Tsabtace rigar (Wet Clean) yana ɗaya daga cikin matakai masu mahimmanci a cikin matakan masana'antu na semiconductor, da nufin cire gurɓataccen gurɓataccen abu daga saman wafer don tabbatar da cewa za a iya aiwatar da matakan tsari na gaba akan tsaftataccen wuri.

Yayin da girman na'urorin semiconductor ke ci gaba da raguwa kuma daidaitattun buƙatun suna ƙaruwa, buƙatun fasaha na hanyoyin tsabtace wafer sun zama masu ƙarfi. Ko da mafi ƙanƙanta barbashi, kayan halitta, ions ƙarfe, ko ragowar oxide akan saman wafer na iya yin tasiri sosai akan aikin na'urar, ta haka yana shafar yawan amfanin ƙasa da amincin na'urorin semiconductor.

Mahimman Ka'idojin Tsabtace Wafer

Tushen tsaftacewar wafer ya ta'allaka ne da yadda ya kamata a cire gurɓata daban-daban daga saman wafer ta hanyar zahiri, sinadarai, da sauran hanyoyin don tabbatar da cewa wafer yana da tsaftataccen wuri mai dacewa da aiki na gaba.

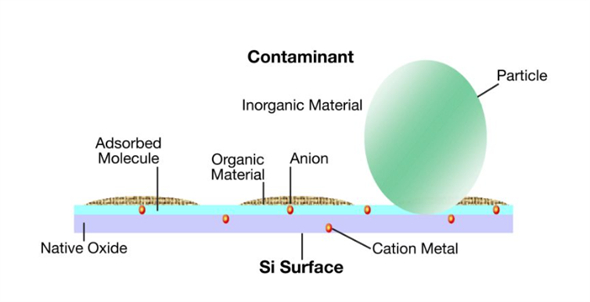

Nau'in Gurbata

Babban Tasiri kan Halayen Na'ura

| labarin Gurbata | Lalacewar tsari

ion implantation lahani

Insulating lalacewar lalacewar fim

| |

| Gurbacewar Karfe | Karfe Alkali | MOS transistor rashin zaman lafiya

Rushewar fim ɗin Gate oxide / lalata

|

| Karfe masu nauyi | Ƙaruwa junction na PN mai juye juye halin yanzu

Ƙofar oxide fim lalata lahani

Karamar dillali lalacewa ta rayuwa

Oxide excitation Layer lahani tsara

| |

| Gurbatar Sinadari | Kayan Halitta | Ƙofar oxide fim lalata lahani

Bambance-bambancen fim na CVD (lokacin shiryawa)

Bambance-bambancen kauri na thermal oxide fim (hanzarin iskar shaka)

Haze faru (wafer, ruwan tabarau, madubi, abin rufe fuska, reticle)

|

| Inorganic Dopants (B, P) | MOS transistor Vth yana canzawa

Si substrate da high juriya poly-silicon takardar juriya bambancin

| |

| Inorganic Bases (amines, ammonia) & Acids (SOx) | Lalacewar ƙudurin haɓaka juriya na sinadarai

Faruwar gurbacewar barbashi da hazo sakamakon samar da gishiri

| |

| Fina-finan Oxide na Ƙasa da Kemikal Saboda Danshi, Iska | Ƙara juriya na lamba

Rushewar fim ɗin Gate oxide / lalata

| |

Musamman, makasudin aikin tsabtace wafer sun haɗa da:

Cire ɓangarorin: Yin amfani da hanyoyin jiki ko sinadarai don cire ƙananan barbashi da ke haɗe zuwa saman wafer. Ƙananan barbashi sun fi wahalar cirewa saboda ƙarfin ƙarfin lantarki da ke tsakanin su da farfajiyar wafer, suna buƙatar magani na musamman.

Cire Kayayyakin Halitta: Abubuwan gurɓata halitta kamar maiko da ragowar photoresist na iya mannewa saman wafer. Ana cire waɗannan gurɓatattun abubuwa ta hanyar amfani da magunguna masu ƙarfi ko masu ƙarfi.

