SiC wafer's abtract

Silicon carbide (SiC) waferssun zama madaidaicin zaɓi don babban iko, babban mitoci, da na'urorin lantarki masu zafi a cikin sassan kera motoci, sabunta makamashi, da sassan sararin samaniya. Bayanin mu na Portfolio ya ƙunshi maɓallin polytypes da doping makirci-nitrogen-doped 4h (3h-n), nitrogen-nitrating 3h (hpsi), nitran-n), da p-/h-n), nitran-n) (ya fadi ko ba a rufe shi ba gwaje-gwajen tsari), da BINCIKE (na al'ada epi yadudduka da bayanan doping don R&D). Wafer diamita 2 ″, 4″, 6″, 8″, da 12″ don dacewa da kayan aikin gado da manyan fabs. Hakanan muna samar da boules na monocrystalline da daidaitattun nau'ikan lu'ulu'u don tallafawa ci gaban kristal na cikin gida.

Wafers ɗin mu na 4H-N yana nuna nau'ikan nau'ikan jigilar kaya daga 1 × 10¹⁶ zuwa 1 × 10¹⁹ cm⁻³ da juriya na 0.01-10 Ω·cm, suna isar da ingantacciyar motsi na lantarki da filayen fashe sama da 2 MV/cm—madaidaicin ga Schottky diodes, da JSFET. Matsalolin HPSI sun wuce 1 × 10¹² Ω·cm juriya tare da ƙarancin micropipe ƙasa da 0.1 cm⁻², yana tabbatar da ƙyalli kaɗan don na'urorin RF da microwave. Cubic 3C-N, samuwa a cikin 2 ″ da 4 ″ tsari, yana ba da damar heteroepitaxy akan silicon kuma yana goyan bayan aikace-aikacen photonic da MEMS. P-type 4H/6H-P wafers, doped tare da aluminum zuwa 1×10¹⁶–5×10¹⁸ cm⁻³, sauƙaƙe kayan gine-ginen na'ura.

SiC wafer, PRIME wafers suna jurewa sinadarai-kayan aikin injiniya zuwa <0.2 nm RMS roughness surface, jimlar kauri bambancin ƙarƙashin 3 µm, da baka <10 μm. Abubuwan DUMMY suna haɓaka haɗuwa da gwaje-gwajen marufi, yayin da wafers BINCIKE ke nuna kauri na epi-Layer na 2-30 µm da bespoke doping. Duk samfuran an tabbatar da su ta hanyar diffraction X-ray (rocking curve <30 arcsec) da Raman spectroscopy, tare da gwaje-gwajen lantarki-Ma'aunin Hall, bayanin C-V, da sikanin micropipe-tabbatar da yarda da JEDEC da SEMI.

Ana yin girma har zuwa diamita mm 150 ta hanyar PVT da CVD tare da ɗimbin rarrabuwa a ƙasa 1 × 10³ cm⁻² da ƙananan ƙidayar micropipe. An yanke lu'ulu'u iri a cikin 0.1° na axis na c-axis don tabbatar da haɓakar haɓakawa da yawan slicing amfanin gona.

Ta hanyar hada pololypes da yawa, bambance-bambancen doping, maki mai inganci, sic wafer mai girma da kuma samar da kayan aiki na kayan aikinmu, da Subdrater Plint Playerarfin motocin lantarki.

SiC wafer's abtract

Silicon carbide (SiC) waferssun zama madaidaicin SiC na zaɓi don babban iko, mai ƙarfi, da na'urorin lantarki masu zafi a cikin sassan kera motoci, sabunta makamashi, da sassan sararin samaniya. Fayil ɗinmu ya ƙunshi maɓallin polytypes da doping makirci-nitrogen-doped 4h (3C-n), nitrogen-nitulating 3h (hpshi), nitrogen-p)-piaferPRIME (cikakkiyar gogewa, kayan aikin na'ura), DUMMY (wanda ba a goge shi ba don gwaje-gwajen tsari), da BINCIKE (na al'ada na al'ada da bayanan doping don R&D). SiC Wafer diamita ya kai 2 ″, 4″, 6″, 8″, da 12″ don dacewa da kayan aikin gado da manyan fabs. Hakanan muna samar da boules na monocrystalline da daidaitattun nau'ikan lu'ulu'u don tallafawa ci gaban kristal na cikin gida.

