Tambaya: Menene manyan fasahohin da ake amfani da su a cikin slicing da sarrafa wafer na SiC?

A:Silicon carbide (SiC) yana da taurin na biyu kawai zuwa lu'u-lu'u kuma ana ɗaukarsa abu ne mai wuya kuma mai karye. Tsarin slicing, wanda ya ƙunshi yankan lu'ulu'u masu girma a cikin wafers na bakin ciki, yana ɗaukar lokaci kuma yana yiwuwa ga guntu. A matsayin farkon matakin shigaSiCsarrafa kristal guda ɗaya, ingancin slicing yana da tasiri mai mahimmanci na niƙa, gogewa, da bakin ciki. Yanke sau da yawa yana gabatar da fashewar ƙasa da ƙasa, haɓaka ƙimar wafer da farashin samarwa. Don haka, sarrafa lalacewar fashe yayin yanka yana da mahimmanci don haɓaka ƙirƙira na'urar SiC.

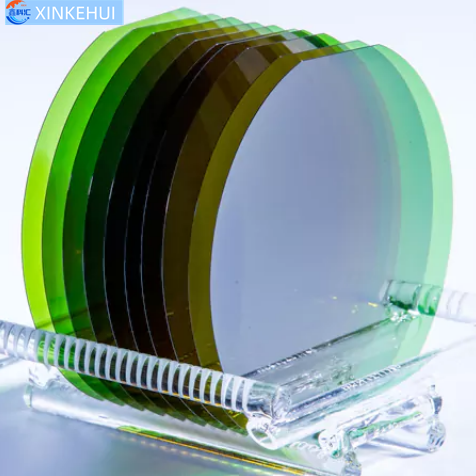

A halin yanzu an ba da rahoton hanyoyin slicing SiC sun haɗa da ƙayyadaddun abrasive, slicing kyauta, yankan Laser, canja wurin Layer (rabuwar sanyi), da slicing fitarwa na lantarki. Daga cikin waɗannan, slicing multi-waya slicing tare da kafaffen lu'u-lu'u abrasives shine mafi yawan amfani da hanyar sarrafa lu'ulu'u ɗaya na SiC. Koyaya, yayin da girman ingot ya kai inci 8 da sama, tsinken waya na gargajiya ya zama ƙasa da amfani saboda manyan buƙatun kayan aiki, farashi, da ƙarancin inganci. Akwai buƙatar gaggawa don ƙarancin farashi, ƙarancin asara, fasahar yankan ƙima mai inganci.

Tambaya: Menene fa'idodin slicing Laser akan yankan wayoyi da yawa na gargajiya?

A: Gargajiya sawing yana yankeSiC samutare da takamaiman shugabanci zuwa yanka da yawa microns kauri. Ana niƙa yankan ta hanyar amfani da lu'u lu'u-lu'u don cire alamar zagi da lalacewar ƙasa, sannan a bi da su tare da goge gogen sinadarai (CMP) don cimma tsarin tsarin duniya, kuma a ƙarshe an tsaftace su don samun wafers na SiC.

Duk da haka, saboda girman taurin SiC da ɓarna, waɗannan matakan na iya haifar da yaƙe-yaƙe cikin sauƙi, fashewa, ƙarar raguwar ƙima, tsadar samar da kayayyaki, da haifar da ƙarancin ƙasa da gurɓata (ƙura, ruwan sharar gida, da sauransu). Bugu da ƙari, zaren waya yana jinkiri kuma yana da ƙarancin amfanin ƙasa. Ƙididdiga sun nuna cewa slicing multi-waya na gargajiya yana samun kusan kashi 50% na amfani da kayan, kuma har zuwa kashi 75% na kayan sun ɓace bayan gogewa da niƙa. Bayanan samar da ƙasashen waje na farko sun nuna cewa zai iya ɗaukar kimanin kwanaki 273 na ci gaba da samarwa na sa'o'i 24 don samar da wafers 10,000-mai tsananin lokaci.

A cikin gida, yawancin kamfanonin haɓaka kristal na SiC suna mai da hankali kan haɓaka ƙarfin tanderu. Duk da haka, maimakon kawai faɗaɗa fitarwa, yana da mahimmanci a yi la'akari da yadda za a rage asara-musamman lokacin da ci gaban kristal bai yi kyau ba tukuna.

Laser slicing kayan aiki na iya rage yawan asarar abu da inganta yawan amfanin ƙasa. Alal misali, amfani da guda 20 mmSiC samu: Waya sawing na iya samar da kusan 30 wafers na 350 μm kauri. Laser slicing iya samar da fiye da 50 wafers. Idan wafer kauri ne rage zuwa 200 μm, fiye da 80 wafers za a iya samar daga wannan ingot. Yayin da waya sawing ne yadu amfani ga wafers 6 inci da karami a 8-slic5 C. kwanaki tare da hanyoyin gargajiya, da ake buƙatar kayan aiki masu mahimmanci kuma suna haifar da farashi mai yawa tare da ƙananan inganci. A ƙarƙashin waɗannan sharuɗɗan, fa'idodin slicing Laser ya bayyana a sarari, yana mai da shi babban fasaha na gaba don wafers 8-inch.

