A matsayin na uku-ƙarni semiconductor abu substrate abu,silicon carbide (SiC)kristal guda ɗaya yana da fa'idodin aikace-aikace masu fa'ida a cikin kera na'urorin lantarki masu ƙarfi da ƙarfi. Fasahar sarrafa kayan aikin SiC tana taka muhimmiyar rawa wajen samar da ingantattun kayan ƙasa. Wannan labarin ya gabatar da halin da ake ciki na bincike kan fasahar sarrafa SiC a cikin kasar Sin da kuma kasashen waje, yin nazari da kwatanta hanyoyin yankan, nika, da goge-goge, da kuma abubuwan da ke faruwa a cikin wafer flatness da roughness surface roughness. Hakanan yana nuna ƙalubalen da ke akwai a cikin sarrafa wafer na SiC da kuma tattauna hanyoyin ci gaban gaba.

Silicon carbide (SiC)wafers sune mahimman kayan tushe don na'urorin semiconductor na ƙarni na uku kuma suna riƙe mahimmancin mahimmanci da yuwuwar kasuwa a fannoni kamar microelectronics, lantarki, da hasken wutar lantarki. Saboda musamman high taurin da sinadaran kwanciyar hankali naSiC guda lu'ulu'u, Hanyoyin sarrafa semiconductor na al'ada ba su dace da aikin injin su gaba ɗaya ba. Kodayake yawancin kamfanonin ƙasa da ƙasa sun gudanar da bincike mai zurfi game da buƙatar fasaha na fasaha na SiC guda lu'ulu'u, fasahar da ta dace ana kiyaye su sosai.

A cikin 'yan shekarun nan, kasar Sin ta kara yunƙurin samar da kayayyaki da na'urori na SiC guda kristal. Koyaya, ci gaban fasahar na'urar SiC a cikin ƙasa a halin yanzu yana takura ta hanyar iyakancewa wajen sarrafa fasahohin da ingancin wafer. Sabili da haka, yana da mahimmanci ga kasar Sin don inganta ikon sarrafa SiC don haɓaka ingancin sinadarai guda ɗaya na SiC da cimma aikace-aikacen su da yawa.

Babban matakan sarrafawa sun haɗa da: yankan → ƙwanƙwasa → niƙa mai kyau → polishing mai ƙaƙƙarfan polishing (don gyaran injiniya) → polishing mai kyau (likitanci na injiniya, CMP) → dubawa.

| Mataki | SiC Wafer Processing | Semiconductor Traditional Semiconductor Single-Crystal Material Processing |

| Yanke | Yana amfani da fasahar sawing na wayoyi da yawa don yanki SiC ingots cikin siraran wafers | Yawanci yana amfani da dabarun yankan ruwan diamita na ciki ko diamita |

| Nika | Rarraba cikin niƙa mai laushi da lafiya don cire alamun gani da lalata yadudduka da yanke | Hanyoyin niƙa na iya bambanta, amma burin ɗaya ne |

| goge baki | Ya haɗa da m da matsananci-daidaici polishing ta amfani da inji da kuma sinadaran polishing (CMP) | Yawancin lokaci ya haɗa da polishing inji (CMP), kodayake takamaiman matakai na iya bambanta |

Yanke na SiC Single Crystals

A cikin sarrafa naSiC guda lu'ulu'u, yankan shine mataki na farko kuma mai matukar mahimmanci. Bakan wafer, warp, da jimlar kauri (TTV) wanda ya samo asali daga tsarin yanke yana ƙayyade inganci da ingancin ayyukan niƙa da gogewa na gaba.

Za a iya rarraba kayan aikin yanka ta hanyar siffa zuwa madaidaitan lu'u-lu'u na ciki (ID) saws, diamita na waje (OD), saws na bandeji, da saws na waya. Waya saws, bi da bi, ana iya rarraba su ta nau'in motsi zuwa tsarin madauki da madauki (marasa iyaka). Dangane da tsarin yankan na abrasive, waya saw dabaru za a iya raba iri biyu: free abrasive waya sawing da abrasive lu'u-lu'u sawing sawing.

1.1 Hanyoyin Yankan Gargajiya

Zurfin yankan diamita na waje (OD) saws yana iyakance ta diamita na ruwa. A lokacin aikin yankan, ruwan wukake yana da sauƙi ga girgizawa da karkatarwa, yana haifar da matakan amo da rashin ƙarfi. Diamita na ciki (ID) saws suna amfani da abrasives lu'u-lu'u akan kewayen ciki na ruwa azaman yankan gefen. Wadannan ruwan wukake na iya zama bakin ciki kamar 0.2 mm. Yayin yankan, igiyar ID tana jujjuya da sauri yayin da kayan da za'a yanke ke tafiya da radially dangane da tsakiyar ruwan, yana samun slicing ta wannan motsi na dangi.

Gilashin band ɗin lu'u-lu'u yana buƙatar tsayawa akai-akai da juyawa, kuma saurin yankan yana da ƙasa sosai - yawanci bai wuce 2 m/s ba. Har ila yau, suna fama da gagarumin lalacewa na inji da kuma tsadar kulawa. Saboda nisa na sawdust, radius yankan ba zai iya zama ƙanƙanta ba, kuma yankan yanki da yawa ba zai yiwu ba. Waɗannan kayan aikin sawing na al'ada suna iyakance ta taurin tushe kuma ba za su iya yin yankan lanƙwasa ba ko kuma sun hana juyawa radii. Suna iya kawai yanke madaidaiciya, suna samar da kerfs masu faɗi, suna da ƙarancin yawan amfanin ƙasa, don haka ba su dace da yanke ba.SiC crystals.

