Tun daga 1980s, yawan haɗin kai na da'irori na lantarki yana ƙaruwa a cikin adadin shekara-shekara na 1.5 × ko sauri. Haɗin kai mafi girma yana haifar da mafi girma na yanzu da kuma samar da zafi yayin aiki.Idan ba a watsar da shi yadda ya kamata ba, wannan zafi zai iya haifar da gazawar thermal kuma ya rage tsawon rayuwar kayan lantarki.

Don saduwa da haɓaka buƙatun sarrafa zafin rana, ana yin bincike da haɓaka haɓaka kayan tattara kayan lantarki masu inganci tare da ingantaccen yanayin zafi.

Lu'u-lu'u/nau'in jan karfe

01 Diamond da Copper

Kayan marufi na al'ada sun haɗa da yumbu, robobi, karafa, da kayan haɗin gwiwar su. Ceramics kamar BeO da AlN suna baje kolin CTEs masu dacewa da semiconductor, kyakkyawan kwanciyar hankali na sinadarai, da matsakaicin yanayin zafi. Koyaya, hadaddun sarrafa su, tsada mai tsada (musamman BeO mai guba), da ƙayyadaddun ƙayyadaddun aikace-aikace. Marufi na filastik yana ba da ƙarancin farashi, nauyi mai sauƙi, da rufi amma yana fama da ƙarancin zafin jiki da rashin kwanciyar hankali. Tsabtace karafa (Cu, Ag, Al) suna da babban ƙarfin zafin jiki amma wuce kima CTE, yayin da gami (Cu-W, Cu-Mo) suna yin sulhu da aikin thermal. Don haka, kayan marufi na zamani waɗanda ke daidaita haɓakar haɓakar zafi da ingantaccen CTE ana buƙatar gaggawa.

| Ƙarfafawa | Ƙarfafa Ƙarfafawa (W/ (m·K)) | CTE (×10⁻⁶/℃) | Girma (g/cm³) |

| Diamond | 700-2000 | 0.9-1.7 | 3.52 |

| BeO barbashi | 300 | 4.1 | 3.01 |

| AlN barbashi | 150-250 | 2.69 | 3.26 |

| SiC barbashi | 80-200 | 4.0 | 3.21 |

| B₄C barbashi | 29-67 | 4.4 | 2.52 |

| Boron fiber | 40 | ~5.0 | 2.6 |

| TiC barbashi | 40 | 7.4 | 4.92 |

| Al₂O₃ barbashi | 20-40 | 4.4 | 3.98 |

| SiC wuski | 32 | 3.4 | - |

| Si₃N₄ barbashi | 28 | 1.44 | 3.18 |

| TiB₂ barbashi | 25 | 4.6 | 4.5 |

| SiO₂ barbashi | 1.4 | <1.0 | 2.65 |

Diamond, mafi wuya sanannun halitta abu (Mohs 10), kuma ya mallaki na kwaraiƘarfafawar thermal (200-2200 W/ (m·K)).

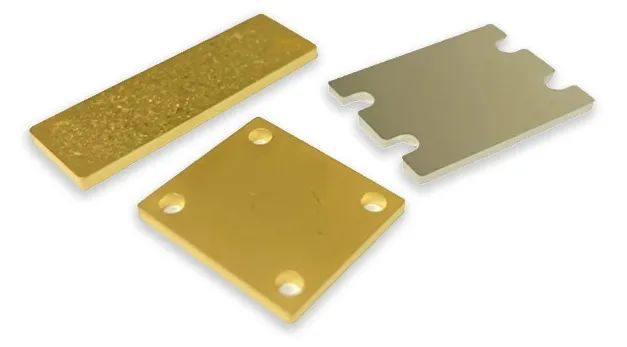

Diamond micro-foda

Copper, tare da high thermal / lantarki watsin (401 W / (m · K)), ductility, da kuma ingancin farashi, ana amfani da su sosai a cikin ICs.

Haɗa waɗannan kaddarorin,lu'u-lu'u / jan ƙarfe (Dia/Cu) abubuwan da aka haɗa-tare da Cu a matsayin matrix da lu'u-lu'u azaman ƙarfafawa - suna fitowa azaman kayan sarrafa zafi na gaba.

02 Maɓalli Hanyoyin Ƙirƙira

Hanyoyin da ake amfani da su don shirya lu'u-lu'u / jan ƙarfe sun haɗa da: ƙarfe na foda, yanayin zafi mai zafi da babban matsi, hanyar narke nutsewa, hanyar zubar da jini, hanyar fesa sanyi, da dai sauransu.