Cire Ion Karfe: Ragowar ion ƙarfe a saman wafer na iya lalata aikin lantarki har ma yana shafar matakan sarrafawa na gaba. Saboda haka, ana amfani da takamaiman maganin sinadarai don cire waɗannan ions.

Cire Oxide: Wasu matakai suna buƙatar farfajiyar wafer don zama 'yanci daga yadudduka na oxide, kamar silicon oxide. A irin waɗannan lokuta, ana buƙatar cire yadudduka na oxide na halitta yayin wasu matakan tsaftacewa.

Kalubalen fasahar tsabtace wafer ya ta'allaka ne wajen kawar da gurɓataccen gurɓataccen abu ba tare da yin illa ga farfajiyar wafer ba, kamar hana ɓacin rai, lalata, ko wasu lahani na jiki.

2. Tsarin Tsabtace Wafer

Tsarin tsaftacewa na wafer yawanci ya ƙunshi matakai da yawa don tabbatar da cikakkiyar kawar da gurɓataccen abu da cimma cikakkiyar tsaftataccen wuri.

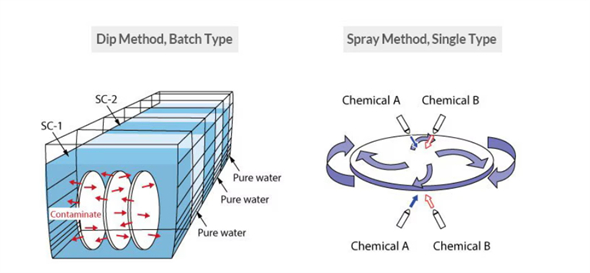

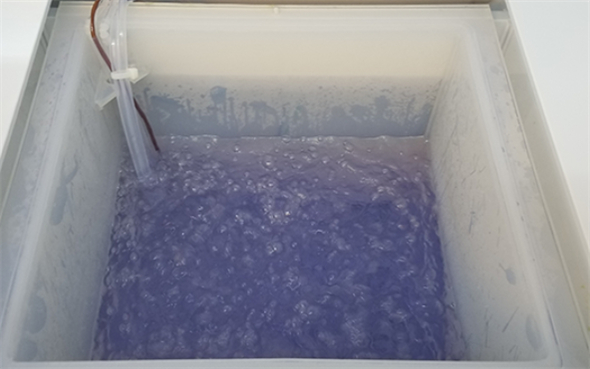

Hoto: Kwatanta Tsakanin Batch-Nau'in da Tsabtace-Wafer Guda

Tsarin tsabtace wafer na yau da kullun ya haɗa da manyan matakai masu zuwa:

1. Pre-Cleaning (Pre-Clean)

Makasudin tsaftacewa na farko shine don cire gurɓataccen gurɓataccen abu da manyan barbashi daga saman wafer, wanda yawanci ana samun su ta hanyar ruwa mai ɗorewa (DI Water) rinsing da ultrasonic tsaftacewa. Deionized ruwa iya fara cire barbashi da kuma narkar da datti daga wafer surface, yayin da ultrasonic tsaftacewa utilizes cavitation effects ya karya bond tsakanin barbashi da wafer surface, sa su sauki narke.

2. Chemical Cleaning

Tsabtace sinadarai ɗaya ne daga cikin mahimman matakai a cikin aikin tsabtace wafer, ta yin amfani da hanyoyin sinadarai don cire kayan halitta, ions ƙarfe, da oxides daga saman wafer.

Cire Kayayyakin Halitta: Yawanci, ana amfani da acetone ko cakuda ammonia/peroxide (SC-1) don narkar da oxidize gurɓatattun ƙwayoyin cuta. A hankula rabo ga SC-1 bayani ne NH₄OH

₂O₂

₂O = 1:1:5, tare da zafin aiki na kusan 20°C.