1.2 Kyautar Waya Mai Kashe Waya Ya Gani Yankan Waya da yawa

Dabarar slicing waya kyauta tana amfani da saurin motsi na waya don ɗaukar slurry cikin kerf, yana ba da damar cire kayan. Da farko yana amfani da tsari mai jujjuyawa kuma a halin yanzu hanya ce ta balagagge kuma ana amfani da ita sosai don ingantaccen yankan wafer da yawa na silicon-crystal guda. Koyaya, aikace-aikacen sa a cikin yankan SiC ba a yi nazari sosai ba.

Waya saws na abrasive kyauta na iya sarrafa wafers tare da kauri da bai wuce μm 300 ba. Suna bayar da ƙarancin asarar kerf, da wuya suna haifar da guntuwa, kuma suna haifar da ingantacciyar ingancin farfajiya. Duk da haka, saboda tsarin cire kayan abu - bisa ga jujjuyawa da shigar da abrasives - saman wafer yana kula da haɓaka damuwa mai saura, microcracks, da zurfin lalacewa. Wannan yana haifar da warping wafer, yana da wahala a sarrafa daidaiton bayanin martaba, kuma yana ƙara nauyi akan matakan sarrafawa na gaba.

Aikin yankan yana da tasiri sosai ta hanyar slurry; wajibi ne a kula da kaifi na abrasives da ƙaddamar da slurry. Maganin slurry da sake amfani da su suna da tsada. Lokacin yanke manyan ingots masu girma, abrasives suna da wahalar shiga cikin kerfs mai zurfi da tsayi. Ƙarƙashin girman hatsi iri ɗaya, asarar kerf ya fi na ƙayyadaddun igiyar waya.

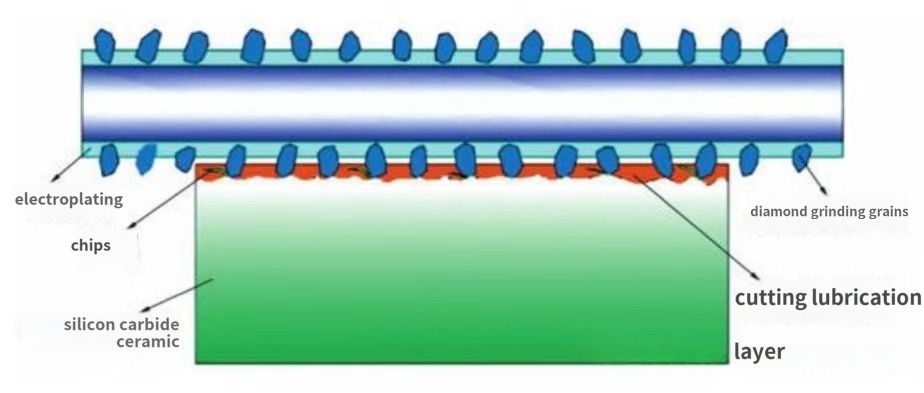

1.3 Kafaffen Abrasive Diamond Waya Ga Yankan Waya da yawa

Kafaffen igiya na lu'u-lu'u masu ɗorewa galibi ana yin su ta hanyar sanya barbashi na lu'u-lu'u a kan madaidaicin waya ta ƙarfe ta hanyar haɗa wutar lantarki, sintering, ko hanyoyin haɗin gwiwar guduro. Zaɓuɓɓukan waya na lu'u-lu'u da aka zaɓa suna ba da fa'idodi irin su kunkuntar kerfs, mafi kyawun yanki, inganci mafi girma, ƙarancin gurɓatawa, da ikon yanke kayan tauri.

Wayar lu'u-lu'u mai jujjuyawar wutar lantarki a halin yanzu ita ce hanyar da aka fi amfani da ita don yanke SiC. Hoto na 1 (ba a nuna a nan ba) yana kwatanta saman shimfidar wafers na SiC da aka yanke ta amfani da wannan fasaha. Yayin da yankan ke ci gaba, wafer warpage yana ƙaruwa. Wannan saboda yankin lamba tsakanin waya da kayan yana ƙaruwa yayin da waya ke motsawa ƙasa, ƙara juriya da girgiza waya. Lokacin da waya ta kai matsakaicin diamita na wafer, girgizar tana kan iyakarsa, yana haifar da iyakar yaƙi.

A cikin matakai na gaba na yanke, saboda wayar da ke fuskantar hanzari, motsi mai tsayi, raguwa, tsayawa, da juyawa, tare da matsalolin cire tarkace tare da mai sanyaya, ingancin wafer yana lalacewa. Juyawar waya da jujjuyawar sauri, da kuma manyan ɓangarorin lu'u-lu'u akan wayar, sune farkon abubuwan da ke haifar da karce.

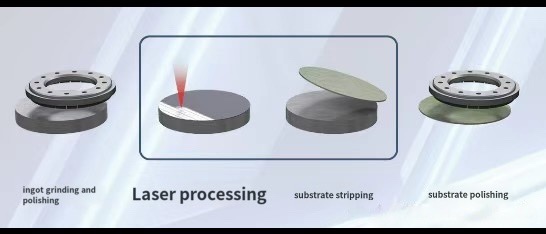

1.4 Fasahar Rabewar sanyi

Rabuwar sanyi na SiC guda lu'ulu'u shine sabon tsari a fagen sarrafa kayan sinadarai na ƙarni na uku. A cikin 'yan shekarun nan, ya jawo hankali sosai saboda sanannen fa'idarsa wajen inganta yawan amfanin ƙasa da rage asarar kayan abu. Ana iya nazarin fasahar daga bangarori uku: ka'idar aiki, kwararar tsari, da fa'idodin mahimmanci.

