Silicon carbide (SiC) ba kawai fasaha ce mai mahimmanci don tsaron ƙasa ba har ma da mahimman abu don masana'antar kera motoci da makamashi ta duniya. A matsayin mataki na farko mai mahimmanci a cikin sarrafa SiC guda-crystal, slicing wafer kai tsaye yana ƙayyade ingancin bakin ciki da gogewa. Hanyoyin slicing na al'ada sau da yawa suna gabatar da fashewar ƙasa da ƙasa, haɓaka ƙimar wafer da farashin masana'anta. Don haka, sarrafa lalacewar fashe yana da mahimmanci don haɓaka masana'antar na'urar SiC.

A halin yanzu, SiC ingot slicing yana fuskantar manyan ƙalubale guda biyu:

- Babban hasara na kayan abu a cikin sawing Multi-waya na gargajiya:Matsanancin taurin SiC da ɓarna suna sa ya zama mai sauƙi ga warping da fashewa yayin yankan, niƙa, da gogewa. Dangane da bayanan Infineon, al'adun gargajiyar lu'u-lu'u-resin-bonded Multi-waya sawing yana samun 50% kawai amfani da kayan a yanka, tare da jimlar wafer guda ɗaya ya kai ~ 250 μm bayan gogewa, yana barin ƙaramin abu mai amfani.

- Ƙananan inganci da kuma tsayin daka na samarwa:Kididdigar samar da kasa da kasa sun nuna cewa samar da wafers 10,000 ta amfani da ci gaba da sawing na wayoyi da yawa na awanni 24 yana ɗaukar kwanaki 273. Wannan hanya tana buƙatar kayan aiki masu yawa da abubuwan da ake amfani da su yayin samar da ƙarancin ƙasa da ƙazanta (ƙura, ruwan sharar gida).

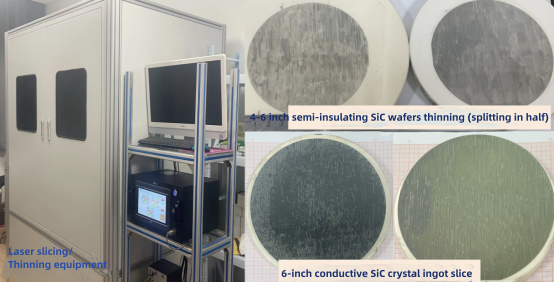

Don magance waɗannan batutuwa, ƙungiyar Farfesa Xiu Xiangqian a Jami'ar Nanjing ta ƙera kayan aikin slicing na Laser mai inganci don SiC, yana ba da damar fasahar laser ultrafast don rage lahani da haɓaka yawan aiki. Don 20-mm SiC ingot, wannan fasaha ta ninka yawan wafer idan aka kwatanta da sawing na waya na gargajiya. Bugu da ƙari, wafers ɗin da aka sliced Laser yana nuna ingantaccen daidaituwa na geometric, yana ba da damar rage kauri zuwa μm 200 a kowace wafer da ƙara haɓaka fitarwa.

Babban Amfani:

- R&D da aka kammala akan manyan kayan samfuri, ingantattun don yanka 4-6-inch Semi-insulating SiC wafers da 6-inch conductive SiC ingots.

- 8-inch ingot yankan yana ƙarƙashin tabbaci.

- Mahimmanci ɗan gajeren lokacin yanka, mafi girman fitarwa na shekara-shekara, da> 50% haɓaka yawan amfanin ƙasa.

