A cikin haɓakar haɓakar haɓakar masana'antar semiconductor, lu'ulu'u ɗaya da aka gogesiliki waferstaka muhimmiyar rawa. Suna aiki a matsayin kayan mahimmanci don samar da na'urorin microelectronic daban-daban. Daga hadaddun da madaidaitan da'irori masu haɗaka zuwa manyan ma'auni masu sauri da na'urori masu auna firikwensin aiki da yawa, kristal da aka goge.siliki waferssuna da mahimmanci. Bambance-bambance a cikin ayyukansu da ƙayyadaddun bayanai suna tasiri kai tsaye ga inganci da aikin samfuran ƙarshe. A ƙasa akwai ƙayyadaddun ƙayyadaddun ƙayyadaddun bayanai da sigogi na wafer silicon crystal ɗin da aka goge:

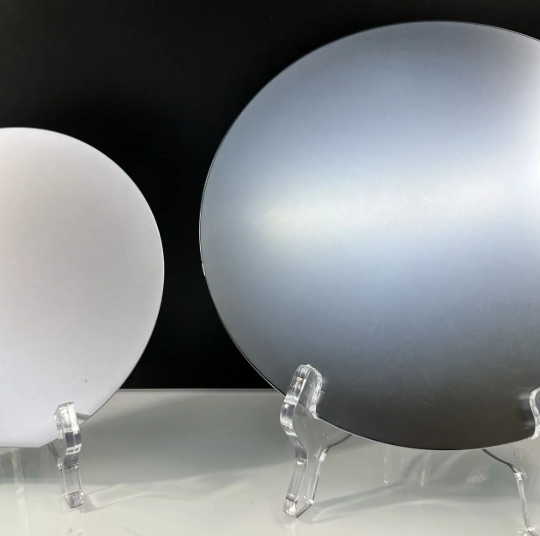

Diamita: Girman semiconductor guda ɗaya kristal wafers ana auna ta da diamita, kuma sun zo cikin ƙayyadaddun bayanai daban-daban. Na kowa diamita sun hada da 2 inci (50.8mm), 3 inci (76.2mm), 4 inci (100mm), 5 inci (125mm), 6 inci (150mm), 8 inci (200mm), 12 inci (300mm), 18 inci (450mm). Diamita daban-daban sun dace da buƙatun samarwa daban-daban da buƙatun tsari. Misali, ana amfani da ƙananan wafers na musamman don na'urorin microelectronic na musamman, yayin da mafi girman diamita yana nuna ingantaccen samarwa da fa'idodin farashi a cikin manyan masana'antar haɗaɗɗun kewaye. Abubuwan buƙatun saman an kasafta su azaman goge gefe ɗaya (SSP) da goge gefe biyu (DSP). Ana amfani da wafer ɗin da aka goge gefe ɗaya don na'urorin da ke buƙatar babban falo a gefe ɗaya, kamar wasu na'urori masu auna firikwensin. Ana amfani da wafers masu goyan bayan gefe biyu don haɗaɗɗun da'irori da sauran samfuran waɗanda ke buƙatar daidaitaccen daidaitattun saman duka biyun. Bukatar saman (Gama): SSP mai goge gefe guda ɗaya / DSP mai goge gefe biyu.

Nau'i/Dopant: (1) Nau'in N-Nau'in Semiconductor: Lokacin da aka shigar da wasu ƙazanta na ƙazanta a cikin semiconductor na ciki, suna canza halayensa. Misali, idan aka kara abubuwan da suka hada da abubuwa kamar nitrogen (N), phosphorus (P), arsenic (As), ko antimony (Sb), su valence electrons suna samar da covalent bond tare da valence electrons na kewayon atom na silicon, suna barin karin wutar lantarkin da ba a daure ta da covalent bond. Wannan yana haifar da ƙwayar lantarki mafi girma fiye da ramin ramuka, samar da nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'in lantarki. Nau'in semiconductor na nau'in N suna da mahimmanci a cikin na'urorin kera waɗanda ke buƙatar electrons azaman manyan masu ɗaukar kaya, kamar wasu na'urorin wuta. (2) Semiconductor na nau'in P: Lokacin da abubuwa masu ƙazanta irin su boron (B), gallium (Ga), ko indium (In) aka shigar da su a cikin siliki semiconductor, valence electrons na ƙazanta na ƙazanta suna yin haɗin gwiwa tare da ƙwayoyin silicon da ke kewaye, amma ba su da aƙalla valence electron kuma ba za su iya samar da cikakkiyar haɗin gwiwa ba. Wannan yana haifar da ramuka mai girma fiye da na'urar lantarki, samar da nau'in nau'in nau'in P, wanda kuma aka sani da nau'in semiconductor. Semiconductor nau'in P suna taka muhimmiyar rawa wajen kera na'urori inda ramuka ke aiki a matsayin manyan masu ɗaukar kaya, kamar diodes da wasu transistor.