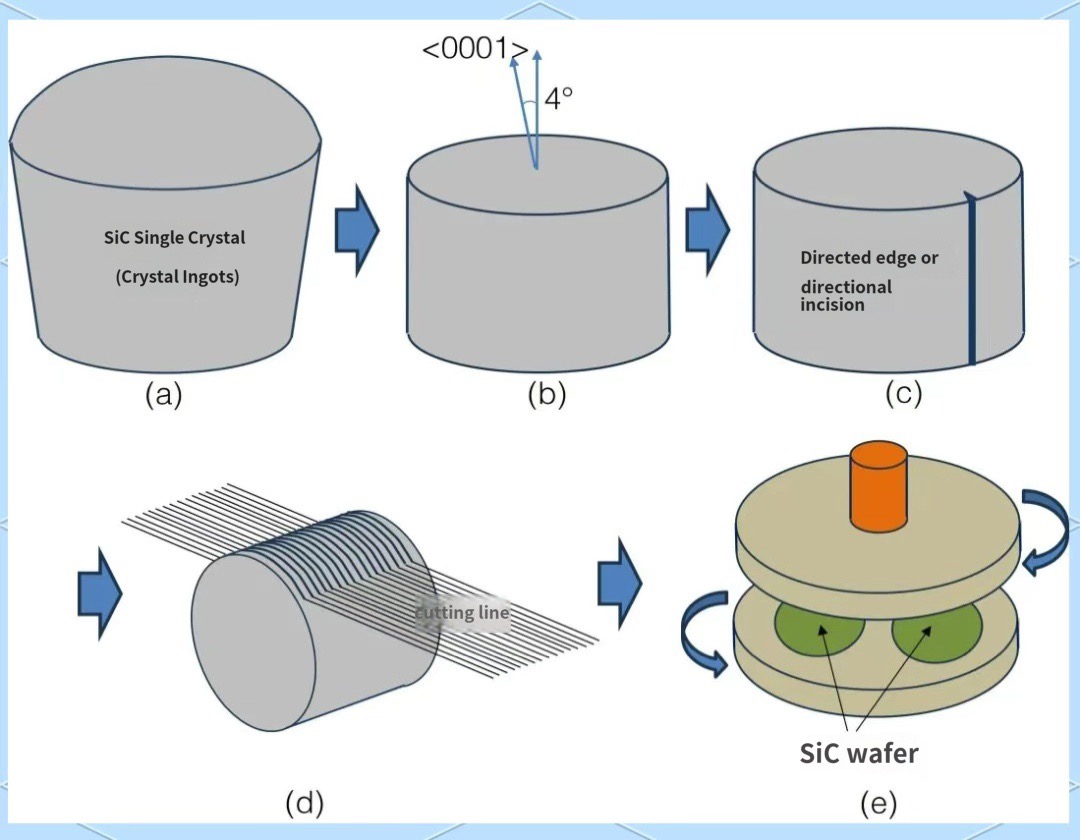

Ƙayyadaddun Ƙaddamarwar Crystal da Niƙa na Diamita na Waje: Kafin aiki, dole ne a ƙididdige madaidaicin ƙira na SiC ingot. Ana siffanta ingot ɗin zuwa tsarin siliki (wanda aka fi sani da SiC puck) ta hanyar niƙa diamita na waje. Wannan matakin yana kafa harsashin yankewa na gaba da yankewa.

Yankan Waya da yawa: Wannan hanyar tana amfani da barbashi masu ɓarna haɗe tare da yankan wayoyi don yanki ingot ɗin silinda. Koyaya, yana fama da babban asarar kerf da al'amuran rashin daidaituwa.

Fasaha Yanke Laser: Ana amfani da Laser don samar da gyare-gyaren Layer a cikin crystal, wanda za'a iya cire ɓangarorin bakin ciki daga ciki. Wannan tsarin yana rage asarar kayan abu kuma yana haɓaka ingantaccen aiki, yana mai da shi sabon alƙawarin sabon jagora don yankan wafer na SiC.

Inganta Tsarin Yanke

Kafaffen Abrasive Multi-Wire Yanke: Wannan a halin yanzu shine fasaha na yau da kullun, wanda ya dace da manyan halayen taurin SiC.

Kayan Kayan Wutar Lantarki (EDM) da Fasahar Rarraba Cold: Waɗannan hanyoyin suna ba da mafita iri-iri waɗanda aka keɓance da takamaiman buƙatu.

Tsarin goge goge: Yana da mahimmanci don daidaita ƙimar cire kayan abu da lalacewar ƙasa. Ana amfani da Polishing Mechanical Mechanical (CMP) don inganta daidaiton saman.

Sa Ido-lokacin-Gaskiya: Ana gabatar da fasahohin binciken kan layi don saka idanu kan rashin ƙarfi a cikin ainihin lokaci.

Laser Slicing: Wannan dabarar tana rage asarar kerf kuma tana gajarta zagayowar sarrafawa, kodayake yankin da zafin jiki ya shafa ya kasance kalubale.

Hybrid Processing Technologies: Haɗa hanyoyin inji da sinadarai suna haɓaka haɓakar sarrafawa.

Wannan fasaha ta riga ta cimma aikace-aikacen masana'antu. Infineon, alal misali, ya sami SILTECTRA kuma yanzu yana riƙe da ainihin haƙƙin mallaka wanda ke tallafawa yawan samar da wafers 8-inch. A kasar Sin, kamfanoni irin su Delong Laser sun sami nasarar samar da kayan aiki na wafers 30 a kowace ingot don sarrafa wafer mai inci 6, wanda ke wakiltar haɓaka 40% akan hanyoyin gargajiya.