Tare da yankan Laser, lokacin yankan kowane 8-inch wafer na iya zama ƙasa da mintuna 20, tare da asarar abu a kowace wafer ƙarƙashin 60 μm.

A taƙaice, idan aka kwatanta da yankan wayoyi da yawa, slicing laser yana ba da sauri mafi girma, mafi kyawun yawan amfanin ƙasa, ƙananan asarar kayan abu, da aiki mai tsabta.

Tambaya: Menene babban kalubalen fasaha a cikin slicing Laser SiC?

A: Tsarin slicing Laser ya ƙunshi manyan matakai guda biyu: gyare-gyaren laser da rabuwar wafer.

Babban gyare-gyaren laser shine ƙirar katako da haɓaka siga. Sigogi kamar wutar lantarki, diamita tabo, da saurin duba duk suna shafar ingancin zubar da kayan da nasarar rabuwar wafer na gaba. Geometry na yankin da aka gyara yana ƙayyade ƙayyadaddun yanayi da wahalar rabuwa. Babban rashin ƙarfi yana rikitar da niƙa daga baya kuma yana ƙara asarar kayan abu.

Bayan gyare-gyare, yawanci ana samun rabuwar wafer ta hanyar ƙarfi, kamar karayar sanyi ko damuwa na inji. Wasu tsarin cikin gida suna amfani da masu fassara na ultrasonic don haifar da girgiza don rabuwa, amma wannan na iya haifar da lahani da lahani, rage yawan amfanin ƙasa.

Duk da yake waɗannan matakai guda biyu ba su da wuyar gaske, rashin daidaituwa a cikin ingancin crystal-saboda matakai daban-daban na girma, matakan doping, da rarraba damuwa na ciki - yana tasiri ga wahalar yankewa, yawan amfanin ƙasa, da asarar kayan abu. Gano wuraren matsala kawai da daidaita wuraren sikanin Laser bazai inganta sakamako sosai ba.

Makullin karɓar tallafi ya ta'allaka ne a cikin haɓaka sabbin hanyoyin da kayan aiki waɗanda zasu iya daidaitawa zuwa nau'ikan halayen crystal daga masana'antun daban-daban, inganta sigogin tsari, da gina tsarin slicing Laser tare da aikace-aikacen duniya.

Tambaya: Za a iya amfani da fasahar slicing Laser zuwa wasu kayan semiconductor ban da SiC?

A: A tarihi an yi amfani da fasahar yankan Laser ga abubuwa da yawa. A cikin semiconductor, an fara amfani da shi don dicing ɗin wafer kuma tun daga lokacin ya faɗaɗa zuwa yanka manyan lu'ulu'u masu yawa.

Bayan SiC, ana iya amfani da slicing Laser don wasu abubuwa masu wuya ko gagaru kamar lu'u-lu'u, gallium nitride (GaN), da gallium oxide (Ga₂O₃). Nazarin farko akan waɗannan kayan sun nuna yuwuwar da fa'idar slicing Laser don aikace-aikacen semiconductor.

Tambaya: Shin a halin yanzu akwai samfuran kayan aikin slicing laser na cikin gida balagagge? Wane mataki bincikenku yake a ciki?

A: Babban diamita SiC Laser slicing kayan aiki ana daukar su da yawa kayan aiki na kayan aiki don makomar samar da wafer SiC 8-inch. A halin yanzu, Japan kawai za ta iya samar da irin waɗannan tsarin, kuma suna da tsada kuma suna ƙarƙashin ƙuntatawa na fitarwa.

Bukatar cikin gida don tsarin slicing / thinning laser an kiyasta kusan raka'a 1,000, dangane da tsare-tsaren samar da SiC da ƙarfin gani na waya. Manyan kamfanoni na cikin gida sun saka jari mai yawa don haɓakawa, amma har yanzu babu wani balagagge, kayan aikin gida da ake samarwa da kasuwa wanda ya kai ga tura masana'antu.

