Silica carbide (SiC) yumbura mai tsafta sun fito azaman kayan aiki masu mahimmanci don mahimman abubuwan haɓakawa a cikin semiconductor, sararin samaniya, da masana'antar sinadarai saboda ƙayyadaddun yanayin zafinsu na musamman, kwanciyar hankali sinadarai, da ƙarfin injina. Tare da karuwar buƙatun manyan ayyuka, na'urorin yumbu masu ƙarancin gurɓataccen gurɓataccen gurɓataccen abu, haɓaka ingantaccen fasahar shirye-shirye don tsaftataccen yumbu na SiC ya zama abin da aka fi mayar da hankali kan bincike na duniya. Wannan takarda ta bita da tsare-tsare na manyan hanyoyin shirye-shiryen na yanzu don tsaftataccen tukwane na SiC, gami da recrystallization sintering, sintering mara ƙarfi (PS), zafi mai zafi (HP), spark plasma sintering (SPS), da ƙari masana'antu (AM), tare da mai da hankali kan tattauna hanyoyin sintering, maɓalli masu mahimmanci, kaddarorin kayan aiki, da ƙalubalen da ke akwai na kowane tsari.

Aikace-aikacen yumbura na SiC a fagen soja da injiniyanci

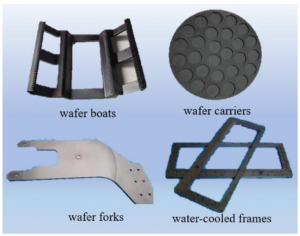

A halin yanzu, manyan abubuwan haɗin yumbu na SiC masu tsafta ana amfani da su sosai a cikin kayan masana'anta na silicon wafer, suna shiga cikin mahimman matakai kamar oxidation, lithography, etching, da ion implantation. Tare da ci gaban fasaha na wafer, haɓaka girman wafer ya zama babban tasiri. Girman wafer na yau da kullum shine 300 mm, samun daidaito mai kyau tsakanin farashi da ƙarfin samarwa. Koyaya, ta hanyar Dokar Moore, yawan samar da wafers na mm 450 ya riga ya kasance kan ajanda. Manyan wafers yawanci suna buƙatar ƙarfin tsari don tsayayya da warping da nakasawa, yana ƙara haɓaka buƙatu don girman girma, ƙarfi mai ƙarfi, tsaftataccen kayan yumbu na SiC. A cikin 'yan shekarun nan, masana'anta ƙari (bugu na 3D), a matsayin fasaha mai saurin samfuri wanda ba ya buƙatar gyare-gyare, ya nuna babban yuwuwar ƙirƙira na rikitattun sassa na yumbura na SiC saboda ginin Layer-by-Layer da ikon ƙira mai sassauƙa, yana jawo hankalin jama'a.

Wannan takarda za ta nazarci hanyoyin shirye-shiryen wakilai guda biyar don tsaftataccen tsaftar SiC ceramics - recrystallization sintering, sintering mara ƙarfi, matsawa mai zafi, ƙwanƙwasa plasma mai walƙiya, da masana'anta ƙari - mai da hankali kan hanyoyin haɗin gwiwar su, dabarun haɓaka aiwatarwa, halayen kayan aikin kayan aiki, da fatan aikace-aikacen masana'antu.

Bukatun albarkatun kasa na silicon carbide mai tsafta

I. Recrystallization Sintering

Recrystallized silicon carbide (RSiC) kayan SiC ne mai tsafta wanda aka shirya ba tare da kayan aikin sintiri ba a yanayin zafi na 2100-2500°C. Tun lokacin da Fredriksson ya fara gano al'amarin recrystallization a ƙarshen karni na 19, RSiC ya sami kulawa sosai saboda tsaftataccen iyakoki na hatsi da rashin matakan gilashi da ƙazanta. A yanayin zafi mai zafi, SiC yana nuna matsananciyar matsananciyar tururi, kuma tsarin sintirin sa da farko ya haɗa da tsarin ƙaura-condensation: kyawawan hatsi suna ƙafewa da sake dawowa akan saman manyan hatsi, haɓaka haɓakar wuyansa da haɗin kai kai tsaye tsakanin hatsi, don haka haɓaka ƙarfin abu.