Kamar yadda masana'antar kayan aikin cikin gida ke haɓaka, ana tsammanin wannan fasahar za ta zama babban mafita don sarrafa sinadarai na SiC. Tare da karuwar diamita na kayan semiconductor, hanyoyin yankan gargajiya sun zama mara amfani. Daga cikin zaɓuɓɓukan yanzu, fasahar gani na wayar lu'u-lu'u mai jujjuyawa tana nuna mafi kyawun fatan aikace-aikacen. Yanke Laser, azaman fasaha mai tasowa, yana ba da fa'idodi masu mahimmanci kuma ana tsammanin ya zama hanyar yanke na farko a nan gaba.

2,SiC Single Crystal Niƙa

A matsayin wakilin semiconductors na ƙarni na uku, silicon carbide (SiC) yana ba da fa'idodi masu mahimmanci saboda fa'idar bandgap ɗin sa, babban filin lantarki mai lalacewa, babban saturation electron drift drift, da kyakkyawan yanayin zafi. Waɗannan kaddarorin suna sa SiC ta fi fa'ida musamman a cikin aikace-aikacen wutar lantarki mai ƙarfi (misali, mahallin 1200V). Fasahar sarrafa kayan masarufi na SiC muhimmin bangare ne na kera na'urar. Ingancin saman da madaidaicin ƙwanƙwasa kai tsaye yana shafar ingancin Layer epitaxial da aikin na'urar ƙarshe.

Babban manufar aikin niƙa shine cire alamun gani na saman da lalata yadudduka da aka haifar yayin yanka, da kuma gyara nakasar da tsarin yanke ya jawo. Ganin girman taurin SiC, niƙa na buƙatar yin amfani da kayan goge baki kamar boron carbide ko lu'u-lu'u. Ana rarraba niƙa na al'ada zuwa niƙa maras kyau da niƙa mai kyau.

2.1 Kyakkyawar nika da Niƙa mai kyau

Ana iya rarraba niƙa bisa ga girman ɓangarorin abrasive:

Nika mai ƙanƙara: Yana amfani da abrasives mafi girma da farko don cire alamun gani da lalata yadudduka da aka haifar yayin yankan, haɓaka ingantaccen aiki.

Nika Mai Kyau: Yana amfani da abrasives mafi kyawu don cire ɓangarorin lalacewa ta wurin niƙa mai ƙaƙƙarfan niƙa, rage ƙaƙƙarfan saman, da haɓaka ingancin saman.

Yawancin masana'antun SiC na gida suna amfani da manyan matakan samarwa. Hanyar gama gari ta ƙunshi niƙa mai gefe biyu ta amfani da farantin ƙarfe na simintin ƙarfe da slurry na lu'u-lu'u monocrystalline. Wannan tsari yana kawar da ɓarnar ɓarnar da aka bari ta hanyar tsinken waya, yana gyara sifar wafer, kuma yana rage TTV (Total Thickness Variation), Bow, da Warp. Adadin cire kayan yana da ƙarfi, yawanci ya kai 0.8-1.2 μm/min. Koyaya, saman wafer ɗin da aka samu shine matte tare da ƙarancin ƙarancin inganci - yawanci kusan 50 nm - wanda ke sanya buƙatu mafi girma akan matakan gogewa na gaba.

2.2 Nika mai gefe guda

Tsarin niƙa mai gefe guda ɗaya kawai gefe ɗaya na wafer a lokaci ɗaya. A yayin wannan aikin, ana ɗora wafern akan farantin karfe. Ƙarƙashin matsa lamba, ma'aunin yana jurewa kadan nakasawa, kuma saman saman yana lanƙwasa. Bayan nika, ƙananan saman yana daidaitawa. Lokacin da aka cire matsa lamba, saman saman yana ƙoƙari ya dawo zuwa ainihin siffarsa, wanda kuma yana rinjayar ƙasa da ƙasa - yana haifar da ɓarna biyu da raguwa a cikin kwanciyar hankali.

Bugu da ƙari, farantin niƙa na iya zama maɗaukaki a cikin ɗan gajeren lokaci, yana sa wafer ya zama convex. Don kula da shimfidar farantin, ana buƙatar yin sutura akai-akai. Saboda ƙarancin inganci da ƙarancin wafer flatness, niƙa mai gefe ɗaya bai dace da samar da taro ba.

Yawanci, # 8000 ƙafafun niƙa ana amfani da su don niƙa mai kyau. A Japan, wannan tsari yana da ɗan girma kuma har yana amfani da ƙafafun #30000 na goge goge. Wannan yana ba da damar daɗaɗɗen wafers ɗin da aka sarrafa su isa ƙasa da 2 nm, yin wafers a shirye don CMP na ƙarshe (Chemical Mechanical Polishing) ba tare da ƙarin sarrafawa ba.

2.3 Fasahar Bakin Gindi Mai Sided Guda

Diamond Single-Sided Thinning Technology wata sabuwar hanya ce ta niƙa gefe guda. Kamar yadda aka kwatanta a hoto na 5 (ba a nuna a nan ba), tsarin yana amfani da farantin niƙa mai ɗaure da lu'u-lu'u. Ana gyara wafer ta hanyar tallan injin, yayin da wafer da dabaran niƙa na lu'u-lu'u suna juyawa lokaci guda. Dabarar niƙa a hankali tana motsawa zuwa ƙasa don siriri wafer zuwa kaurin manufa. Bayan an gama ɗaya gefe, ana jujjuya wafer ɗin don sarrafa ɗaya gefen.

Bayan thinning, wafer 100 mm zai iya cimma:

Baka <5 μm

TTV <2 μm

Ƙunƙarar saman <1 nm

Wannan hanyar sarrafa wafer guda ɗaya yana ba da kwanciyar hankali, ingantaccen daidaito, da ƙimar cire kayan abu mai girma. Idan aka kwatanta da niƙa mai gefe biyu na al'ada, wannan dabarar tana haɓaka haɓakar niƙa da sama da 50%.