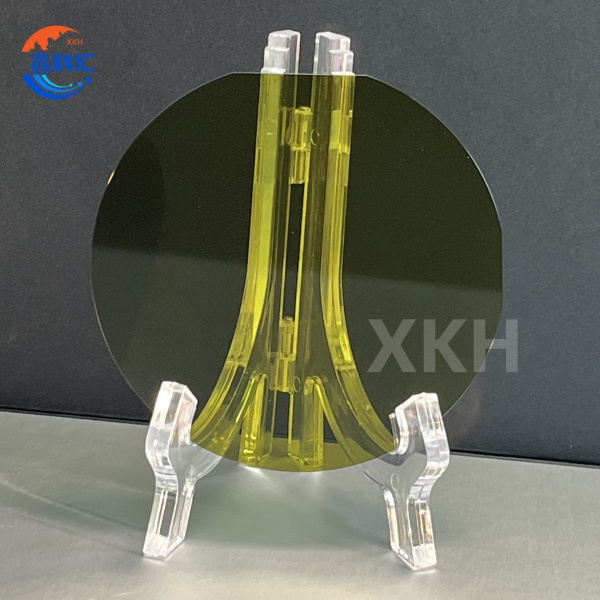

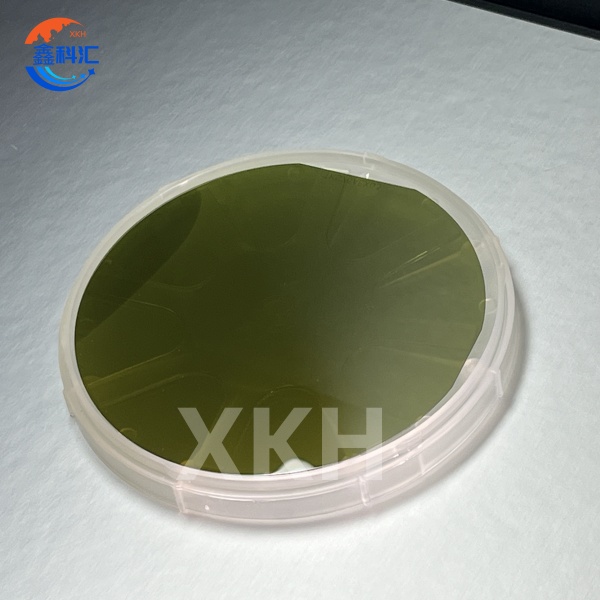

SiC na XKH na nau'in 4H-N

Yiwuwar Kasuwa:

Wannan kayan aikin yana shirye don zama ainihin mafita don slicing SiC ingot 8-inch, a halin yanzu shigo da Jafananci ya mamaye tare da tsada mai tsada da ƙuntatawa fitarwa. Bukatar cikin gida don kayan yankan Laser / bakin ciki ya zarce raka'a 1,000, duk da haka babu wani balagaggen madadin da Sinanci ke yi. Fasahar Jami'ar Nanjing tana da kimar kasuwa da karfin tattalin arziki.

Daidaituwar Kayayyaki da yawa:

Bayan SiC, kayan aikin suna tallafawa sarrafa Laser na gallium nitride (GaN), aluminum oxide (Al₂O₃), da lu'u-lu'u, yana faɗaɗa aikace-aikacen masana'anta.

Ta hanyar jujjuya sarrafa wafer na SiC, wannan ƙirƙira tana magance ƙuƙumman ƙulli a cikin masana'antar semiconductor yayin daidaitawa tare da yanayin duniya zuwa babban aiki, kayan aiki masu ƙarfi.

Kammalawa

A matsayin jagoran masana'antu a cikin masana'antar siliki carbide (SiC), XKH ya ƙware a samar da 2-12-inch cikakken girman SiC substrates Yin amfani da fasaha mai ƙarancin hasarar slicing wafer da fasaha mai inganci, mun sami yawan samar da ɗimbin ɗimbin inci 8 da ci gaba a cikin fasahar ci gaban SiC crystal mai inci 12-inch, tare da rage farashin guntu kowane raka'a. Ci gaba, za mu ci gaba da inganta ingot-level Laser slicing da kuma hanyoyin sarrafa damuwa na hankali don haɓaka 12-inch substrate yawan amfanin ƙasa zuwa gasa na duniya, ƙarfafa masana'antar SiC na cikin gida don karya ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun kayan aiki kamar kwakwalwan kwamfuta-maki da uwar garken AI.

SiC na XKH na nau'in 4H-N

Lokacin aikawa: Agusta-15-2025