A cikin 1990, Kriegesmann ya shirya RSiC tare da ƙarancin dangi na 79.1% ta amfani da simintin simintin gyare-gyare a 2200 ° C, tare da ɓangaren giciye yana nuna ƙaramin tsari wanda ya ƙunshi ƙananan hatsi da pores. Bayan haka, Yi et al. An yi amfani da simintin gel don shirya koren jikin kuma a sanya su a 2450°C, samun yumbura na RSiC tare da girma mai girma na 2.53 g/cm³ da ƙarfin sassauƙa na 55.4 MPa.

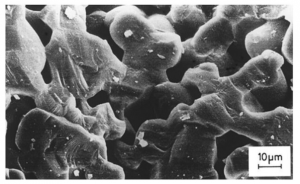

SEM fracture surface na RSiC

Idan aka kwatanta da SiC mai yawa, RSiC yana da ƙananan ƙima (kimanin 2.5 g/cm³) kuma kusan 20% buɗaɗɗen porosity, yana iyakance aikinsa a aikace-aikace masu ƙarfi. Saboda haka, inganta yawa da kayan aikin injiniya na RSiC ya zama mahimmin mayar da hankali kan bincike. Sung et al. ya ba da shawarar shigar da narkakkar siliki cikin carbon/β-SiC gauraye compacts da recrystallizing a 2200°C, cikin nasarar gina tsarin hanyar sadarwa wanda ya ƙunshi babban hatsi na α-SiC. Sakamakon RSiC ya sami nauyin 2.7 g/cm³ da ƙarfin sassauƙa na 134 MPa, yana riƙe kyakkyawan kwanciyar hankali na inji a babban yanayin zafi.

Don ƙara haɓaka ƙima, Guo et al. aiki da polymer infiltration da fasahar pyrolysis (PIP) don jiyya da yawa na RSiC. Yin amfani da mafita na PCS/xylene da SiC/PCS/xylene slurries a matsayin masu shiga tsakani, bayan zagayowar 3-6 PIP, an inganta yawan RSiC (har zuwa 2.90 g/cm³), tare da ƙarfin sassauƙansa. Bugu da ƙari, sun ba da shawarar dabarun cyclic da ke haɗa PIP da recrystallization: pyrolysis a 1400 ° C tare da recrystallization a 2400 ° C, yadda ya kamata share barbashi blockages da rage porosity. Abun RSiC na ƙarshe ya sami girman 2.99 g/cm³ da ƙarfin sassauƙa na 162.3 MPa, yana nuna ingantaccen aiki.

Hotunan SEM na juyin halittar microstructure na RSiC mai gogewa bayan polymer impregnation da pyrolysis (PIP) - recrystallization cycles: RSiC na farko (A), bayan sake zagayowar PIP-recrystallization na farko (B), da kuma bayan sake zagayowar ta uku (C)

II. Sintering mara matsi

Silicon carbide (SiC) yumbura marasa matsi (SiC) ana shirya su ne ta amfani da tsafta mai tsafta, ultrafine SiC foda azaman albarkatun ƙasa, tare da ƙaramin adadin kayan taimako da aka ƙara, kuma an haɗa su cikin yanayi mara amfani ko injin a 1800-2150 ° C. Wannan hanya ta dace don samar da manyan abubuwa masu girma da kuma hadaddun tsarin yumbura. Koyaya, tunda SiC yana da alaƙa da haɗin gwiwa da farko, ƙimar watsawar kansa yana da ƙasa sosai, yana yin wahalar ƙima ba tare da kayan taimako ba.

Dangane da tsarin sintering, za a iya raba sintering maras matsi zuwa nau'i biyu: rashin matsi mara ƙarfi (PLS-SiC) da kuma matsi mara ƙarfi (PSS-SiC).

