SOI (Silicon-On-Insulator) waferswakiltar wani abu na musamman na semiconductor wanda ke nuna wani Layer silicon mai kauri wanda aka kafa a saman Layer oxide mai rufewa. Wannan tsarin sanwici na musamman yana ba da ingantaccen kayan haɓaka aiki don na'urorin semiconductor.

Haɗin Tsari:

Layin Na'ura (Babban Silicon):

Kauri daga nanometers da yawa zuwa micrometers, yana aiki azaman Layer mai aiki don ƙirƙirar transistor.

Buried Oxide Layer (BOX):

Silicon dioxide Layer insulating Layer (0.05-15μm lokacin farin ciki) wanda ke ware Layer na'urar ta hanyar lantarki daga ma'auni.

Tushe Substrate:

Babban silicon (100-500μm lokacin farin ciki) yana ba da tallafin injiniya.

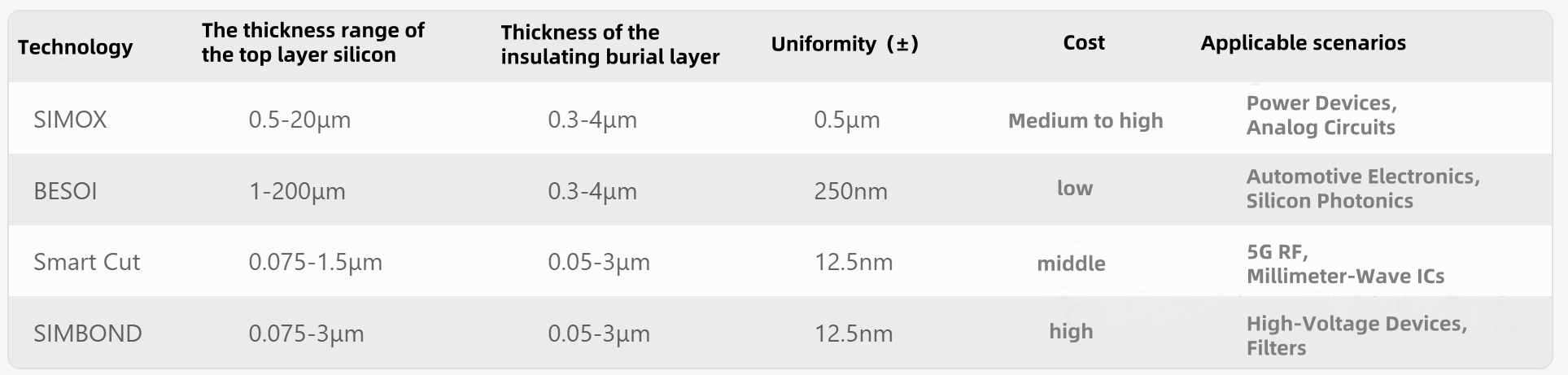

Dangane da fasahar aiwatar da shirye-shiryen, ana iya rarraba manyan hanyoyin aiwatar da wafers na SOI a matsayin: SIMOX (fasahar keɓewar allurar iskar oxygen), BESOI (fasaha mai ɗaukar nauyi), da Smart Cut (fasaha na tsiri mai hankali).