Resistivity: Juriya shine maɓalli maɓalli na jiki wanda ke auna ƙarfin ƙarfin lantarki na wafers silicon crystal ɗin da aka goge. Ƙimar sa tana nuna aikin sarrafa kayan. Ƙananan juriya, mafi kyawun abin da ke cikin wafer silicon; akasin haka, mafi girma da resistivity, da matalauta da conductivity. Resistivity na siliki wafers an ƙaddara ta hanyar abubuwan da ke tattare da su, kuma zafin jiki yana da tasiri mai mahimmanci. Gabaɗaya, juriya na wafer siliki yana ƙaruwa da zafin jiki. A aikace-aikace masu amfani, na'urorin microelectronic daban-daban suna da buƙatun tsayayya daban-daban don wafern silicon. Misali, wafers da aka yi amfani da su a haɗaɗɗen kera da'ira suna buƙatar daidaitaccen iko na juriya don tabbatar da ingantaccen aiki na na'ura.

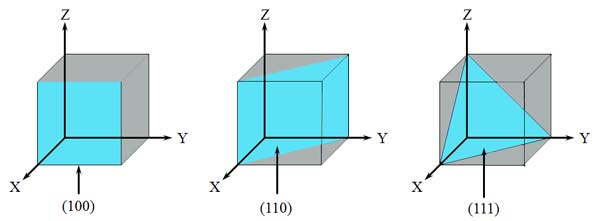

Gabatarwa: Tsarin lu'ulu'u na wafer yana wakiltar jagorar crystallographic na lattice silicon, yawanci ƙayyadaddun fihirisar Miller kamar (100), (110), (111), da sauransu. Wannan bambance-bambance na iya shafar aikin wafer a matakan sarrafawa na gaba da aikin ƙarshe na na'urorin microelectronic. A cikin tsarin masana'antu, zaɓar wafer silicon tare da daidaitawar da ta dace don buƙatun na'urori daban-daban na iya haɓaka aikin na'urar, haɓaka haɓakar samarwa, da haɓaka ingancin samfur.

