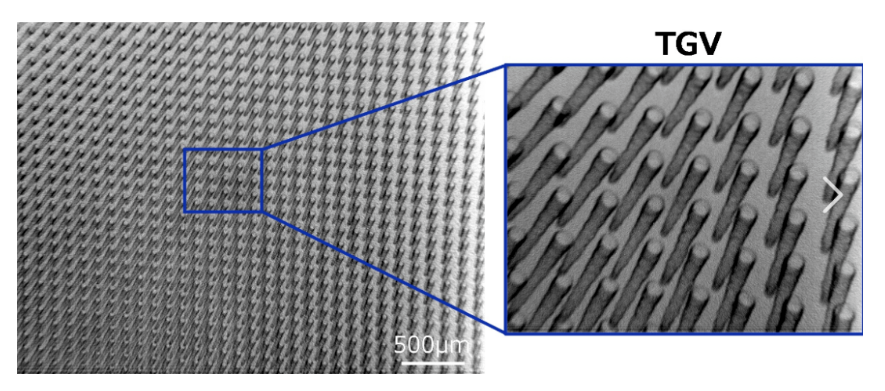

Menene TGV?

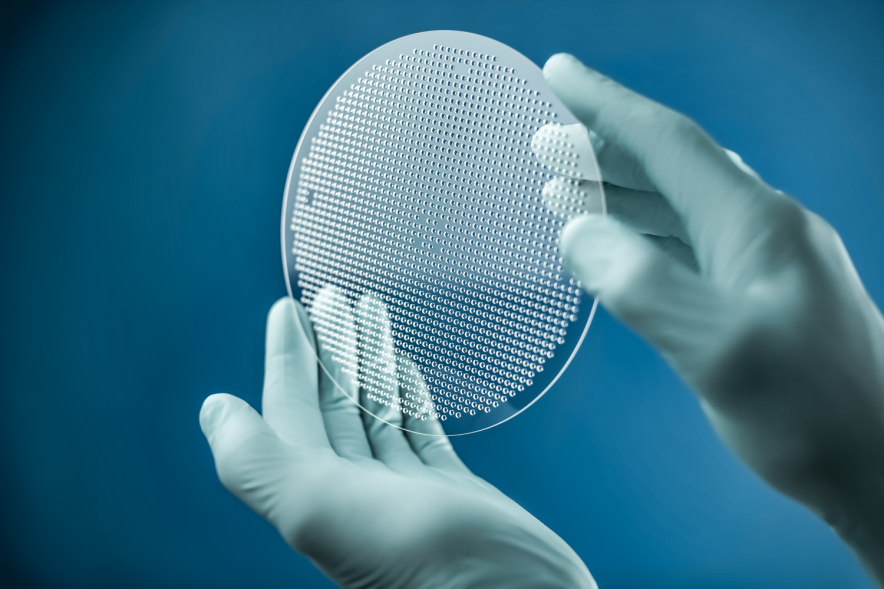

TGV, (Ta hanyar Gilashin ta), Fasaha na ƙirƙirar ramuka ta hanyar ramuka akan gilashin gilashi, A cikin sauƙi mai sauƙi, TGV babban gini ne mai tsayi wanda ke bugawa, cikawa da haɗawa sama da ƙasa gilashin don gina haɗin haɗin kai a kan gilashin gilashi. Ana ɗaukar wannan fasaha azaman fasaha mai mahimmanci don tsararrun marufi na 3D na gaba.

Menene halayen TGV?

1. Tsarin: TGV shine mai shiga tsakani a tsaye ta rami da aka yi akan gilashin gilashi. Ta hanyar ajiye ma'aunin ƙarfe mai ɗaukar nauyi akan bangon pore, babba da ƙananan yadudduka na siginar lantarki suna haɗuwa.

2. Tsarin masana'antu: TGV masana'antu sun haɗa da pretreatment na substrate, yin rami, ƙaddamar da ƙirar ƙarfe, cika rami da matakan daidaitawa. Hanyoyin masana'antu na yau da kullum sune sinadaran etching, Laser hakowa, electroplating da sauransu.