Wafers ɗin mu na 4H-N SiC yana haɓaka nau'ikan jigilar kaya daga 1 × 10¹⁶ zuwa 1 × 10¹⁹ cm⁻³ da juriya na 0.01-10 Ω·cm, suna isar da ingantacciyar motsi na lantarki da filayen fashe sama da 2 MV/cm-madaidaicin ga Schottky diodes, da MOSFET. Matsalolin HPSI sun wuce 1 × 10¹² Ω·cm juriya tare da ƙarancin micropipe ƙasa da 0.1 cm⁻², yana tabbatar da ƙyalli kaɗan don na'urorin RF da microwave. Cubic 3C-N, samuwa a cikin 2 ″ da 4 ″ tsari, yana ba da damar heteroepitaxy akan silicon kuma yana goyan bayan aikace-aikacen photonic da MEMS. SiC wafer P-type 4H/6H-P wafers, doped tare da aluminum zuwa 1×10¹⁶-5×10¹⁸ cm⁻³, sauƙaƙe kayan gine-ginen na'ura.

SiC wafer PRIME wafers suna juyar da sinadarai-kayan aikin injiniya zuwa <0.2nm RMS roughness surface, jimlar bambancin kauri a ƙarƙashin 3 µm, da baka <10 μm. Abubuwan DUMMY suna haɓaka haɗuwa da gwaje-gwajen marufi, yayin da wafers BINCIKE ke nuna kauri na epi-Layer na 2-30 µm da bespoke doping. Duk samfuran an tabbatar da su ta hanyar diffraction X-ray (rocking curve <30 arcsec) da Raman spectroscopy, tare da gwaje-gwajen lantarki-Ma'aunin Hall, bayanin C-V, da sikanin micropipe-tabbatar da yarda da JEDEC da SEMI.

Ana yin girma har zuwa diamita mm 150 ta hanyar PVT da CVD tare da ɗimbin rarrabuwa a ƙasa 1 × 10³ cm⁻² da ƙananan ƙidayar micropipe. An yanke lu'ulu'u iri a cikin 0.1° na axis na c-axis don tabbatar da haɓakar haɓakawa da yawan slicing amfanin gona.

Ta hanyar hada pololypes da yawa, bambance-bambancen doping, maki mai inganci, sic wafer mai girma da kuma samar da kayan aiki na kayan aikinmu, da Subdrater Plint Playerarfin motocin lantarki.

6inch 4H-N nau'in SiC wafer's data sheet

| 6 inch SiC wafers data takardar | ||||

| Siga | Sub-Parameter | Babban darajar Z | P daraja | D darajar |

| Diamita | 149.5-150.0 mm | 149.5-150.0 mm | 149.5-150.0 mm | |

| Kauri | 4H-N | 350 µm ± 15 µm | 350 µm ± 25 µm | 350 µm ± 25 µm |

| Kauri | 4H-SI | 500 µm ± 15 µm | 500 µm ± 25 µm | 500 µm ± 25 µm |

| Wafer Orientation | Kashe axis: 4.0° zuwa <11-20> ± 0.5° (4H-N); Kan axis: <0001> ± 0.5° (4H-SI) | Kashe axis: 4.0° zuwa <11-20> ± 0.5° (4H-N); Kan axis: <0001> ± 0.5° (4H-SI) | Kashe axis: 4.0° zuwa <11-20> ± 0.5° (4H-N); Kan axis: <0001> ± 0.5° (4H-SI) | |

| Maƙarƙashiya Maɗaukaki | 4H-N | ≤ 0.2cm⁻² | ≤ 2 cm² | ≤ 15 cm² |

| Maƙarƙashiya Maɗaukaki | 4H-SI | ≤ 1 cm² | ≤5 cm² | ≤ 15 cm² |

| Resistivity | 4H-N | 0.015-0.024 Ω · cm | 0.015-0.028 Ω · cm | 0.015-0.028 Ω · cm |

| Resistivity | 4H-SI | ≥ 1×10¹⁰ Ω·cm | ≥ 1 × 10⁵ Ω·cm | |

| Hannun Filayen Firamare | [10-10] ± 5.0° | [10-10] ± 5.0° | [10-10] ± 5.0° | |

| Tsawon Lantarki na Farko | 4H-N | 47.5 mm ± 2.0 mm | ||

| Tsawon Lantarki na Farko | 4H-SI | Daraja | ||

| Ƙarƙashin Ƙarfi | 3 mm ku | |||

| Warp/LTV/TTV/Baka | ≤2.5µm / ≤6 µm / ≤25 µm / ≤35 µm | ≤5 µm / ≤15 µm / ≤40 µm / ≤60 µm | ||