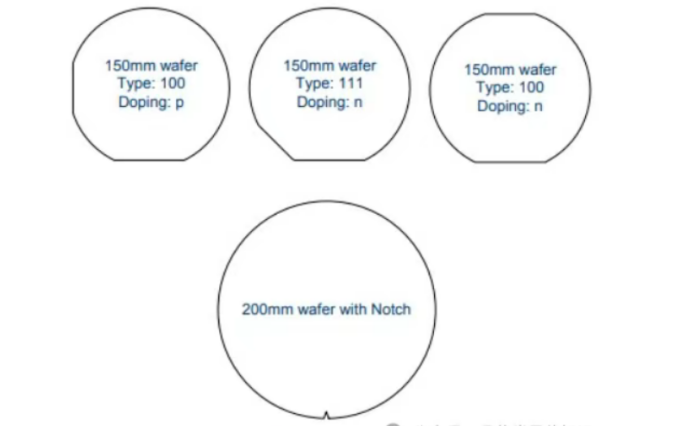

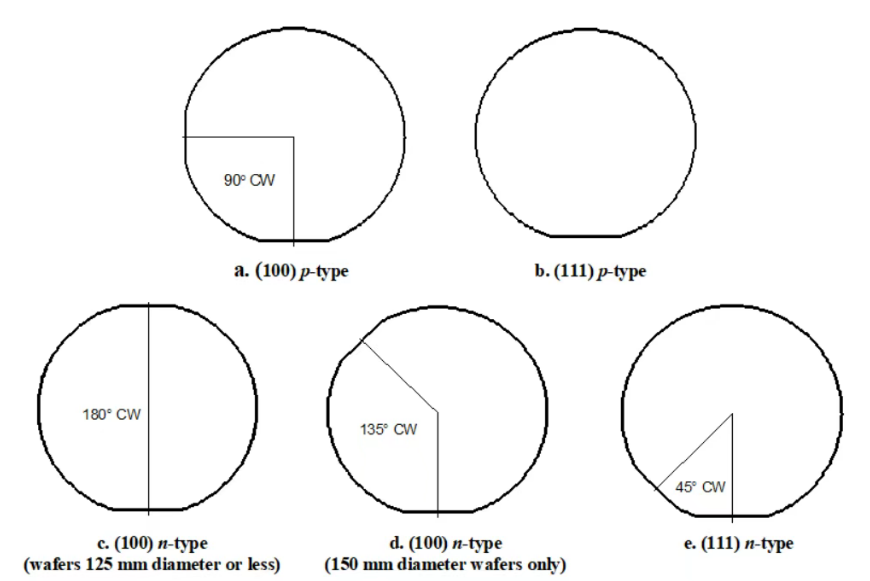

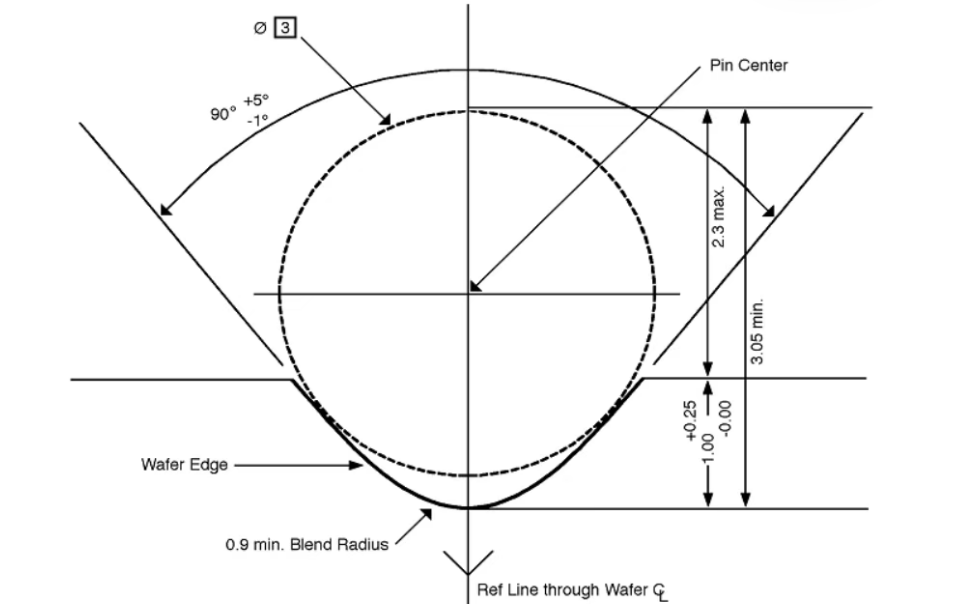

Flat/Notch: Lebur gefen (Flat) ko V-notch (Notch) akan kewayen wafer siliki yana taka muhimmiyar rawa a daidaita daidaitawar crystal kuma muhimmin mai ganowa a cikin masana'anta da sarrafa wafer. Wafers na diamita daban-daban sun dace da ma'auni daban-daban don tsayin Flat ko Notch. An rarraba gefuna masu daidaitawa zuwa firamare flat da sakandare. Ana amfani da firamare na farko don tantance ainihin madaidaicin kristal da ma'anar sarrafa wafer, yayin da ɗakin sakandaren ya ƙara taimakawa a daidai daidaitawa da sarrafawa, yana tabbatar da ingantaccen aiki da daidaiton wafer a duk layin samarwa.

Kauri: An ƙayyade kauri na wafer a cikin micrometers (μm), tare da kauri na gama gari tsakanin 100μm da 1000μm. Wafers na kauri daban-daban sun dace da nau'ikan na'urorin microelectronic daban-daban. Ƙananan wafers (misali, 100μm - 300μm) ana amfani da su sau da yawa don masana'antar guntu wanda ke buƙatar kulawa mai mahimmanci, rage girman da nauyin guntu da ƙara yawan haɗin kai. Ƙaƙƙarfan wafers (misali, 500μm - 1000μm) ana amfani da su sosai a cikin na'urorin da ke buƙatar ƙarfin injiniya mafi girma, irin su na'urorin semiconductor, don tabbatar da kwanciyar hankali yayin aiki.