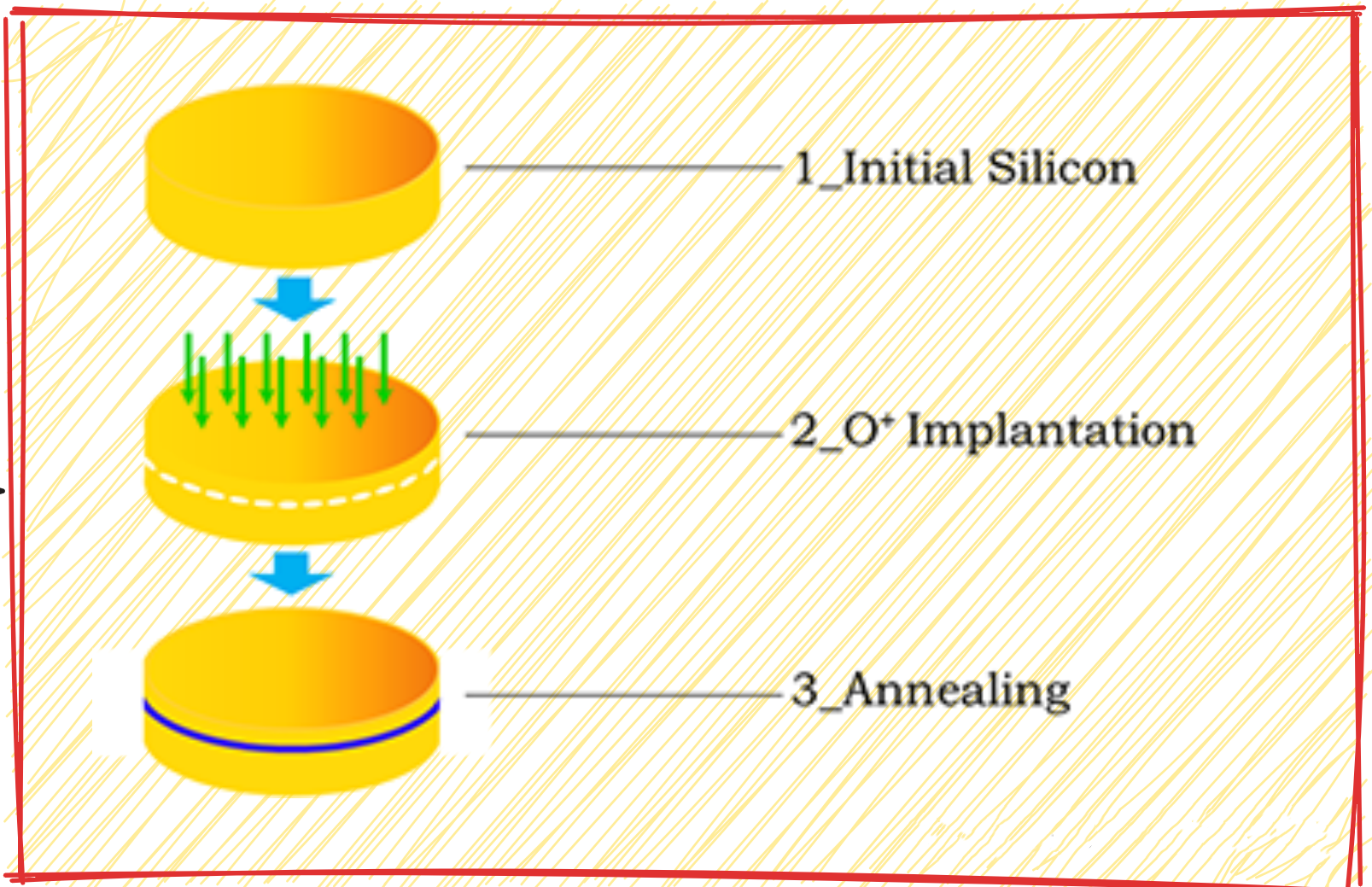

SIMOX ( fasahar kebewar allurar Oxygen) wata dabara ce da ta kunshi allurar ion iskar oxygen mai karfi a cikin wafers na silicon don samar da silinda mai dauke da sinadarin silicon dioxide, wanda sai a sanya shi cikin zafi mai zafi don gyara lahani. Babban shine allurar oxygen ta ion kai tsaye don samar da iskar oxygen da aka binne.