| Tashin hankali | Yaren mutanen Poland | Ra ≤ 1 nm | ||

| Tashin hankali | CMP | Ra ≤ 0.2 nm | Ra ≤ 0.5 nm | |

| Tsagewar Gefen | Babu | Tsayin tarawa ≤ 20 mm, guda ≤ 2 mm | ||

| Hex Plates | Tarin yanki ≤ 0.05% | Tarin yanki ≤ 0.1% | Tarin yanki ≤ 1% | |

| Yankunan Polytype | Babu | Tarin yanki ≤ 3% | Tarin yanki ≤ 3% | |

| Haɗin Carbon | Tarin yanki ≤ 0.05% | Tarin yanki ≤ 3% | ||

| Scratches Surface | Babu | Tsayin tarawa ≤ 1 × diamita wafer | ||

| Kwakwalwa na Edge | Babu wanda aka halatta ≥ 0.2 mm nisa & zurfin | Har zuwa kwakwalwan kwamfuta 7, ≤ 1 mm kowanne | ||

| TSD (Threading Screw Dislocation) | ≤ 500 cm ² | N/A | ||

| BPD (Base Plane Dilocation) | ≤ 1000 cm⁻² | N/A | ||

| Gurbatar Sama | Babu | |||

| Marufi | Cassette mai yawa-wafer ko kwandon wafer guda ɗaya | Cassette mai yawa-wafer ko kwandon wafer guda ɗaya | Cassette mai yawa-wafer ko kwandon wafer guda ɗaya | |

4inch 4H-N irin SiC wafer's data sheet

| 4inch SiC wafer's data sheet | |||

| Siga | Zero MPD Production | Madaidaicin Matsayin Ƙirƙira (P Grade) | Dummy Grade (D Grade) |

| Diamita | 99.5 mm-100.0 mm | ||

| Kauri (4H-N) | 350 µm± 15 µm | 350 µm± 25 µm | |

| Kauri (4H-Si) | 500 µm± 15 µm | 500 µm± 25 µm | |

| Wafer Orientation | Kashe axis: 4.0 ° zuwa <1120> ± 0.5 ° don 4H-N; Kan axis: <0001> ± 0.5° don 4H-Si | ||

| Maƙarƙashiyar Ƙarfafa (4H-N) | ≤0.2cm⁻² | ≤2 cm² | ≤15 cm² |

| Yawan Bututu (4H-Si) | ≤1 cm² | ≤5 cm² | ≤15 cm² |

| Resistivity (4H-N) | 0.015-0.024 Ω · cm | 0.015-0.028 Ω · cm | |

| Resistivity (4H-Si) | ≥1E10 Ω·cm | ≥1E5 Ω·cm | |

| Hannun Filayen Firamare | [10-10] ± 5.0° | ||

| Tsawon Lantarki na Farko | 32.5 mm ± 2.0 mm | ||

| Tsawon Lantarki na Sakandare | 18.0 mm ± 2.0 mm | ||

| Gabatarwar Flat na Sakandare | Fuskar Silicon: 90° CW daga babban lebur ± 5.0° | ||

| Ƙarƙashin Ƙarfi | 3 mm ku | ||

| LTV/TTV/Bakan Warp | ≤2.5µm/≤5 µm/≤15 µm/≤30 µm | ≤10 µm/≤15 µm/≤25 µm/≤40 µm | |

| Tashin hankali | Yaren mutanen Poland Ra ≤1 nm; CMP Ra ≤0.2 nm | Ra ≤0.5 nm | |

| Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙwara | Babu | Babu | Tsayin tarawa ≤10 mm; tsayi guda ≤2 mm |

| Hex Plates Ta Babban Haske mai ƙarfi | Tarin yanki ≤0.05% | Tarin yanki ≤0.05% | Tarin yanki ≤0.1% |

| Wuraren Polytype Ta Hanyar Ƙarfin Ƙarfi | Babu | Tarin yanki ≤3% | |

| Haɗin Carbon Na gani | Tarin yanki ≤0.05% | Tarin yanki ≤3% | |

| Silicon Surface Scratches By High Intensity Light | Babu | Tsayin tarawa ≤1 diamita wafer | |

| Chips Gefe Ta Babban Haske mai ƙarfi | Babu wanda aka halatta ≥0.2 mm faɗi da zurfin | 5 izini, ≤1 mm kowanne | |

| Lalacewar Silicon Surface Ta Babban Haske mai ƙarfi | Babu | ||

| Rushewar zaren dunƙulewa | ≤500 cm² | N/A | |

| Marufi | Cassette mai yawa-wafer ko kwandon wafer guda ɗaya | Cassette mai yawa-wafer ko kwandon wafer guda ɗaya | Cassette mai yawa-wafer ko kwandon wafer guda ɗaya |