1.1 PLS-SiC (Liquid-Phase Sintering)

PLS-SiC yawanci sintered a kasa 2000 ° C ta ƙara kusan 10 wt.% na eutectic sintering aids (kamar Al₂O₃, CaO, MgO, TiO₂, da rare-earth oxides RE₂O₃) don samar da wani ruwa ruwa, inganta ci gaban da barbashi rearrange. Wannan tsari ya dace da yumbu na SiC na masana'antu, amma ba a sami rahotannin babban tsaftar SiC da aka samu ta hanyar sintiri na ruwa.

1.2 PSS-SiC (Ƙarfafa-Jihar Sintering)

PSS-SiC ya ƙunshi ƙaƙƙarfan ƙaƙƙarfan yanayi a yanayin zafi sama da 2000C tare da kusan 1 wt.% na ƙari. Wannan tsari ya dogara ne akan yaduwar atomic da sake tsara hatsi da yanayin zafi ke motsawa don rage ƙarfin saman ƙasa da samun haɓaka. Tsarin BC (boron-carbon) haɗuwa ne na gama gari, wanda zai iya rage ƙarfin iyakar hatsi kuma ya cire SiO₂ daga saman SiC. Koyaya, abubuwan ƙari na BC na al'ada galibi suna gabatar da gurɓatattun ƙazanta, suna rage tsaftar SiC.

Ta hanyar sarrafa abun ciki na ƙari (B 0.4 wt.%, C 1.8 wt.%) da sintering a 2150 ° C na 0.5 hours, high-tsarki SiC ceramics tare da tsarki na 99.6 wt.% da kuma dangi density na 98.4% aka samu. Microstructure ya nuna hatsi na ginshiƙi (wasu sun wuce 450 µm tsayin su), tare da ƙananan pores a iyakokin hatsi da ɓangarori na graphite a cikin hatsi. Abubuwan yumbu sun nuna ƙarfin juzu'i na 443 ± 27 MPa, modul na roba na 420 ± 1 GPa, da haɓakar haɓakar thermal na 3.84 × 10⁻⁶ K⁻¹ a cikin kewayon zafin ɗakin zuwa 600 ° C, yana nuna kyakkyawan aiki gabaɗaya.

Microstructure na PSS-SiC: (A) Hoton SEM bayan gogewa da NaOH etching; (BD) Hotunan BSD bayan gogewa da etching

III. Zafin Latsa Sintering

Matsakaicin zafi (HP) dabarar ƙima ce wacce ke amfani da zafi da matsa lamba na uniaxial zuwa kayan foda a ƙarƙashin yanayin zafi da matsanancin yanayi. Babban matsin lamba yana hana haɓakar pore kuma yana iyakance haɓakar hatsi, yayin da yawan zafin jiki yana haɓaka haɓakar hatsi da kuma samar da sifofi masu yawa, a ƙarshe yana samar da adadi mai yawa, manyan tukwane na SiC masu tsabta. Saboda yanayin shugabanci na latsawa, wannan tsari yana kula da haifar da anisotropy hatsi, yana shafar kayan inji da lalacewa.

Tsaftataccen yumbu na SiC yana da wahala a ƙirƙira ba tare da ƙari ba, yana buƙatar sintering mai matsananciyar matsa lamba. Nadeau et al. nasarar shirya cikakken SiC mai yawa ba tare da ƙari ba a 2500 ° C da 5000 MPa; Sun et al. samu β-SiC babban kayan aiki tare da taurin Vickers har zuwa 41.5 GPa a 25 GPa da 1400°C. Yin amfani da matsa lamba 4 GPa, SiC yumbura tare da ƙarancin dangi na kusan 98% da 99%, taurin 35GPa, da na roba na 450GPa an shirya su a 1500°C da 1900°C, bi da bi. Sintering micron-sized SiC foda a 5 GPa da 1500 ° C ya haifar da yumbu tare da taurin 31.3 GPa da ƙarancin dangi na 98.4%.

Ko da yake waɗannan sakamakon sun nuna cewa matsa lamba na ultrahigh na iya cimma ƙarancin ƙarancin ƙima, rikitarwa da tsadar kayan aikin da ake buƙata suna iyakance aikace-aikacen masana'antu. Sabili da haka, a cikin shirye-shiryen aiki, ana amfani da abubuwan ƙari ko foda sau da yawa don haɓaka ƙarfin tuƙi.