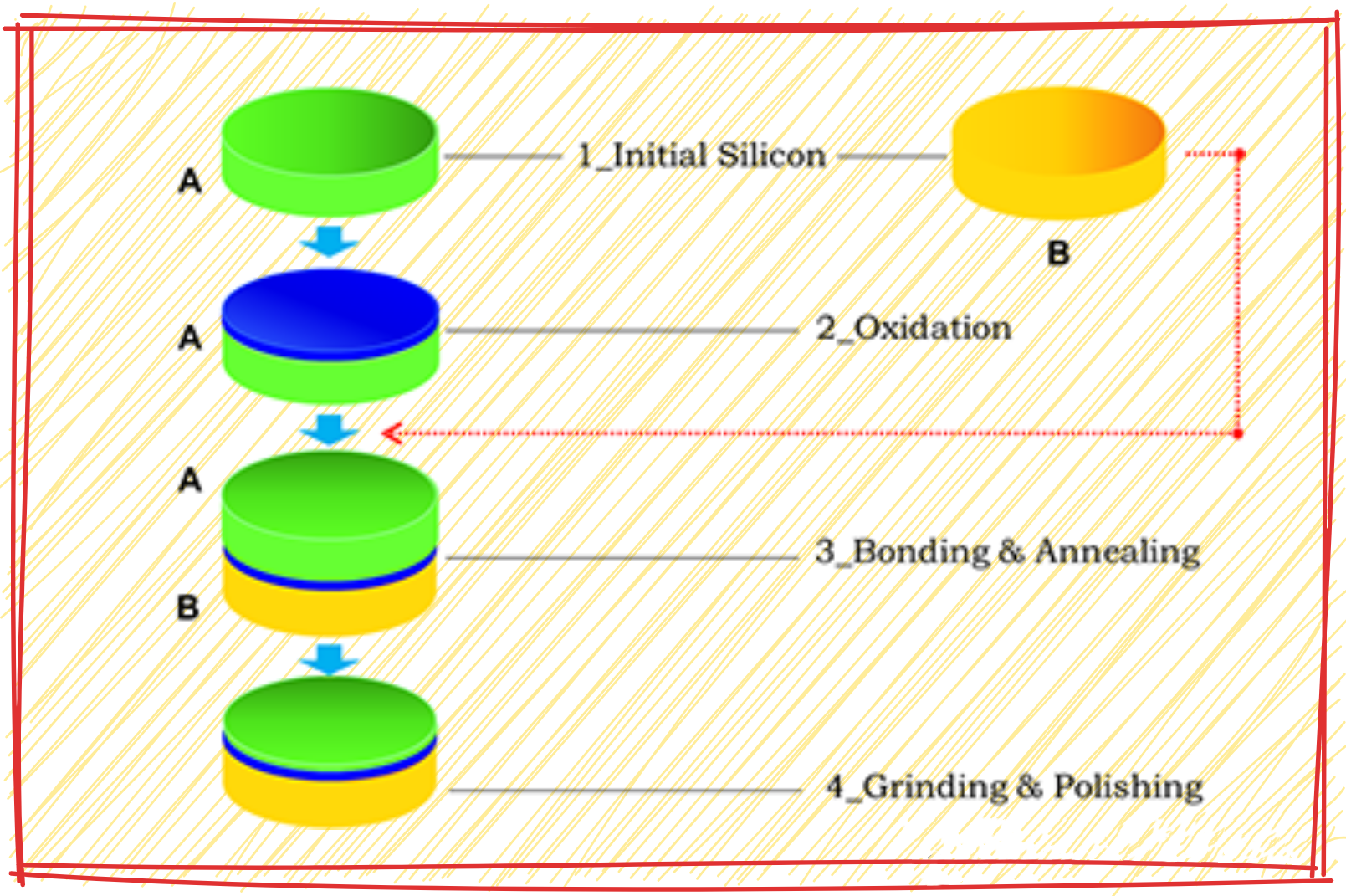

BESOI (Fasaha na Bonding Thinning) ya ƙunshi haɗa nau'ikan wafers guda biyu na silicon sannan a rage ɗayansu ta hanyar niƙa na inji da etching na sinadarai don samar da tsarin SOI. Jigon ya ta'allaka ne a bonding da thinning.