4inch HPSI irin SiC wafer's data sheet

| 4inch HPSI irin SiC wafer's data sheet | |||

| Siga | Zero MPD Production Grade (Z Grade) | Madaidaicin Matsayin Ƙirƙira (P Grade) | Dummy Grade (D Grade) |

| Diamita | 99.5-100.0 mm | ||

| Kauri (4H-Si) | 500 µm ± 20 µm | 500 µm ± 25 µm | |

| Wafer Orientation | Kashe axis: 4.0 ° zuwa <11-20> ± 0.5 ° don 4H-N; Kan axis: <0001> ± 0.5° don 4H-Si | ||

| Yawan Bututu (4H-Si) | ≤1 cm² | ≤5 cm² | ≤15 cm² |

| Resistivity (4H-Si) | ≥1E9 Ω·cm | ≥1E5 Ω·cm | |

| Hannun Filayen Firamare | (10-10) ± 5.0° | ||

| Tsawon Lantarki na Farko | 32.5 mm ± 2.0 mm | ||

| Tsawon Lantarki na Sakandare | 18.0 mm ± 2.0 mm | ||

| Gabatarwar Flat na Sakandare | Fuskar Silicon: 90° CW daga babban lebur ± 5.0° | ||

| Ƙarƙashin Ƙarfi | 3 mm ku | ||

| LTV/TTV/Bakan Warp | ≤3 µm/≤5 µm/≤15 µm/≤30 µm | ≤10 µm/≤15 µm/≤25 µm/≤40 µm | |

| Tashin hankali (C face) | Yaren mutanen Poland | Ra ≤1 nm | |

| Tashin hankali (Si face) | CMP | Ra ≤0.2 nm | Ra ≤0.5 nm |

| Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙwara | Babu | Tsayin tarawa ≤10 mm; tsayi guda ≤2 mm | |

| Hex Plates Ta Babban Haske mai ƙarfi | Tarin yanki ≤0.05% | Tarin yanki ≤0.05% | Tarin yanki ≤0.1% |

| Wuraren Polytype Ta Hanyar Ƙarfin Ƙarfi | Babu | Tarin yanki ≤3% | |

| Haɗin Carbon Na gani | Tarin yanki ≤0.05% | Tarin yanki ≤3% | |

| Silicon Surface Scratches By High Intensity Light | Babu | Tsayin tarawa ≤1 diamita wafer | |

| Chips Gefe Ta Babban Haske mai ƙarfi | Babu wanda aka halatta ≥0.2 mm faɗi da zurfin | 5 izini, ≤1 mm kowanne | |

| Lalacewar Silicon Surface Ta Babban Haske mai ƙarfi | Babu | Babu | |

| Rushewar Zaren Zare | ≤500 cm² | N/A | |

| Marufi | Cassette mai yawa-wafer ko kwandon wafer guda ɗaya | ||

Aikace-aikacen wafer na SiC

-

SiC Wafer Power Modules don EV Inverters

MOSFETs na tushen SiC wafer da diodes waɗanda aka gina akan sinadarai masu inganci na SiC wafer suna ba da asara mai ƙaranci. Ta hanyar yin amfani da fasahar wafer na SiC, waɗannan nau'ikan wutar lantarki suna aiki a mafi girman ƙarfin lantarki da yanayin zafi, suna ba da damar inverter masu inverter masu inganci. Haɗa wafer na SiC ya mutu cikin matakan wutar lantarki yana rage buƙatun sanyaya da sawun sawun, yana nuna cikakken yuwuwar ƙirar wafer ta SiC. -

Babban Mitar RF & Na'urorin 5G akan SiC Wafer

RF amplifiers da maɓalli waɗanda aka ƙirƙira akan dandamalin wafer na SiC masu rufewa da ke nuna ingantacciyar wutar lantarki da rushewar wutar lantarki. SiC wafer substrate yana rage asarar dielectric a mitocin GHz, yayin da ƙarfin kayan wafer na SiC yana ba da izinin aiki mai ƙarfi a ƙarƙashin iko mai ƙarfi, yanayin zafi mai ƙarfi - yin SiC wafer azaman zaɓi don tashoshin tushe na 5G na gaba da tsarin radar. -

Optoelectronic & LED Substrates daga SiC Wafer

Blue da UV LEDs waɗanda aka girma akan siginar wafer na SiC suna amfana daga ingantacciyar madaidaicin lattice da ɓarkewar zafi. Yin amfani da wafer SiC mai gogewa na C-face yana tabbatar da nau'ikan nau'ikan epitaxial iri ɗaya, yayin da ƙaƙƙarfan ƙaƙƙarfan wafer na SiC yana ba da damar ɓacin rai mai kyau da abin dogaro da kayan na'ura. Wannan ya sa SiC wafer ta tafi-zuwa dandamali don babban iko, aikace-aikacen LED na tsawon rai.