Ta ƙara 4 wt.% phenolic resin a matsayin ƙari da sintering a 2350 ° C da 50 MPa, SiC yumbura tare da ƙimar ƙima na 92% da tsarki na 99.998% an samu. Yin amfani da ƙananan ƙari (boric acid da D-fructose) da sintering a 2050 ° C da 40 MPa, SiC mai tsabta tare da ƙarancin dangi> 99.5% da ragowar B abun ciki na 556 ppm kawai an shirya. Hotunan SEM sun nuna cewa, idan aka kwatanta da samfurori marasa matsi, samfurori masu zafi suna da ƙananan hatsi, ƙananan pores, da ƙananan yawa. Ƙarfin ƙwanƙwasa shine 453.7 ± 44.9 MPa, kuma maɗaukaki na roba ya kai 444.3 ± 1.1 GPa.

Ta hanyar tsawaita lokacin riƙewa a 1900 ° C, girman hatsi ya ƙaru daga 1.5 μm zuwa 1.8 μm, kuma haɓakawar thermal ya inganta daga 155 zuwa 167 W·m⁻¹·K⁻¹, yayin da kuma yana haɓaka juriya na lalata plasma.

A ƙarƙashin yanayi na 1850 ° C da 30 MPa, matsawa mai zafi da saurin matsananciyar zafi na granulated da annealed SiC foda ya ba da cikakkiyar ma'auni na β-SiC ba tare da wani ƙari ba, tare da yawa na 3.2 g / cm³ da zafin jiki na 150-200 ° C ƙasa da tsarin gargajiya. Abubuwan yumbu sun nuna taurin 2729 GPa, raunin karaya na 5.25-5.30 MPa·m^1/2, da kyakkyawan juriya mai raɗaɗi (yawan ƙima na 9.9 × 10⁻¹⁰ s⁻¹ da 3.8 × 10⁻ ⁹ 1400°C/1450°C da 100MPa).

(A) Hoton SEM na fuskar da aka goge; (B) Hoton SEM na farfajiyar karaya; (C, D) Hoton BSD na fuskar da aka goge

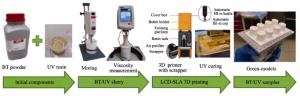

A cikin binciken bugu na 3D don tukwane na piezoelectric, yumbu slurry, a matsayin babban abin da ke tasiri samarwa da aiki, ya zama babban abin da ake mayar da hankali a cikin gida da na duniya. Yanzu karatu gaba ɗaya nuna cewa sigogi kamar foda size size, slurry danko, da kuma m abun ciki muhimmanci rinjayar forming inganci da piezoelectric Properties na karshe samfurin.

Bincike ya gano cewa yumbun slurries da aka shirya ta amfani da micron-, submicron-, da nano-sized barium titanate foda suna nuna bambance-bambance masu mahimmanci a cikin matakai na stereolithography (misali, LCD-SLA). Yayin da girman barbashi ke raguwa, slurry danko yana ƙaruwa sosai, tare da foda masu girman nano suna samar da slurries tare da danko da ya kai biliyoyin mPa·s. Slurries da micron-sized powders suna da wuya ga delamination da peeling yayin bugu, yayin da submicron da nano-sized powders nuna mafi barga kafa hali. Bayan babban zafin jiki na zafin jiki, samfuran yumbu da aka samu sun sami ƙimar 5.44 g/cm³, madaidaicin piezoelectric (d₃₃) na kusan 200 pC/N, da ƙananan abubuwan hasara, suna nuna kyawawan kaddarorin amsawar lantarki.

Bugu da ƙari, a cikin matakan micro-stereolithography, daidaita ƙaƙƙarfan abun ciki na nau'in PZT-slurries (misali, 75 wt.%) ya haifar da jikkunan da ba su da yawa tare da yawa na 7.35 g/cm³, suna samun madaidaicin piezoelectric har zuwa 600 pC/N a ƙarƙashin filayen lantarki. Bincike kan diyya na nakasar ƙanƙanta ya inganta haɓaka daidaiton ƙima, yana haɓaka daidaitaccen lissafi har zuwa 80%.