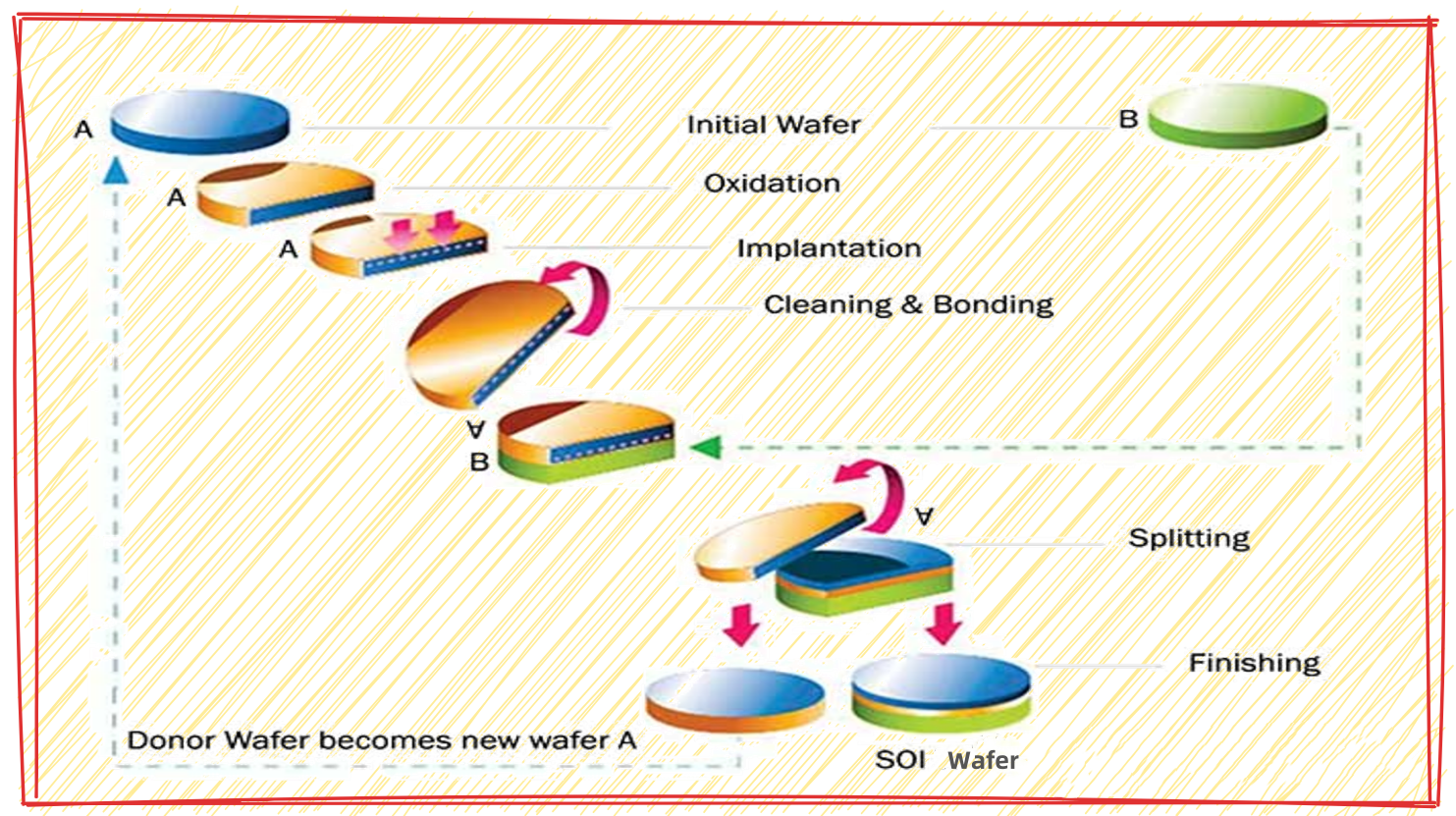

Smart Cut (fasaha na haɓakawa na hankali) yana samar da Layer na fitar da ruwa ta hanyar allurar ion hydrogen. Bayan haɗin gwiwa, ana aiwatar da maganin zafi don kawar da wafer siliki tare da Layer ion Layer, yana samar da Layer silicon mai ƙwanƙwasa. Babban abu shine cire allurar hydrogen.