Roughness na Surface: Ƙarfin saman yana ɗaya daga cikin mahimman sigogi don kimanta ingancin wafer, saboda kai tsaye yana rinjayar mannewa tsakanin wafer da kayan fim na bakin ciki na gaba, da kuma aikin lantarki na na'urar. Yawancin lokaci ana bayyana shi azaman tushen ma'anar murabba'i (RMS) roughness (a nm). Ƙarƙashin ƙarancin ƙasa yana nufin saman wafer ya fi santsi, wanda ke taimakawa rage al'amura kamar watsawar lantarki da inganta aikin na'urar da aminci. A ci-gaba na semiconductor masana'antu tafiyar matakai, surface roughness bukatun suna ƙara stringent, musamman ga high-karshen hadedde kewaye da'ira, inda surface roughness dole ne a sarrafa zuwa ƴan nanometers ko ma kasa.

Jimlar Bambancin Kauri (TTV): Jimlar bambancin kauri yana nufin bambanci tsakanin matsakaicin matsakaici da mafi ƙarancin kauri da aka auna a wurare da yawa akan saman wafer, yawanci ana bayyana a cikin μm. Babban TTV na iya haifar da sabani a cikin matakai kamar photolithography da etching, tasiri daidaitaccen aikin na'urar da yawan amfanin ƙasa. Don haka, sarrafa TTV yayin masana'antar wafer shine babban mataki na tabbatar da ingancin samfur. Don ƙera na'urorin microelectronic madaidaici, ana buƙatar TTV yawanci ya kasance tsakanin ƴan mitoci kaɗan.

Baka: Baka tana nufin karkacewa tsakanin saman wafer da madaidaicin jirgin sama, yawanci ana auna shi cikin μm. Wafers tare da yawan ruku'u na iya karya ko fuskanci damuwa mara daidaituwa yayin aiki na gaba, yana shafar ingancin samarwa da ingancin samfur. Musamman a cikin matakan da ke buƙatar babban lebur, kamar hoto na hoto, dole ne a sarrafa ruku'u a cikin takamaiman kewayon don tabbatar da daidaito da daidaiton ƙirar hoto.

Warp: Warp yana nuna karkatar da ke tsakanin farfajiyar wafer da madaidaicin siffar siffa, kuma ana auna shi cikin μm. Hakazalika da baka, warp alama ce mai mahimmanci na wafer flatness. Yaƙi da yawa ba wai kawai yana rinjayar daidaiton jeri na wafer a cikin kayan sarrafawa ba amma kuma yana iya haifar da al'amura yayin aiwatar da marufi na guntu, kamar ƙarancin haɗin gwiwa tsakanin guntu da kayan tattarawa, wanda hakan ke shafar amincin na'urar. A cikin manyan masana'antar semiconductor, buƙatun warp suna ƙara ɗorewa don biyan buƙatun masana'antar guntu na ci gaba da tsarin marufi.

Bayanin Bayanin Edge: Bayanan martaba na gefen wafer yana da mahimmanci don sarrafawa da sarrafa sa na gaba. Yawanci ana ayyana shi ta Yankin Exclusion na Edge (EEZ), wanda ke bayyana nisa daga gefen wafer inda ba a yarda da sarrafawa ba. Bayanan martabar da aka ƙera da kyau da madaidaicin kulawar EEZ na taimakawa wajen guje wa lahani, yawan damuwa, da sauran batutuwa yayin aiki, haɓaka ƙimar wafer gabaɗaya da yawan amfanin ƙasa. A wasu ci-gaba na masana'antu matakai, ana buƙatar madaidaicin bayanin martaba don kasancewa a matakin ƙananan micron.

Barbashi Count: Lamba da girman rarraba barbashi a kan wafer surface muhimmanci rinjayar aikin microelectronic na'urorin. Wuce kima ko manyan barbashi na iya haifar da gazawar na'urar, kamar gajeriyar da'ira ko ɗigowa, rage yawan amfanin samfur. Don haka, ana auna ƙidayar barbashi ta hanyar kirga barbashi a kowane yanki, kamar adadin barbashi da ya fi 0.3μm girma. Ƙuntataccen iko na ƙididdige ɓangarorin yayin masana'antar wafer shine ma'auni mai mahimmanci don tabbatar da ingancin samfur. Ana amfani da ingantattun fasahohin tsaftacewa da tsaftataccen muhallin samarwa don rage gurɓacewar barbashi a saman wafer.

![]()

![]()

![]()

![]()

![]()

Samar da alaƙa

Single Crystal Silicon Wafer Si Substrate Nau'in N/P Zaɓaɓɓen Silicon Carbide Wafer

FZ CZ Si wafer a cikin hannun jari 12inch Silicon wafer Prime ko Gwaji

Lokacin aikawa: Afrilu-18-2025