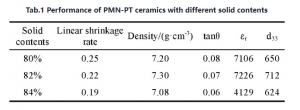

Wani bincike akan tukwane na PMN-PT piezoelectric ya bayyana cewa ingantaccen abun ciki yana tasiri sosai akan tsarin yumbu da kaddarorin lantarki. A 80 wt.% m abun ciki, byproducts sauƙi bayyana a cikin tukwane; kamar yadda m abun ciki ya karu zuwa 82 wt.% da sama, byproducts sannu a hankali bace, da yumbu tsarin zama mafi tsarki, tare da muhimmanci inganta yi. A 82 wt.%, tukwane sun nuna mafi kyawun kayan lantarki: ƙarancin piezoelectric na 730 pC/N, izinin dangi na 7226, da asarar dielectric kawai 0.07.

A taƙaice, barbashi size, m abun ciki, da rheological Properties na yumbu slurries ba kawai rinjayar da kwanciyar hankali da daidaito na bugu tsari amma kuma kai tsaye ƙayyade yawa da piezoelectric amsa na sintered jikin, sa su key sigogi ga cimma high-yi 3D-buga piezoelectric tukwane.

Babban tsari na LCD-SLA 3D bugu na samfuran BT/UV

Kaddarorin tukwane na PMN-PT tare da ingantaccen abun ciki daban-daban

IV. Spark Plasma Sintering

Spark plasma sintering (SPS) fasaha ce ta ci-gaba wacce ke amfani da matsa lamba na yanzu da na inji a lokaci guda ana amfani da foda don cimma saurin ƙima. A cikin wannan tsari, halin yanzu kai tsaye yana zafi da mold da foda, yana haifar da zafi na Joule da plasma, yana ba da damar ingantacciyar sintesa a cikin ɗan gajeren lokaci (yawanci cikin mintuna 10). Dumama cikin sauri yana haɓaka yaduwar ƙasa, yayin da fitar da walƙiya yana taimakawa cire iskar gas da yadudduka na oxide daga filayen foda, haɓaka aikin sintering. Tasirin lantarki da filayen lantarki ke haifar da shi shima yana haɓaka yaduwar atomic.

Idan aka kwatanta da matsi mai zafi na gargajiya, SPS tana ɗaukar ƙarin dumama kai tsaye, yana ba da damar haɓakawa a ƙananan yanayin zafi yayin da yake hana haɓakar hatsi yadda ya kamata don samun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙaya. Misali:

- Ba tare da ƙari ba, yin amfani da ƙasa SiC foda a matsayin albarkatun kasa, sintering a 2100 ° C da 70 MPa na 30 minutes samar da samfurori tare da 98% dangi yawa.

- Sintering a 1700 ° C da 40 MPa na 10 minutes samar cubic SiC tare da 98% yawa da hatsi girma na 30-50 nm kawai.

- Yin amfani da 80 µm granular SiC foda da sintering a 1860 ° C da 50 MPa na 5 mintuna ya haifar da babban aikin SiC yumbura tare da 98.5% dangi density, Vickers microhardness na 28.5 GPa, flexural ƙarfi na 395 MPa, da fracture taurin · 4.5 MPa.

Binciken microstructural ya nuna cewa yayin da zafin jiki ya karu daga 1600 ° C zuwa 1860 ° C, porosity na kayan ya ragu sosai, yana gabatowa da yawa a yanayin zafi.

SiC ceramics microstructure na sintered a yanayin zafi daban-daban: (A) 1600°C, (B) 1700°C, (C) 1790°C da (D) 1860°C

V. Ƙarfafa Manufacturing

Ƙarfafa masana'anta (AM) kwanan nan ya nuna babban yuwuwar ƙirƙira hadaddun abubuwan yumbu saboda tsarin aikin sa na Layer-Layer. Don tukwane na SiC, an haɓaka fasahar AM da yawa, gami da jetting jetting (BJ), 3DP, zaɓaɓɓen Laser sintering (SLS), rubutun tawada kai tsaye (DIW), da stereolithography (SL, DLP). Koyaya, 3DP da DIW suna da ƙananan daidaito, yayin da SLS ke ƙoƙarin haifar da damuwa na thermal da fasa. Sabanin haka, BJ da SL suna ba da fa'idodi mafi girma wajen samar da tsaftataccen tsafta, ingantattun yumbu masu mahimmanci.