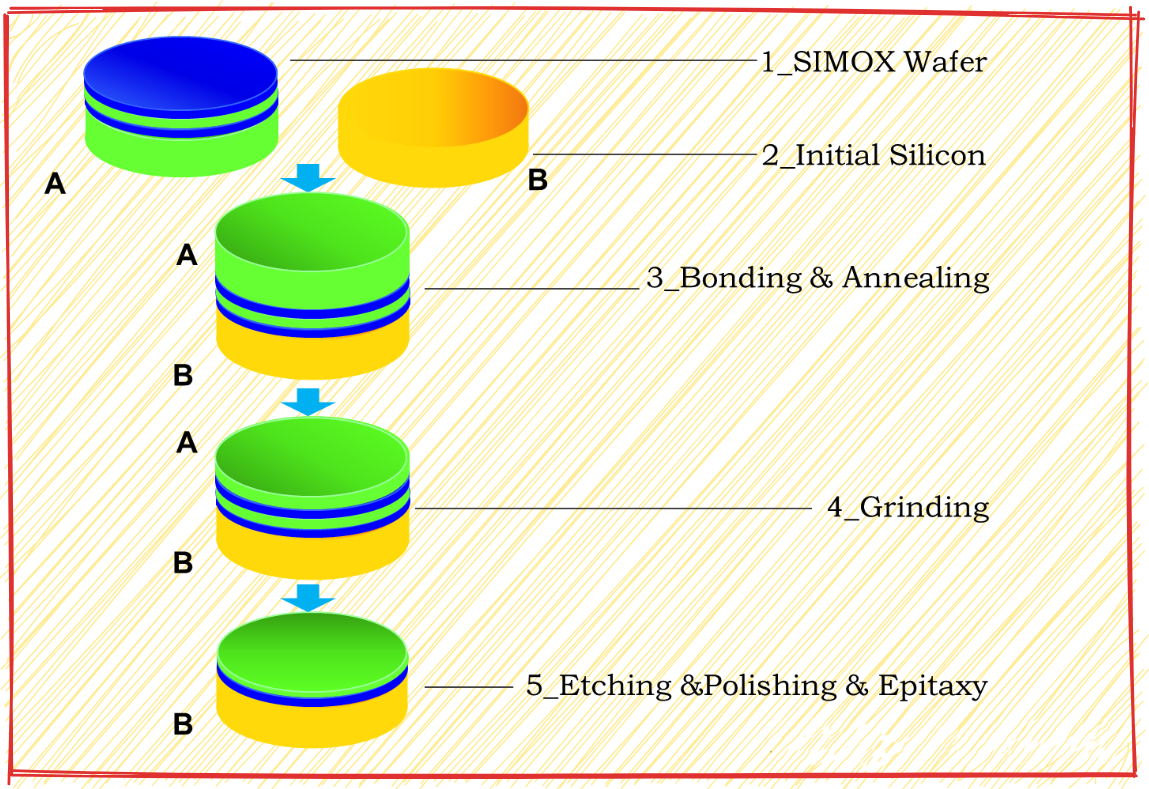

A halin yanzu, akwai wata fasaha da aka fi sani da SIMBOND (fasahar allurar iskar oxygen), wacce kamfanin Xinao ya kirkira. A zahiri, hanya ce da ta haɗu da keɓewar allurar oxygen da fasahar haɗin gwiwa. A cikin wannan hanyar fasaha, ana amfani da iskar oxygen da aka yi amfani da ita azaman shinge mai shinge, kuma ainihin abin da aka binne shi shine Layer oxidation na thermal. Sabili da haka, lokaci guda yana inganta sigogi kamar daidaitattun siliki na saman da ingancin murfin oxygen da aka binne.

SOI silicon wafers ƙera ta hanyoyi daban-daban na fasaha suna da sigogin aiki daban-daban kuma sun dace da yanayin aikace-aikacen daban-daban.

Mai zuwa shine taƙaitaccen tebur na ainihin fa'idodin aikin wafers silicon na SOI, haɗe tare da fasalulluka na fasaha da ainihin yanayin aikace-aikacen. Idan aka kwatanta da babban siliki na gargajiya, SOI yana da fa'idodi masu mahimmanci a cikin ma'aunin saurin gudu da amfani da wutar lantarki. (PS: Ayyukan 22nm FD-SOI yana kusa da na FinFET, kuma an rage farashin da 30%).