Q&A na SiC wafer

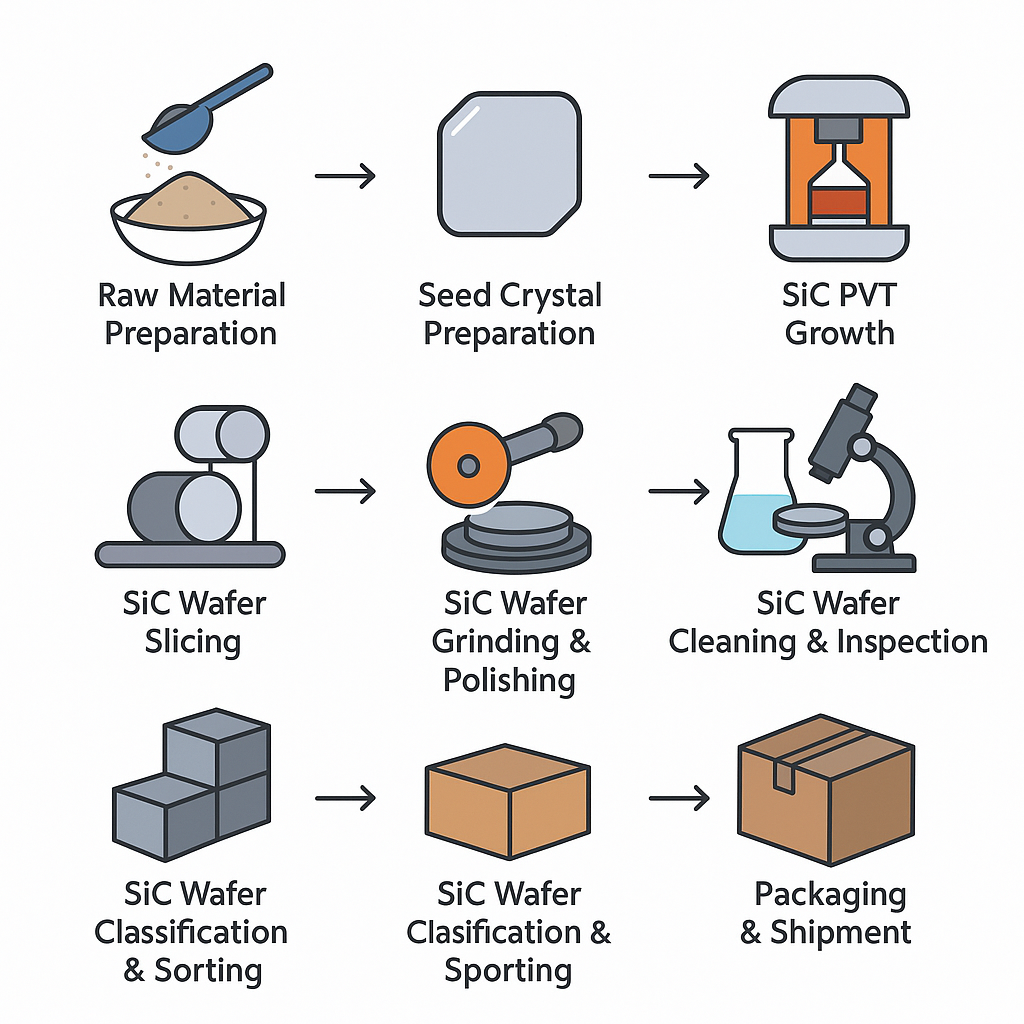

1. Tambaya: Ta yaya ake kera wafers na SiC?

A:

SiC wafers ƙeraCikakken Matakai

-

SiC wafersDanyen Kayan Shiri

- Yi amfani da ≥5N-grade SiC foda (ƙazanta ≤1 ppm).

- Seve da pre-gasa don cire ragowar mahaɗan carbon ko nitrogen.