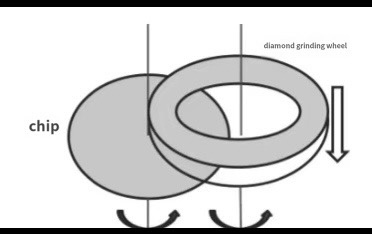

2.4 Nika mai gefe biyu

Nika mai gefe biyu yana amfani da farantin nika na sama da na ƙasa don niƙa ɓangarorin biyu a lokaci guda, yana tabbatar da kyakkyawan ingancin farfajiya a ɓangarorin biyu.

A yayin aiwatar da aikin, faranti na niƙa suna fara matsa lamba zuwa mafi girman maki na kayan aikin, haifar da nakasawa da cire kayan a hankali a waɗannan wuraren. Yayin da manyan tabo suna daidaitawa, matsa lamba akan ma'aunin a hankali ya zama iri ɗaya, yana haifar da nakasar da ta dace a duk faɗin. Wannan yana ba da damar duka na sama da na ƙasa su zama ƙasa daidai. Da zarar an gama niƙa kuma an saki matsin lamba, kowane ɓangaren da ake amfani da shi yana murmurewa daidai gwargwado saboda matsi daidai da ya samu. Wannan yana haifar da ƙarancin warping da kyau flatness.

Ƙaƙƙarfan walƙiya bayan niƙa ya dogara da girman barbashi - ƙananan barbashi suna samar da filaye masu santsi. Lokacin amfani da abrasives 5 μm don niƙa mai gefe biyu, za'a iya sarrafa ƙarancin wafer da bambancin kauri a cikin 5 μm. Atomic Force Microscope (AFM) ma'auni yana nuna rashin ƙarfi (Rq) na kusan 100 nm, tare da ramukan niƙa har zuwa zurfin 380 nm da alamun layin layi wanda aka haifar da aikin abrasive.

Hanya mafi ci gaba ta haɗa da niƙa mai gefe biyu ta amfani da pad ɗin kumfa na polyurethane haɗe da lu'u-lu'u na polycrystalline. Wannan tsari yana samar da wafers tare da ƙarancin ƙarancin ƙasa, cimma Ra <3 nm, wanda ke da fa'ida sosai don gogewar sifofin SiC na gaba.

Koyaya, zazzage saman ƙasa ya kasance batun da ba a warware shi ba. Bugu da ƙari, lu'u lu'u-lu'u na polycrystalline da ake amfani da shi a cikin wannan tsari ana samar da shi ta hanyar hada abubuwa masu fashewa, wanda ke da kalubale a fasaha, yana samar da ƙananan yawa, kuma yana da tsada sosai.

Gyaran SiC Single Crystals

Don cimma ingantaccen ingantaccen farfajiya akan wafers ɗin silicon carbide (SiC), polishing ɗin dole ne ya cire gaba ɗaya ramukan niƙa da sikelin saman nanometer. Manufar ita ce samar da ƙasa mai santsi, mara lahani ba tare da gurɓatawa ko lalacewa ba, babu lalacewar ƙasa, kuma babu ragowar damuwa.

3.1 Gyaran Injini da CMP na SiC Wafers

Bayan haɓakar ingot na SiC guda ɗaya, lahani na saman yana hana yin amfani da shi kai tsaye don haɓakar epitaxial. Saboda haka, ana buƙatar ƙarin aiki. Ingot an fara siffata shi zuwa daidaitaccen nau'i na silinda ta hanyar zagaye, sannan a yanka shi cikin wafers ta amfani da yankan waya, sannan kuma tabbatar da daidaitawar crystallographic. Polishing mataki ne mai mahimmanci don haɓaka ingancin wafer, magance yuwuwar lalacewar saman ƙasa da lahani na ci gaban kristal ke haifar da matakan sarrafawa.

Akwai manyan hanyoyi guda huɗu don cire yadudduka lalacewa akan SiC:

Gyaran injina: Sauƙaƙe amma ya bar karce; dace da farko polishing.

Chemical Mechanical Polishing (CMP): Yana kawar da karce ta hanyar etching sinadaran; dace da daidaito polishing.

Hydrogen etching: Yana buƙatar hadaddun kayan aiki, waɗanda aka saba amfani da su a cikin hanyoyin HTCVD.

Plasma-taimaka goge goge: Haɗaɗɗe kuma ba kasafai ake amfani dashi ba.

Gyaran injina-kawai yana haifar da ɓarna, yayin da goge-gwiwar sinadarai kawai zai iya haifar da rashin daidaituwa. CMP ya haɗu da fa'idodi guda biyu kuma yana ba da ingantaccen, mafita mai tsada.

Ka'idodin Aiki na CMP

CMP yana aiki ta hanyar jujjuya wafer a ƙarƙashin saiti na matsa lamba akan kushin goge mai juyawa. Wannan motsi na dangi, haɗe tare da ɓarna na inji daga nano-sized abrasives a cikin slurry da aikin sinadarai na jami'ai masu amsawa, sun cimma shirin tsarawa.

Mahimmin kayan da aka yi amfani da su:

Goge slurry: Ya ƙunshi abrasives da sinadaran reagents.

Kushin goge: Yana lalacewa yayin amfani, yana rage girman pore da ingancin isar da slurry. Tufafi na yau da kullun, yawanci ana amfani da kayan ado na lu'u-lu'u, don dawo da rashin ƙarfi.