Kwatanta hanyoyin shirye-shirye daban-daban, matakai da kaddarorin girman nau'in lu'u-lu'u/kopper

| Siga | Powder Metallurgy | Vacuum Hot-Matsawa | Spark Plasma Sintering (SPS) | Babban Zazzabi (HPHT) | Sanyi Fasa Zuciya | Narke Kutse |

| Nau'in Diamond | MB8 | HFD-D | MB8 | MB4 | PDA | MBD8/HHD |

| Matrix | 99.8% Ku foda | 99.9% electrolytic Cu foda | 99.9% Ku foda | Alloy/pure Cu foda | Pure Cu foda | Pure Cu girma / sanda |

| Gyaran Interface | - | - | - | B, Ti, Si, Cr, Zr, W, Mo | - | - |

| Girman Barbashi (μm) | 100 | 106-125 | 100-400 | 20-200 | 35-200 | 50-400 |

| Juzu'i na girma (%) | 20-60 | 40-60 | 35-60 | 60-90 | 20-40 | 60-65 |

| Zazzabi (°C) | 900 | 800-1050 | 880-950 | 1100-1300 | 350 | 1100-1300 |

| Matsi (MPa) | 110 | 70 | 40-50 | 8000 | 3 | 1-4 |

| Lokaci (minti) | 60 | 60-180 | 20 | 6-10 | - | 5-30 |

| Yawan Dangi (%) | 98.5 | 99.2–99.7 | - | - | - | 99.4-99.7 |

| Ayyuka | ||||||

| Ingantacciyar Haɓakawa ta thermal (W/(m·K)) | 305 | 536 | 687 | 907 | - | 943 |

Hanyoyi na gama-gari na Dia/C sun haɗa da:

(1)Powder Metallurgy

Ganyayyakin lu'u-lu'u/C an haɗa su kuma an haɗa su. Duk da yake yana da tsada kuma mai sauƙi, wannan hanyar tana haifar da ƙayyadaddun ƙima, ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun abubuwa, da ƙayyadaddun ƙimar samfurin.

Snaúrar intering

(1)Babban Zazzabi (HPHT)

Yin amfani da matsi da matsi da yawa, narkakkar Cu yana kutsawa cikin lattices na lu'u-lu'u a ƙarƙashin matsanancin yanayi, yana samar da abubuwa masu yawa. Koyaya, HPHT yana buƙatar ƙira mai tsada kuma bai dace da samarwa mai girma ba.

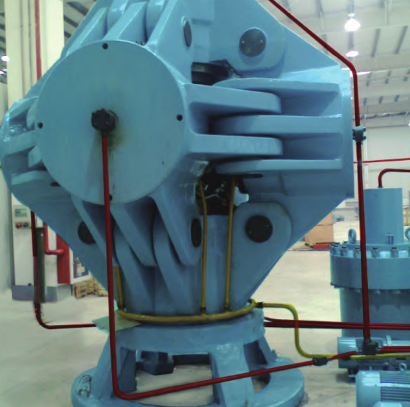

Cubic press

(1)Narke Kutse

Molten Cu yana ratsa ƙirar lu'u-lu'u ta hanyar matsi-taimaka ko kutsawa ta capillary. Abubuwan da suka haifar sun cimma> 446 W/(m·K) halayen thermal conductivity.

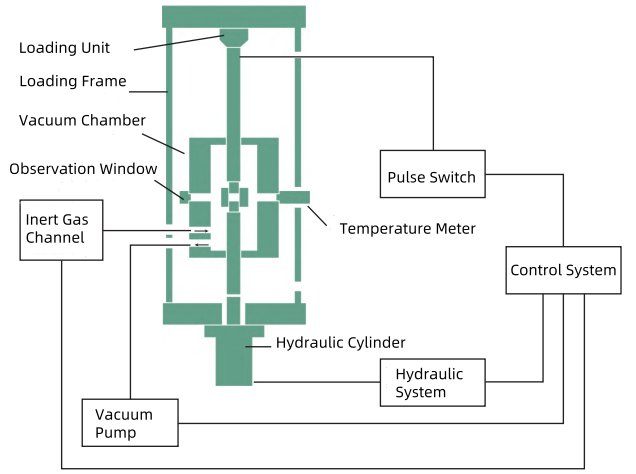

(2)Spark Plasma Sintering (SPS)

Pulsed halin yanzu cikin hanzari sinters gauraye foda a ƙarƙashin matsin lamba. Ko da yake yana da inganci, aikin SPS yana raguwa a ɓangarorin lu'u-lu'u> 65 vol.

Tsarin tsari na tsarin siginar jini na fitarwa

(5) Ciwon sanyi

Ana haɓaka foda kuma ana ajiye su a kan abubuwan da ake buƙata. Wannan sabuwar hanyar tana fuskantar ƙalubale a cikin sarrafa ƙarewar ƙasa da ingancin aikin zafi.