- Binder Jetting (BJ)

Fasahar BJ ta ƙunshi feshin dauri-by-Layer na ɗaure zuwa haɗin foda, wanda ke biye da debinding da sintering don samun samfurin yumbu na ƙarshe. Haɗuwa da BJ tare da infiltration tururi na sinadarai (CVI), babban-tsarki, cikakken kristal SiC yumbura an yi nasarar shirya su. Tsarin ya haɗa da:

① Samar da jikin SiC yumbu kore ta amfani da BJ.

② Densifying ta hanyar CVI a 1000 ° C da 200 Torr.

③ Ƙarshen SiC yumbura yana da nauyin 2.95 g/cm³, ƙarfin zafin jiki na 37 W/m·K, da ƙarfin sassauƙa na 297 MPa.

Tsarin tsari na buga jet (BJ). (A) ƙirar ƙira (CAD) mai taimakon kwamfuta, (B) ƙirar ƙirar ƙa'idar BJ, (C) bugu na SiC ta BJ, (D) ƙaddamar da SiC ta hanyar shigar da tururin sinadarai (CVI)

- Stereolithography (SL)

SL fasaha ce ta samar da yumbu na tushen UV tare da ingantacciyar madaidaici da ƙwarewar ƙirƙira tsarin. Wannan hanyar tana amfani da slurries na yumbu masu ɗaukar hoto tare da babban abun ciki mai ƙarfi da ƙarancin danko don samar da jikin yumburan kore na 3D ta hanyar ɗaukar hoto, wanda ke biye da ƙaddamarwa da ƙarancin zafin jiki don samun samfurin ƙarshe.

Yin amfani da 35 vol.% SiC slurry, high quality-3D kore jikin an shirya a karkashin 405 nm UV irradiation da kuma kara densified via polymer burnout a 800 ° C da PIP jiyya. Sakamako ya nuna cewa samfuran da aka shirya tare da 35 vol.% slurry sun sami ƙarancin dangi na 84.8%, fiye da 30% da 40% ƙungiyoyin sarrafawa.

Ta hanyar gabatar da SiO₂ lipophilic da phenolic epoxy resin (PEA) don gyara slurry, aikin photopolymerization ya inganta sosai. Bayan yin gyare-gyare a 1600 ° C na 4 h, an sami kusan cikar juyawa zuwa SiC, tare da abun ciki na oxygen na ƙarshe na 0.12% kawai, yana ba da damar ƙirƙira mataki ɗaya na tsattsauran ra'ayi, ƙirar SiC mai rikitarwa ba tare da pre-oxidation ko matakan shigarwa ba.

Misalin tsarin buga bugu da tsarin sa. Bayyanar samfurin bayan bushewa a (A) 25 ° C, pyrolysis a (B) 1000 ° C, da sintering a (C) 1600 ° C.

By zayyana photosensitive Si₃N₄ yumbu slurries ga stereolithography 3D bugu da kuma yin amfani da debinding-presintering da high-zazzabi matakai na tsufa, Si₃N₄ tukwane da 93.3% ka'idar yawa, tensile ƙarfi na 279.8 MPa ƙarfi. aka shirya. Nazarin ya gano cewa a ƙarƙashin yanayin 45 vol.% m abun ciki da 10 s lokacin bayyanarwa, ana iya samun jikin kore mai launi ɗaya tare da daidaitattun matakan IT77. Tsarin rage ƙarancin zafin jiki tare da ƙimar dumama na 0.1 ° C/min ya taimaka samar da jikin kore mara fasa.