Tsarin CMP na al'ada

Abrasive: 0.5 μm lu'u-lu'u lu'u-lu'u

Maƙasudin maƙasudi: ~ 0.7 nm

Kayan Aikin Kemikal:

Kayan aikin goge baki: AP-810 goge mai gefe guda

Matsa lamba: 200 g/cm²

Gudun faranti: 50 rpm

Gudun mariƙin yumbu: 38 rpm

Abun da ke ciki:

SiO₂ (30 wt%, pH = 10.15)

0-70 wt% H₂O₂ (30 wt%, reagent sa)

Daidaita pH zuwa 8.5 ta amfani da 5 wt% KOH da 1 wt% HNO₃

Yawan kwarara ruwa: 3 l/min, sake zagayawa

Wannan tsari yana inganta ingancin wafer na SiC yadda ya kamata kuma ya cika buƙatun don tafiyar matakai na ƙasa.

Kalubalen fasaha a cikin aikin gyaran injina

SiC, a matsayin babban mai sarrafa bandgap, yana taka muhimmiyar rawa a masana'antar lantarki. Tare da kyawawan kaddarorin jiki da sinadarai, lu'ulu'u na SiC guda ɗaya sun dace da matsananciyar yanayi, kamar babban zafin jiki, babban mitar, babban iko, da juriya na radiation. Duk da haka, yanayin sa mai wuyar gaske yana ba da babban ƙalubale don niƙa da goge goge.

Kamar yadda manyan masana'antun duniya ke canzawa daga 6-inch zuwa 8-inch wafers, batutuwa kamar fatattaka da lalacewar wafer yayin sarrafawa sun zama mafi shahara, suna tasiri ga yawan amfanin ƙasa. Magance ƙalubalen fasaha na 8-inch SiC substrates yanzu shine mahimmin ma'auni don ci gaban masana'antu.

A cikin lokacin inch 8, sarrafa wafer na SiC yana fuskantar ƙalubale da yawa:

Sikelin wafer yana da mahimmanci don haɓaka kayan aikin guntu kowane tsari, rage hasara, da rage farashin samarwa-musamman da aka ba da hauhawar buƙatu a aikace-aikacen motocin lantarki.

Yayin da girma na 8-inch SiC guda lu'ulu'u ya balaga, matakai na baya-baya kamar niƙa da gogewa har yanzu suna fuskantar ƙuƙumman ƙugiya, wanda ke haifar da ƙarancin albarkatu (kawai 40-50%).

Manyan wafers suna samun ƙarin hadaddun rarraba matsi, suna ƙara wahalar sarrafa danniya mai gogewa da samun daidaito.

Ko da yake kaurin wafer 8-inch yana gabatowa na wafers 6-inch, sun fi saurin lalacewa yayin kulawa saboda damuwa da warping.

Don rage danniya da ke da alaƙa, warpage, da fatattaka, ana ƙara amfani da yankan Laser. Duk da haka:

Laser mai tsayi mai tsayi yana haifar da lalacewar thermal.

Laser na gajeren zango yana haifar da tarkace mai nauyi kuma suna zurfafa layin lalacewa, yana ƙara haɓakar gogewa.

Gudun Aikin Gyaran Injini na SiC

Gudun tsarin gaba ɗaya ya haɗa da:

Yanke fuskantarwa

M nika

Nika mai kyau

Gyaran injina

Chemical Mechanical Polishing (CMP) azaman mataki na ƙarshe

Zaɓin hanyar CMP, ƙirar hanya, da haɓaka sigogi suna da mahimmanci. A cikin masana'antar semiconductor, CMP shine ƙayyadaddun matakin don samar da wafers na SiC tare da ɗorewa, mara lahani, da filaye marasa lalacewa, waɗanda ke da mahimmanci don haɓakar haɓakar haɓakar epitaxial.

(a) Cire SiC ingot daga crucible;

(b) Yi siffa ta farko ta amfani da niƙa diamita na waje;

(c) Ƙayyade daidaitawar lu'ulu'u ta amfani da jeri ko filaye;

(d) Yanke ingot cikin siraran wafers ta amfani da sawing multi-wire;

(e) Samun santsi mai kama da madubi ta hanyar niƙa da matakan goge baki.

Bayan kammala jerin matakan sarrafawa, gefen waje na wafer SiC yakan zama mai kaifi, wanda ke ƙara haɗarin guntu yayin sarrafawa ko amfani. Don guje wa irin wannan rashin ƙarfi, ana buƙatar niƙa gefen.

