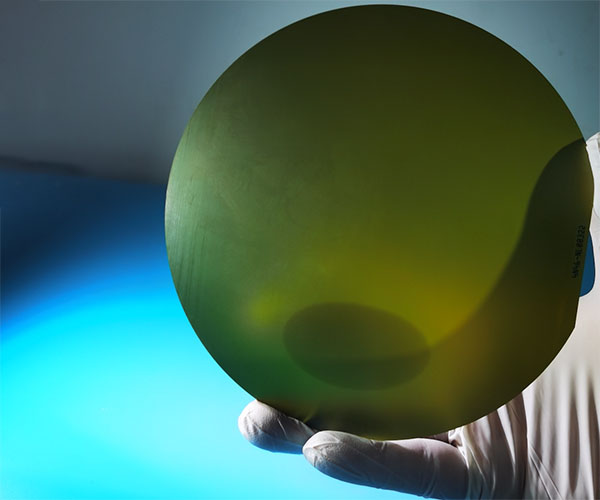

A halin yanzu, kamfaninmu na iya ci gaba da samar da ƙananan nau'in 8inchN nau'in sic wafers, idan kuna da buƙatun samfurin, da fatan za ku iya tuntuɓar ni. Muna da wasu samfuran wafers a shirye don jigilar kaya.

A fagen kayan aikin semiconductor, kamfanin ya sami babban ci gaba a cikin bincike da haɓaka manyan lu'ulu'u na SiC. Ta yin amfani da nasa iri lu'ulu'u bayan mahara zagaye na diamita girma girma, kamfanin ya samu nasarar girma 8-inch N-type SiC lu'ulu'u, wanda solves wuya matsaloli kamar m zafin jiki filin, crystal fatattaka da gas lokaci albarkatun kasa rarraba a cikin ci gaban aiwatar da 8-inch SIC lu'ulu'u, da kuma accelerates da girma na manyan size SIC lu'ulu'u da kuma m da sarrafawa fasahar. Haɓaka babban gasa na kamfani a cikin masana'antar simintin kristal guda ɗaya na SiC. A lokaci guda, kamfanin rayayye inganta jari na fasaha da kuma aiwatar da manyan size silicon carbide substrate shirye-shiryen gwaji line, ƙarfafa da fasaha musayar da kuma masana'antu hadin gwiwa a sama da kasa filayen, da kuma hada gwiwa tare da abokan ciniki zuwa kullum iterate samfurin yi, da kuma hadin gwiwa inganta taki na masana'antu aikace-aikace na silicon carbide kayan.

| 8inch N-type SiC DSP Specs | |||||

| Lamba | Abu | Naúrar | Production | Bincike | Dummy |

| 1. Ma'auni | |||||

| 1.1 | nau'in poly | -- | 4H | 4H | 4H |

| 1.2 | fuskar fuska | ° | <11-20>4±0.5 | <11-20>4±0.5 | <11-20>4±0.5 |

| 2. Wutar lantarki | |||||

| 2.1 | dopant | -- | n-nau'in Nitrogen | n-nau'in Nitrogen | n-nau'in Nitrogen |

| 2.2 | resistivity | ku · cm | 0.015 ~ 0.025 | 0.01 ~ 0.03 | NA |

| 3. Mechanical siga | |||||

| 3.1 | diamita | mm | 200± 0.2 | 200± 0.2 | 200± 0.2 |

| 3.2 | kauri | μm | 500± 25 | 500± 25 | 500± 25 |

| 3.3 | Matsayin daraja | ° | [1-100] ± 5 | [1-100] ± 5 | [1-100] ± 5 |

| 3.4 | Zurfin Daraja | mm | 1 ~ 1.5 | 1 ~ 1.5 | 1 ~ 1.5 |

| 3.5 | LTV | μm | ≤5(10mm*10mm) | ≤5(10mm*10mm) | ≤10 (10mm*10mm) |

| 3.6 | TTV | μm | ≤10 | ≤10 | ≤15 |

| 3.7 | Ruku'u | μm | -25-25 | -45-45 | -65-65 |

| 3.8 | Warp | μm | ≤30 | ≤50 | ≤70 |

| 3.9 | AFM | nm | ≤0.2 | ≤0.2 | ≤0.2 |

| 4. Tsari | |||||

| 4.1 | micropipe yawa | ku/cm2 | ≤2 | ≤10 | ≤50 |

| 4.2 | abun ciki na karfe | atom/cm2 | ≤1E11 | ≤1E11 | NA |

| 4.3 | TSD | ku/cm2 | ≤500 | ≤1000 | NA |

| 4.4 | BPD | ku/cm2 | ≤2000 | ≤5000 | NA |

| 4.5 | TED | ku/cm2 | ≤7000 | ≤10000 | NA |

| 5. Kyakkyawan inganci | |||||

| 5.1 | gaba | -- | Si | Si | Si |

| 5.2 | saman gamawa | -- | Farashin CMP | Farashin CMP | Farashin CMP |

| 5.3 | barbashi | e/wafar | ≤100(size≥0.3μm) | NA | NA |

| 5.4 | karce | e/wafar | ≤5, Jimlar Tsawon≤200mm | NA | NA |

| 5.5 | Gefen kwakwalwan kwamfuta / indents / fasa / tabo / gurɓatawa | -- | Babu | Babu | NA |

| 5.6 | Yankunan polytype | -- | Babu | Yanki ≤10% | Yanki ≤30% |

| 5.7 | alamar gaba | -- | Babu | Babu | Babu |

| 6. Baya ingancin | |||||

| 6.1 | dawo gama | -- | C-face MP | C-face MP | C-face MP |

| 6.2 | karce | mm | NA | NA | NA |

| 6.3 | Gefen lahani na baya kwakwalwan kwamfuta / indents | -- | Babu | Babu | NA |

| 6.4 | Baƙar fata | nm | Ra ≤5 | Ra ≤5 | Ra ≤5 |

| 6.5 | Alamar baya | -- | Daraja | Daraja | Daraja |

| 7. Gaba | |||||

| 7.1 | baki | -- | Chamfer | Chamfer | Chamfer |

| 8. Kunshin | |||||

| 8.1 | marufi | -- | Epi-shirye tare da injin marufi | Epi-shirye tare da injin marufi | Epi-shirye tare da injin marufi |

| 8.2 | marufi | -- | Multi-wafer kaset marufi | Multi-wafer kaset marufi | Multi-wafer kaset marufi |

Lokacin aikawa: Afrilu-18-2023