Karfe Ion Cire: Nitric acid ko hydrochloric acid/peroxide cakudaddun (SC-2) Ana amfani da su cire karfe ions daga wafer surface. Matsakaicin rabo don maganin SC-2 shine HCl

₂O₂

₂O = 1:1:6, tare da kiyaye zafin jiki a kusan 80°C.

Cire Oxide: A wasu matakai, ana buƙatar kawar da Layer oxide na asali daga saman wafer, wanda ake amfani da maganin hydrofluoric acid (HF). Matsakaicin rabo na maganin HF shine HF

₂O = 1:50, kuma ana iya amfani dashi a yanayin zafi.

3. Tsabtace Karshe

Bayan tsaftace sinadarai, wafers yawanci suna ɗaukar matakin tsaftacewa na ƙarshe don tabbatar da cewa babu ragowar sinadarai da suka rage a saman. Tsaftacewa ta ƙarshe yana amfani da ruwan da ba a iya jurewa ba don kurkura sosai. Bugu da ƙari, ana amfani da tsaftace ruwan ozone (O₃/H₂O) don ƙara cire duk wani gurɓataccen abu daga saman wafer.

4. Bushewa

Dole ne a bushe wafers ɗin da aka tsaftace da sauri don hana alamar ruwa ko sake haɗawa da gurɓataccen abu. Hanyoyin bushewa na gama-gari sun haɗa da bushewar juyi da tsabtace nitrogen. Tsohon yana kawar da danshi daga saman wafer ta hanyar jujjuya cikin sauri, yayin da na karshen yana tabbatar da bushewa gaba daya ta hanyar busa busasshen iskar nitrogen a saman saman wafer.

gurɓatacce

Sunan Tsarin Tsaftacewa

Bayanin Cakudar Sinadari

Sinadaran

| Barbashi | Piranha (SPM) | Sulfuric acid/hydrogen peroxide/DI ruwa | H2SO4/H2O2/H2O 3-4:1; 90°C |

| SC-1 (APM) | Ammonium hydroxide/hydrogen peroxide/DI ruwa | NH4OH/H2O2/H2O 1:4:20; 80°C | |

| Karfe (ba tagulla ba) | SC-2 (HPM) | Hydrochloric acid/hydrogen peroxide/DI ruwa | HCl/H2O2/H2O1:1:6; 85°C |

| Piranha (SPM) | Sulfuric acid/hydrogen peroxide/DI ruwa | H2SO4/H2O2/H2O3-4:1; 90°C | |

| DHF | Dilute hydrofluoric acid/DI ruwa (ba zai cire jan karfe) | HF/H2O1:50 | |

| Organics | Piranha (SPM) | Sulfuric acid/hydrogen peroxide/DI ruwa | H2SO4/H2O2/H2O 3-4:1; 90°C |

| SC-1 (APM) | Ammonium hydroxide/hydrogen peroxide/DI ruwa | NH4OH/H2O2/H2O 1:4:20; 80°C | |

| DIO3 | Ozone a cikin de-ionized ruwa | O3/H2O Ingantaccen Cakuda | |

| Oxide na asali | DHF | Tsarma hydrofluoric acid/DI ruwa | HF/H2O 1:100 |

| BHF | Buffered hydrofluoric acid | NH4F/HF/H2O |

3. Hanyoyin Tsabtace Wafer na kowa

1. Hanyar Tsabtace RCA

Hanyar tsaftacewa ta RCA tana ɗaya daga cikin mafi kyawun fasahar tsabtace wafer a cikin masana'antar semiconductor, wanda RCA Corporation ya haɓaka sama da shekaru 40 da suka gabata. Ana amfani da wannan hanyar da farko don cire gurɓataccen ƙwayoyin cuta da ƙazantattun ion ƙarfe kuma ana iya kammala su ta matakai biyu: SC-1 (Standard Clean 1) da SC-2 (Standard Clean 2).

SC-1 Tsaftacewa: Ana amfani da wannan matakin musamman don cire gurɓatattun ƙwayoyin cuta da ƙwayoyin cuta. Maganin shine cakuda ammonia, hydrogen peroxide, da ruwa, wanda ke samar da siliki na siliki na bakin ciki akan saman wafer.