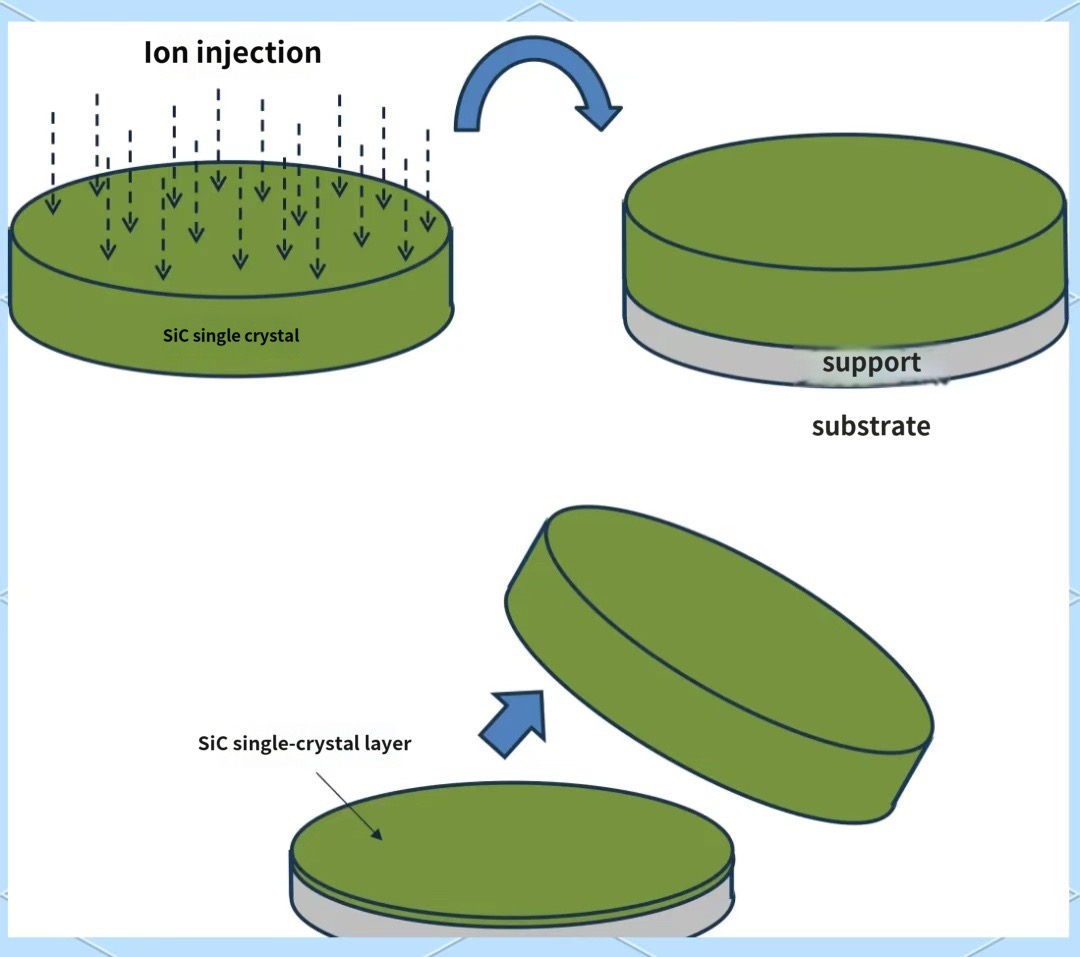

Baya ga tsarin slicing na gargajiya, wata sabuwar hanya don shirya wafers na SiC ya ƙunshi fasahar haɗin gwiwa. Wannan tsarin yana ba da damar ƙirƙira wafer ta hanyar haɗa sirin SiC-crystal Layer na bakin ciki zuwa wani maɓalli daban-daban (mai goyan baya).

Hoto na 3 yana kwatanta tsarin tafiyar da aiki:

Da farko, an kafa Layer delamination a wani ƙayyadadden zurfin zurfin saman SiC guda kristal ta hanyar shigar da hydrogen ion ko dabaru iri ɗaya. SiC guda kristal da aka sarrafa sannan an haɗa shi zuwa wani ɗaki mai goyan baya kuma ana fuskantar matsi da zafi. Wannan yana ba da damar canja wuri mai nasara da rabuwa na SiC single-crystal Layer uwa mai goyan baya.

Layin SiC da aka ware yana fuskantar jiyya ta sama don cimma daidaitattun da ake buƙata kuma ana iya sake amfani da shi a cikin hanyoyin haɗin kai na gaba. Idan aka kwatanta da yankan gargajiya na lu'ulu'u na SiC, wannan dabarar tana rage buƙatar kayan tsada. Kodayake kalubalen fasaha sun kasance, bincike da haɓaka suna ci gaba sosai don ba da damar samar da wafer mai ƙarancin farashi.

Ganin babban taurin da kwanciyar hankali na sinadarai na SiC-wanda ya sa ya zama mai juriya ga halayen a dakin da zafin jiki-ana buƙatar gyaran injin injiniya don cire ramukan niƙa mai kyau, rage lalacewar ƙasa, kawar da ɓarna, pitting, da lahani na kwasfa na orange, ƙananan tarkace, inganta shimfidar wuri, da haɓaka ingancin saman.

Don cimma babban inganci mai gogewa, ya zama dole:

Daidaita nau'ikan abrasive,

Rage girman barbashi,

Inganta sigogin tsari,

Zaɓi kayan goge-goge da gammaye tare da isasshen taurin.

Hoto na 7 ya nuna cewa goge fuska biyu tare da abrasives 1 μm na iya sarrafa flatness da bambancin kauri a cikin 10 μm, kuma ya rage ƙarancin ƙasa zuwa kusan 0.25 nm.

3.2 Chemical Mechanical Polishing (CMP)

Chemical Mechanical Polishing (CMP) yana haɗa ultrafine barbashi abrasion tare da sinadaran etching don samar da santsi, planar saman kan kayan da ake sarrafa. Babban ƙa'idar ita ce:

Halin sinadarai yana faruwa tsakanin slurry mai gogewa da saman wafer, yana samar da Layer mai laushi.

Tsayawa tsakanin barbashi masu lalata da laushi mai laushi yana cire kayan.

Amfanin CMP:

Ya shawo kan kurakuran gogewar injina ko sinadarai kawai,

Yana samun nasarar tsara tsarin duniya da na gida,

Yana samar da filaye tare da babban flatness da ƙarancin rashin ƙarfi,

Ba ya barin ƙasa ko lalacewar ƙasa.

Dalla-dalla:

Wafer yana motsawa dangane da kushin gogewa a ƙarƙashin matsin lamba.

Nanometer-sikelin abrasives (misali, SiO₂) a cikin slurry suna shiga cikin shearing, raunana Si-C covalent bond da haɓaka cire kayan.

Nau'in Dabarun CMP:

Gyaran Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙira (misali, SiO₂) ana dakatar da shi a cikin slurry. Cire kayan abu yana faruwa ta hanyar ɓarna jiki uku (wafer-pad-abrasive). Girman abrasive (yawanci 60-200 nm), pH, da zafin jiki dole ne a sarrafa su daidai don inganta daidaituwa.

Kafaffen goge-goge: Abrasives an saka su a cikin kushin goge goge don hana haɓakawa-madaidaicin aiki mai inganci.