Sintering mataki ne mai mahimmanci wanda ke shafar aikin ƙarshe a cikin stereolithography. Bincike ya nuna cewa ƙara kayan aikin sintering na iya inganta haɓaka yumbura da kaddarorin inji yadda ya kamata. Yin amfani da CeO₂ azaman taimakon sintering da fasahar sintering da ke taimaka wa filin lantarki don shirya manyan yumbu na Si₃N₄, CeO₂ an gano ya keɓe a iyakokin hatsi, yana haɓaka iyakokin hatsi da zamewa. Sakamakon yumbura ya nuna taurin Vickers na HV10/10 (1347.9 ± 2.4) da taurin karaya na (6.57 ± 0.07) MPa·m¹/². Tare da MgO-Y₂O₃ azaman ƙari, yumbu microstructure homogeneity an inganta, yana haɓaka aiki sosai. A jimlar matakin doping na 8 wt.%, ƙarfin sassauƙa da haɓakar zafin jiki ya kai 915.54 MPa da 59.58 W·m⁻¹·K⁻¹, bi da bi.

VI. Kammalawa

A taƙaice, yumbun silicon carbide (SiC) mai tsafta, a matsayin fitaccen kayan yumbu na injiniya, sun nuna fa'idodin aikace-aikacen a cikin na'urori masu ɗaukar hoto, sararin samaniya, da kayan aiki masu ƙarfi. Wannan takarda ta yi nazari sosai kan hanyoyin shirye-shirye guda biyar don tsaftataccen yumbu na SiC - recrystallization sintering, sintering mara ƙarfi, matsawa mai zafi, walƙiya plasma sintering, da kuma masana'anta - tare da cikakkun bayanai kan hanyoyin haɓakar su, haɓaka madaidaicin maɓalli, aikin kayan aiki, da fa'idodi da iyakancewa.

A bayyane yake cewa matakai daban-daban kowanne yana da halaye na musamman dangane da samun tsafta mai girma, girma mai yawa, sarƙaƙƙiya tsarin, da yuwuwar masana'antu. Fasahar masana'anta ta haɓaka, musamman, ta nuna ƙarfin ƙarfi wajen ƙirƙira hadaddun abubuwa masu siffa da keɓancewa, tare da nasarorin da aka samu a cikin ƙananan filayen kamar stereolithography da jetting, yana mai da shi muhimmin jagorar ci gaba don ingantaccen shiri na SiC mai tsabta.

Binciken gaba game da shirye-shiryen yumbu na SiC mai tsafta yana buƙatar zurfafa zurfi, haɓaka sauye-sauye daga sikelin dakin gwaje-gwaje zuwa manyan aikace-aikacen injiniya abin dogaro sosai, ta haka ne ke ba da tallafin kayan aiki mai mahimmanci don masana'antar kayan aiki mai ƙarfi da fasahar bayanai na gaba.

XKH babban kamfani ne na fasaha wanda ya kware a cikin bincike da samar da kayan yumbu masu inganci. An ƙaddamar da shi don samar da mafita na musamman ga abokan ciniki a cikin nau'i mai tsabta na silicon carbide (SiC) yumbu. Kamfanin ya mallaki fasahar shirye-shiryen kayan haɓakawa da ingantattun damar sarrafawa. Kasuwancin sa ya ƙunshi bincike, samarwa, daidaitaccen aiki, da kuma kula da saman tukwane na SiC masu tsafta, saduwa da stringent buƙatun na semiconductor, sabon makamashi, sararin samaniya da sauran filayen don manyan abubuwan yumbu masu inganci. Leveraging balagagge sintering matakai da ƙari masana'antu fasahar, za mu iya ba abokan ciniki sabis na tsayawa daya daga kayan haɓaka dabara, hadaddun tsarin samuwar zuwa daidai aiki, tabbatar da cewa kayayyakin mallaka m inji Properties, thermal kwanciyar hankali da kuma lalata juriya.

Lokacin aikawa: Yuli-30-2025

-300x228.png)

1600°C、(B)1700°C、(C)1790°C-和(D)1860°C-300x223.png)

25°C-下干燥、(B)1000°C-下热解和(C)1600°C-下烧结后的外观-300x225.png)