03 Gyaran Interface

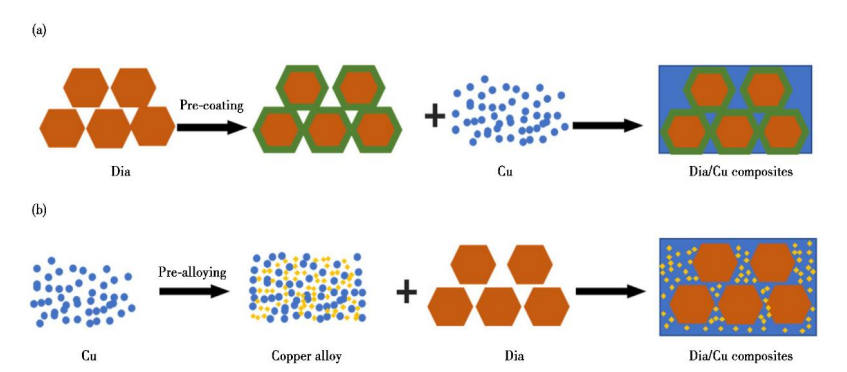

Don shirye-shiryen kayan haɗin gwiwa, jigon juna tsakanin abubuwan da aka haɗa shine buƙatun da ake buƙata don tsarin haɗin gwiwa da muhimmin abu da ke shafar tsarin dubawa da yanayin haɗin kai. Yanayin rashin jika a mahaɗin tsakanin lu'u-lu'u da Cu yana haifar da juriya na zafi mai girma sosai. Don haka, yana da matuƙar mahimmanci a gudanar da bincike na gyare-gyare kan mu'amalar da ke tsakanin su ta hanyoyi daban-daban na fasaha. A halin yanzu, akwai galibin hanyoyi guda biyu don inganta matsalar mu'amala tsakanin lu'u-lu'u da Cu matrix: (1) Maganin gyaran fuskar lu'u-lu'u; (2) Alloying jiyya na jan karfe matrix.

gyare-gyaren zane mai tsari: (a) Rufewa kai tsaye a saman lu'u-lu'u; (b) Matrix alloying

(1) Gyaran fuskar lu'u-lu'u

Sanya abubuwa masu aiki kamar su Mo, Ti, W da Cr akan saman shimfidar lokaci na ƙarfafawa na iya haɓaka halayen tsaka-tsakin lu'u-lu'u, don haka haɓaka haɓakar yanayin zafi. Sintering zai iya ba da damar abubuwan da ke sama su yi amsa tare da carbon a saman lu'u-lu'u foda don samar da Layer mika mulki na carbide. Wannan yana inganta yanayin jika tsakanin lu'u-lu'u da tushe na karfe, kuma rufin zai iya hana tsarin lu'u-lu'u daga canzawa a yanayin zafi.

(2) Aloying na jan karfe matrix

Kafin sarrafa kayan da aka haɗa, ana yin maganin alloying a kan ƙarfe na ƙarfe, wanda zai iya samar da kayan haɗin gwiwa tare da haɓakar haɓakar zafi gabaɗaya. Doping abubuwa masu aiki a cikin matrix na jan karfe ba kawai zai iya rage yadda ya kamata ya rage magudanar ruwa tsakanin lu'u-lu'u da jan karfe ba, amma kuma yana haifar da Layer na carbide wanda ke da ƙarfi mai narkewa a cikin matrix na jan karfe a ƙirar lu'u-lu'u / Cu bayan amsawa. Ta wannan hanyar, yawancin gibin da ke akwai a cikin kayan haɗin gwiwar ana gyara su kuma an cika su, ta haka ne ke inganta haɓakar thermal.

04 Kammalawa

Kayan marufi na al'ada sun gaza wajen sarrafa zafi daga ci-gaba kwakwalwan kwamfuta. Haɗaɗɗen Dia/C, tare da CTE mai daidaitawa da ƙarfin ƙarfin zafin jiki, suna wakiltar mafita mai canzawa don na'urorin lantarki na gaba.

A matsayin babban kamfani na fasaha da ke haɗa masana'antu da cinikayya, XKH yana mai da hankali kan bincike da haɓakawa da samar da lu'u-lu'u / jan ƙarfe da kayan aikin ƙarfe na ƙarfe kamar SiC / Al da Gr / Cu, suna ba da sabbin hanyoyin sarrafa yanayin thermal tare da haɓakar thermal na kan 900W / (m · K) don fannonin marufi na lantarki da kayan masarufi.

XKH's Diamond jan karfe laminate kayan hade:

Lokacin aikawa: Mayu-12-2025