ba da fa'idodi masu yawa na wafers na SiC masu inganci da kayan aiki. Suna samuwa a cikin nau'in N-nau'i da nau'i-nau'i masu rufi.

2--- Silicon Carbide: Zuwa wani sabon zamanin wafers

Kaddarorin jiki da halayen silicon carbide

Silicon carbide yana da tsari na musamman na crystal, yana amfani da tsari mai cike da kusada hexagonal mai kama da lu'u-lu'u. Wannan tsarin yana ba da damar silicon carbide ya sami kyakkyawan yanayin zafi da juriya mai zafi. Idan aka kwatanta da kayan siliki na gargajiya, siliki carbide yana da nisa mafi girma na band, wanda ke ba da tazara mafi girma na rukunin lantarki, yana haifar da mafi girman motsin lantarki da ƙananan ɗigogi na halin yanzu. Bugu da kari, silicon carbide kuma yana da mafi girma electron jikewa drift gudun da ƙananan resistivity na kayan da kanta, samar da mafi kyau yi ga high iko aikace-aikace.

Sharuɗɗan aikace-aikace da abubuwan da ake sa ran silikon carbide wafers

Aikace-aikacen lantarki na wutar lantarki

Silicon carbide wafer yana da fa'idar aikace-aikace a filin lantarki. Saboda girman motsin wutar lantarki da kyakkyawan yanayin zafi, ana iya amfani da wafers na SIC don kera manyan na'urori masu sauyawa, kamar na'urorin wutar lantarki don motocin lantarki da masu canza hasken rana. Babban kwanciyar hankali na siliki carbide wafers yana ba wa waɗannan na'urori damar yin aiki a cikin yanayin zafi mai girma, samar da inganci da aminci.

Aikace-aikacen Optoelectronic

A fagen na'urorin optoelectronic, silicon carbide wafers suna nuna fa'idodinsu na musamman. Silicon carbide abu yana da faffadan halayen rata na band, wanda ke ba shi damar cimma babban makamashi na photonon da ƙarancin haske a cikin na'urorin optoelectronic. Ana iya amfani da wafers na siliki don shirya na'urorin sadarwa masu sauri, masu gano hoto da lasers. Kyawawan halayen yanayin zafi da ƙarancin ƙarancin kristal sun sa ya dace don shirye-shiryen na'urorin optoelectronic masu inganci.

Outlook

Tare da haɓaka buƙatun na'urorin lantarki masu inganci, silicon carbide wafers suna da makoma mai ban sha'awa azaman abu tare da kyawawan kaddarorin da yuwuwar aikace-aikacen fa'ida. Tare da ci gaba da inganta fasahar shirye-shirye da rage farashin, za a inganta aikace-aikacen kasuwanci na siliki carbide wafers. Ana sa ran cewa a cikin 'yan shekaru masu zuwa, siliki carbide wafers sannu a hankali zai shiga kasuwa kuma ya zama babban zaɓi don babban iko, babban mita da aikace-aikacen zafin jiki.

3--- Zurfafa bincike na kasuwar wafer na SiC da yanayin fasaha

Bincike mai zurfi na direbobin kasuwar wafer silicon carbide (SiC).

Haɓaka kasuwar wafer silicon carbide (SiC) tana da tasiri da mahimman abubuwa da yawa, kuma zurfin bincike game da tasirin waɗannan abubuwan akan kasuwa yana da mahimmanci. Ga wasu manyan direbobin kasuwa:

Ajiye makamashi da kariyar muhalli: Babban aiki da ƙananan halayen amfani da wutar lantarki na kayan silicon carbide sun sa ya shahara a fagen ceton makamashi da kariyar muhalli. Bukatar motocin lantarki, masu canza hasken rana da sauran na'urorin canza makamashi suna haifar da haɓakar kasuwa na wafers na silicon carbide saboda yana taimakawa rage sharar makamashi.

Aikace-aikacen Kayan Wutar Lantarki: Silicon carbide ya ƙware a aikace-aikacen lantarki na lantarki kuma ana iya amfani dashi a cikin wutar lantarki a ƙarƙashin matsanancin matsin lamba da yanayin zafin jiki. Tare da yaduwar makamashi mai sabuntawa da haɓaka canjin wutar lantarki, buƙatun siliki carbide wafers a cikin kasuwar lantarki yana ci gaba da ƙaruwa.

SiC wafers na gaba masana'antu ci gaban fasaha yanayin cikakken bincike

Samar da yawan jama'a da rage farashi: Masana'antar wafer ta SiC ta gaba za ta fi mai da hankali kan samarwa da yawa da rage farashi. Wannan ya haɗa da ingantattun fasahohin haɓaka kamar haɓakar tururin sinadarai (CVD) da ɗimbin tururi ta jiki (PVD) don ƙara yawan aiki da rage farashin samarwa. Bugu da kari, ana sa ran daukar matakan samar da hankali da sarrafa kansa zai kara inganta inganci.

Sabon girman wafer da tsari: Girma da tsarin wafers na SiC na iya canzawa a nan gaba don biyan bukatun aikace-aikace daban-daban. Wannan na iya haɗawa da filayen diamita mafi girma, sifofi iri-iri, ko wafers masu yawa don samar da ƙarin sassaucin ƙira da zaɓuɓɓukan aiki.

Ingantacciyar Makamashi da Masana'antar Kore: Samar da wafers na SiC a nan gaba zai ba da fifiko kan ingancin makamashi da masana'anta kore. Kamfanonin da ke da ƙarfi ta hanyar makamashi mai sabuntawa, kayan kore, sake yin amfani da sharar gida da ƙananan hanyoyin samar da carbon za su zama yanayin masana'antu.

Lokacin aikawa: Janairu-19-2024