SC-2 Tsaftacewa: Ana amfani da wannan matakin da farko don cire gurɓataccen ion ƙarfe, ta amfani da cakuda hydrochloric acid, hydrogen peroxide, da ruwa. Yana barin wani siriri na wucewa akan saman wafer don hana sake gurɓacewa.

2. Hanyar Tsabtace Piranha (Piranha Etch Clean)

Hanyar tsaftacewa ta Piranha wata hanya ce mai matukar tasiri don cire kayan halitta, ta amfani da cakuda sulfuric acid da hydrogen peroxide, yawanci a cikin rabo na 3: 1 ko 4: 1. Saboda daɗaɗɗen kaddarorin oxidative na wannan bayani, zai iya cire babban adadin kwayoyin halitta da ƙazanta masu taurin kai. Wannan hanya tana buƙatar tsananin kulawa da yanayi, musamman dangane da yanayin zafi da maida hankali, don guje wa lalata wafer.

Ultrasonic tsaftacewa yana amfani da tasirin cavitation da aka haifar ta hanyar raƙuman sauti mai girma a cikin ruwa don cire gurɓataccen abu daga farfajiyar wafer. Idan aka kwatanta da tsaftacewa na gargajiya na ultrasonic, tsaftacewa na megasonic yana aiki a mafi girma mita, yana ba da damar kawar da ƙananan ƙananan ƙananan ƙwayoyin cuta ba tare da haifar da lalacewa ga wafer ba.

4. Ozone Cleaning

Fasahar tsaftacewa ta Ozone tana amfani da ƙaƙƙarfan kaddarorin oxidizing na ozone don bazuwa da cire gurɓatattun ƙwayoyin halitta daga saman wafer, a ƙarshe yana canza su zuwa carbon dioxide da ruwa mara lahani. Wannan hanyar ba ta buƙatar yin amfani da magungunan sinadarai masu tsada kuma yana haifar da ƙarancin gurɓataccen muhalli, yana mai da shi fasaha mai tasowa a fagen tsabtace wafer.

4. Kayan aikin Tsabtace Wafer

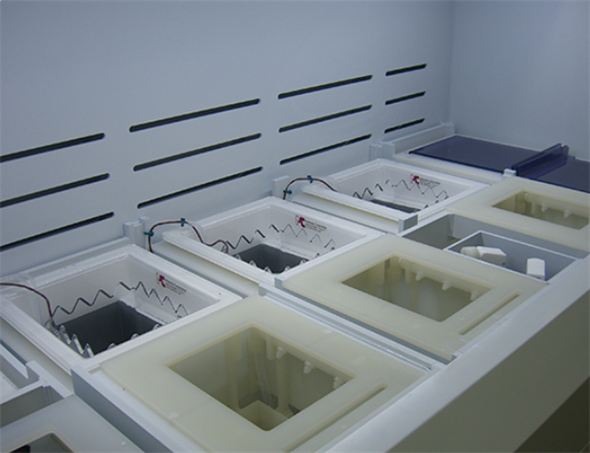

Don tabbatar da inganci da amincin hanyoyin tsabtace wafer, ana amfani da kayan aikin tsaftacewa iri-iri a masana'antar semiconductor. Manyan nau'ikan sun haɗa da:

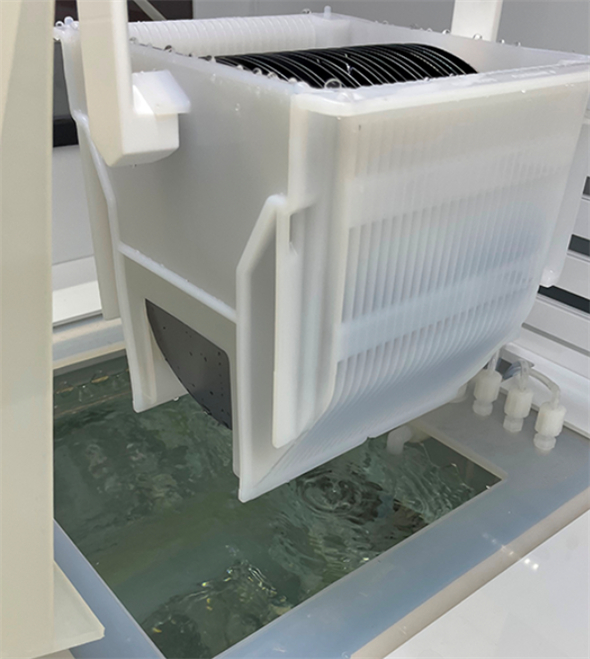

1. Kayayyakin Tsabtace Rigar

Kayan aikin tsabtace rigar sun haɗa da tankuna na nutsewa daban-daban, tankunan tsaftacewa na ultrasonic, da na'urorin bushewa. Waɗannan na'urori sun haɗu da ƙarfin injina da masu sarrafa sinadarai don cire gurɓata daga saman wafer. Tankunan nutsewa galibi ana sanye su da tsarin sarrafa zafin jiki don tabbatar da kwanciyar hankali da ingancin hanyoyin sinadarai.

2. Busassun Kayan Aiki

Kayan aikin bushewa sun haɗa da masu tsabtace plasma, waɗanda ke amfani da ɓangarorin ƙarfi mai ƙarfi a cikin plasma don amsawa da cire ragowar daga saman wafer. Tsaftace Plasma ya dace musamman don matakan da ke buƙatar kiyaye amincin saman ba tare da gabatar da ragowar sinadarai ba.

3. Tsaftace Tsabtace Mai sarrafa kansa

Tare da ci gaba da fadada samar da semiconductor, tsarin tsaftacewa ta atomatik ya zama zaɓin da aka fi so don tsaftacewa mai girma. Waɗannan tsarin galibi sun haɗa da hanyoyin canja wuri ta atomatik, tsarin tsabtace tanki da yawa, da tsarin kulawa daidai don tabbatar da daidaiton sakamakon tsaftacewa ga kowane wafer.

5. Yanayin Gaba

Yayin da na'urorin semiconductor ke ci gaba da raguwa, fasahar tsabtace wafer tana haɓaka zuwa mafi inganci da mafita ga muhalli. Fasahar tsaftacewa ta gaba za ta mayar da hankali kan:

Cire ƙwayar cuta na NANETOME: Tsarin tsabtatawa na yanzu zai iya ɗaukar barbashi na Nanometer, amma tare da ƙarin ragi a girman na'urori, cire sub-nanometer na samar da barbashi zai zama sabon kalubale.

Green da Tsabtace Tsabtace Tsabtace Tsabtace: Rage amfani da sinadarai masu cutarwa da haɓaka ƙarin hanyoyin tsabtace muhalli, kamar tsaftacewar ozone da tsabtace megasonic, zai ƙara zama mahimmanci.

Matsayi mafi girma na aiki da kai da hankali: Tsarin hankali zai ba da damar saka idanu na lokaci-lokaci da daidaita ma'auni daban-daban yayin aikin tsaftacewa, ƙara haɓaka aikin tsaftacewa da ingantaccen samarwa.

Fasahar tsaftacewa ta Wafer, a matsayin muhimmin mataki a masana'antar semiconductor, tana taka muhimmiyar rawa wajen tabbatar da tsaftataccen shimfidar wafer don matakai na gaba. Haɗuwa da hanyoyi daban-daban na tsaftacewa yadda ya kamata yana kawar da gurɓataccen abu, yana samar da wuri mai tsabta don matakai na gaba. Yayin da fasahar ke ci gaba, za a ci gaba da inganta ayyukan tsaftacewa don biyan buƙatun mafi girman daidaici da ƙarancin lahani a masana'antar semiconductor.

Lokacin aikawa: Oktoba-08-2024