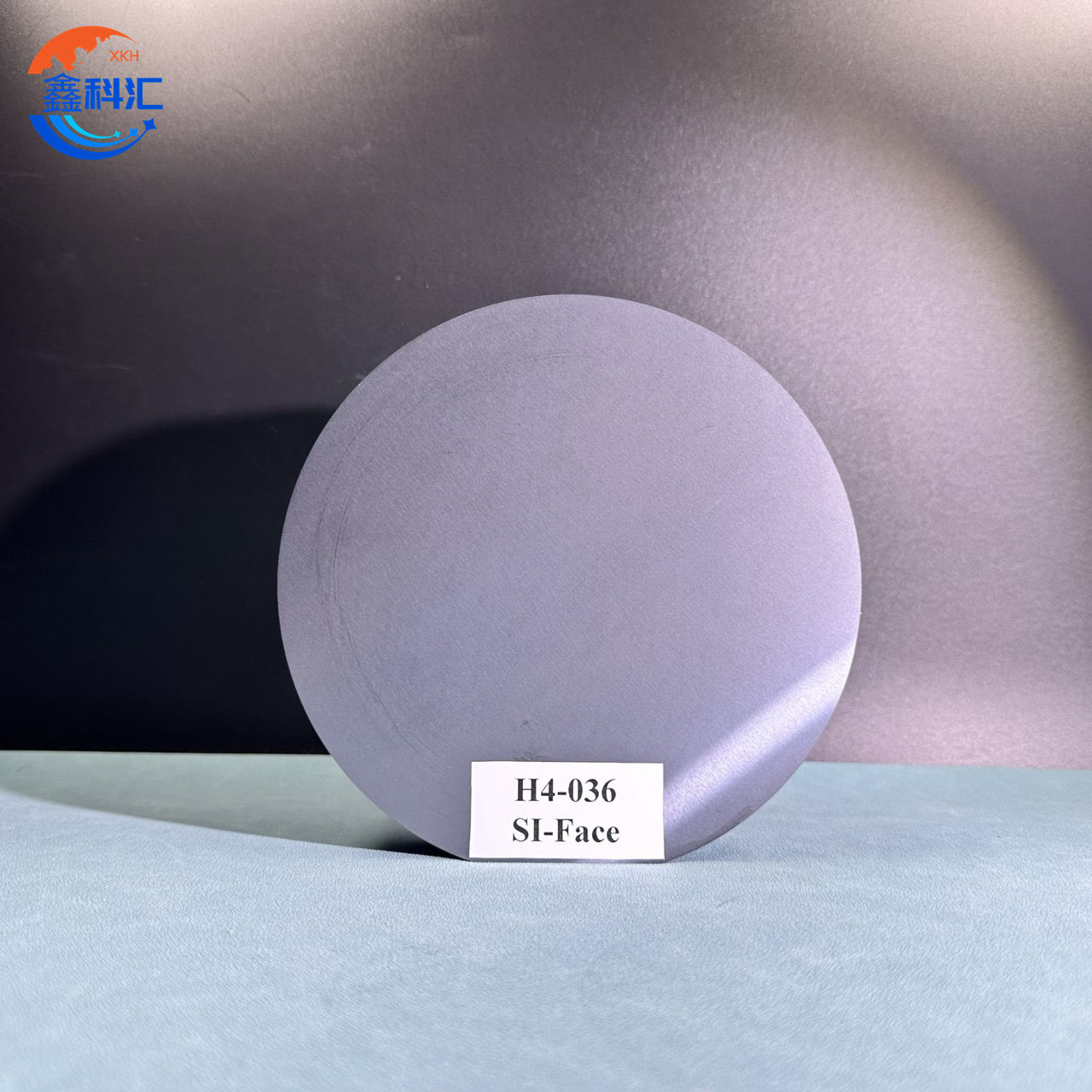

Ƙungiyoyin bincike suna haɓaka fasahar ɗagawa ta Laser na mallakar mallakar tun daga 2001 kuma yanzu sun tsawaita wannan zuwa babban diamita na SiC Laser slicing da thinning. Sun ɓullo da tsarin samfuri da matakai na slicing wanda zai iya: Yankewa da ɓacin rai 4-6 inch Semi-insulating SiC wafersSlicing 6-8 inch conductive SiC ingotsAyyukan ma'auni: 6-8 inch Semi-insulating SiC: lokacin yanka 10-15 mintuna / wafer; asarar kayan abu <30 μm6-8 inch mai gudanarwa SiC: lokacin yanka 14-20 mintuna / wafer; asarar abu <60 μm

Kiyasin amfanin wafer ya karu da sama da 50%

Bayan slicing, wafers sun cika ka'idodin ƙasa don lissafi bayan niƙa da gogewa. Har ila yau, binciken ya nuna cewa tasirin zafi da ke haifar da Laser ba ya tasiri sosai ga damuwa ko lissafi a cikin wafers.

Hakanan an yi amfani da kayan aiki iri ɗaya don tabbatar da yuwuwar yanke lu'u-lu'u, GaN, da Ga₂O₃ lu'ulu'u ɗaya.

Lokacin aikawa: Mayu-23-2025