| Amfanin Aiki | Ƙa'idar Fasaha | Takamaiman Bayyanawa | Yanayin Aikace-aikace na al'ada |

| Low Parasitic Capacitance | Insulating Layer (BOX) yana toshe cajin haɗin gwiwa tsakanin na'ura da ƙasa | Saurin sauyawa ya ƙaru da 15% -30%, rage amfani da wutar lantarki da 20% -50% | 5G RF, kwakwalwan sadarwar sadarwa mai girma |

| Rage Leaka A halin yanzu | Insulating Layer yana hana zubewar hanyoyin yanzu | Leaka halin yanzu an rage da>90%, tsawan rayuwar baturi | Na'urorin IoT, Kayan lantarki masu sawa |

| Ingantattun Taurin Radiation | Insulating Layer yana toshe tarin cajin da radiation ta haifar | Haƙurin radiation ya inganta 3-5x, rage tashin hankali na taron guda ɗaya | Jirgin sama, kayan aikin nukiliya |

| Ikon Tasirin Tashoshin Gajeren Tashar | Silikon siliki na bakin ciki yana rage tsangwama a filin lantarki tsakanin magudanar ruwa da tushe | Ingantattun ƙarfin ƙarfin wutan kofa, ingantacciyar gangariyar ƙasa | Babban guntu dabaru na node (<14nm) |

| Ingantattun Gudanar da Zazzabi | Insulating Layer rage thermal conduction hada guda biyu | 30% ƙarancin tarin zafi, 15-25°C ƙananan zafin aiki | 3D ICs, Automotive Electronics |

| Haɓaka Babban Mita | Rage ƙarfin ƙarfin parasitic da haɓaka motsin mai ɗaukar kaya | 20% ƙananan jinkiri, yana goyan bayan sarrafa siginar 30GHz | Sadarwar mmWave, Tauraron Dan Adam comm chips |

| Ƙarfafa Ƙirar Ƙira | Ba a buƙatar maganin ƙara kuzari mai kyau, yana goyan bayan son zuciya | 13% -20% ƙananan matakai na tsari, 40% mafi girman haɗin haɗin kai | Mixed-signal ICs, Sensors |

| Latch-up Immunity | Insulating Layer yana ware mahaɗar PN parasitic | Matsakaicin latch-up na yanzu ya ƙaru zuwa> 100mA | Na'urorin wutar lantarki masu ƙarfi |

Don taƙaitawa, babban fa'idodin SOI shine: yana aiki da sauri kuma yana da ƙarfi sosai.

Saboda waɗannan halayen aikin SOI, yana da aikace-aikace masu fa'ida a cikin filayen da ke buƙatar ingantaccen aikin mitar da aikin amfani da wutar lantarki.

Kamar yadda aka nuna a ƙasa, dangane da rabon filayen aikace-aikacen da suka dace da SOI, ana iya ganin cewa RF da na'urorin wuta suna lissafin mafi yawan kasuwar SOI.

| Filin Aikace-aikace | Raba Kasuwa |

| RF-SOI (Mitar rediyo) | 45% |

| Power SOI | 30% |

| FD-SOI (Cikakken Ragewa) | 15% |

| SOI na gani | 8% |

| Sensor SOI | 2% |

Tare da haɓakar kasuwanni kamar sadarwar wayar hannu da tuƙi mai cin gashin kai, SOI silicon wafers ana kuma sa ran kiyaye ƙimar haɓaka.

XKH, a matsayin babban mai ƙididdigewa a cikin fasahar wafer na Silicon-On-Insulator (SOI), yana ba da cikakkiyar mafita na SOI daga R&D zuwa samar da girma ta hanyar amfani da hanyoyin masana'antu masu jagorancin masana'antu. Cikakken fayil ɗin mu ya haɗa da 200mm / 300mm SOI wafers wanda ke kewaye da RF-SOI, Power-SOI da bambance-bambancen FD-SOI, tare da ingantaccen sarrafa ingancin yana tabbatar da daidaiton aiki na musamman (daidaituwar kauri tsakanin ± 1.5%). Muna ba da mafita na musamman tare da kauri wanda aka binne oxide (BOX) wanda ya fito daga 50nm zuwa 1.5μm da ƙayyadaddun ƙididdiga daban-daban don saduwa da takamaiman buƙatu. Yin amfani da shekaru 15 na ƙwarewar fasaha da sarkar samar da kayayyaki ta duniya, muna dogaro da samar da ingantaccen kayan aikin SOI ga manyan masana'antun semiconductor a duk duniya, yana ba da damar sabbin guntun guntu a cikin sadarwar 5G, na'urorin lantarki, da aikace-aikacen fasaha na wucin gadi.

Lokacin aikawa: Afrilu-24-2025