-

SiCShiri Crystal iri

-

Ɗauki yanki na kristal guda 4H-SiC, yanki tare da daidaitawar 〈0001〉 zuwa ~10 × 10 mm².

-

Madaidaicin goge zuwa Ra ≤0.1 nm da alama daidaitawar crystal.

-

-

SiCGirman PVT (Tsarin Turin Jiki)

-

Load graphite crucible: kasa da SiC foda, saman tare da iri crystal.

-

Fita zuwa 10⁻³–10⁻ Torr ko cikawa da helium mai tsafta mai tsayi a 1 atm.

-

Yankin tushen zafi zuwa 2100-2300 ℃, kula da yankin iri 100-150 ℃ mai sanyaya.

-

Sarrafa ƙimar girma a 1-5 mm / h don daidaita inganci da kayan aiki.

-

-

SiCIngot Annealing

-

Anneal SiC ɗin da aka girma kamar yadda aka girma a 1600-1800 ℃ na awanni 4-8.

-

Manufa: Sauƙaƙe matsi na thermal da rage yawan rarrabuwa.

-

-

SiCYankan Wafer

-

Yi amfani da sawon lu'u-lu'u don yanki ingot cikin kauri na 0.5-1 mm.

-

Rage rawar jiki da ƙarfi na gefe don guje wa ƙananan fashe-fashe.

-

-

SiCWaferNika & goge baki

-

M nikadon cire lalacewar sawing (roughness ~ 10-30 µm).

-

Nika mai kyaudon cimma kwanciyar hankali ≤5 µm.

-

Chemical-Mechanical Polishing (CMP)don isa gama-kamar madubi (Ra ≤0.2 nm).

-

-

SiCWaferTsaftacewa & Dubawa

-

Ultrasonic tsaftacewaa cikin maganin Piranha (H₂SO₄: H₂O₂), ruwa DI, sannan IPA.

-

XRD/Raman spectroscopydon tabbatar da polytype (4H, 6H, 3C).

-

Interferometrydon auna flatness (<5 µm) da warp (<20 µm).

-

Binciken maki hududon gwada juriya (misali HPSI ≥10⁹ Ω · cm).

-

Lalacewar dubawaKarkashin microscope mai haske na polarized da mai gwajin karce.

-

-

SiCWaferRabewa & Rarraba

-

A ware wafers ta nau'in polytype da na lantarki:

-

4H-SiC N-type (4H-N): maida hankali mai ɗaukar hoto 10¹⁶-10¹⁸ cm⁻³

-

4H-SiC Babban Tsabtace Semi-Insulating (4H-HPSI): tsayayya ≥10⁹ Ω · cm

-

6H-SiC N-nau'in (6H-N)

-

Sauran: 3C-SiC, P-type, da dai sauransu.

-

-

-

SiCWaferMarufi & Jigila

-

Sanya a cikin akwatunan wafer mai tsabta, mara ƙura.

-

Yi wa kowane akwati lakabi da diamita, kauri, nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau’in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau’in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau’in nau'in nau'in nau'in nau'in nau'in nau'in nau’in nau'in nau'in nau'in nau'in nau'in nau’in nau'in nau'in nau'in nau'in nau’in nau'in nau'in nau'in nau'i, nau'in juriya, ƙimar juriya, da lambar tsari.

-

2. Q: Menene mabuɗin fa'idodin SiC wafers akan wafer siliki?

A: Idan aka kwatanta da wafers na silicon, wafers na SiC suna kunna:

-

Higher ƙarfin lantarki aiki(> 1,200 V) tare da ƙananan juriya.

-

Mafi girman kwanciyar hankali(> 300 ° C) da ingantaccen kula da thermal.

-

Saurin saurin sauyawatare da ƙananan hasara na sauyawa, rage tsarin sanyi-matakin sanyi da girma a cikin masu canza wuta.

4. Q: Wadanne lahani na yau da kullum yana shafar yawan amfanin SiC wafer da aiki?

A: Lalacewar farko a cikin wafers na SiC sun haɗa da micropipes, dislocations basal jirgin sama (BPDs), da tarkace saman. Micropipes na iya haifar da gazawar na'urar bala'i; BPDs suna ƙaruwa akan juriya akan lokaci; da karcewar saman yana haifar da karyewar wafer ko rashin girma epitaxial. Tsananin dubawa da rage lahani suna da mahimmanci don haɓaka yawan amfanin wafer na SiC.

Lokacin aikawa: Juni-30-2025