3. Abubuwan amfani da aikace-aikacen: Idan aka kwatanta da ƙarfe na gargajiya ta hanyar rami, TGV yana da fa'idodin ƙananan girman, mafi girman girman wayoyi, mafi kyawun aikin watsawa da sauransu. An yi amfani da shi sosai a cikin microelectronics, optoelectronics, MEMS da sauran fannonin haɗin kai mai girma.

4. Ci gaba Trend: Tare da ci gaba da kayan lantarki zuwa miniaturization da babban haɗin kai, fasahar TGV tana karɓar ƙarin hankali da aikace-aikace. A nan gaba, za a ci gaba da inganta tsarin masana'anta, kuma girmansa da aikinsa zai ci gaba da inganta.

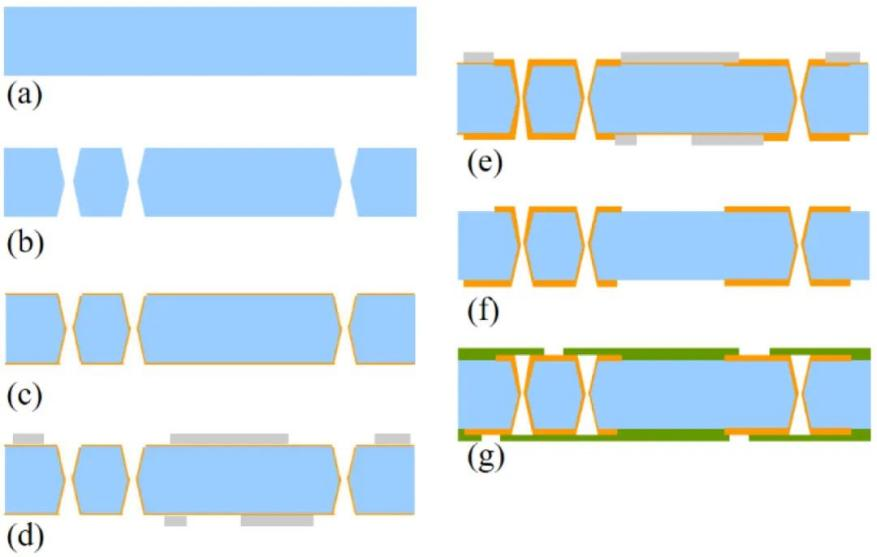

Menene tsarin TGV:

1. Gilashin gilashin gilashi (a): Shirya gilashin gilashi a farkon don tabbatar da cewa samansa yana da santsi da tsabta.

2. Gilashin hakowa (b): Ana amfani da Laser don samar da rami mai shiga cikin gilashin gilashi. Siffar ramin gabaɗaya conical ne, kuma bayan maganin Laser a gefe ɗaya, ana jujjuya shi kuma a sarrafa shi a gefe guda.

3. Hole bango metallization (c): Metallization ne da za'ayi a kan rami bango, yawanci ta hanyar PVD, CVD da sauran matakai don samar da wani conductive karfe iri Layer a kan rami bango, kamar Ti / Cu, Cr / Cu, da dai sauransu.

4. Lithography (d): An rufe saman gilashin gilashin tare da photoresisist da photopatterned. Fitar da sassan da ba sa buƙatar plating, ta yadda kawai sassan da ke buƙatar plating su fito fili.

5. Cikowar rami (e): Electroplating jan karfe don cika gilashin ta cikin ramuka don samar da cikakkiyar hanyar gudanarwa. Ana buƙatar gabaɗaya cewa ramin ya cika ba tare da ramuka ba. Lura cewa Cu da ke cikin zanen bai cika yawan jama'a ba.

6. Flat surface na substrate (f): Wasu matakai na TGV za su daidaita fuskar gilashin gilashin da aka cika da su don tabbatar da cewa farfajiyar ta kasance mai santsi, wanda ya dace da matakai na gaba.

7.Protective Layer da haɗin kai (g): An kafa Layer mai kariya (kamar polyimide) a saman gilashin gilashi.

A takaice, kowane mataki na tsarin TGV yana da mahimmanci kuma yana buƙatar ingantaccen sarrafawa da haɓakawa. A halin yanzu muna ba da gilashin TGV ta hanyar fasahar rami idan an buƙata. Da fatan za a ji daɗin tuntuɓar mu!

(Bayanan da ke sama sun fito daga Intanet, tantancewa)

Lokacin aikawa: Juni-25-2024