Bayan-Polishing:

Wafers da aka goge suna fuskantar:

Tsabtace sinadarai (ciki har da ruwan DI da cire ragowar slurry),

DI ruwa kurkura, da

Hot nitrogen bushewa

don rage gurɓatar ƙasa.

Ingancin saman & Aiki

Za'a iya rage ƙancewar saman zuwa Ra <0.3 nm, saduwa da buƙatun epitaxy semiconductor.

Shirye-shiryen Duniya: Haɗin laushin sinadarai da kawar da injina yana rage ƙazanta da rashin daidaituwar etching, ƙetare hanyoyin inji ko sinadarai masu tsafta.

Babban Haɓaka: Ya dace da kayan aiki masu wuya da gagajewa kamar SiC, tare da ƙimar cire kayan sama da 200 nm/h.

Wasu Dabarun goge goge masu tasowa

Baya ga CMP, an gabatar da wasu hanyoyin daban, gami da:

Electrochemical polishing,Catalyst-taimaka polishing ko etching, da

Tribochemical polishing.

Koyaya, waɗannan hanyoyin har yanzu suna cikin matakin bincike kuma sun haɓaka sannu a hankali saboda ƙalubalen kayan kayan SiC.

Daga qarshe, sarrafa SiC wani tsari ne a hankali na rage wargin da rashin ƙarfi don haɓaka ingancin saman, inda zazzagewa da sarrafa rashin ƙarfi ke da mahimmanci a kowane mataki.

Fasahar Gudanarwa

A lokacin wafer niƙa mataki, lu'u-lu'u slurry da daban-daban barbashi masu girma dabam da ake amfani da nika wafer zuwa da ake bukata flatness da surface roughness. Ana biye da wannan ta hanyar gogewa, ta yin amfani da dabaru na injina da na sinadarai (CMP) don samar da wafers ɗin silicon carbide (SiC) mara lalacewa.

Bayan goge-goge, wafers na SiC suna fuskantar ƙayyadaddun ingancin dubawa ta amfani da kayan aiki irin su microscopes na gani da na'urar diffractometer X-ray don tabbatar da duk sigogin fasaha sun cika ka'idojin da ake buƙata. A ƙarshe, ana tsabtace wafers ɗin da aka goge ta amfani da na'urori masu tsabta na musamman da ruwa mai ƙarfi don cire gurɓataccen ƙasa. Sannan ana busar da su ta amfani da iskar iskar iskar iskar gas mai tsafta da kuma busar da busar da su, suna kammala aikin samarwa gaba daya.

Bayan shekaru na ƙoƙari, an sami gagarumin ci gaba a cikin sarrafa SiC guda ɗaya a cikin Sin. A cikin gida, 100 mm doped Semi-insulating 4H-SiC lu'ulu'u guda an sami nasarar haɓaka, kuma n-type 4H-SiC da 6H-SiC lu'ulu'u ɗaya yanzu ana iya samar da su a cikin batches. Kamfanoni kamar TankeBlue da TYST sun riga sun haɓaka lu'ulu'u ɗaya na SiC na mm 150.

Dangane da fasahar sarrafa wafer na SiC, cibiyoyin gida sun fara bincika yanayin tsari da hanyoyin slicing crystal, niƙa, da goge goge. Suna da ikon samar da samfuran da suka dace da ƙa'idodin ƙirƙira na'urar. Koyaya, idan aka kwatanta da ƙa'idodin ƙasashen duniya, ingancin sarrafa kayan wafer na gida har yanzu yana baya sosai. Akwai batutuwa da dama:

Ka'idodin SiC na kasa da kasa da fasahar sarrafawa suna da kariya sosai kuma ba a iya samun sauƙin shiga ba.

Akwai ƙarancin bincike na ka'idar da goyan baya don haɓaka tsari da haɓakawa.

Kudin shigo da kayan aiki da kayan aikin waje yana da yawa.

Binciken cikin gida game da ƙirar kayan aiki, daidaiton sarrafawa, da kayan har yanzu yana nuna manyan gibi idan aka kwatanta da matakan ƙasa da ƙasa.

A halin yanzu, ana shigo da mafi ingancin kayan aikin da ake amfani da su a kasar Sin. Kayan aikin gwaji da hanyoyin kuma suna buƙatar ƙarin haɓakawa.

Tare da ci gaba da haɓaka semiconductor na ƙarni na uku, diamita na SiC single crystal substrates yana ƙaruwa akai-akai, tare da mafi girman buƙatu don ingancin sarrafa saman. Fasahar sarrafa wafer ta zama ɗayan mafi ƙalubalen matakai na fasaha bayan ci gaban SiC guda ɗaya.

Don magance ƙalubalen da ake da su a cikin aiki, yana da mahimmanci don ƙara nazarin hanyoyin da ke cikin yankan, niƙa, da goge goge, da kuma bincika hanyoyin tsari da hanyoyin da suka dace don masana'antar wafer na SiC. Har ila yau, ya zama dole a koyo daga ci-gaban fasahar sarrafa kayayyaki na kasa da kasa da kuma yin amfani da fasahar kere-kere da kayan aiki na zamani don samar da ingantattun na'urori masu inganci.

Yayin da girman wafer ya karu, wahalar girma da sarrafa kristal shima yana tashi. Koyaya, ingancin masana'anta na na'urori na ƙasa yana inganta sosai, kuma an rage farashin rukunin. A halin yanzu, manyan masu samar da wafer na SiC a duk duniya suna ba da samfuran daga inci 4 zuwa inci 6 a diamita. Manyan kamfanoni irin su Cree da II-VI sun riga sun fara shiri don haɓaka layin samar da wafer na SiC mai inci 8.

Lokacin aikawa: Mayu-23-2025